Fixation member and fixation apparatus having the fixation member

A technology of fixing parts and fixing parts, applied in the fields of fixing parts and fixing devices, can solve the problems of wear, stick-slip, and lack of lubrication of sliding layers, and achieve the effect of improving wear resistance and sliding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0041] The fixing member according to the present invention is applied to a fixing unit of an image forming apparatus, and is used in the fixing unit to fix an unfixed toner image on a recording medium by heat and pressure. In Embodiment 1, an endless fixing belt (endless belt or endless film) is exemplified as a fixing member.

[0042] figure 1 is a schematic cross-sectional view of the fixing belt. The fixing belt 1 has: a metal base 10 having at least one layer of seamless electroforming belt; a sliding layer 11 formed on the inner peripheral surface of the metal base 10; an elastic layer 12 formed on the outer peripheral surface of the metal base 10; The release layer 13 on the outer peripheral surface of 12 is sequentially laminated with the sliding layer 11, the metal substrate 10, the elastic layer 12, and the release layer 13 from the inside.

[0043] The metal base 10 has at least one layer of seamless electroformed strip of nickel or nickel alloy with excellent the...

Embodiment approach 2

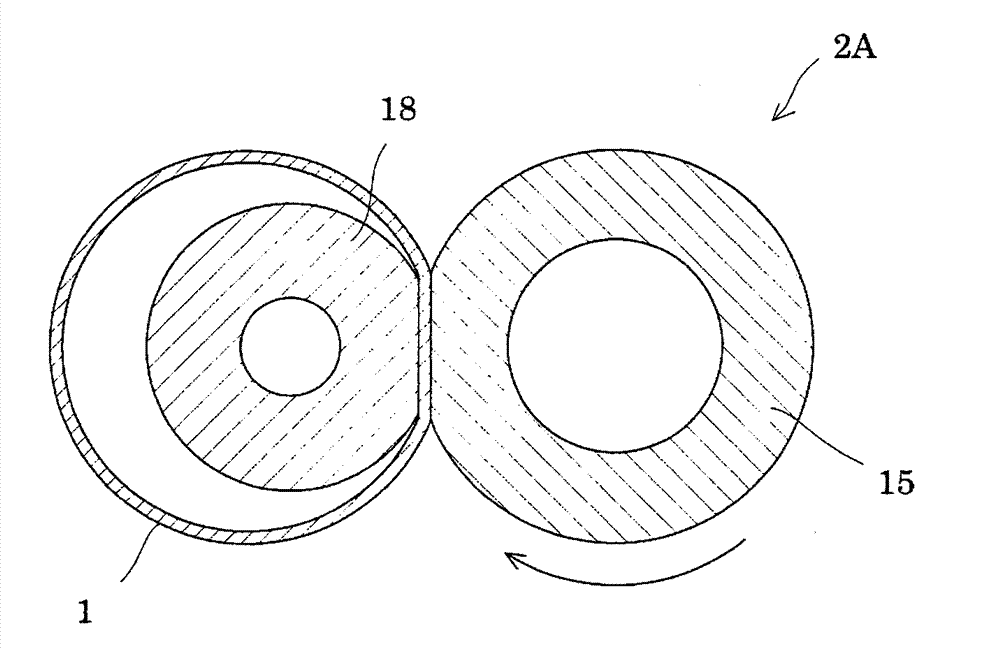

[0077] Embodiment 2 is a modified example of the configuration of the fixing device, and the same components as those in Embodiment 1 are assigned the same reference numerals, and redundant descriptions are omitted. image 3 It is a schematic sectional view showing the fixing device according to the second embodiment.

[0078] Such as image 3 As shown, fixing device 2A includes: fixing belt 1 ; pressure roller 15 disposed opposite to fixing belt 1 ; and fixing roller 18 pressing fixing belt 1 against pressure roller 15 from inside instead of pressing member 14 . In addition, a heating unit for heating the fixing belt 1 may be built in the fixing roller 18 or may be arranged outside the fixing belt 1 .

Embodiment approach 3

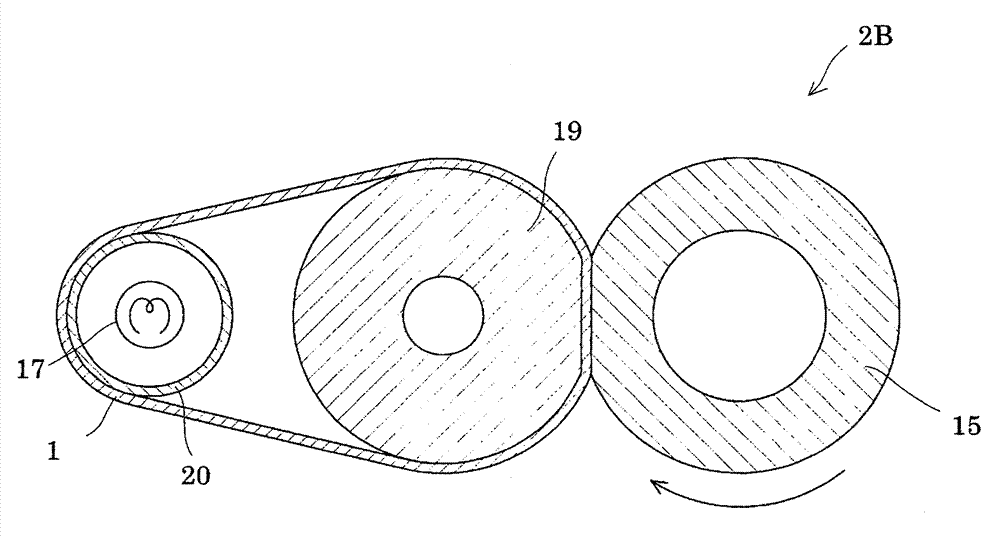

[0080] Embodiment 3 is a modified example of the configuration of the fixing device, and the same components as those in Embodiment 1 are assigned the same reference numerals, and redundant descriptions are omitted. Figure 4 It is a schematic cross-sectional view showing a fixing device according to Embodiment 3. FIG.

[0081] Such as Figure 4 As shown, the fixing device 2B includes: a fixing belt 1; a pressure roller 15 arranged to face the fixing belt 1; an inner roller 19 that presses the fixing belt 1 against the pressure roller 15 from the inside; and a heating roller with a built-in heating unit 17. 20. Inside the fixing belt 1 , an inner roller 19 and a heating roller 20 with a built-in heating unit 17 are arranged, and the fixing belt 1 is rotationally driven by the inner roller 19 and the heating roller 20 . In addition, in this case, the heating unit 17 of the heating roller 20 may be arranged outside the fixing belt 1 .

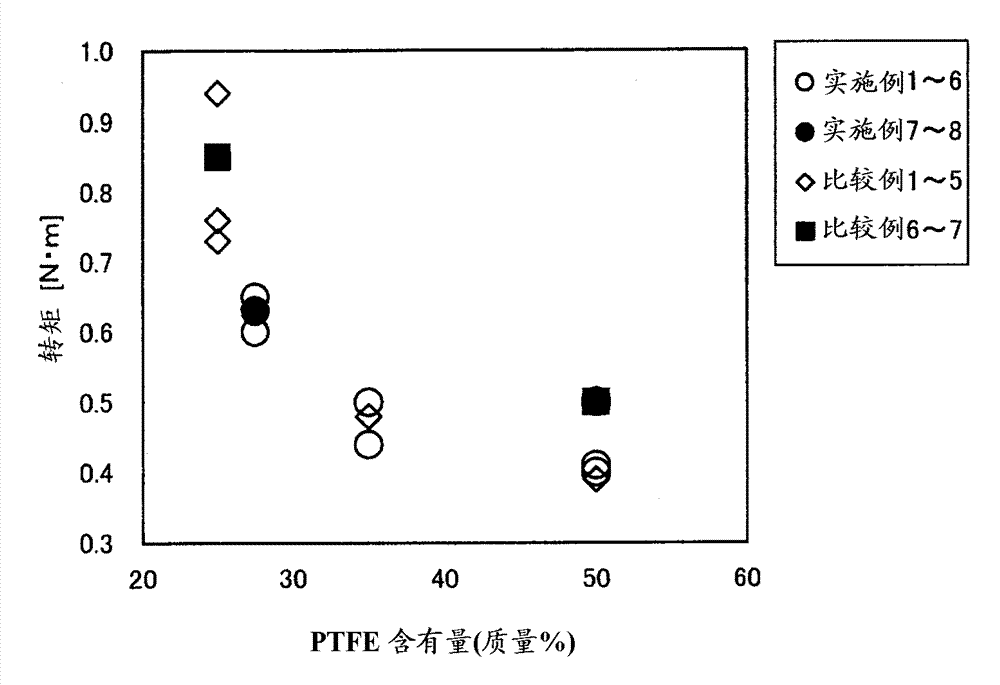

[0082] (Example)

[0083] Hereinafter,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com