Soil grinding device with soil drying function

A technology of drying function and grinding device, applied in heating device, measuring device, drying and other directions, can solve the problems of soil pollution, low degree of automation, difficult cleaning, etc., and achieve the effect of ensuring the working environment, simple operation and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

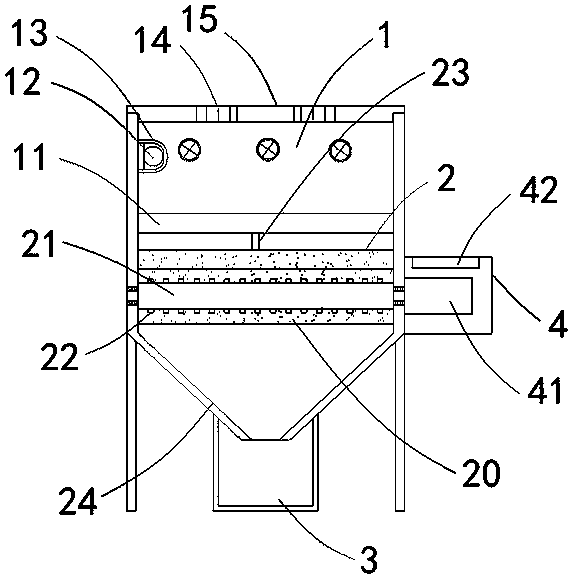

[0020] Such as Figure 1-2 As shown, this kind of soil grinding device with soil drying function includes an equipment box through which both ends are connected. The bottom end of the equipment box has a support frame. The drying area 1 for soil drying and the grinding area 2 for soil grinding, the drying area 1 and the grinding area 2 are separated by a double door 11, and the side wall of the drying area 1 is provided with multiple A baking lamp 12, the baking lamp 12 is covered with a detachable lampshade 13, through the setting of the lampshade 13, when cleaning the equipment, the baking lamp 12 is waterproof, and the top port of the equipment box is provided for Closing the closure lid 14 of the equipment box;

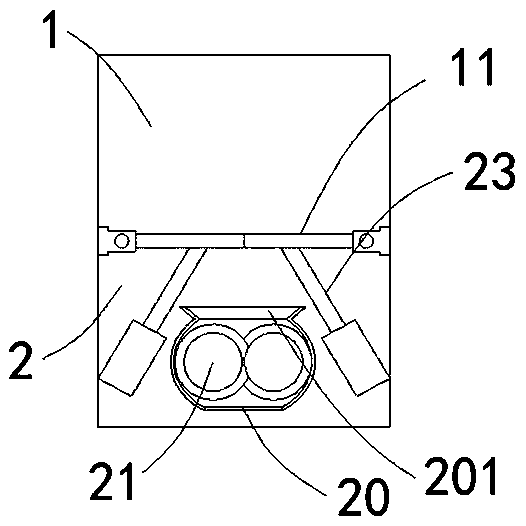

[0021] The grinding area 2 is provided with a grinding cylinder 20 fixed on the equipment box, and the grinding cylinder 20 includes a grinding chamber 201, a feeding port at the top of the grinding chamber 201, and a discharge port at the bottom of the grinding ...

Embodiment 2

[0028] Such as figure 1 As shown, on the basis of Example 1, further, the closure cover 14 has a plurality of air vents, after the soil is added to the drying area 1, the drying area 1 is closed by the closing cover, and when the licorice soil is used, the reduction The loss rate of heat energy is small, and the moisture generated during the soil drying process is discharged from the vent.

[0029] All the other operating principles of embodiment 2 are the same as embodiment 1.

[0030] As a preferred solution of Embodiment 2, in order to prevent the dust generated during the process of adding soil into the grinding cylinder 20 and soil grinding from passing through the vent, the vent has a dust-proof net 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com