Patents

Literature

53results about How to "Ensure sliding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

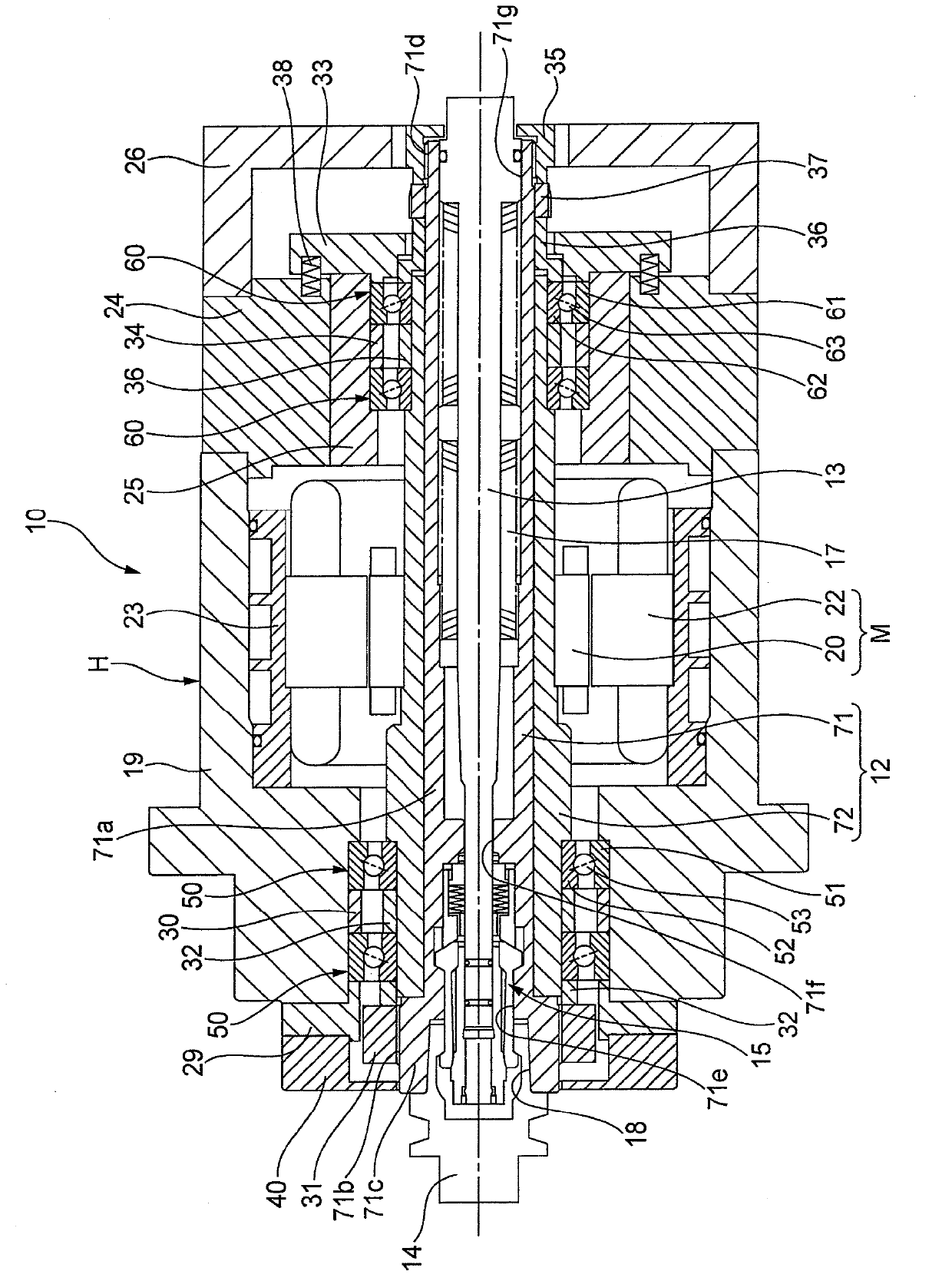

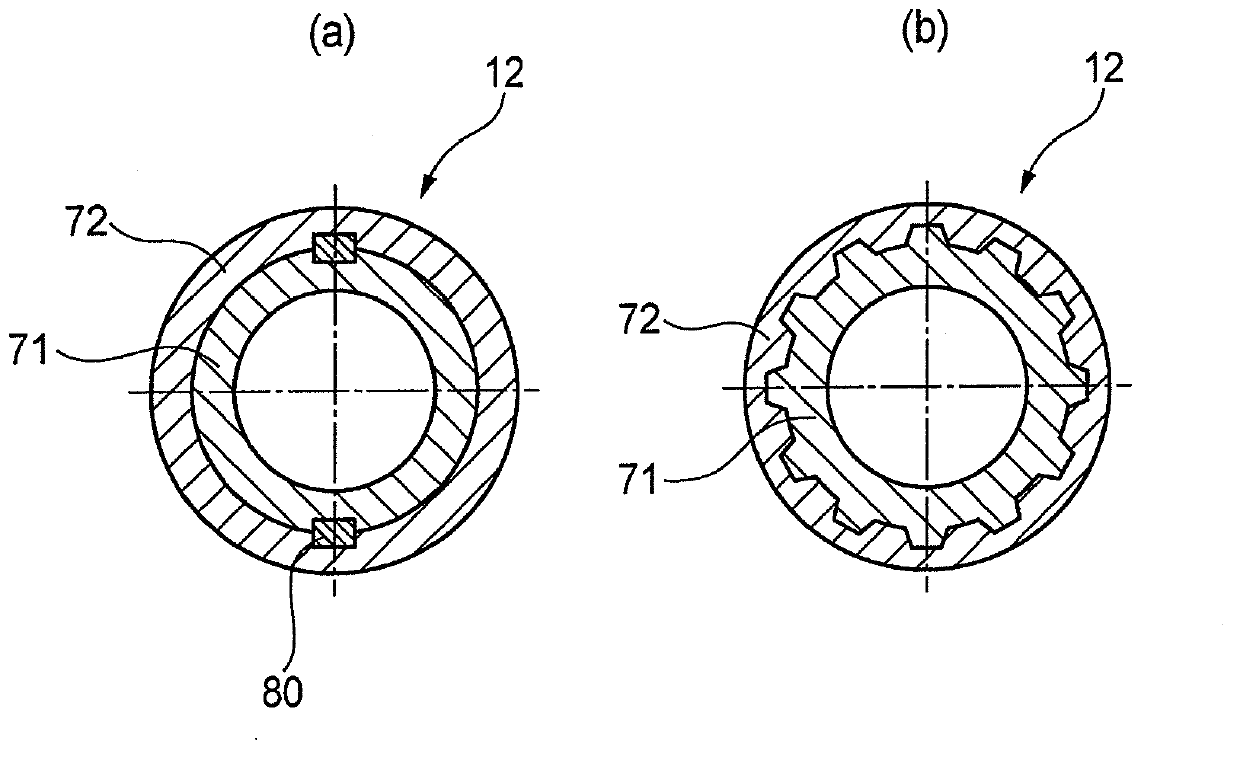

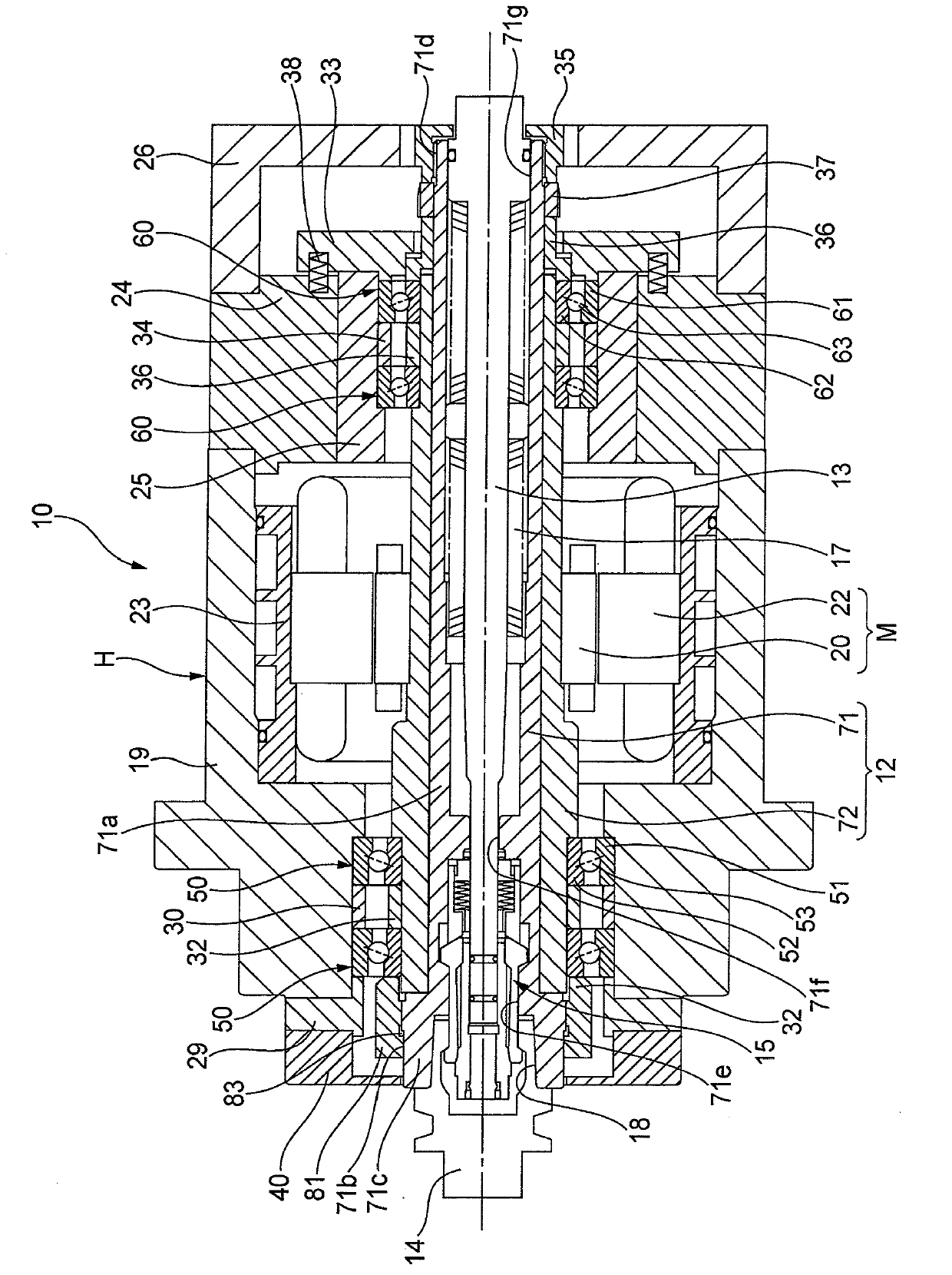

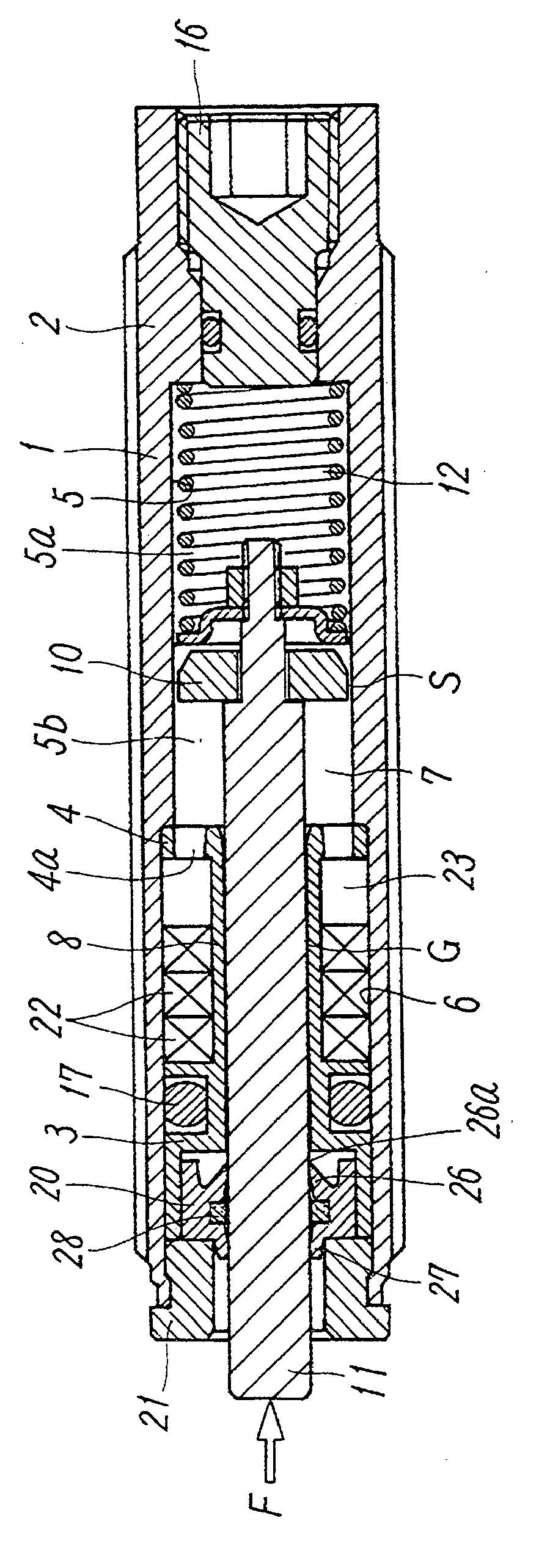

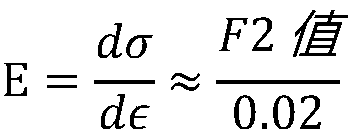

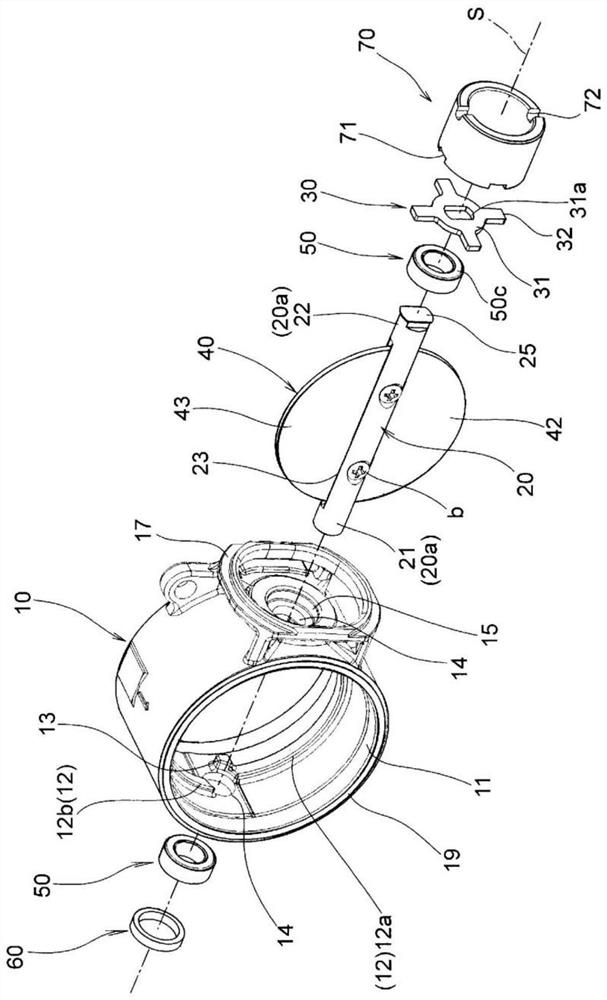

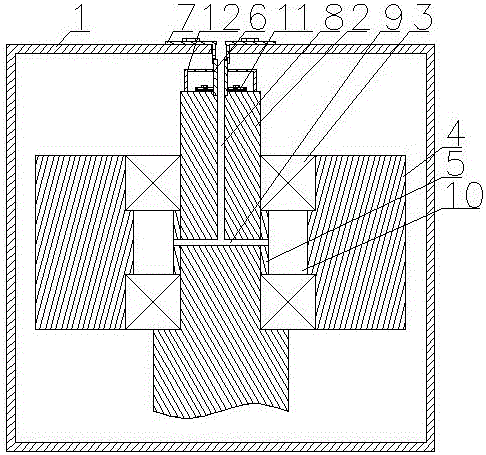

Main shaft apparatus

ActiveCN103003014AIncrease temperatureImprove machining accuracyLarge fixed membersMaintainance and safety accessoriesMetallic materialsEngineering

A main shaft apparatus (10) of a built-in motor system, wherein a rotary shaft (12) is provided with: a first cylindrical component (71) made of metal material; and a second cylindrical component (72) made of carbon fibre composite material, which is positioned on the outer peripheral surface of the first cylindrical component (71) and into the outer peripheral surface of which a rotor (20) fits. By virtue of this, the temperature increase of the rotary shaft and a bearing due to the heat produced by the rotor can be controlled and processing precision can be improved.

Owner:NSK LTD

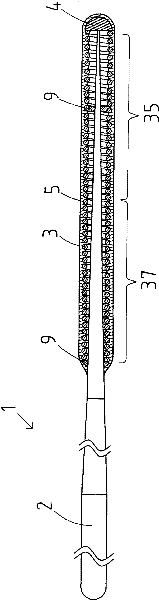

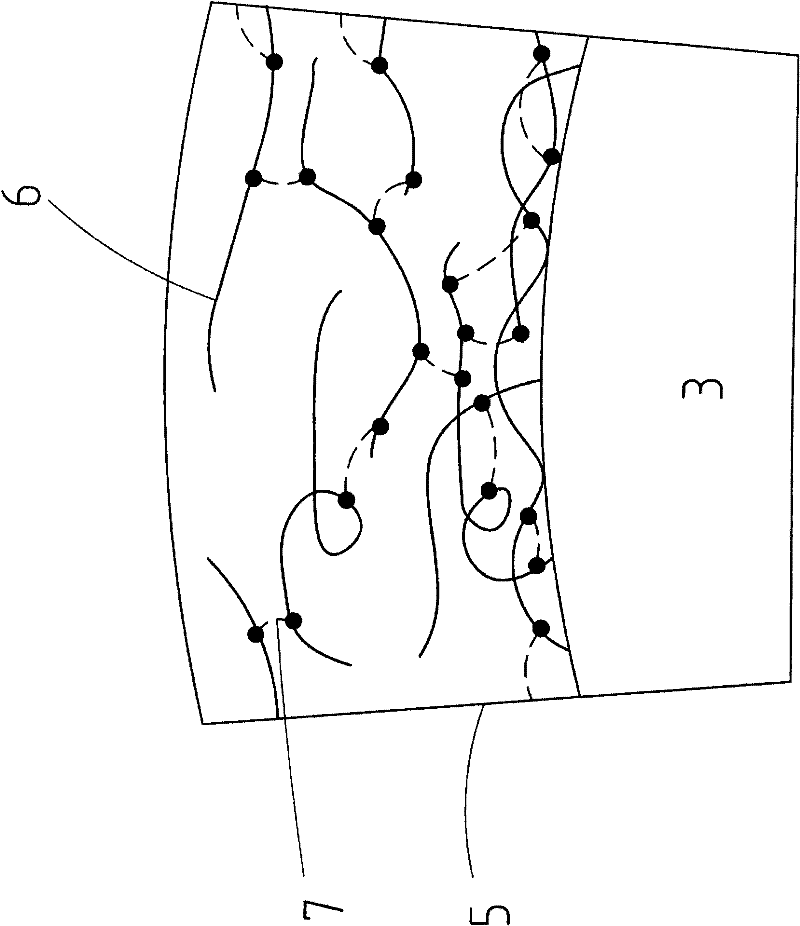

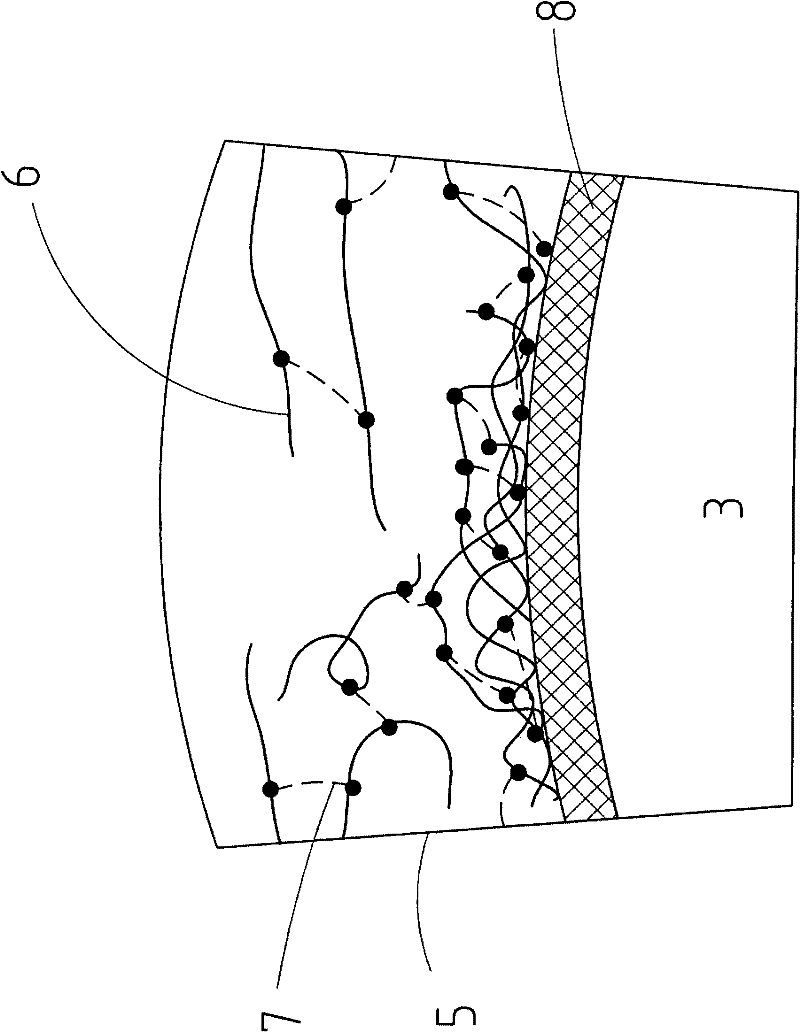

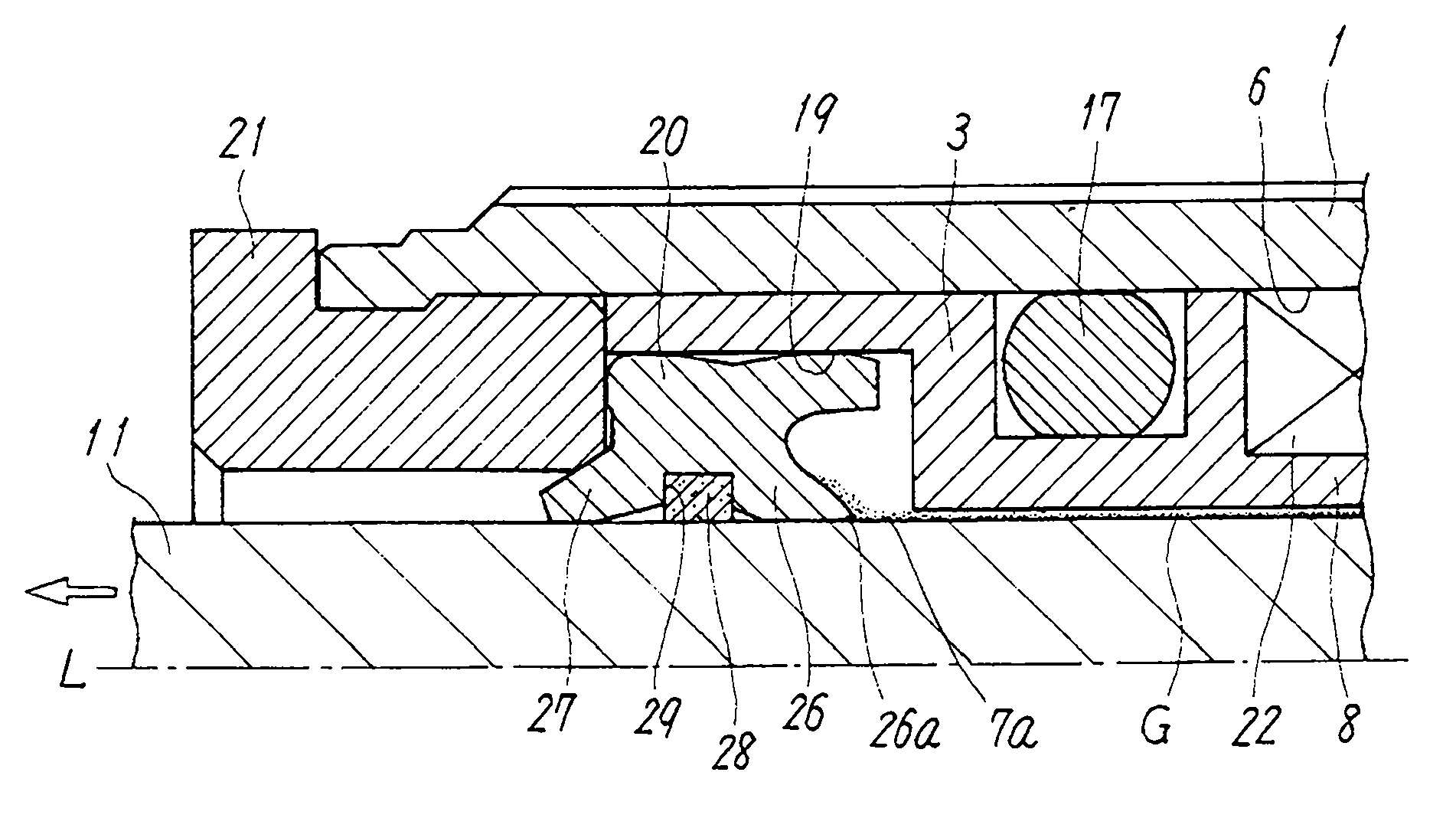

Guidewire

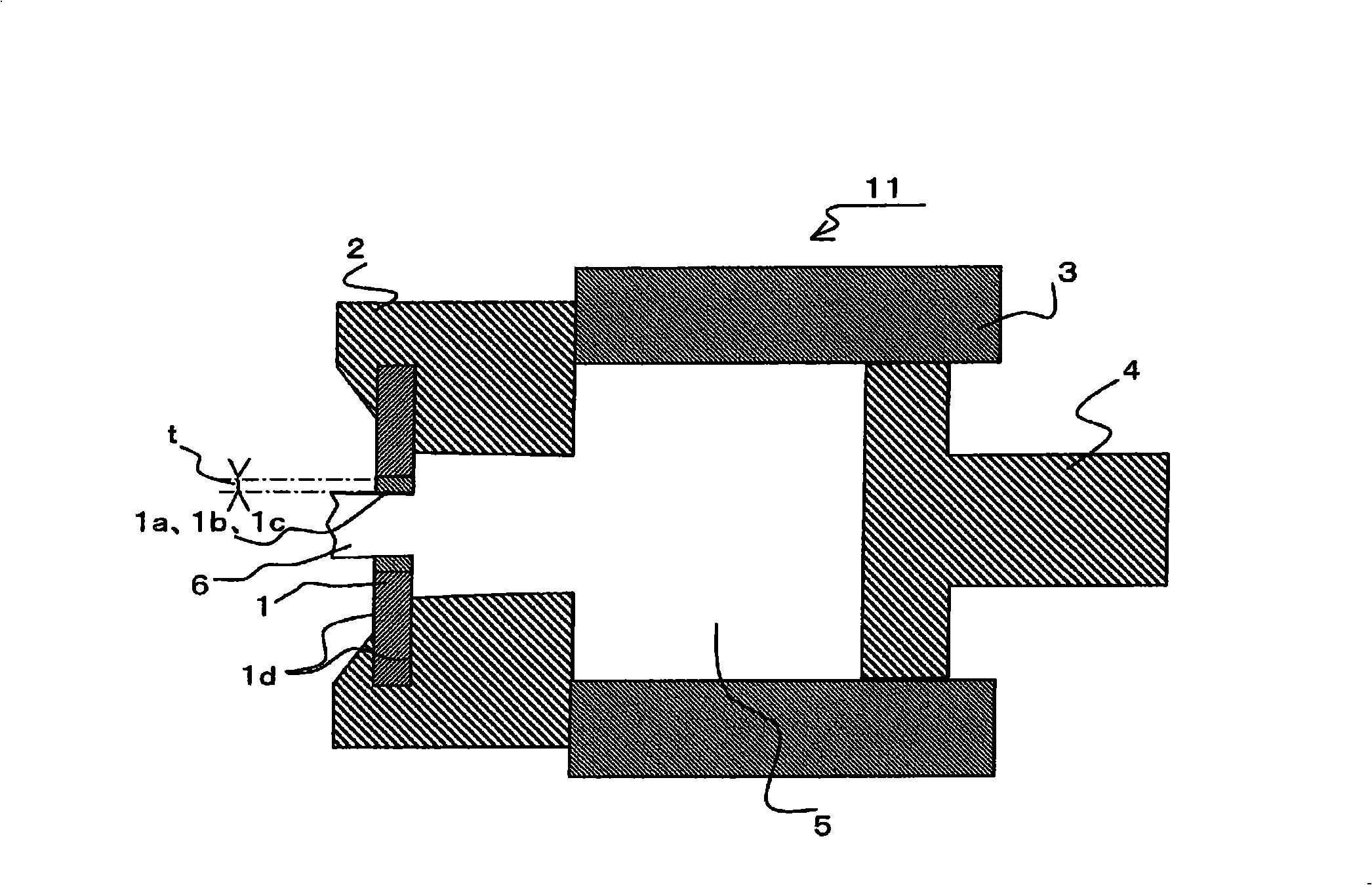

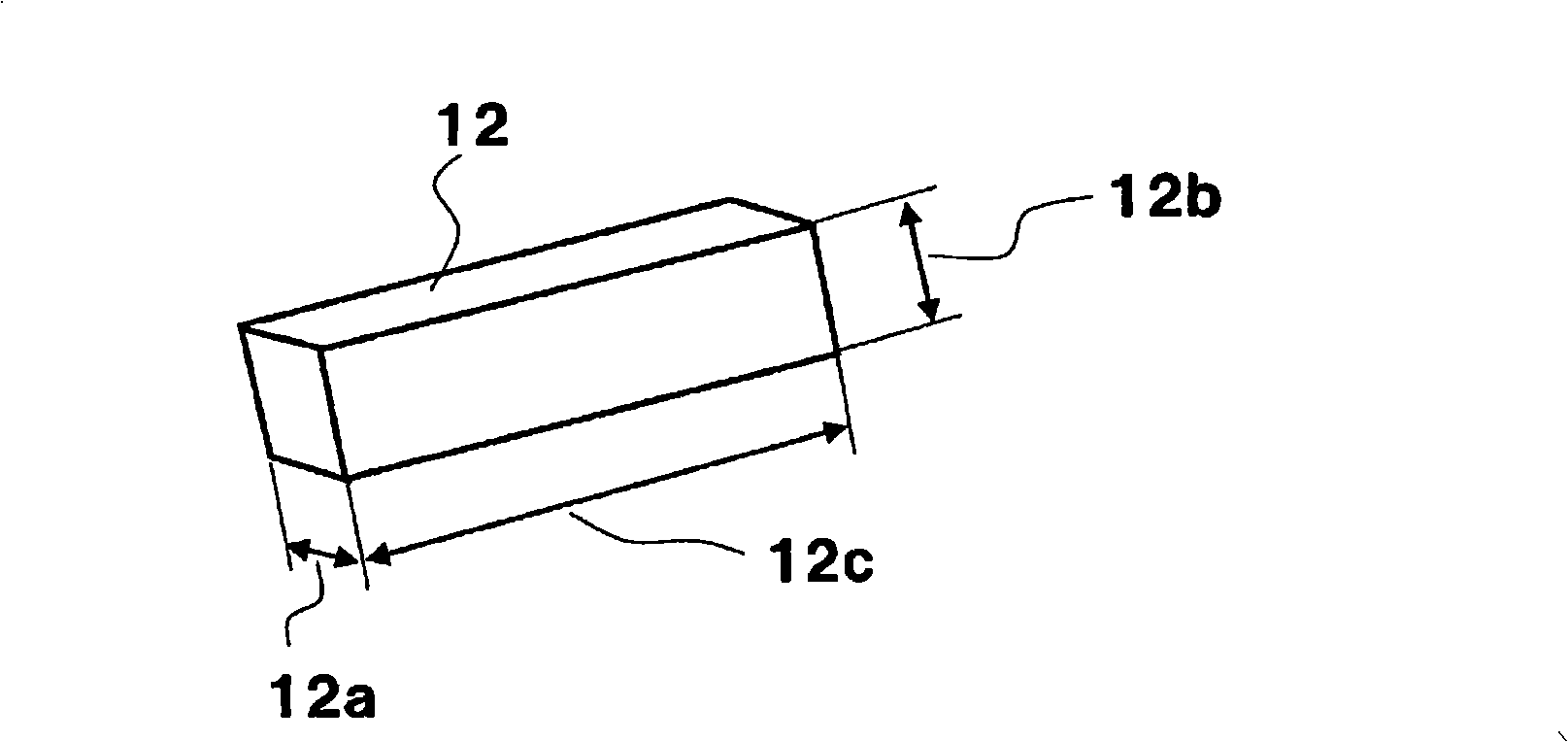

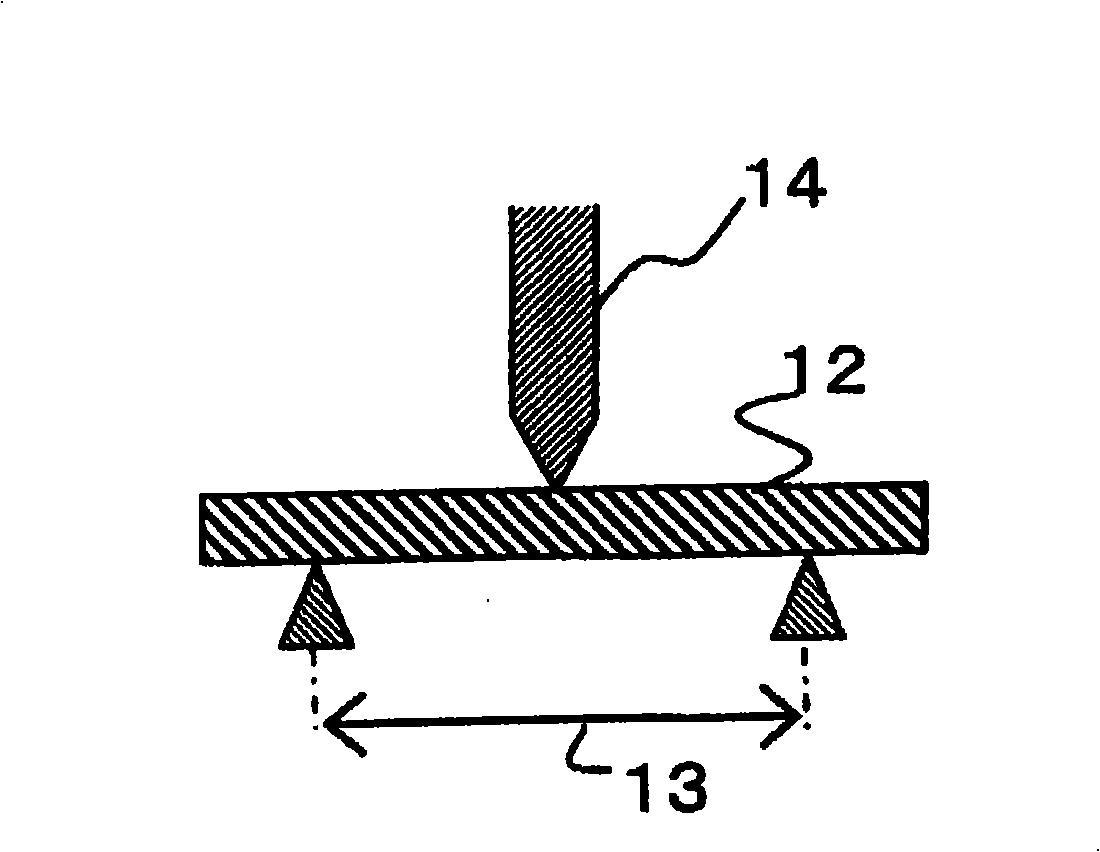

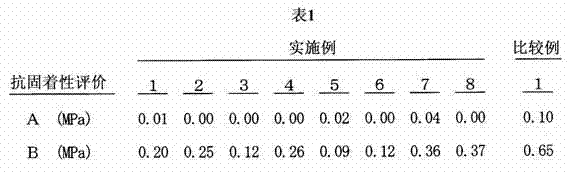

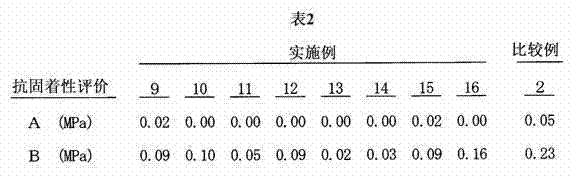

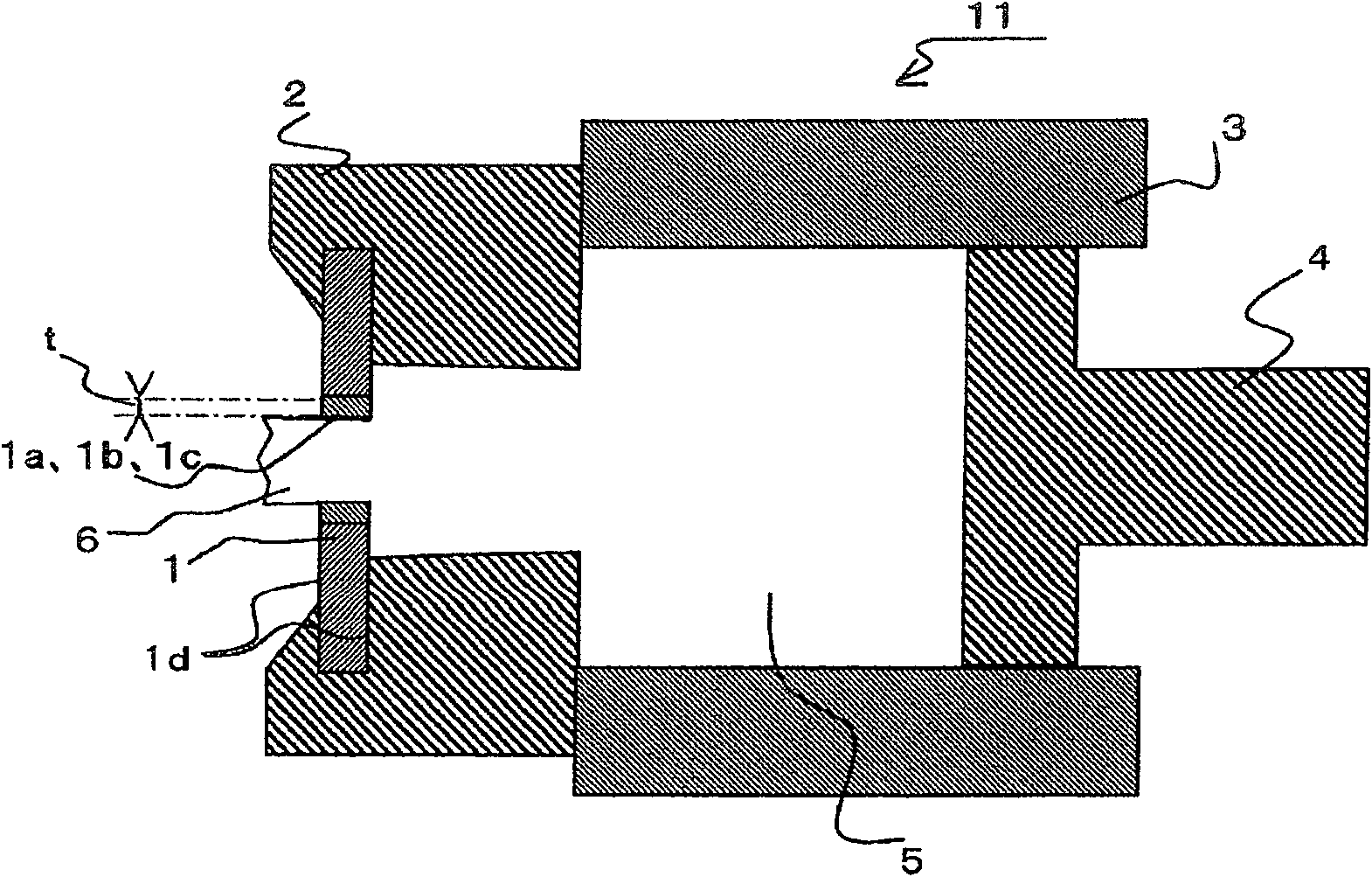

InactiveCN102205165AEnsure slidingIncrease the degree of cross-linkingGuide wiresSurgeryHydrophilic coatingDistal portion

An object of the present invention is to provide a guidewire preventing cracks from being generated at a hydrophilic coating agent and excellent in lubricity by securing flexibility of the hydrophilic coating agent on its surface side even in a case of using the cross-linked hydrophilic coating agent. The guidewire 1 includes a core shaft 2, a coiled body 3 provided at a tip portion of the core shaft 2, a most distal portion 4 fixing a front end of the core shaft 2 and a front end of the coiled body 3, and a hydrophilic coating agent 5 coating the coiled body 3 and the most distal portion 4 and cross-linked by a cross-linking agent 7. The degree of cross-linking of the hydrophilic coating agent 5 decreases from a side of the coiled body 3 toward a surface side.

Owner:ASAHI INTECC CO LTD

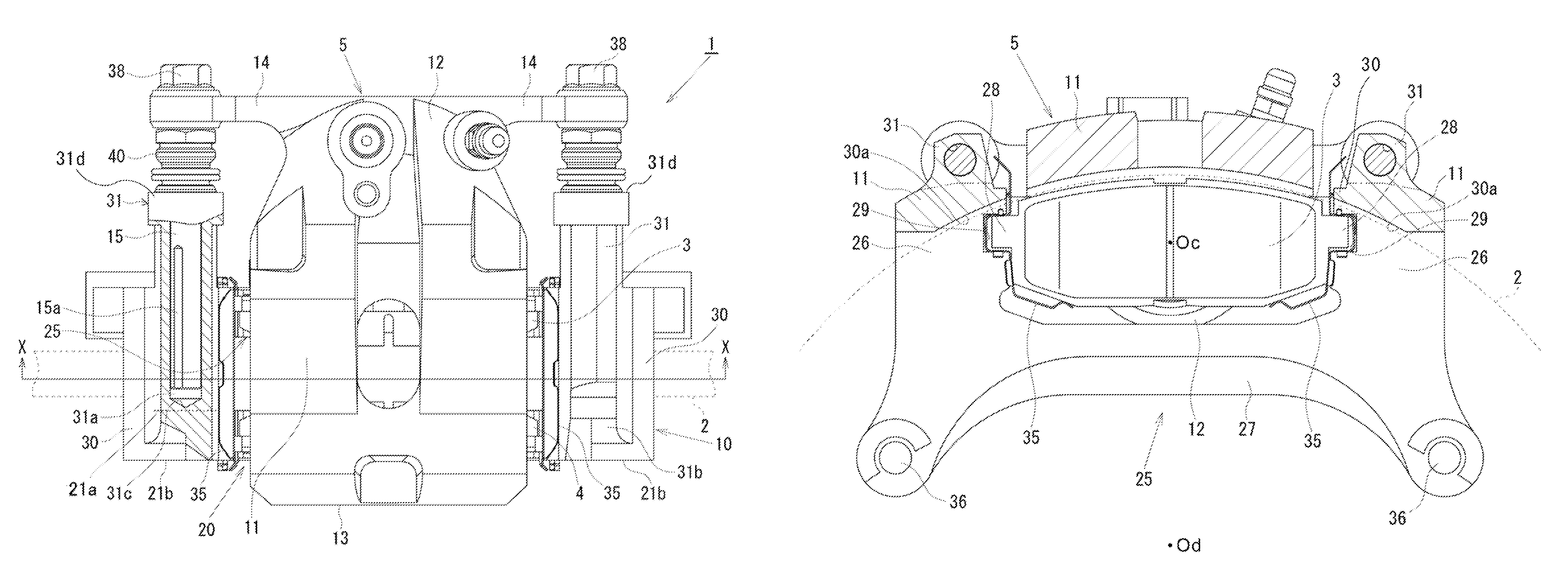

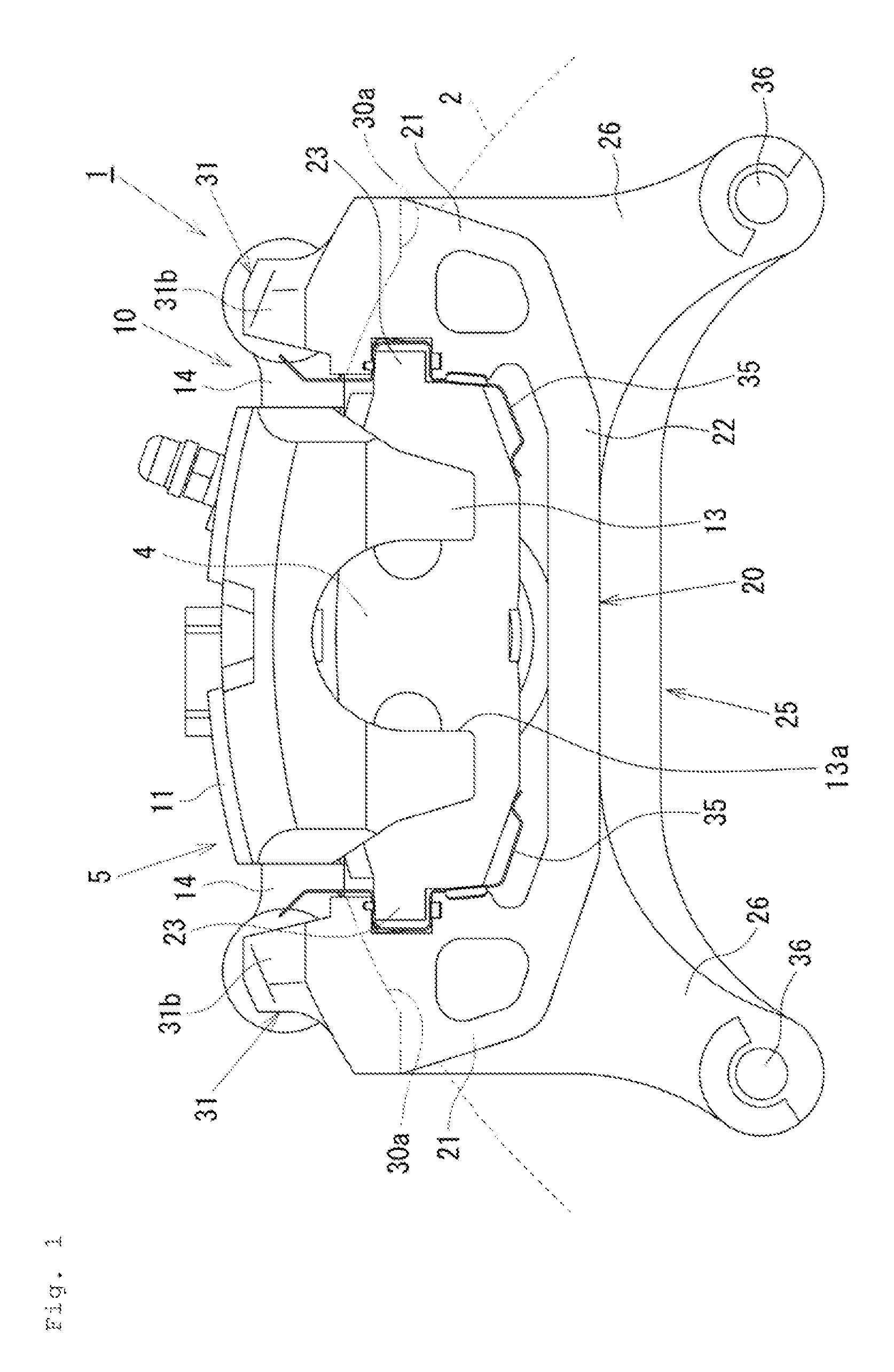

Disk brake

ActiveUS9180841B2Ensure slidingFluid actuated brakesBraking element arrangementsBrake torqueEngineering

A disk brake including a mount member having a pin insertion portion integrally connected to a connection portion so as to outwardly protrude from an outer surface of the connection portion in a radial direction of a disk rotor. A tip of a pin insertion hole of the pin insertion portion is positioned at an inner side of a vehicle relative to an outer portion. Thus, it is possible to prevent a braking torque from affecting the pin insertion portion of the mount member. As a result, it is possible to prevent a slide pin from interfering with an inner wall surface of the pin insertion hole, thereby preventing a brake judder phenomenon from occurring during a braking operation.

Owner:HITACHI ASTEMO LTD

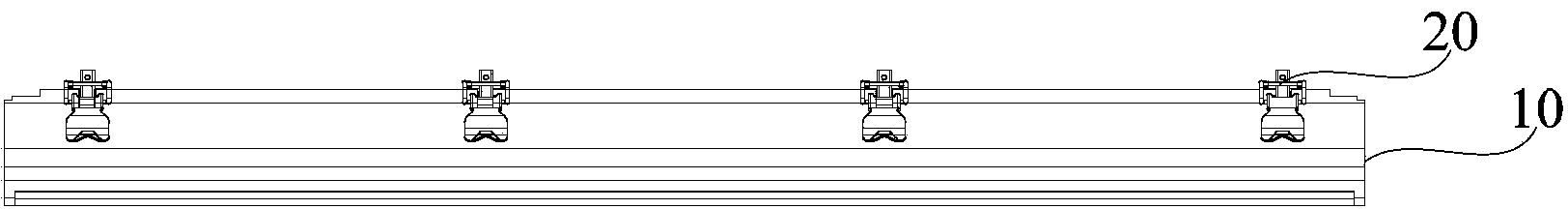

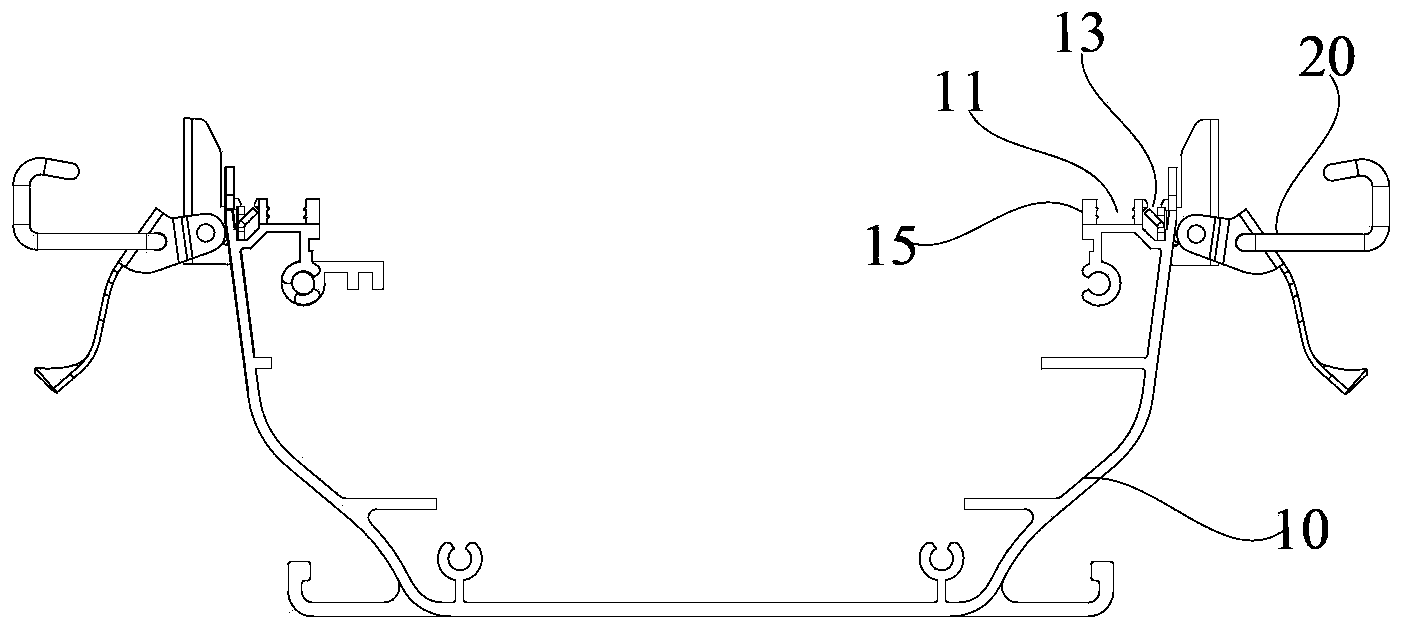

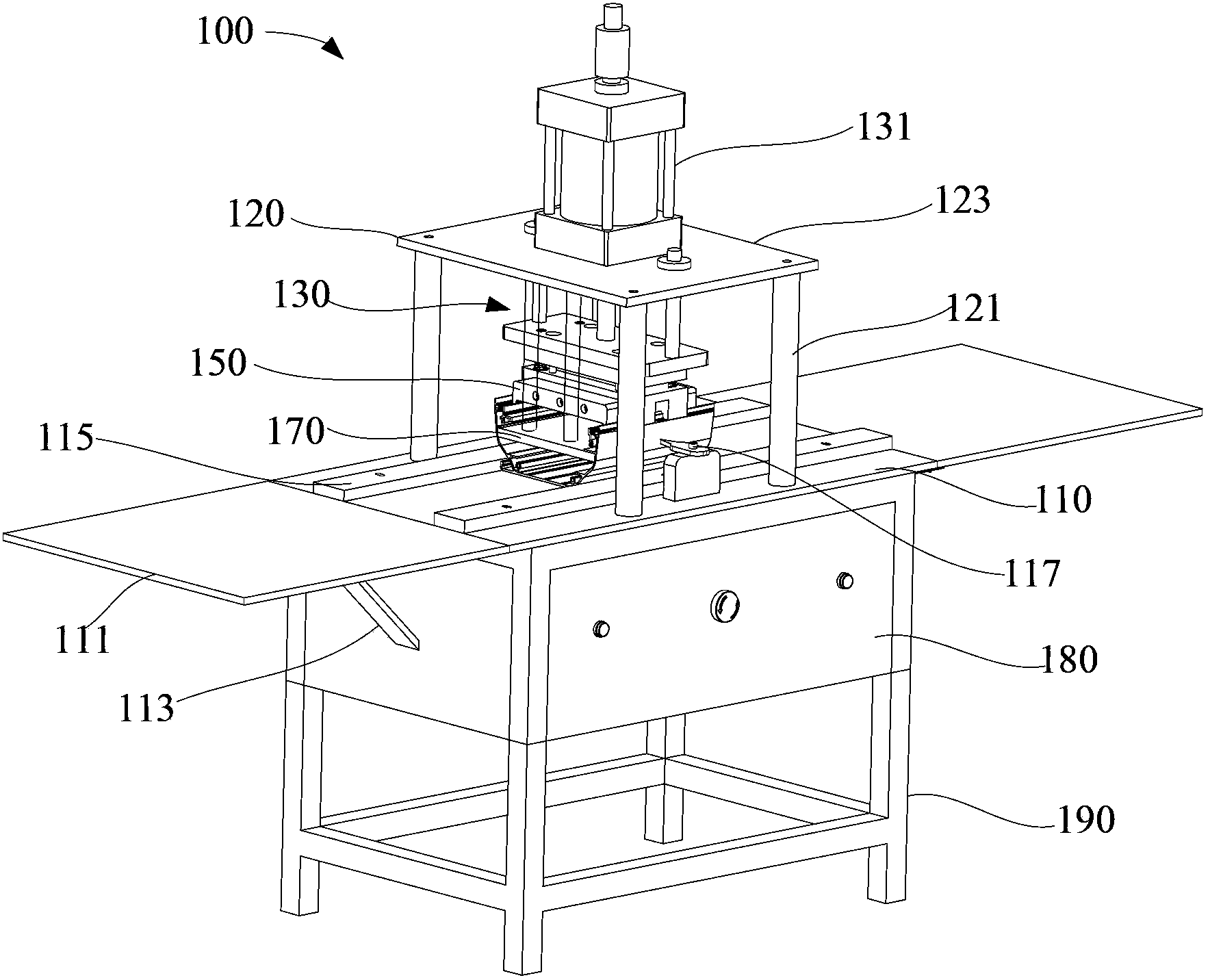

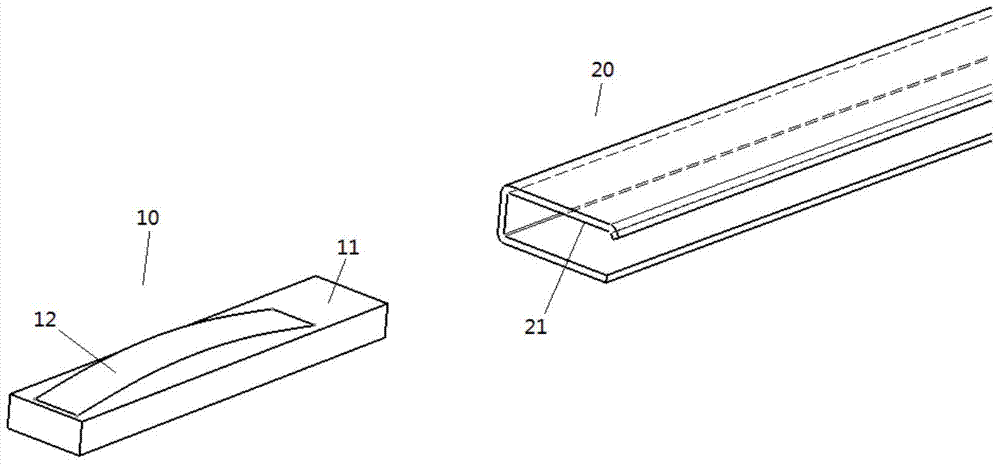

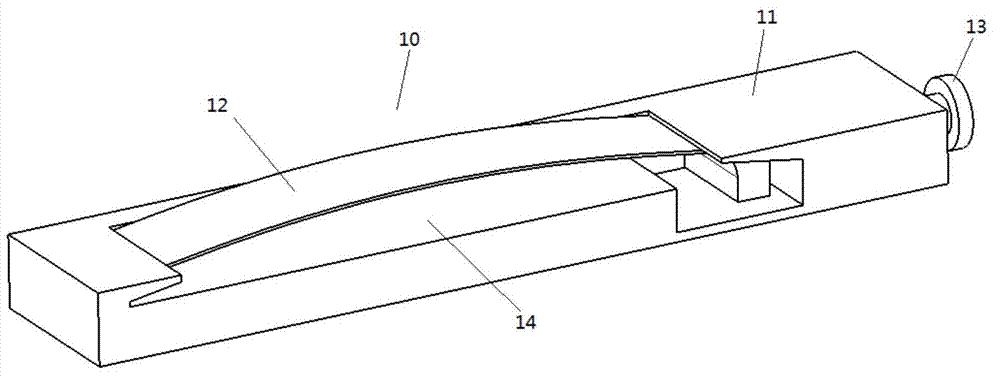

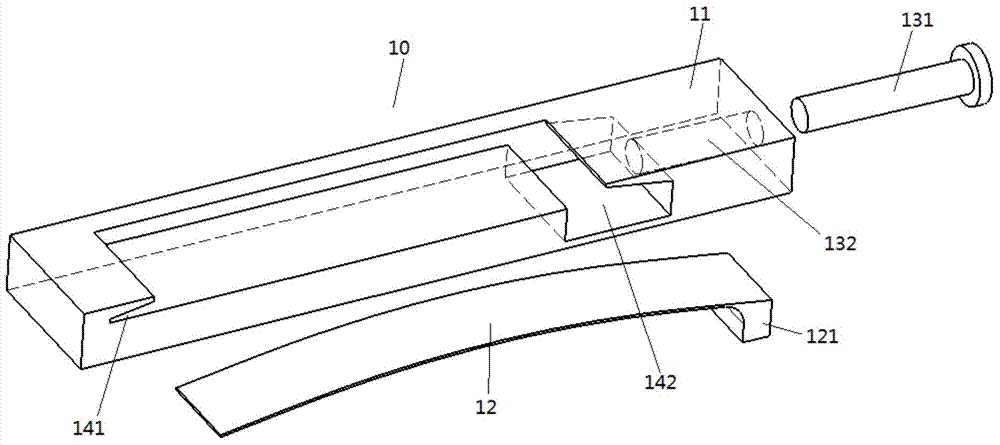

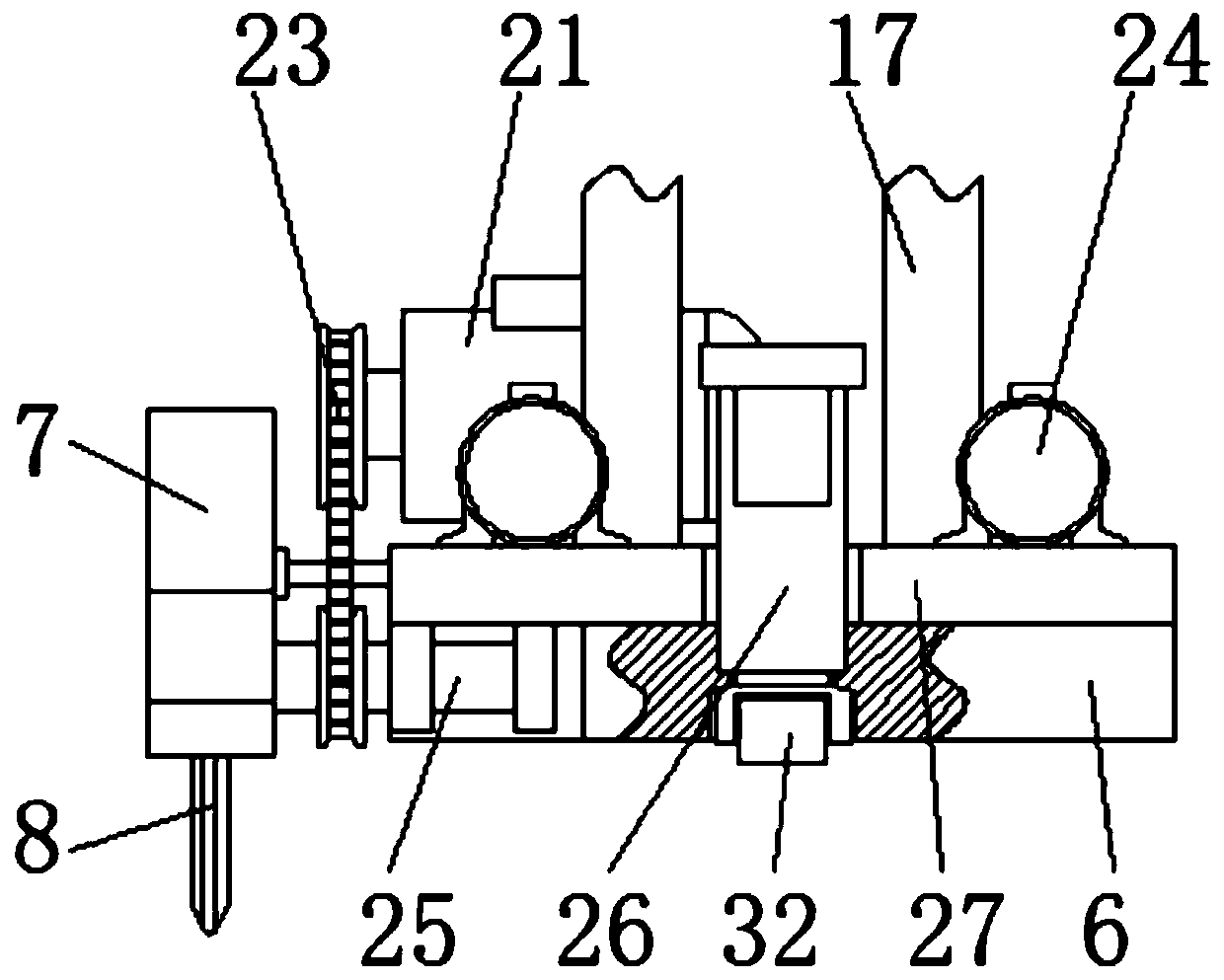

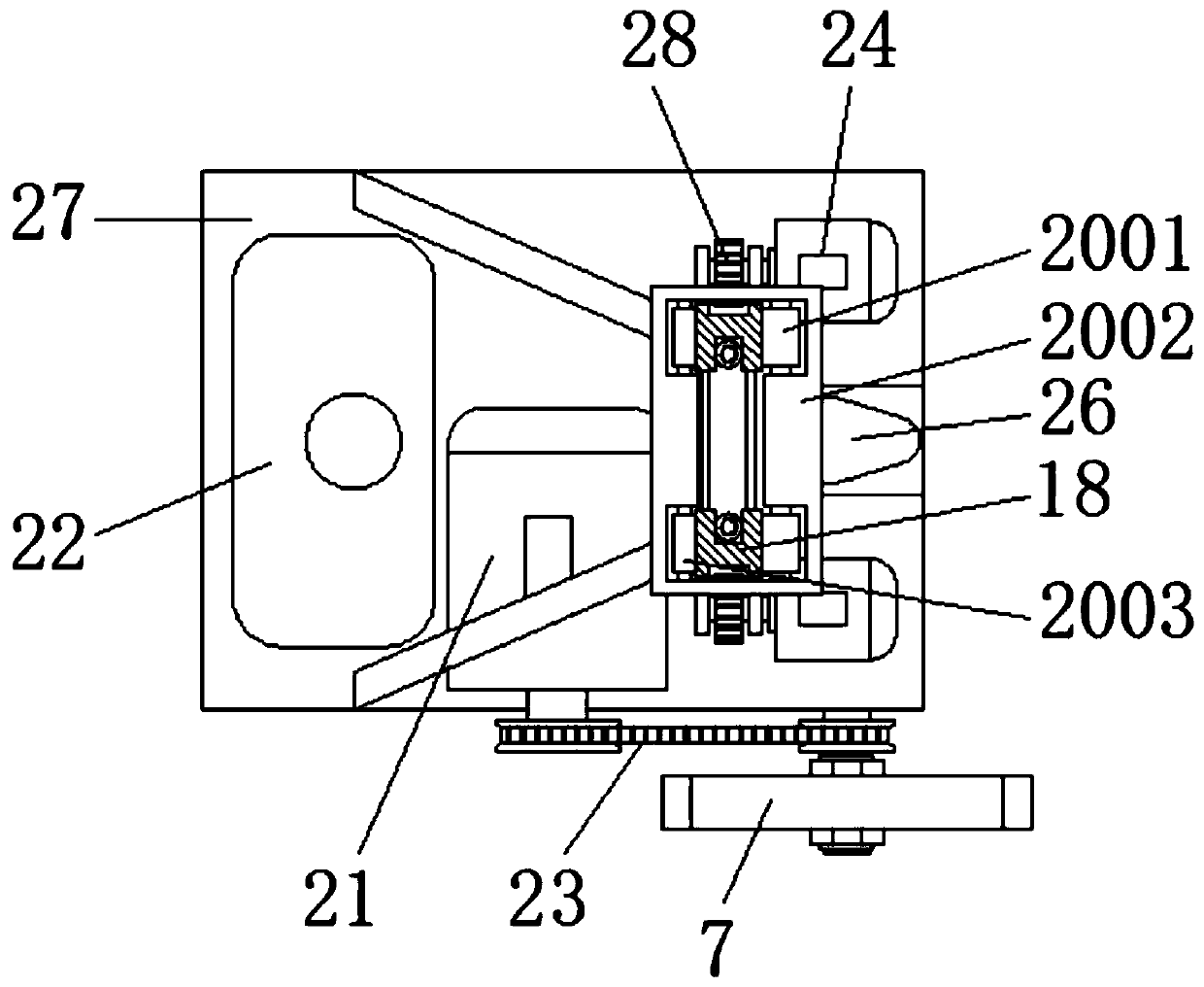

Profile stamping device and profile stamping method

ActiveCN103846352AGuaranteed installationAvoid repeated tappingShaping toolsMetal-working feeding devicesEngineering

A profile stamping device comprises a carrying platform, a supporting member, a stamping module, elastic members and a first positioning plate. The supporting member comprises a plurality of stand columns and a fixing plate. The stamping module comprises an extensible member, a connecting plate and a punch. The extensible member is fixedly arranged on the fixing plate, and the extensible end of the extensible member is penetratingly arranged on the fixing plate. The connecting plate is arranged between the carrying platform and the fixing plate, and is fixedly connected with the extensible end which drives the connecting plate to move. The punch is fixedly arranged on the connecting plate and is far away from the extensible end. The connecting plate drives the punch to move. One end of each elastic member is fixedly connected with the connecting plate. The first positioning plate is connected with one ends, away from the connecting plate, of the elastic members. The distance between the first positioning plate and a profile is smaller than the distance between the punch and the profile. The first positioning plate moves to enable two ends thereof to be accommodated in guide rails and abutted against the side walls of the profile, and the two ends of the first positioning plates support the two side walls of the profile when the punch punches hooks, so that deformation of the profile is avoided. The invention further provides a profile stamping method.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

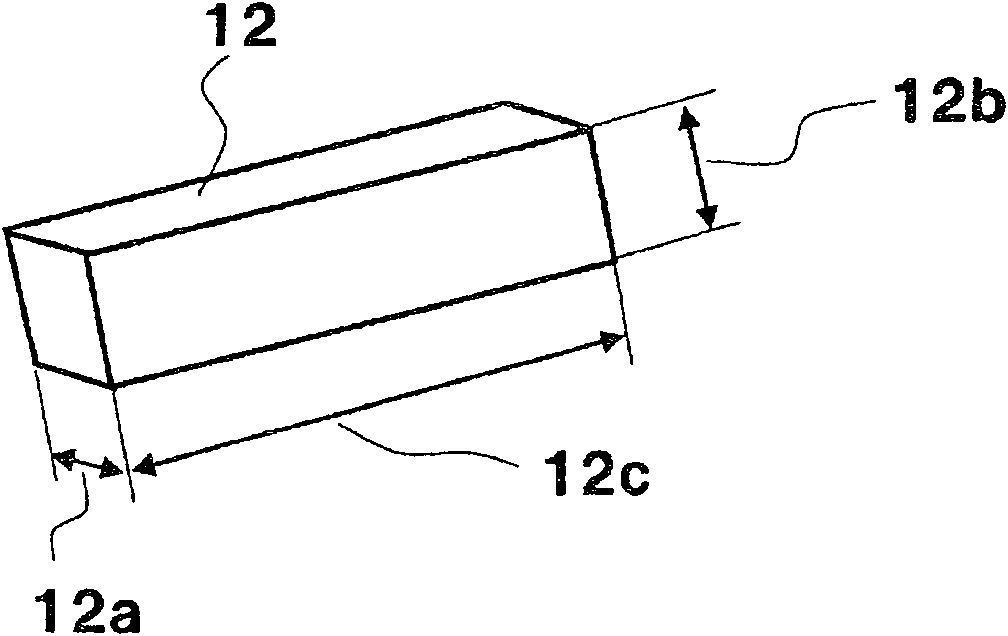

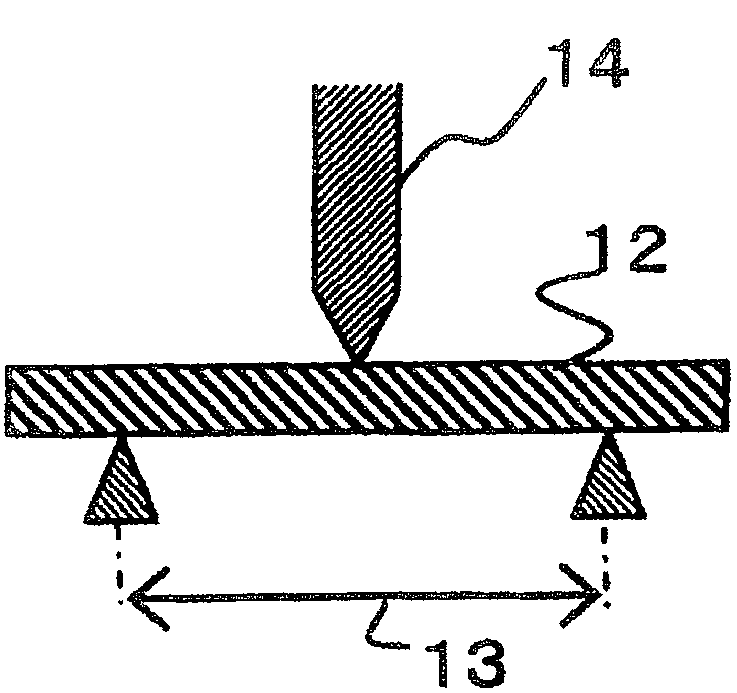

Sintered body and method for producing same sliding member, film-forming material and die for hot extrusion molding each using such sintered body and hot extrusion molding apparatus and hot extrusio

InactiveCN101273150ALow sliding resistanceHigh strengthExtrusion diesTransportation and packagingHardnessHigh intensity

By using a sintered body composed of 58-92.5% by mass of TiCN, 0.01-1% by mass of Ti, 0.01-2% by mass of TiC, 0.01-2% by mass of TiN and the balance of TaC, Ni and Cr, there can be obtained a sliding member, film-forming material and die for hot extrusion molding which exhibit high strength, high hardness, high toughness and high sliding properties in an environment of about 400-600 DEG C, and a hot extrusion molding apparatus using such a die for hot extrusion molding.

Owner:KYOCERA CORP

Fluorine-resin sealing ring

InactiveCN104508334AGuaranteed tightnessEnsure slidingEngine sealsOther chemical processesAutomatic transmissionReciprocating motion

A PTFE resin sealing ring in which at least one surface of an abutting part that forms a discontinuity in the sealing ring has been subjected to a plasma-modification treatment using a non-polymerizable gas and a pressure during plasma exposure of 10 to 500 Pa. Since the abutting surface(s) of this PTFE resin sealing ring has / have been subjected to a low-pressure plasma treatment, changing the states of the C-F bonds in the surface region(s), the abutting part does not stick even after a steady load has been applied at a high temperature, producing the prominent effect of ensuring both sealing performance under pressure and the ability to slide when not under pressure. This sealing ring is effective as a sealing material used with rotation or reciprocal motion, including a hydraulic circuit in a continuously variable transmission (CVT) or an automatic transmission (A / T) in an automobile, for example.

Owner:NOK CORP

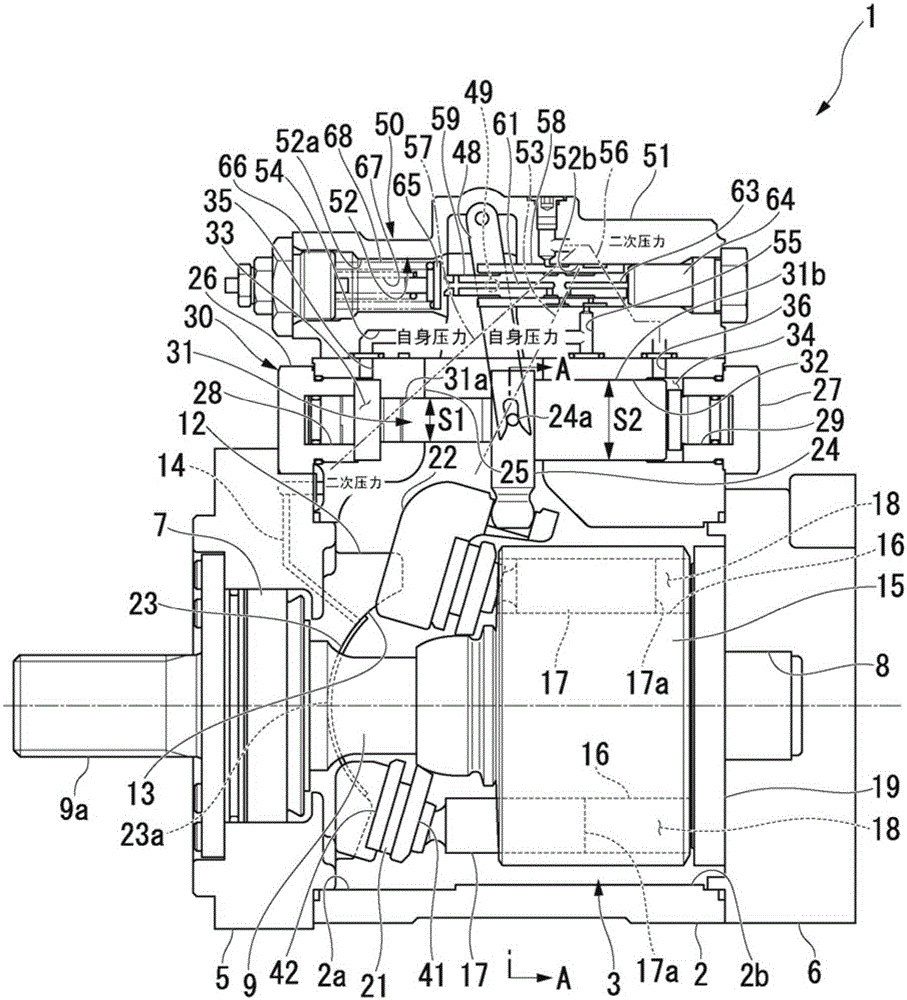

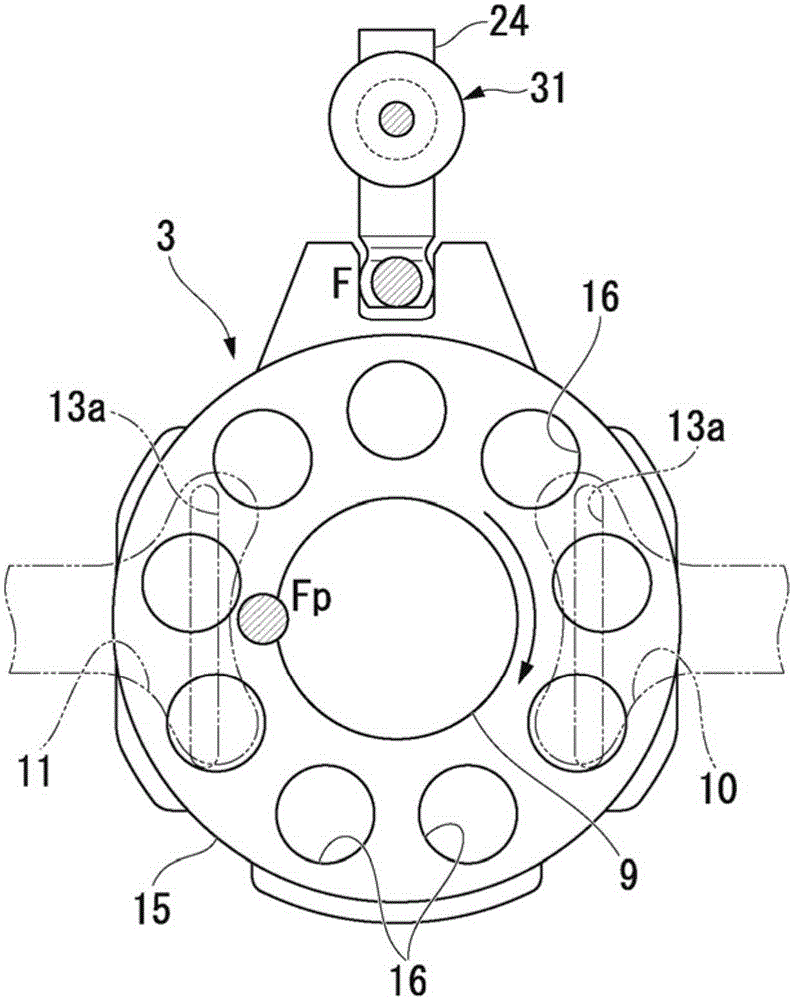

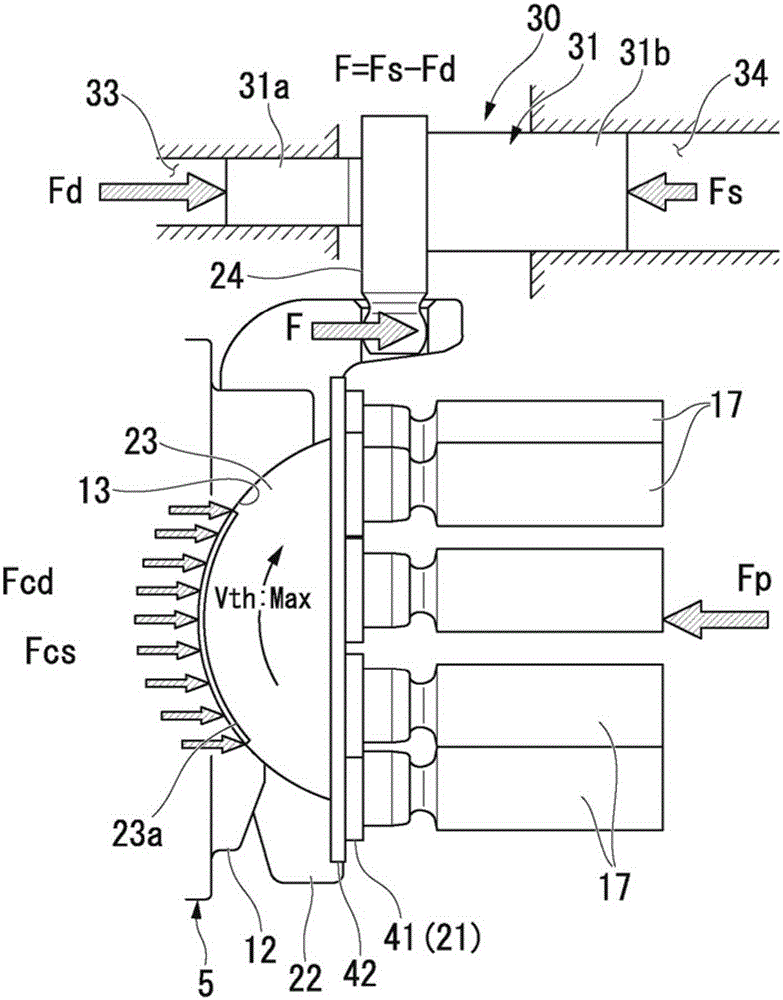

Variable capacity hydraulic device

ActiveCN105298781AEnsure slidingPositive-displacement liquid enginesMulti-cylinder pumpsCylinder blockControl theory

The invention provides a variable capacity hydraulic device. The variable capacity hydraulic device includes a housing, a cylinder, pistons, an inclined plate, an oil groove, a work piston and a servo mechanism, wherein the cylinder is arranged in the housing in the rotary way; the pistons are respectively inserted in a plurality of cylinder holes in the cylinder; the inclined plate is arranged on the pistons and on the opposite side end in the cylinder holes of the pistons, and is arranged in the sliding way relative to the opposite side end, and can move in the inclined way and can slide on the housing; the oil groove is formed on any one of the sliding surface of the housing and the sliding surface of the inclined plate, and is used for guaranteeing the sliding property between the housing and the inclined plate; the work piston is used for moving the inclined plate in the inclined way; and the servo mechanism supplies hydraulic oil to drive the work piston and supplies the secondary pressure generated by the servo mechanism to the oil groove.

Owner:NABLESCO CORP

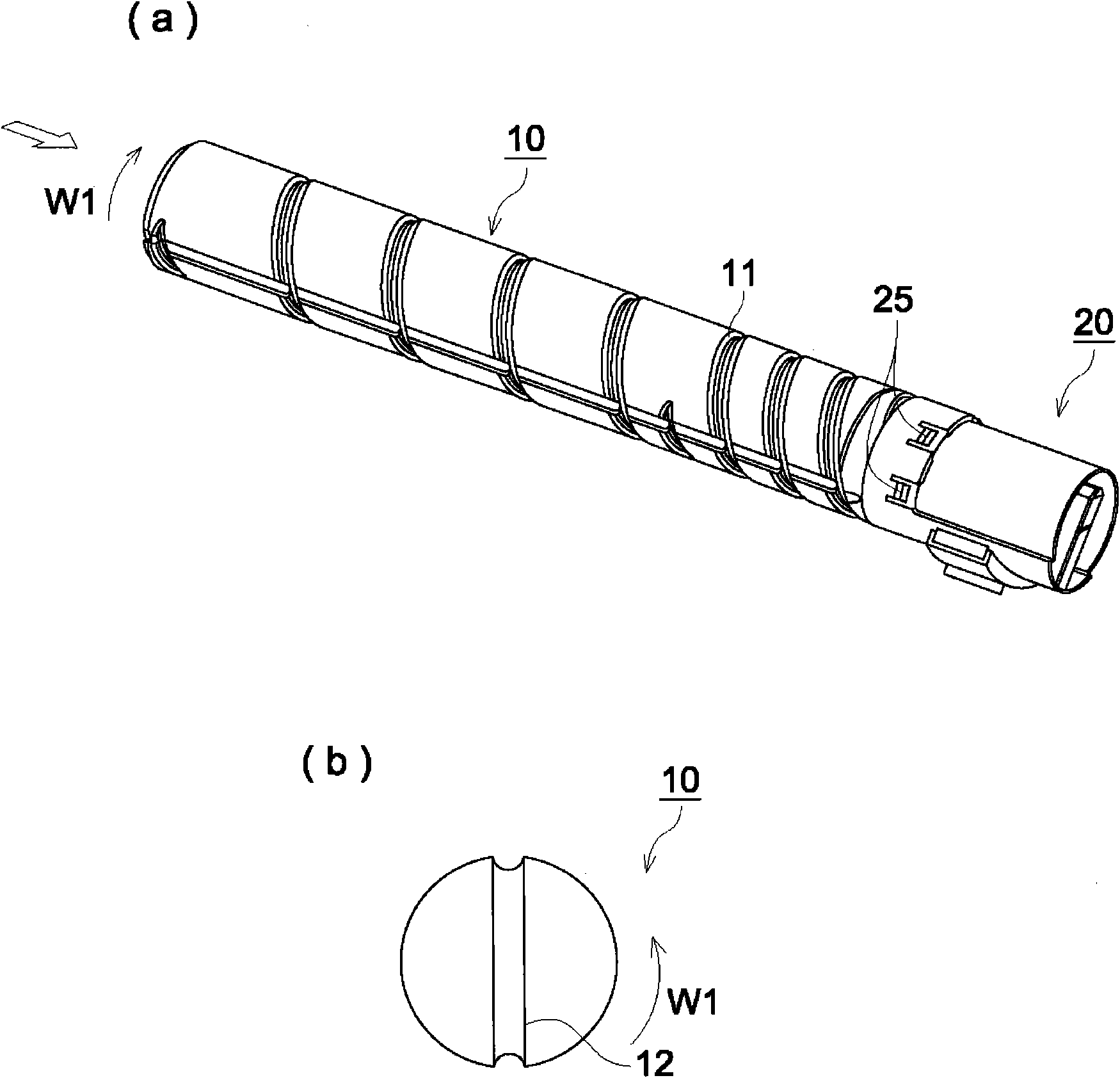

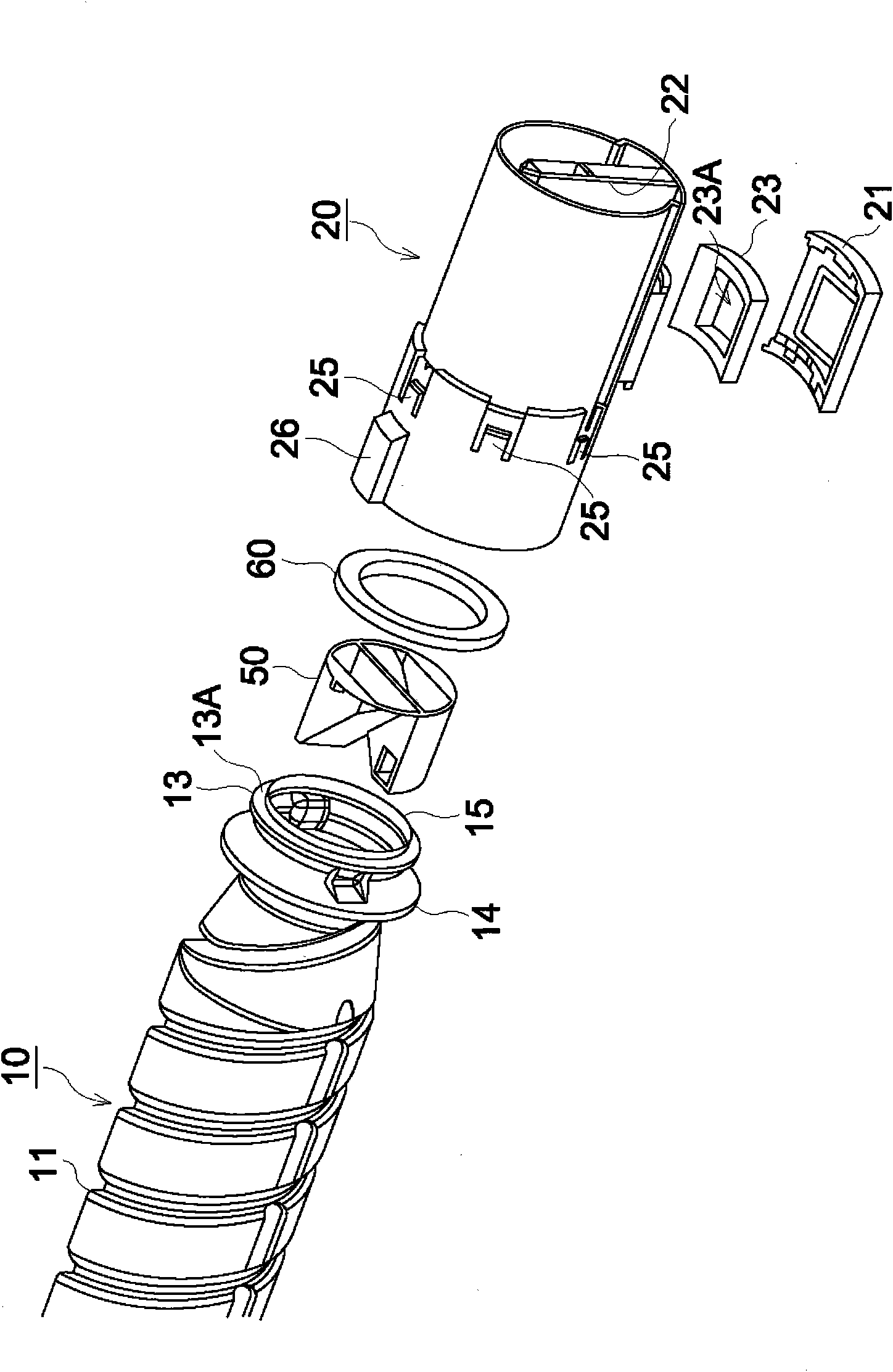

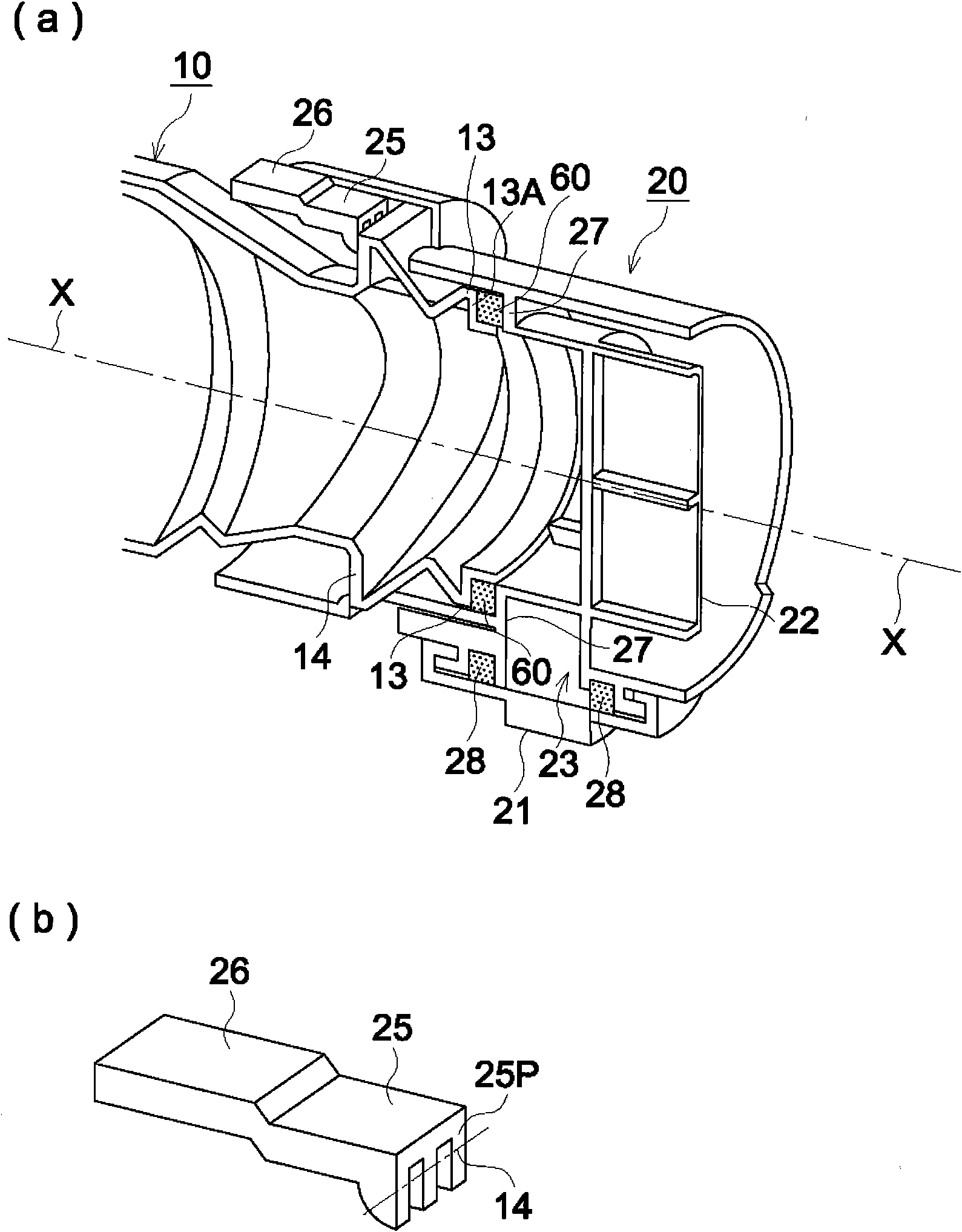

Toning agent container and method for manufacturing the same

InactiveCN101900970AReduce slippageEnsure slidingElectrographic process apparatusEngineeringMechanical engineering

Owner:KONICA MINOLTA BUSINESS TECH INC

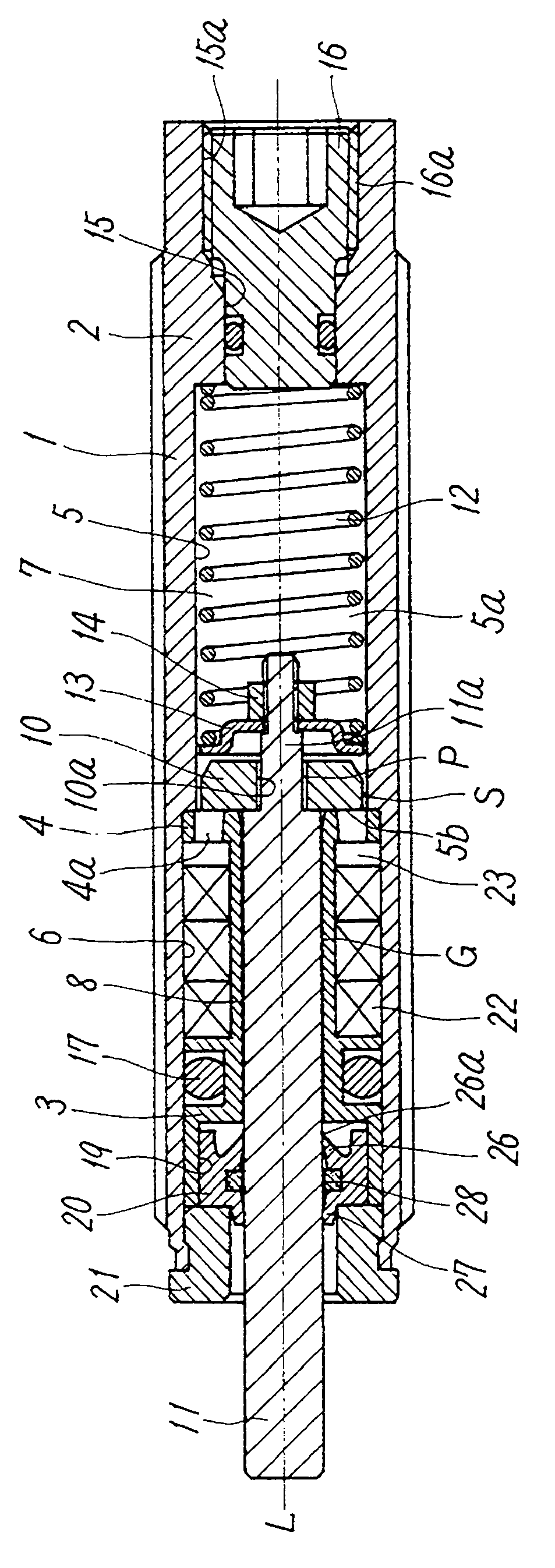

Hydraulic shock absorber

Provided is a hydraulic shock absorber such that an oil film stuck to the outer periphery of a rod is removed to the utmost, resulting in the oil outflow amount being reduced, and that at the same time, it is made possible to secure satisfactory slidability between said rod and a rod gasket and to prevent wear of said rod gasket. A first lip (26) for scraping off the oil film (7a) which is stuck to the outer periphery of the rod (11) is formed in the rod gasket (20), which is interposed between the outer periphery of the rod (11) and the inner periphery of a rod side end wall (3). Furthermore, a ring-shaped grease retaining member (28) which supplies retained grease to the outer periphery of the rod (11) is provided. Said grease retaining member (28) is made to contact the outer periphery of the rod (11) at a position nearer the rod tip than is the first lip (26).

Owner:SMC CORP

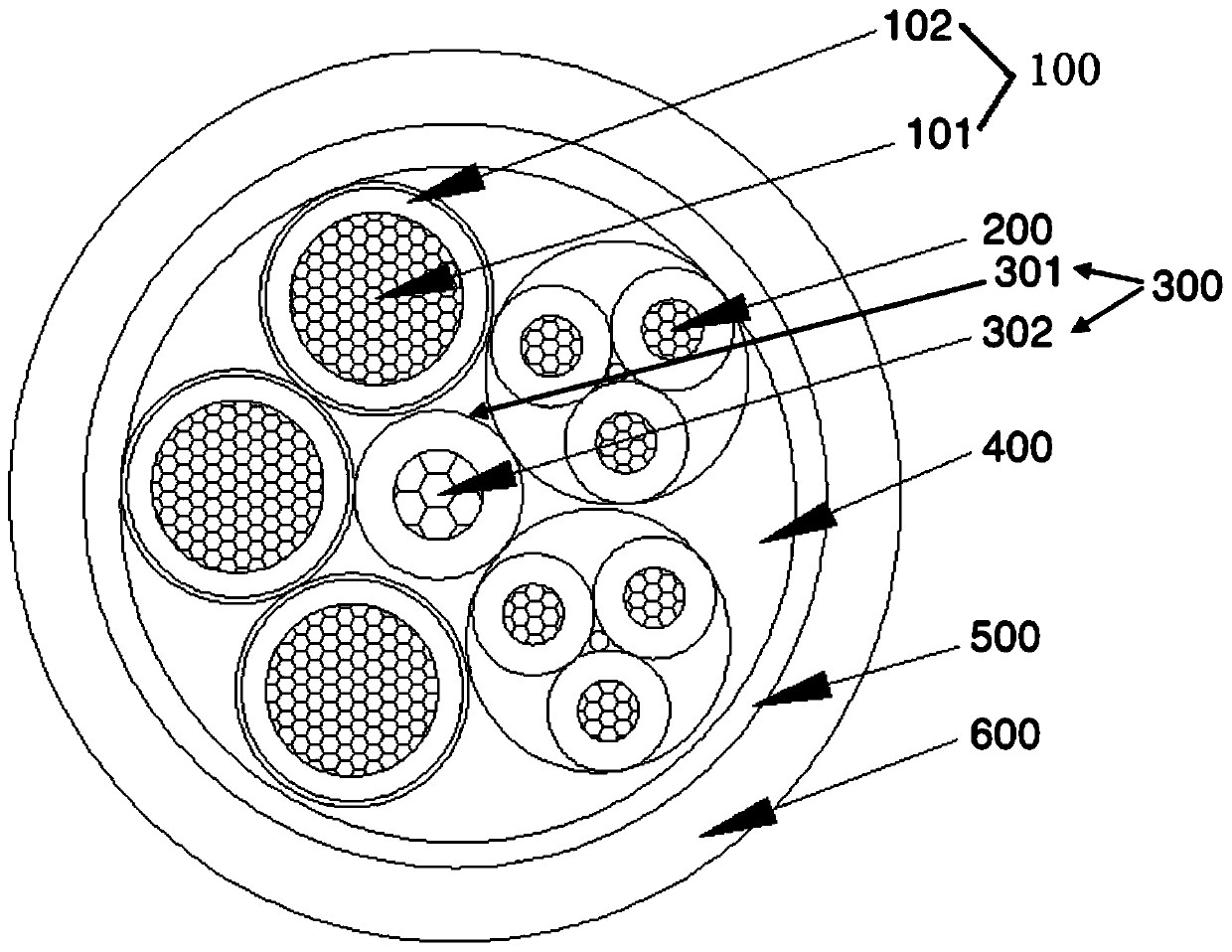

Flexible cable for intelligent equipment and production process thereof

PendingCN110752058AEven by forceImprove overall tensile strengthNon-insulated conductorsConductive materialCorrosion resistantFlexible cable

The invention provides a flexible cable for intelligent equipment and a production process thereof. The cable comprises three power wire cores, two control wire core groups, a central reinforcing member, an inner sheath, a reinforcing layer and an outer sheath, wherein the two control wire core groups and the three power wire cores are arranged in a five-equal-division manner, and the central reinforcing member is arranged at a gap to form a cable core; and the inner sheath, the reinforcing layer and the outer sheath are sequentially arranged outside the cable core. The characteristics of wearresistance, high and low temperature resistance, pulling resistance, bending resistance, corrosion resistance and excellent insulation of the cable are improved, and the problems that the core of a pulling cable is easy to break and faults frequently occur in the prior art are solved.

Owner:FAR EAST CABLE +2

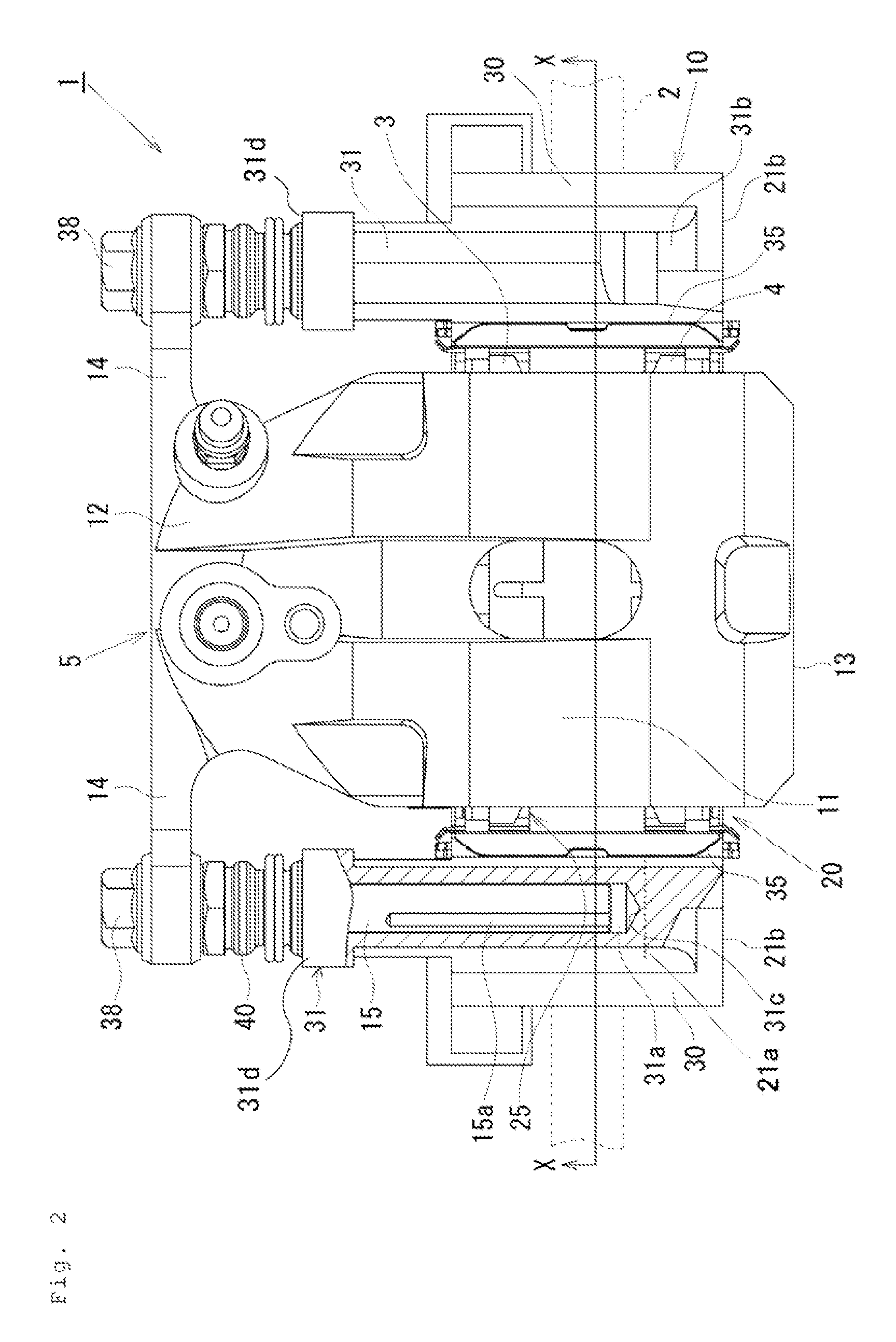

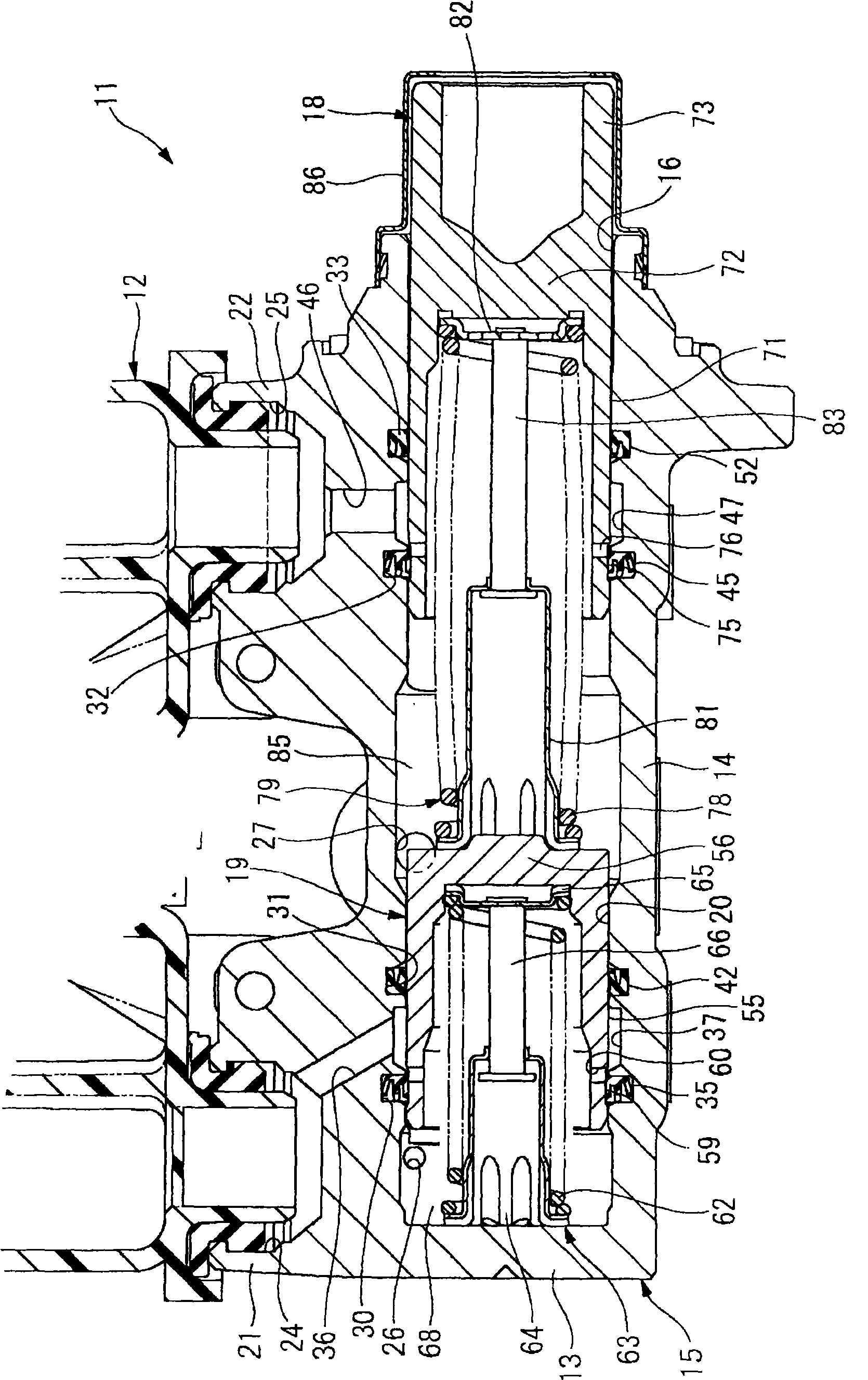

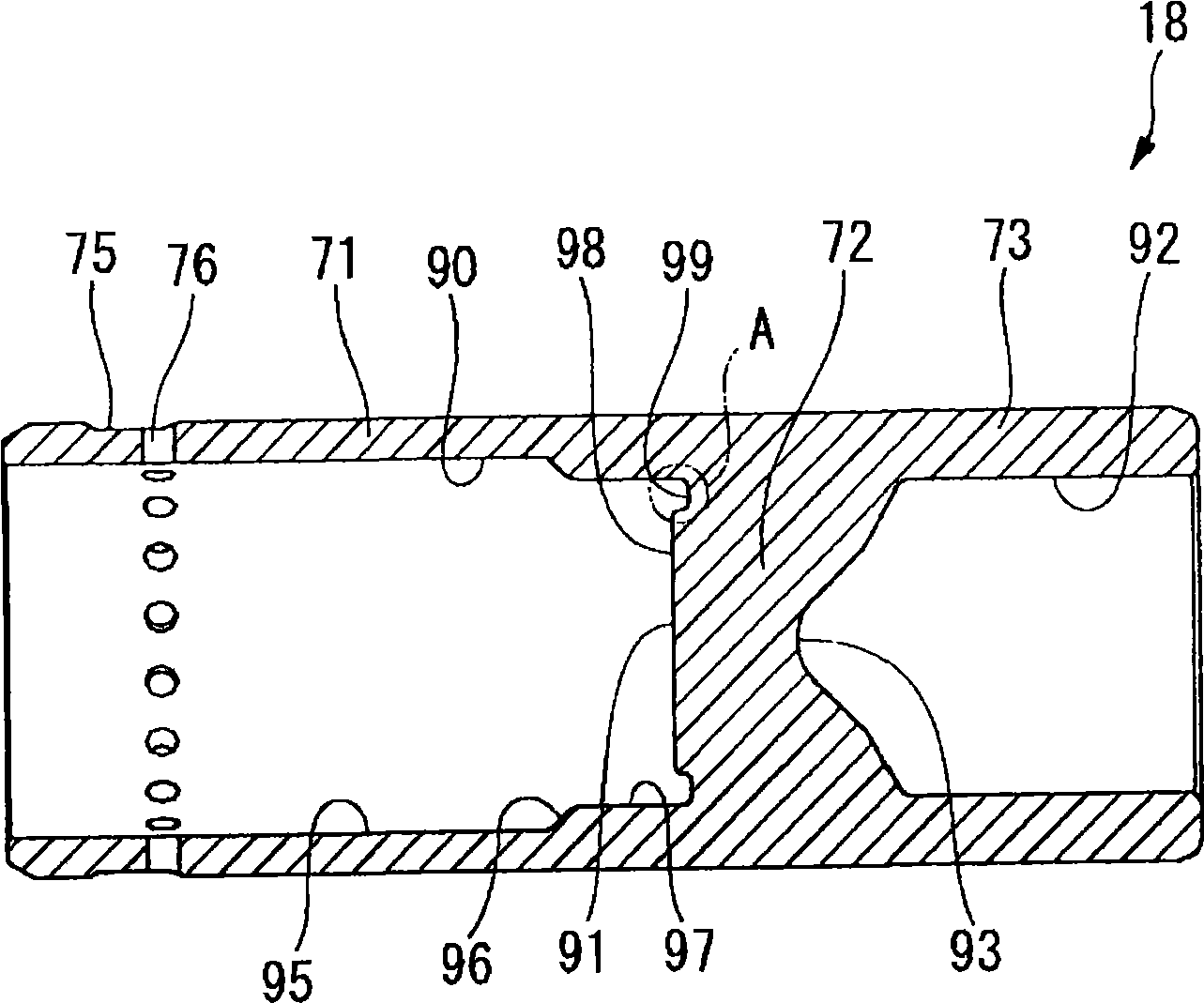

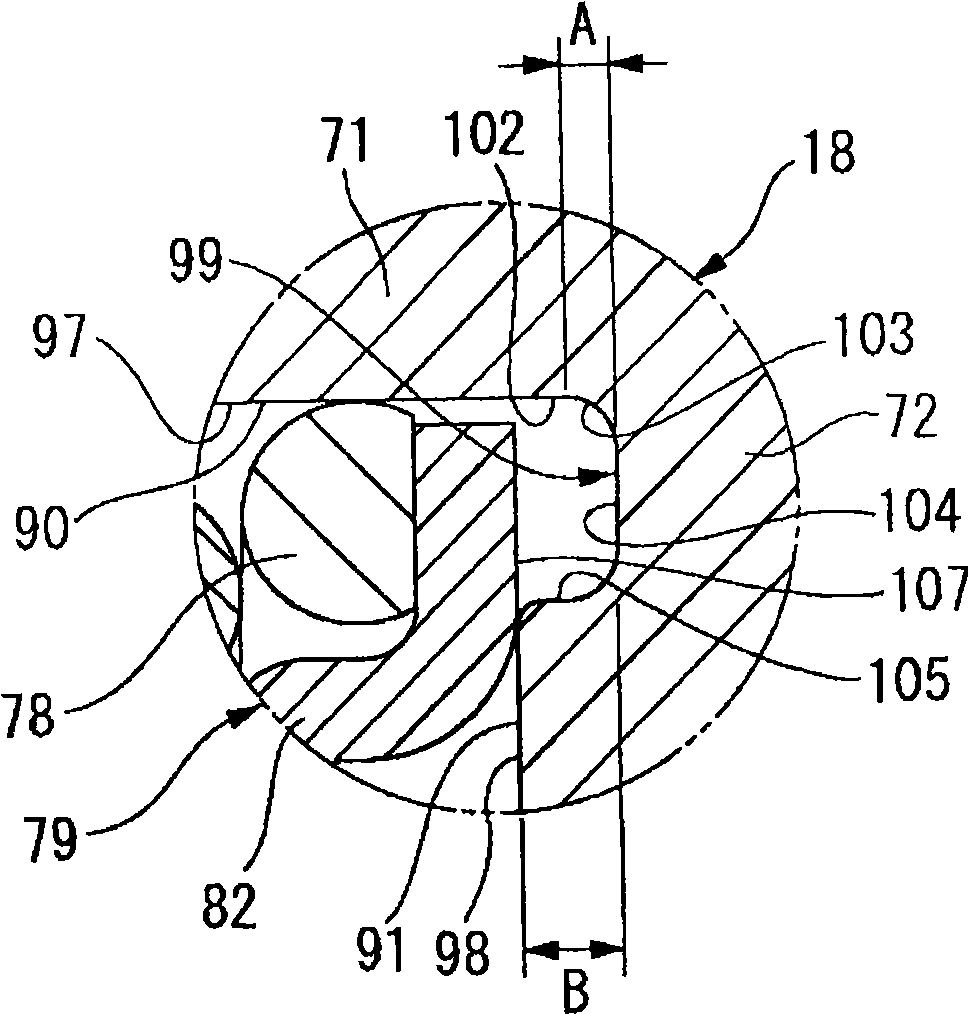

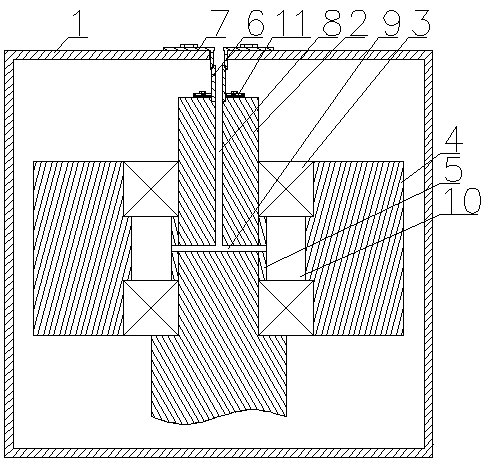

Master cylinder

The invention provides a master cylinder capable of preventing a retainer from interfering with the maintainer inner bottom even a piston is formed by forging and capable of assuring excellent slide performance of the piston. The master cylinder comprises a bottomed cylindrical cylinder body, a piston (18) formed into a bottomed cylindrical shape and slidably disposed in the cylinder body, and a spring assembly (79) comprising a spring (78) urging the piston (18) toward an opening side of the cylinder body and a length of a spring of the spring assembly is determined by a retainer (82) which can abut against an inner bottom portion (91) of the piston (18). An annular groove (99) is formed on the most outer side of the inner bottom portion (91) of the piston (18)by the forging method.

Owner:HITACHI LTD

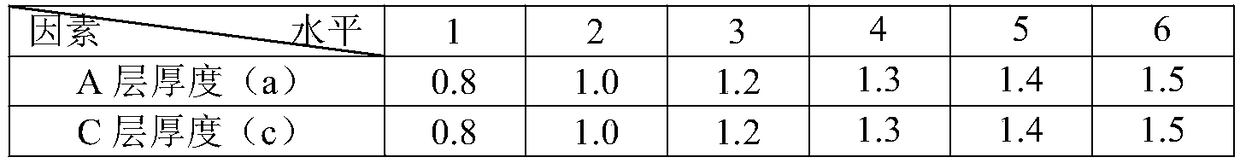

Anti-rib-forming and anti-wrinkling printing film and preparation method thereof

ActiveCN109397916AGood flexibilityReduce coefficient of frictionDuplicating/marking methodsSynthetic resin layered productsEngineeringTotal thickness

The invention discloses an anti-rib-forming and anti-wrinkling printing film and a preparation method thereof, wherein by means of specific components and technologies, the total thickness, as well thickness of every layer and thickness ratio, of the printing film in an A / B / C layered lamination structure are defined, so that stiffness and thickness uniformity of the printing film are improved, thereby improving the anti-rib-forming and anti-wrinkling properties thereof.

Owner:HONGTA PLASTIC CHENGDU CO LTD

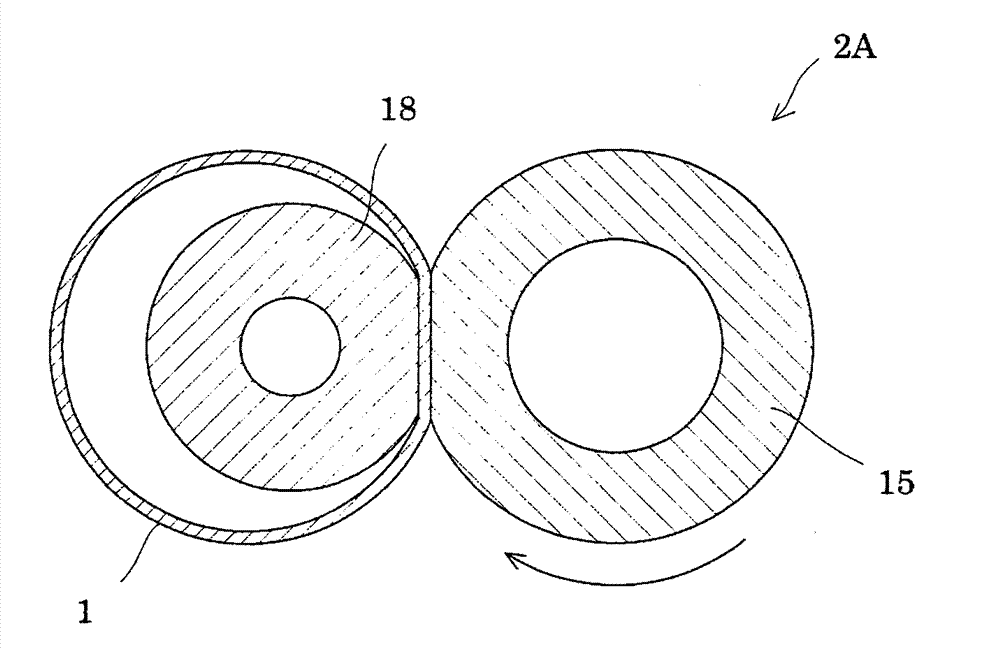

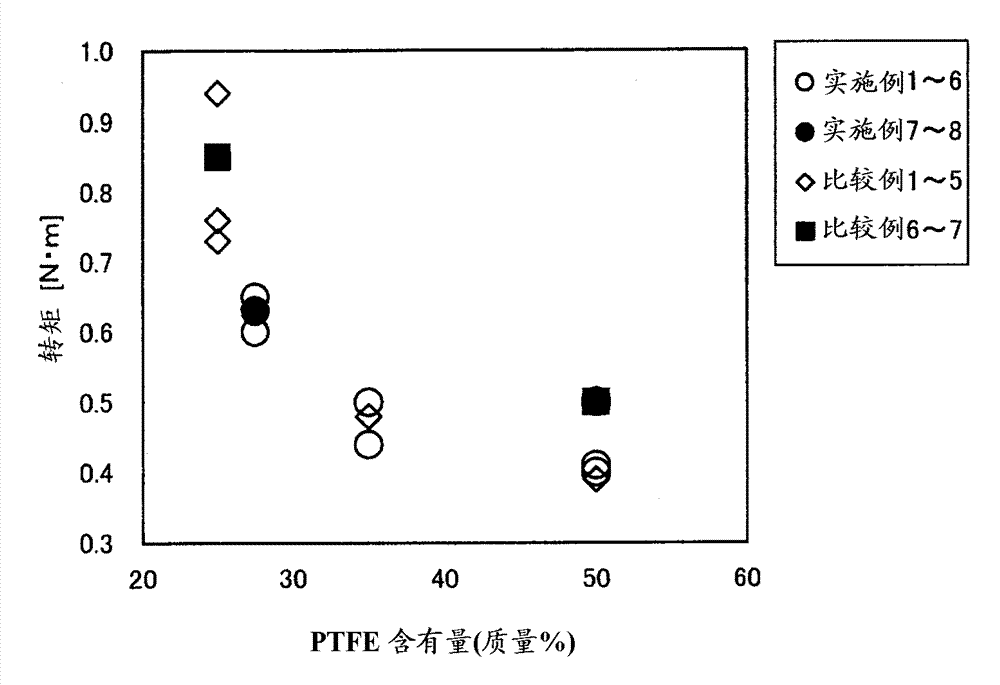

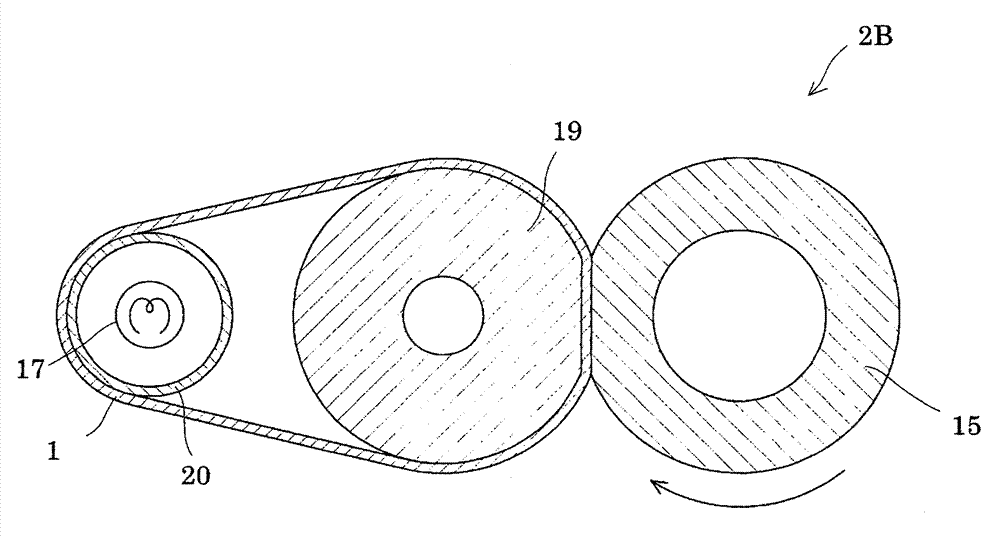

Fixation member and fixation apparatus having the fixation member

InactiveCN103676576AReduce drive torqueAvoid stickyElectrographic process apparatusPolyamide-imideSurface roughness

The present invention relates to a fixation member and a fixation apparatus having the fixation member. The present invention provides a fixation member which exhibits enhanced wear resistance and sliding property between the peripheral surface of the fixation member and a pressure member, which can reduce driving torque at a fixation unit, and which does not cause stick slipping even in a high-load operational mode, and a fixation apparatus having the fixation member. The fixation member (1) employed in a fixation unit of the fixation apparatus has a metallic substrate (10) having at least one layer of an electrocast seamless belt, and a slide layer (11) disposed on the inner peripheral surface of the metallic substrate (10), wherein the slide layer (11) is formed of at least one species of the group consisting of a polyamide-imide resin and a polyimide resin, and a fluororesin; the slide layer (11) has a fluororesin content of 27.5 mass% to 50 mass%; and the slide layer (11) has a surface roughness Ra of 0.4 [mu]m or less.

Owner:NOK CORP +2

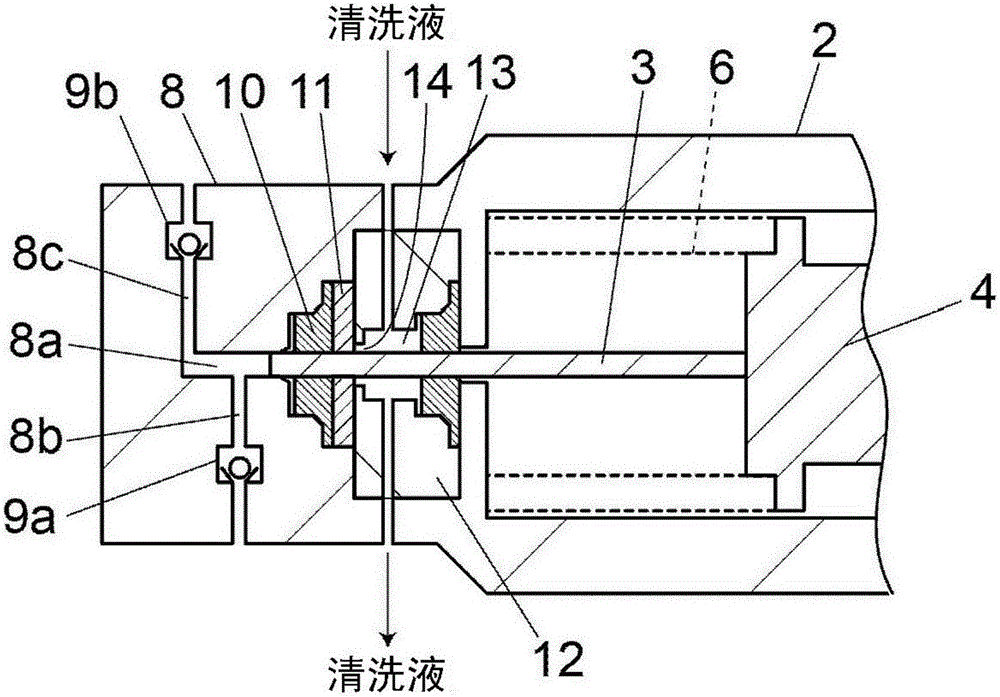

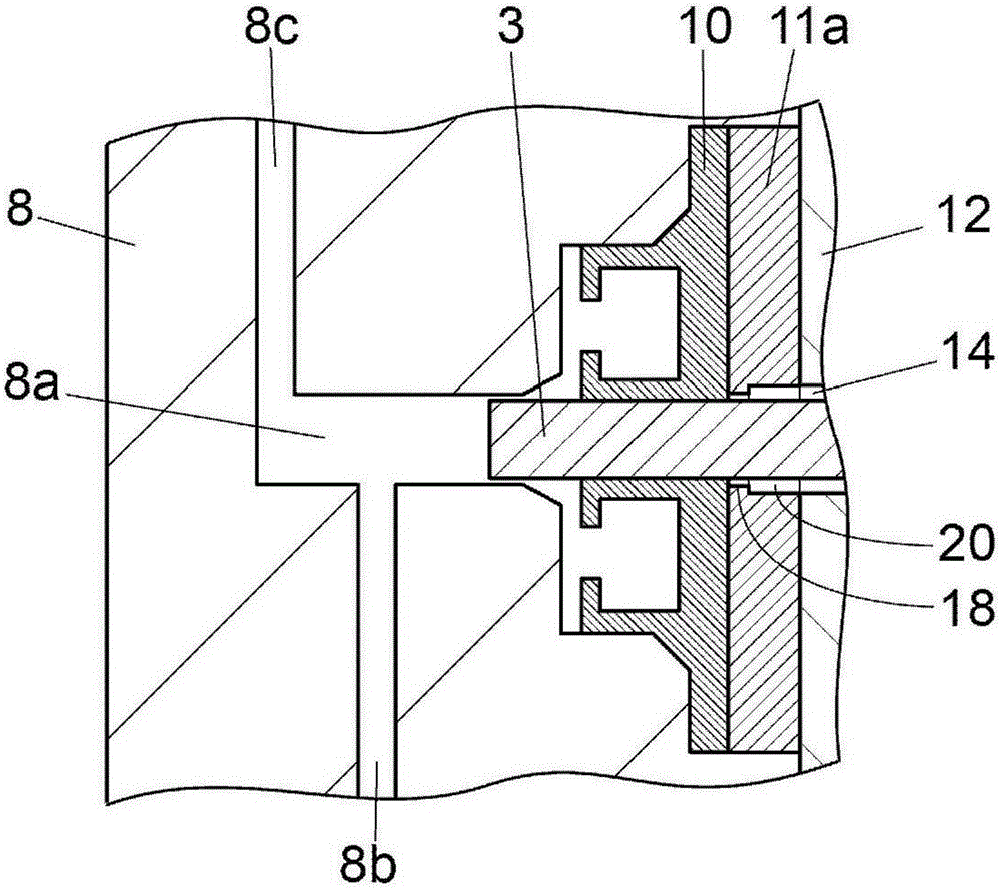

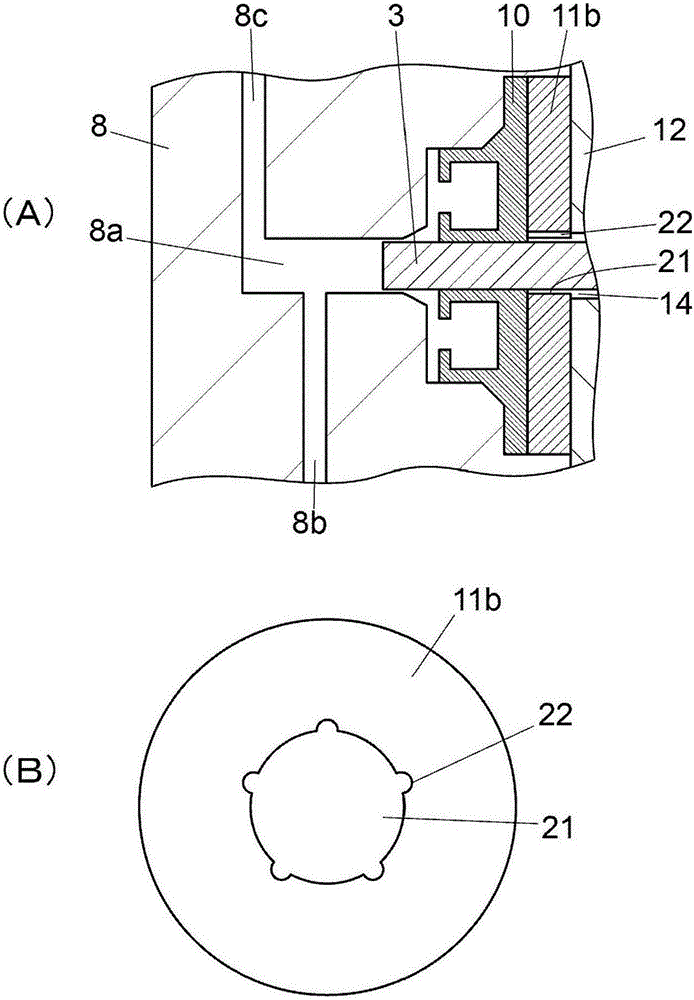

Liquid delivery pump

ActiveCN106257055AReduce precisionInhibit wearPositive displacement pump componentsPiston pumpsMechanical engineeringPlunger

Owner:SHIMADZU SEISAKUSHO CO LTD

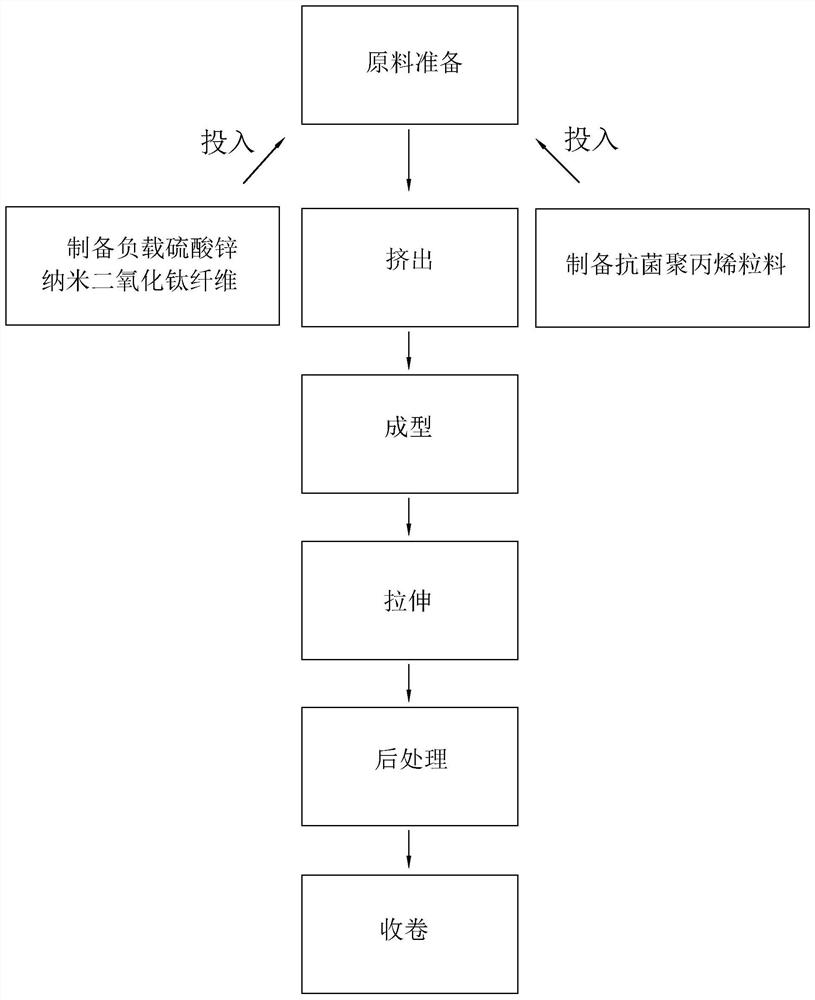

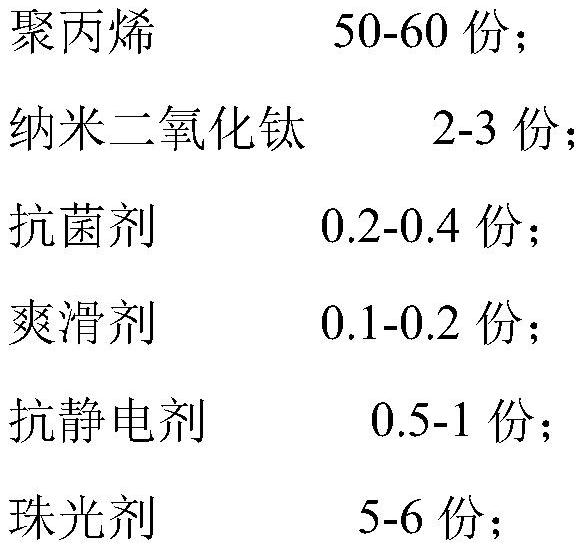

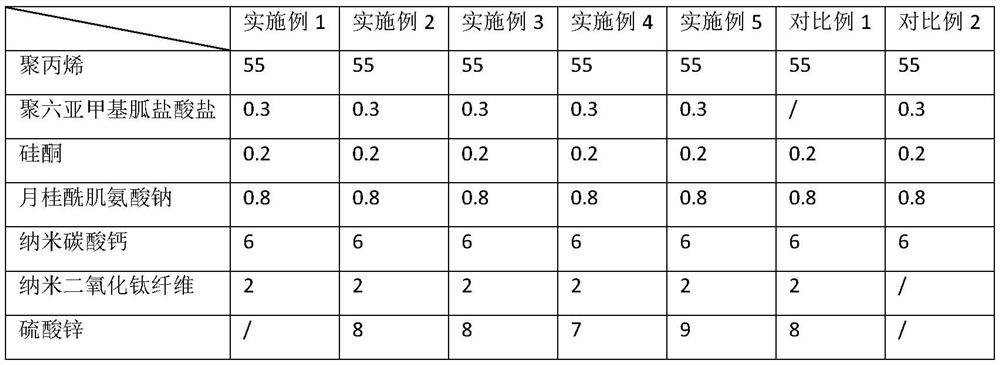

BOPP film and preparation method thereof

ActiveCN112029196AImprove securityImprove antibacterial propertiesSynthetic resin layered productsDomestic articlesPolymer sciencePolyhexamethyleneguanidine hydrochloride

The invention relates to the field of plastic films, and particularly discloses a BOPP film and a preparation method thereof.The BOPP film comprises a surface layer, a core layer and a bottom layer, and the core layer is prepared from, by weight, 50-60 parts of polypropylene; 2-3 parts of nano titanium dioxide; 0.2-0.4 part of an antibacterial agent; 0.1-0.2 part of a slipping agent; 0.5-1 part ofan antistatic agent; and 5-6 parts of a pearling agent. Polyhexamethylene guanidine hydrochloride is adopted as the antibacterial agent. The polyhexamethylene guanidine hydrochloride is an organic antibacterial agent with a certain polymerization degree, does not contain a heterocyclic structure, is relatively high in safety, has a melting point far lower than the processing temperature of polypropylene, can be fully melted in the polypropylene during processing, does not easily influence the haze and light transmittance of the antibacterial BOPP film, and provides a good antibacterial property for the BOPP film.

Owner:浙江森纳新材料科技有限公司

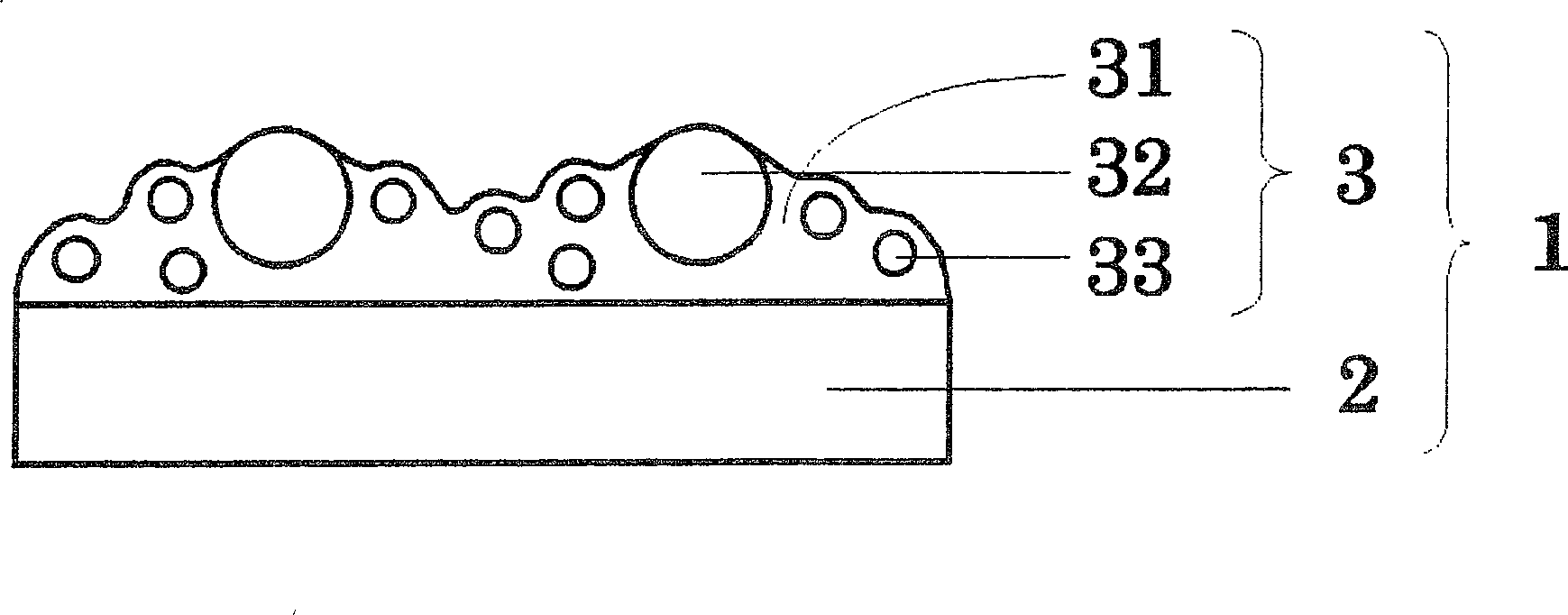

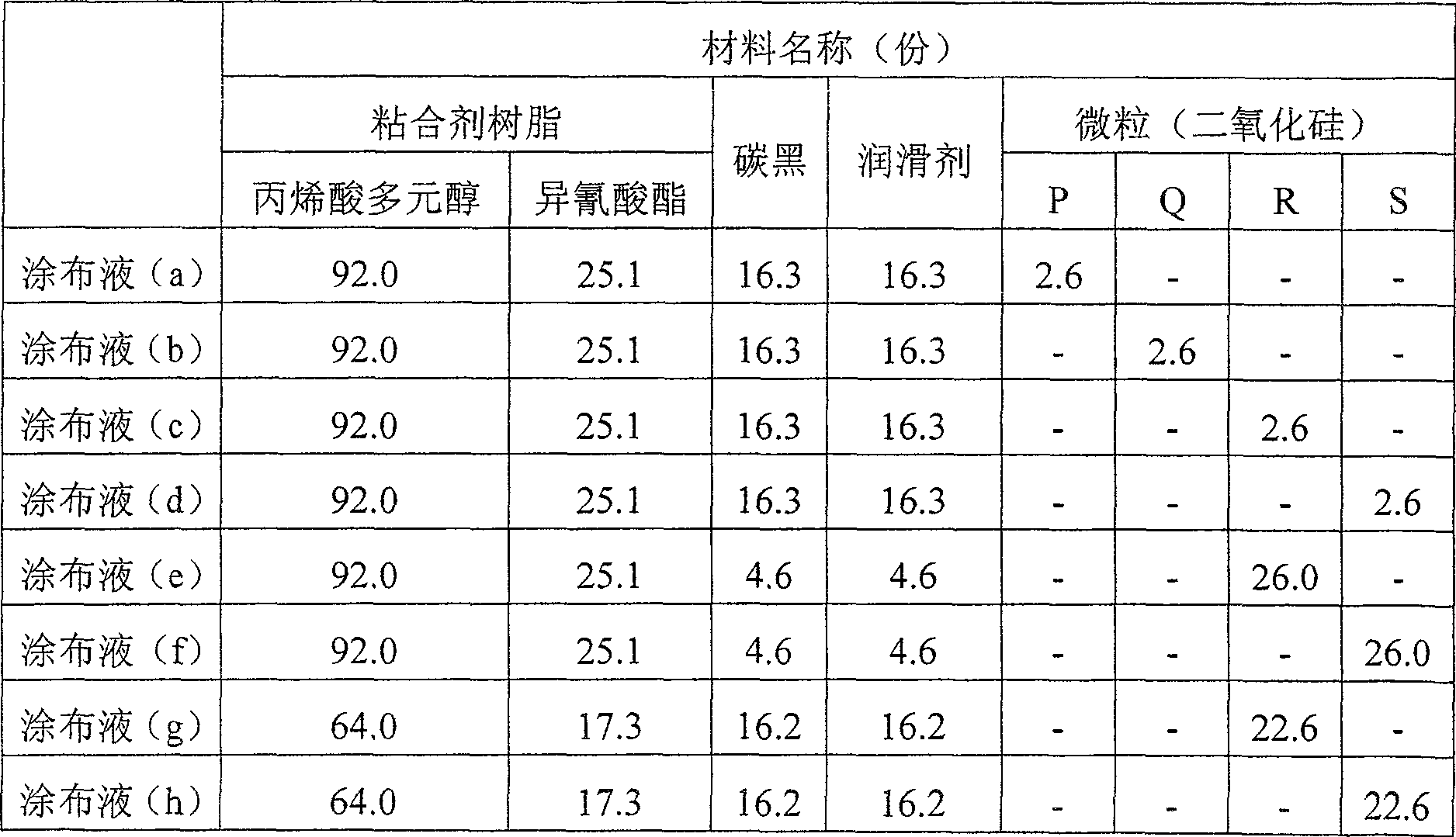

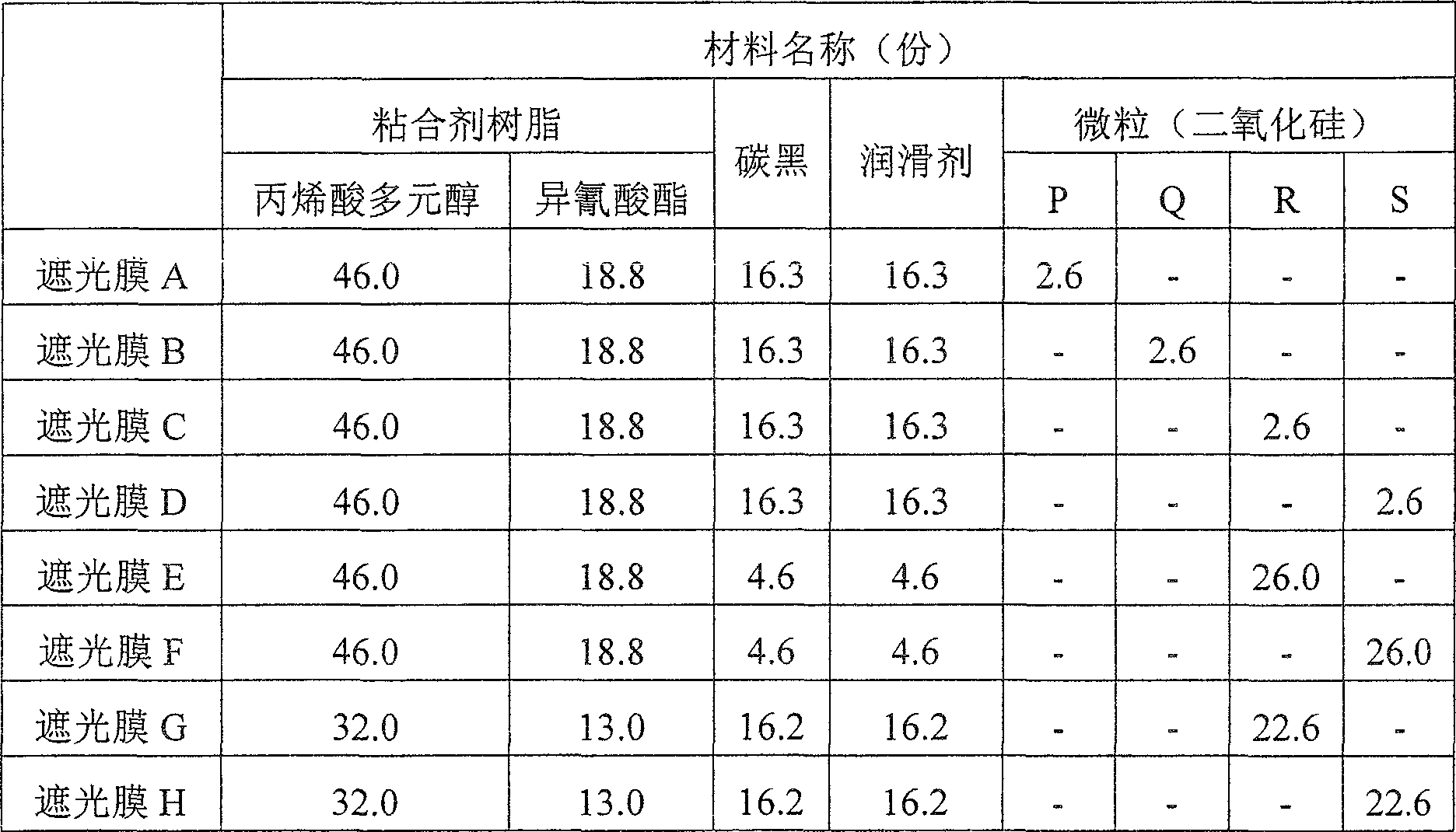

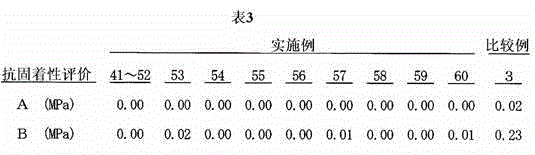

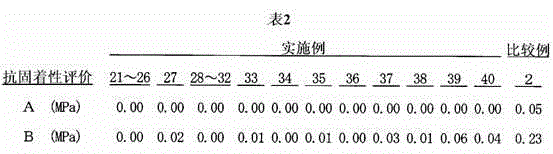

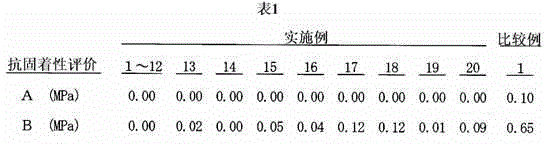

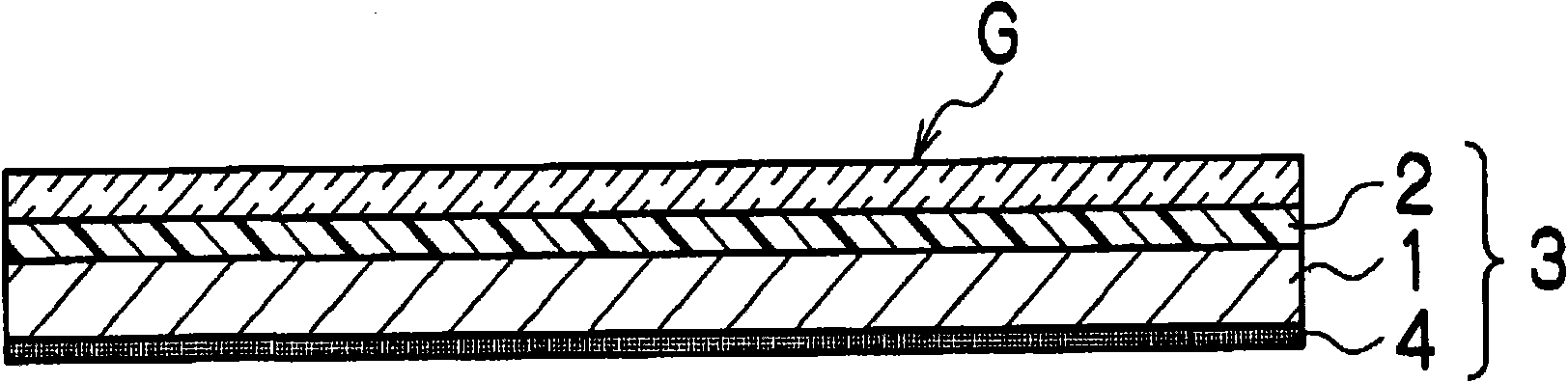

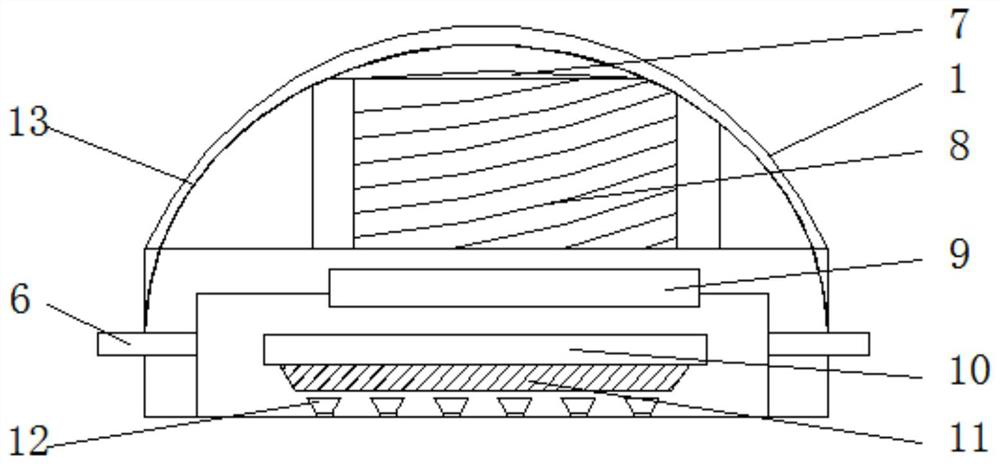

Light-blocking member for optical instrument

ActiveCN100498381CIncrease contentGet matteDiffusing elementsLayered productsParticulatesEngineering

Disclosed is a light-blocking member for optical instruments which has delustering properties while maintaining physical properties of a light-blocking film such as light-shielding properties and sliding properties. Specifically disclosed is a light-blocking member (1) for optical instruments which is composed of a base (2) made of a synthetic resin film, and a light-blocking film (3) formed on at least one side of the base (2). The light-blocking film (3) contains a binder resin and carbon black (31), a particulate lubricant (32), and specific fine particles (33). The specific fine particles (33) are organic or inorganic fine particles having an oil absorption of 250(g / 100g), and silica is particularly preferably used for such specific fine particles.

Owner:KIMOTO CO LTD

Fluorine-resin sealing ring

InactiveCN104471292AGuaranteed tightnessEnsure slidingEngine sealsOther chemical processesCarbon filmAutomatic transmission

A PTFE resin sealing ring wherein an amorphous carbon film is formed on at least one surface of an abutting part that forms a discontinuity in the sealing ring. Since an amorphous carbon film is formed on the abutting surface(s) of this PTFE resin sealing ring, the abutting part does not stick even after a steady load has been applied at a high temperature, producing the prominent effect of ensuring both sealing performance under pressure and the ability to slide when not under pressure. This sealing ring is effective as a sealing material used with rotation or reciprocal motion, including a hydraulic circuit in a continuously variable transmission (CVT) or an automatic transmission (A / T) in an automobile, for example.

Owner:NOK CORP

Sliding block and sliding device

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

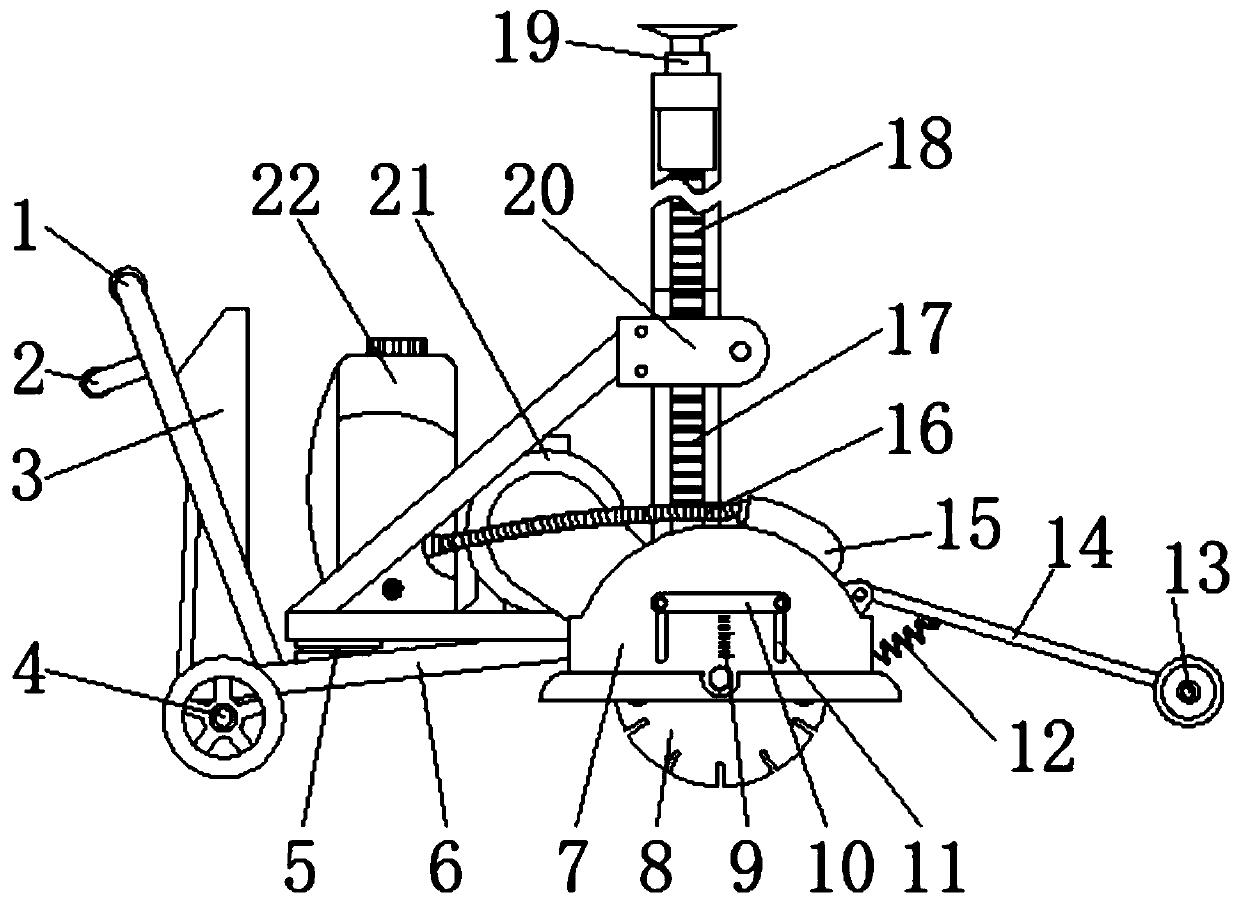

A construction cutting machine capable of converting and cutting walls and grounds

ActiveCN108356991BEffective size controlReduce mistakesWorking accessoriesStone-like material working toolsArchitectural engineeringWater spray

The invention discloses a building cutting machine capable of conducting conversion cutting on the wall surface and the ground. The building cutting machine comprises a main handle and a protection shell. A cutting blade is mounted on the inner side of the protection shell, and the outer side of the protection shell is provided with a scale line, a positioning plate and sliding grooves; the positioning plate is arranged on the sliding grooves, and the scale line is arranged in the middle of the positioning plate; a water-spraying electromagnetic valve is fixed to the upper side of the protection shell, and the outer side of the water-spraying electromagnetic valve is connected with a water-guiding hose; and a main moving rod and an auxiliary moving rod are connected through a connecting bottom plate, and fastening bolts are mounted on the connecting bottom plate. According to the building cutting machine capable of conducting conversion cutting on the wall surface and the ground, corresponding adjusting work can be conducted on different working faces of a building, and accordingly, cutting work on the different working faces of the building is completed; and the size of cutting work can further be controlled effectively in the cutting process, and thus the cutting work error of the device is reduced effectively.

Owner:扬州市生态科技新城润业中小企业服务中心有限公司

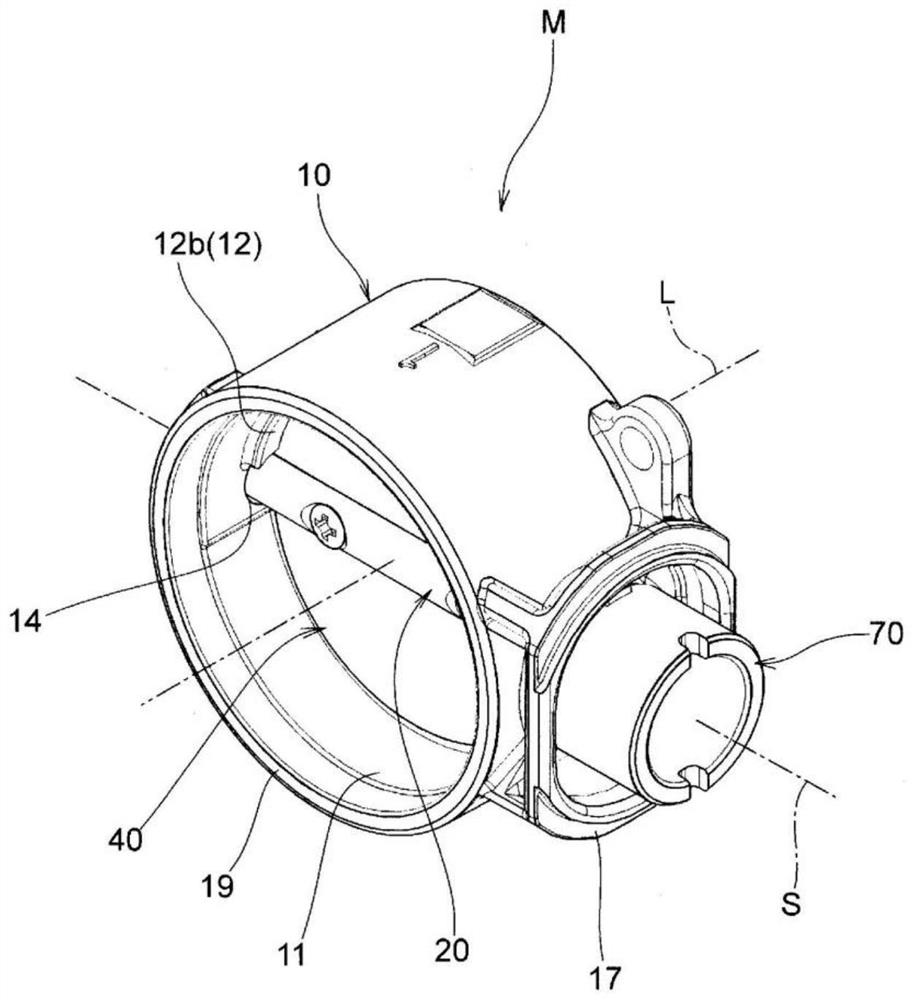

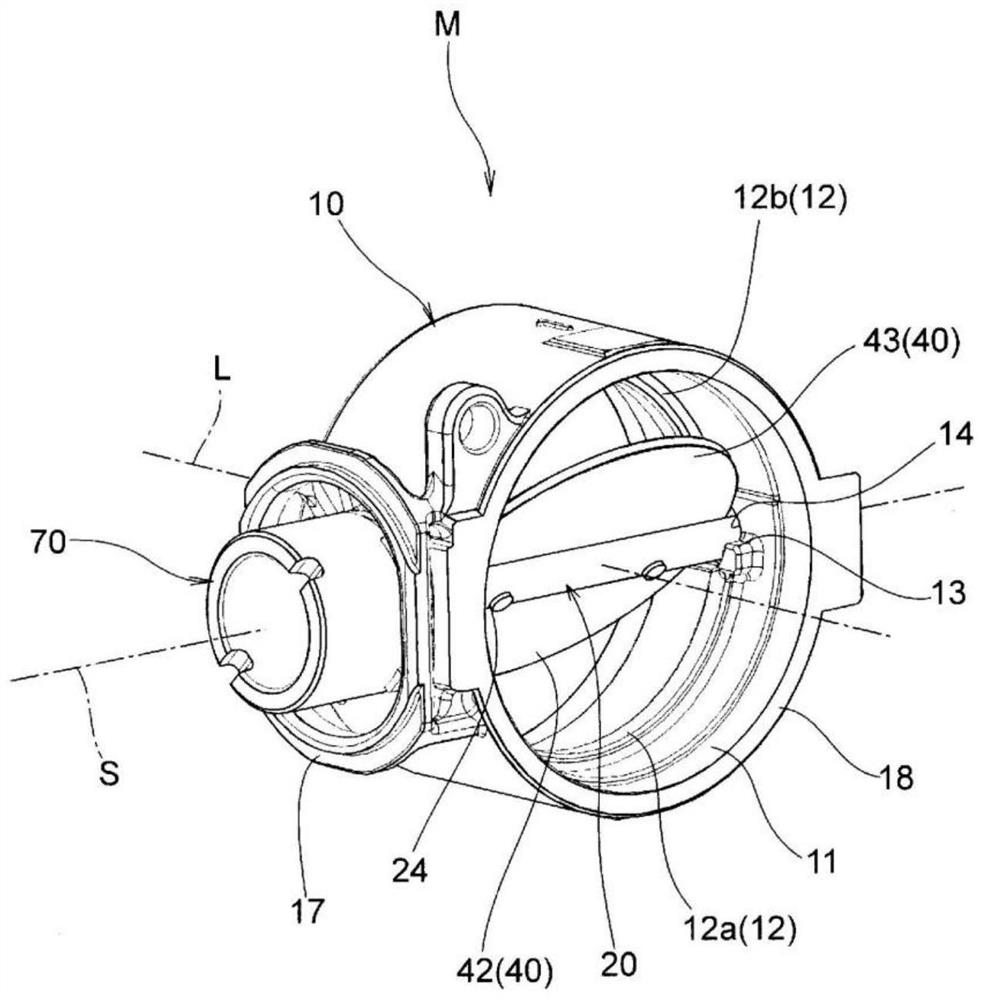

Valve device

PendingCN113803477AEnsure slidingCost increase restraintEngine sealsBearing assemblyEngineeringGraphite

The present invention provides a valve device which suppresses noise or abrasion, ensures sliding performance, and can suppress cost increase, improve productivity, improve durability, improve functional reliability and the like. The valve device includes a body 10 that defines a passage through which a fluid flows, a shaft 20 that is movably supported with respect to the body and defines an axis S, a valve element 40 that is fixed to the shaft to open and close the passage; and a cylindrical bearing bush 50 that movably supports the shaft with respect to the body, includes a mixed region A0 in which a metal core material 51 and expanded graphite 52 are mixed with each other, and a first expanded graphite region A1 made of only the expanded graphite 52 such that the metal core material 51 is not exposed in an inner circumferential side region in contact with an outer circumferential surface 20a of the shaft.

Owner:MIKUNI CORP

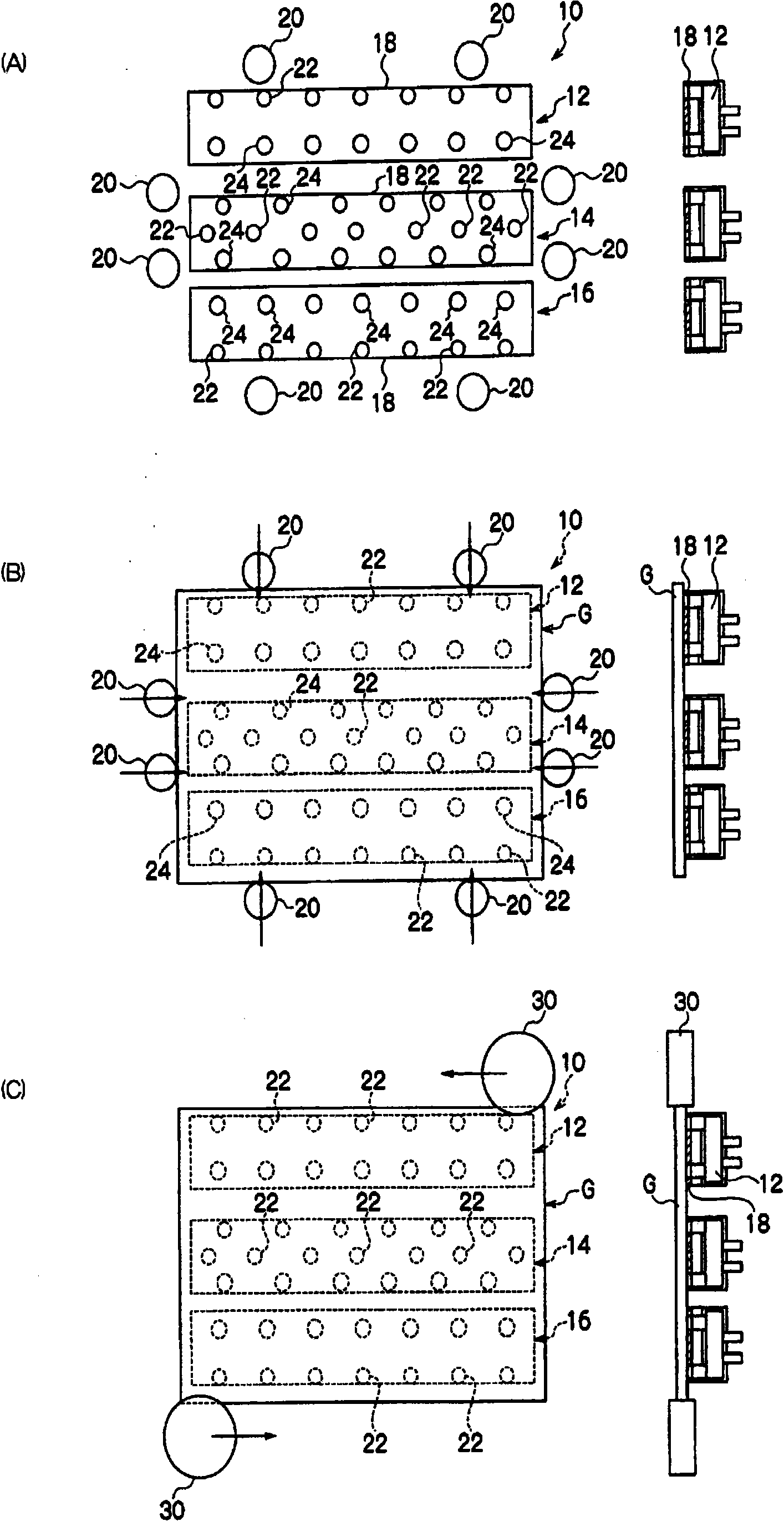

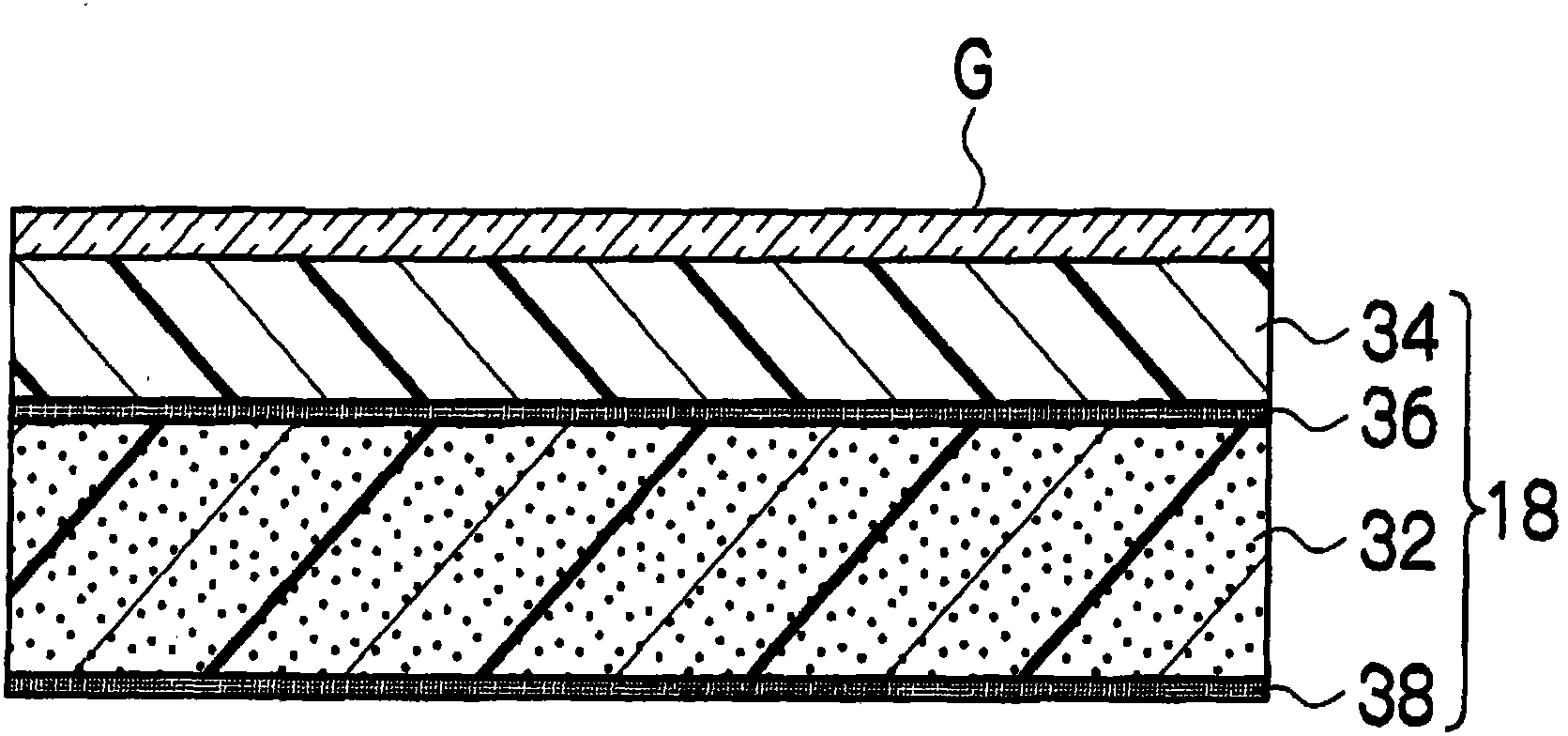

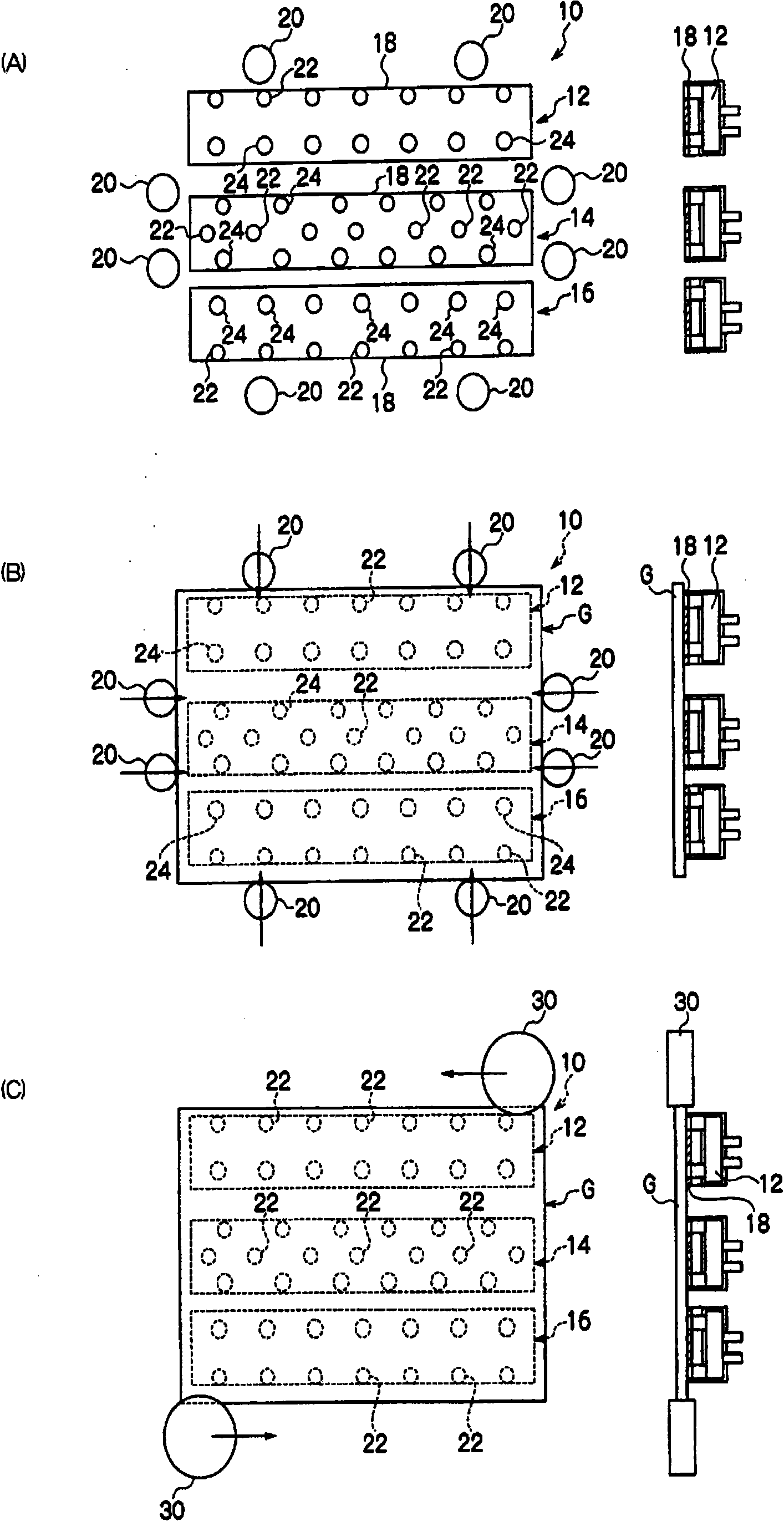

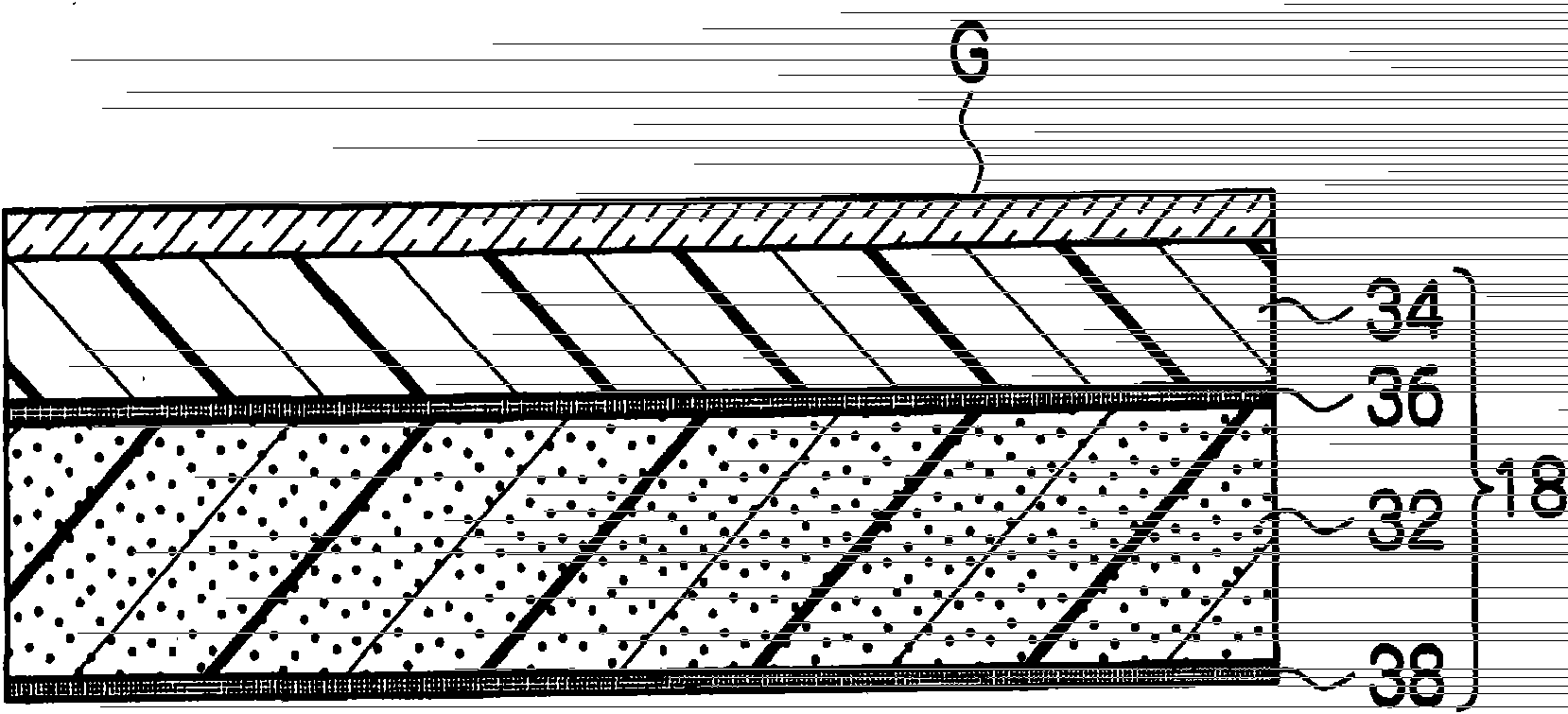

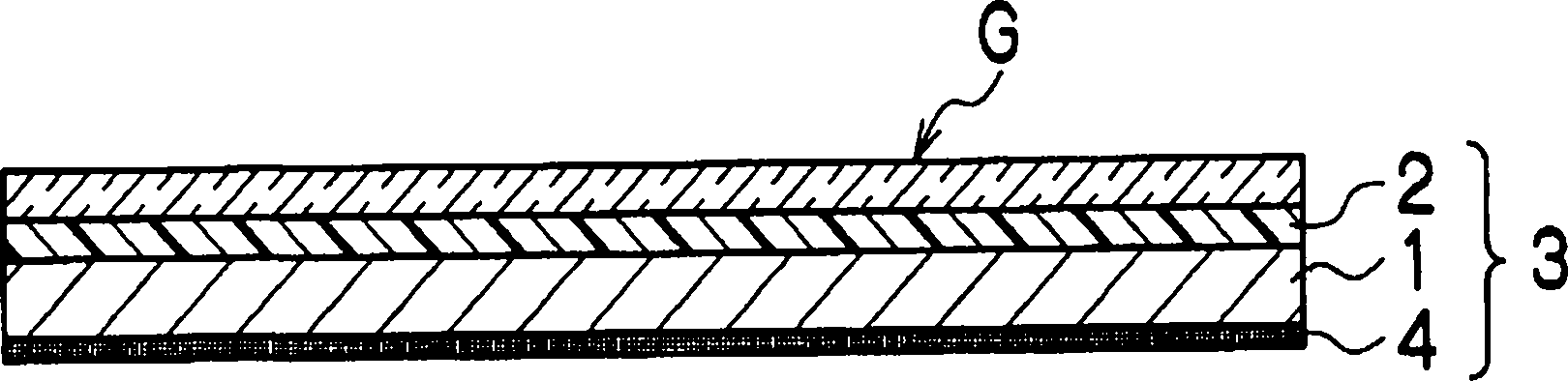

Glass substrate suction table, and method for processing of glass substrate

ActiveCN101959814AAvoid scratchesEnsure slidingEdge grinding machinesConveyorsHardnessTotal thickness

Disclosed is a sheet material (18) which is intended to be adhered to a glass substrate suction table for a glass substrate-processing machine. The sheet material (18) has a hardness of 90 to 95 degrees in accordance with JIS K6253 or JIS K7215, a thickness of 0.7 mm or less, and a coefficient of kinetic friction of 0.3 or less. Preferably, the sheet material (18) has a multi-layered structure composed of at least a urethane sheet material (32) and an olefin sheet material (or a nitflon sheet material) (34), and has a total thickness of 0.7 mm or less.

Owner:ASAHI GLASS CO LTD

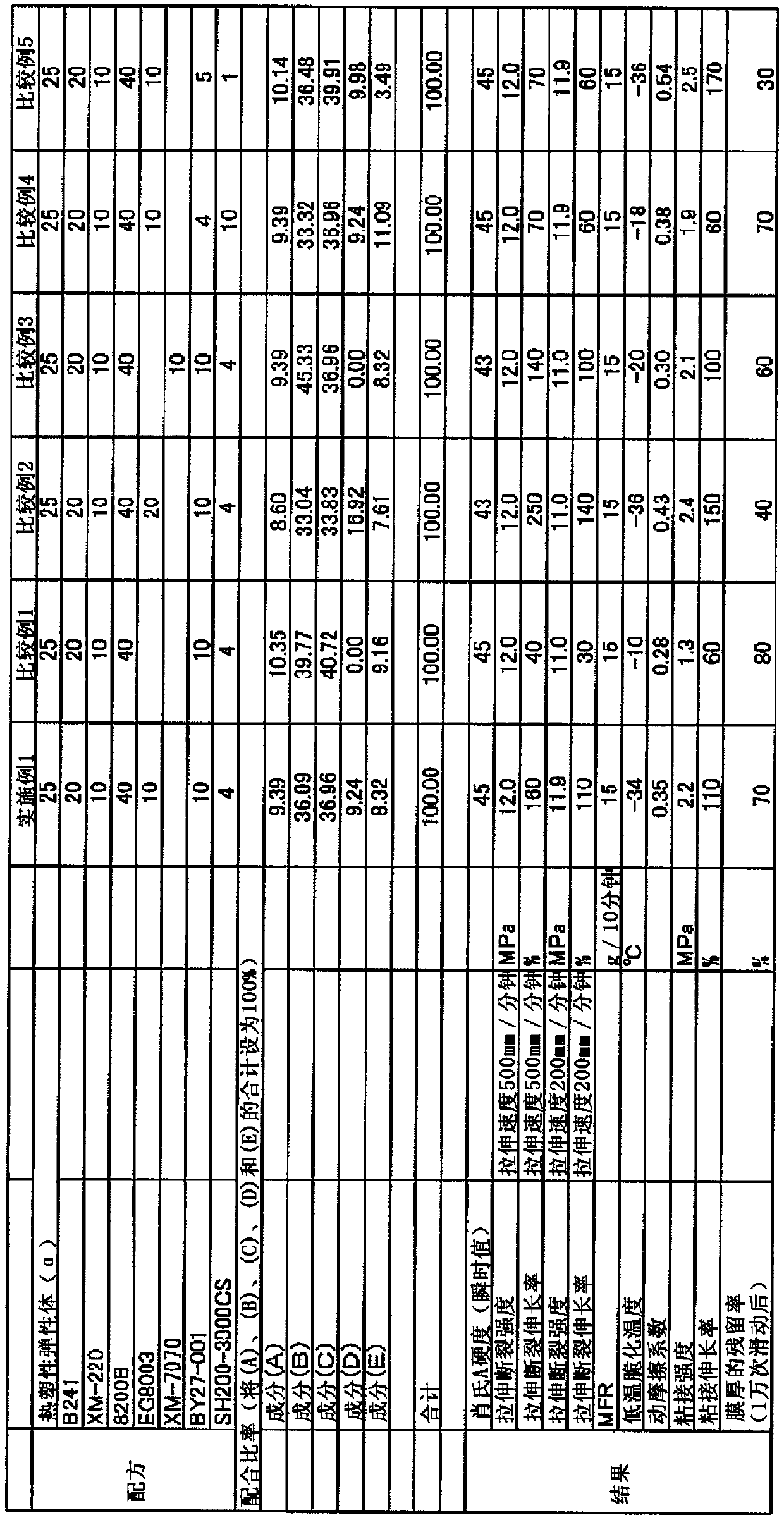

Thermoplastic elastomer composition and use thereof

ActiveCN110494483AExcellent low temperature impact strengthImprove low temperature impact strengthEngine sealsVehicle sealing arrangementsPolyeneOrganosilicon

The present invention relates to: a thermoplastic elastomer composition which comprises 5-30 parts by mass of an ethylene / alpha-olefin / unconjugated polyene copolymer (A), 20-40 parts by mass of a crystalline olefin resin (B) having a density of 0.90-0.92 g / cm<3>, 20-40 parts by mass of a high-density polyethylene (C) having a density of 0.94-0.97 g / cm<3>, 5-12 parts by mass of an ethylene / alpha-olefin copolymer (D) formed from ethylene and a C3-12 alpha-olefin, and 5-9 parts by mass of a silicone compound (E) (the sum of components (A), (B), (C), (D), and (E) is taken as 100 parts by mass); and an automotive glass run channel formed from the thermoplastic elastomer composition.

Owner:MITSUI CHEM INC

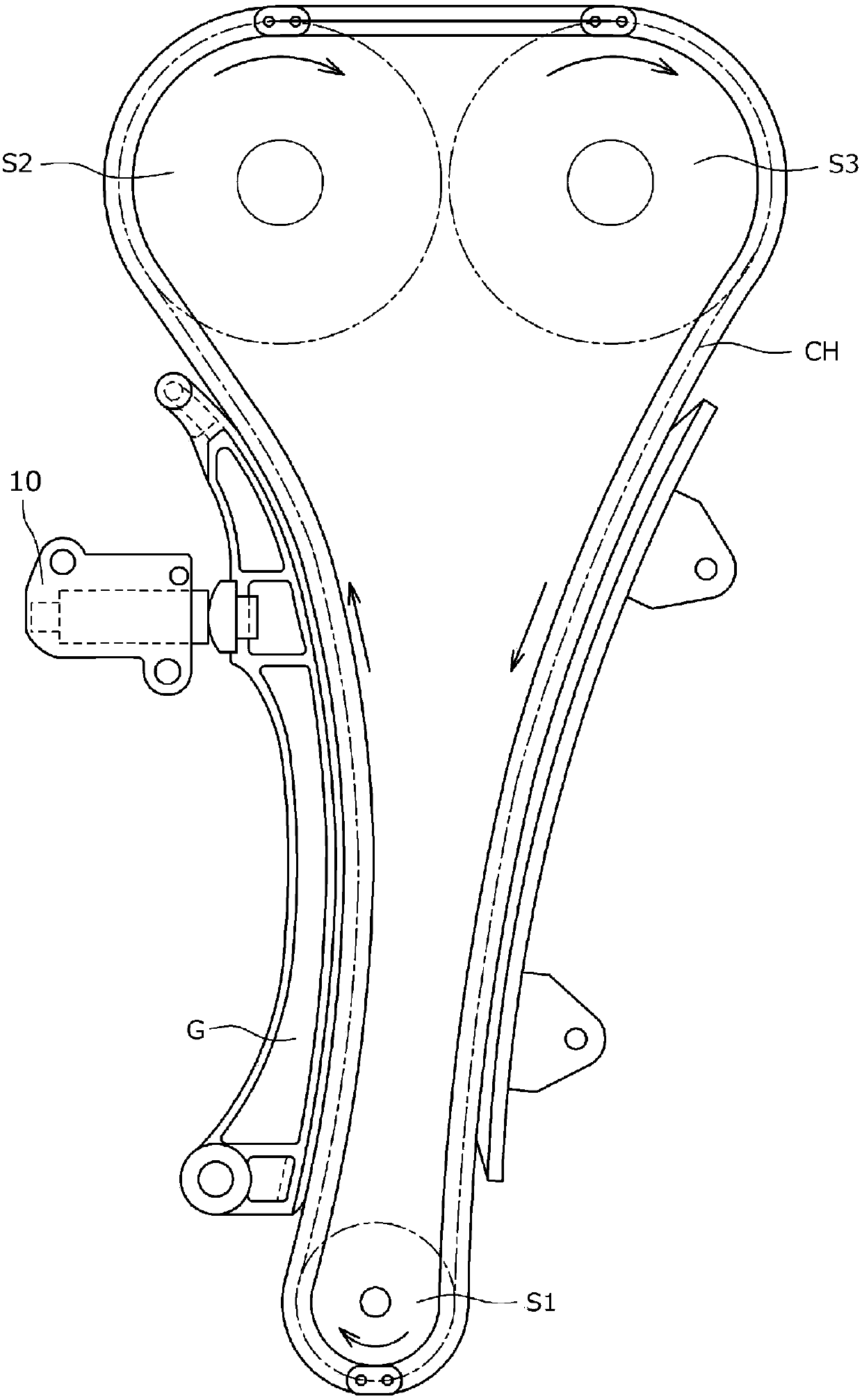

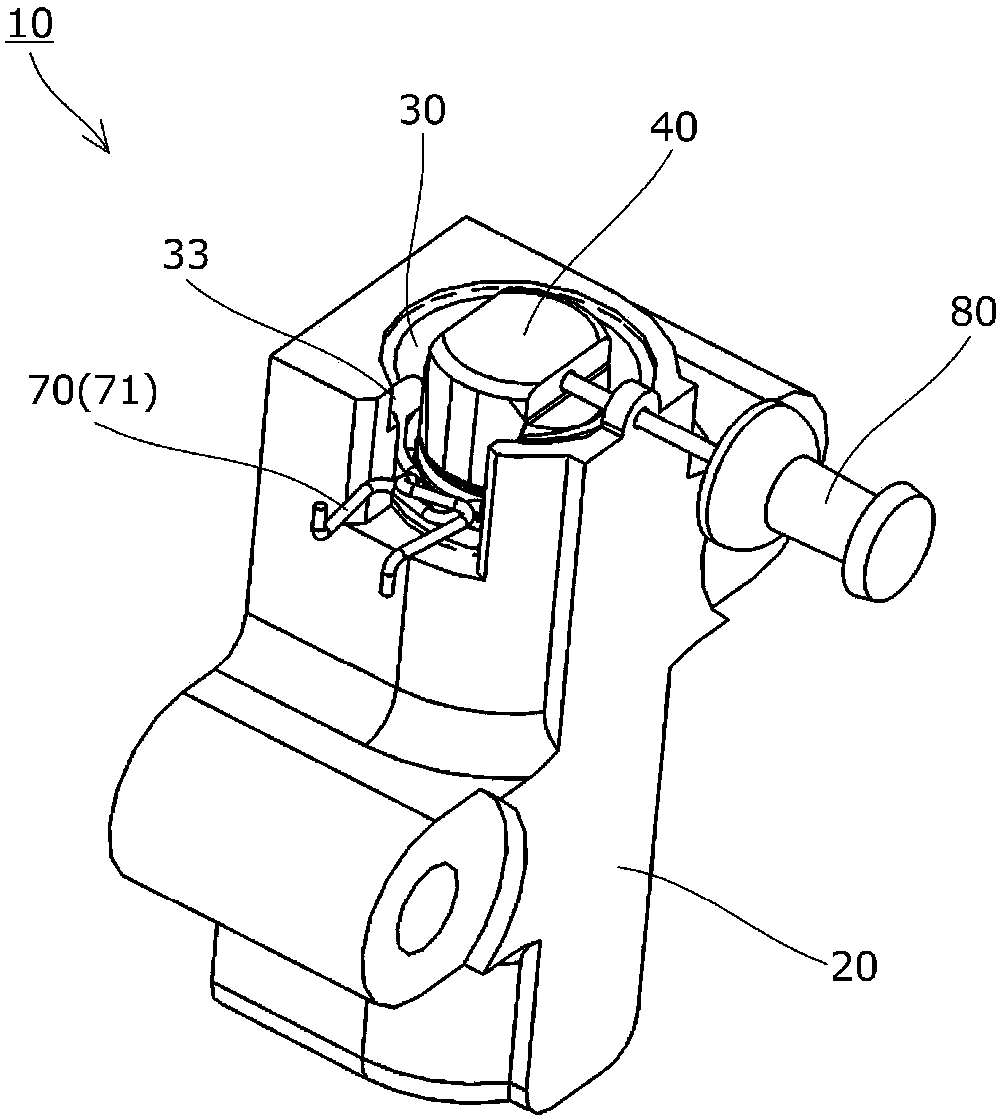

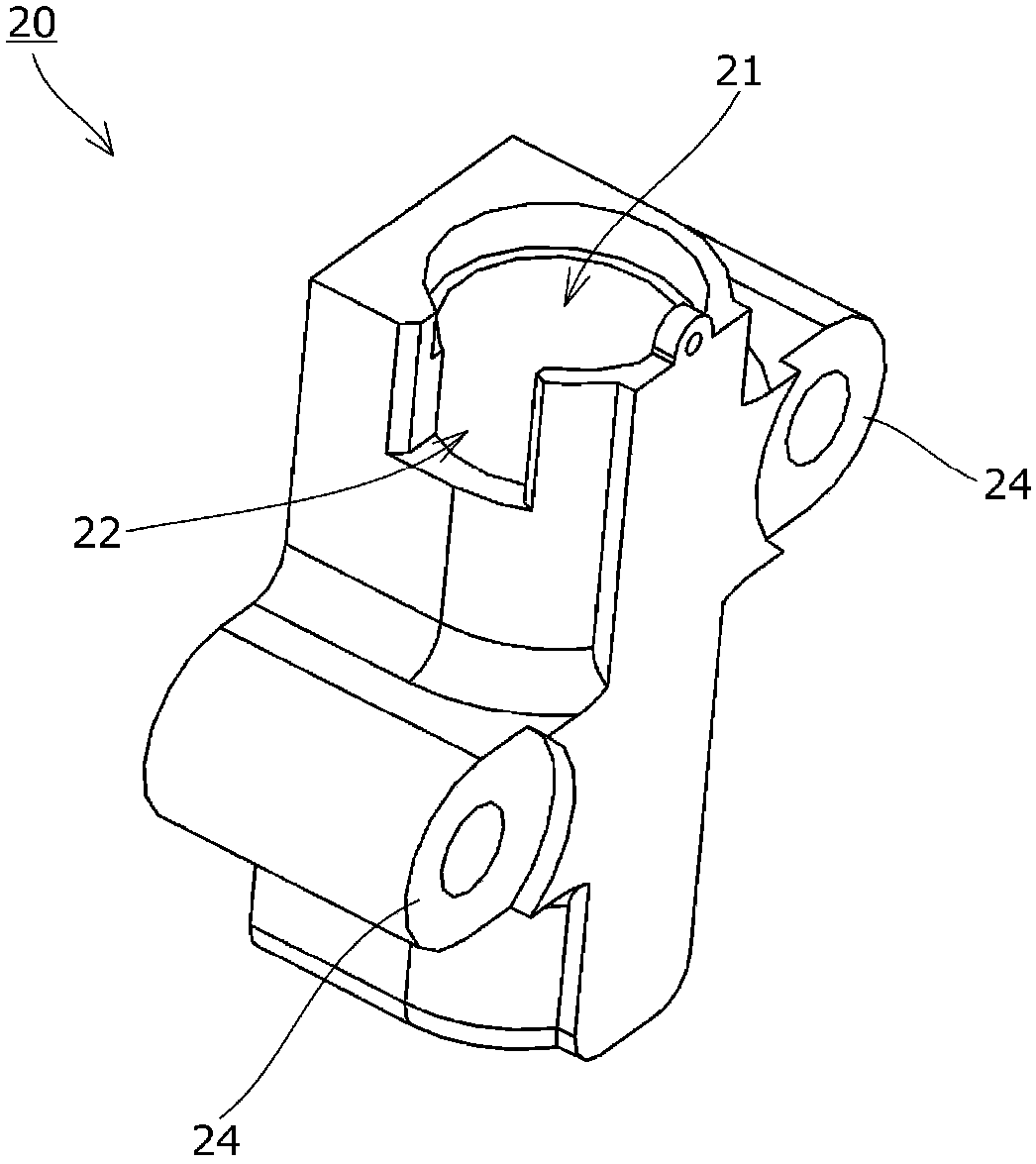

Tensioner

To provide a simple-structured tensioner that can maintain good sliding properties of and hydraulic pressure for the plunger. The tensioner 10 includes a sleeve 30 inserted into a cylindrical body hole 21, a plunger 40 inserted in the sleeve 30 such as to be able to advance and retract along an axial direction of the sleeve 30, and biasing unit 60 for biasing the plunger 40 toward a front side. The sleeve 30 has, at a front end of a sleeve body 31 thereof, a flange part 33 extending radially outward.

Owner:TSUBAKIMOTO CHAIN CO

Sintered body and die for hot extrusion molding each using such sintered body

InactiveCN101273150BLow sliding resistanceHigh strengthExtrusion diesTransportation and packagingHardnessHigh intensity

By using a sintered body composed of 58-92.5% by mass of TiCN, 0.01-1% by mass of Ti, 0.01-2% by mass of TiC, 0.01-2% by mass of TiN and the balance of TaC, Ni and Cr, there can be obtained a sliding member, film-forming material and die for hot extrusion molding which exhibit high strength, high hardness, high toughness and high sliding properties in an environment of about 400-600 DEG C, and a hot extrusion molding apparatus using such a die for hot extrusion molding.

Owner:KYOCERA CORP

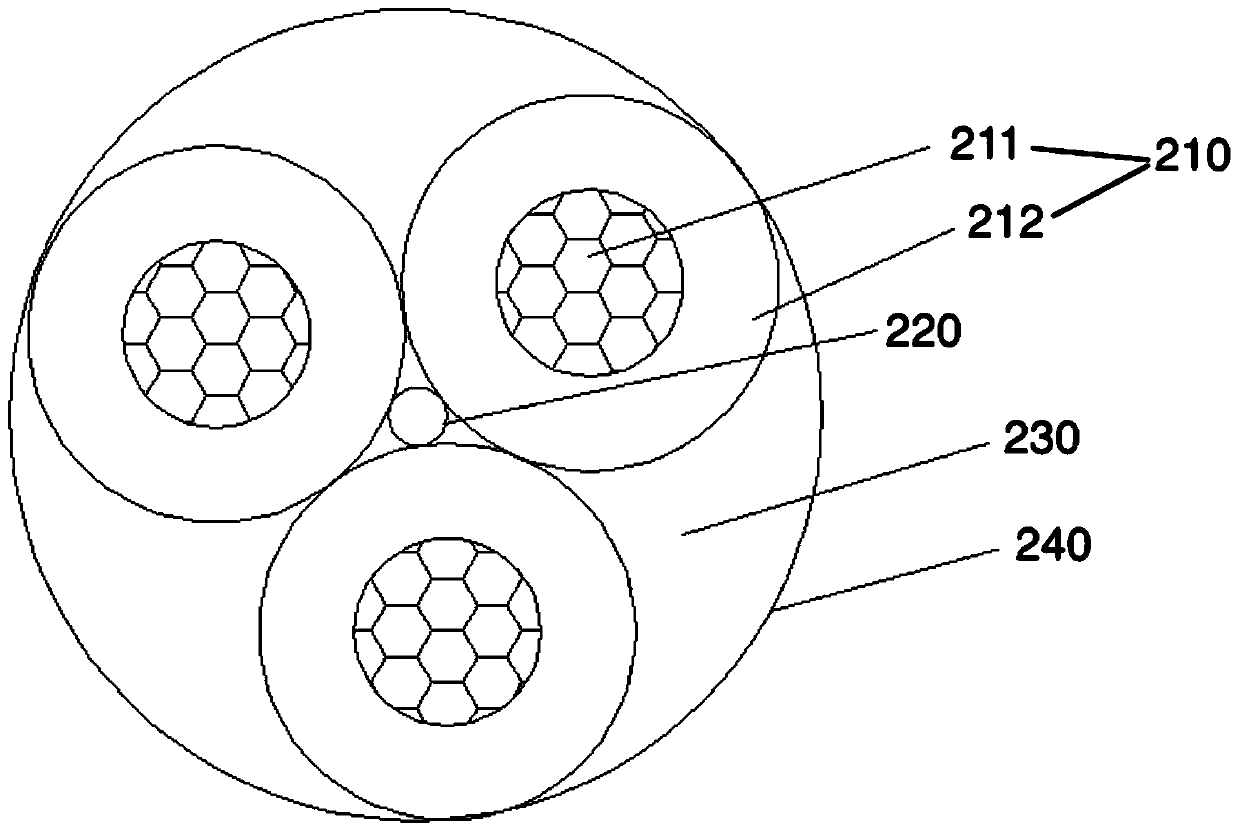

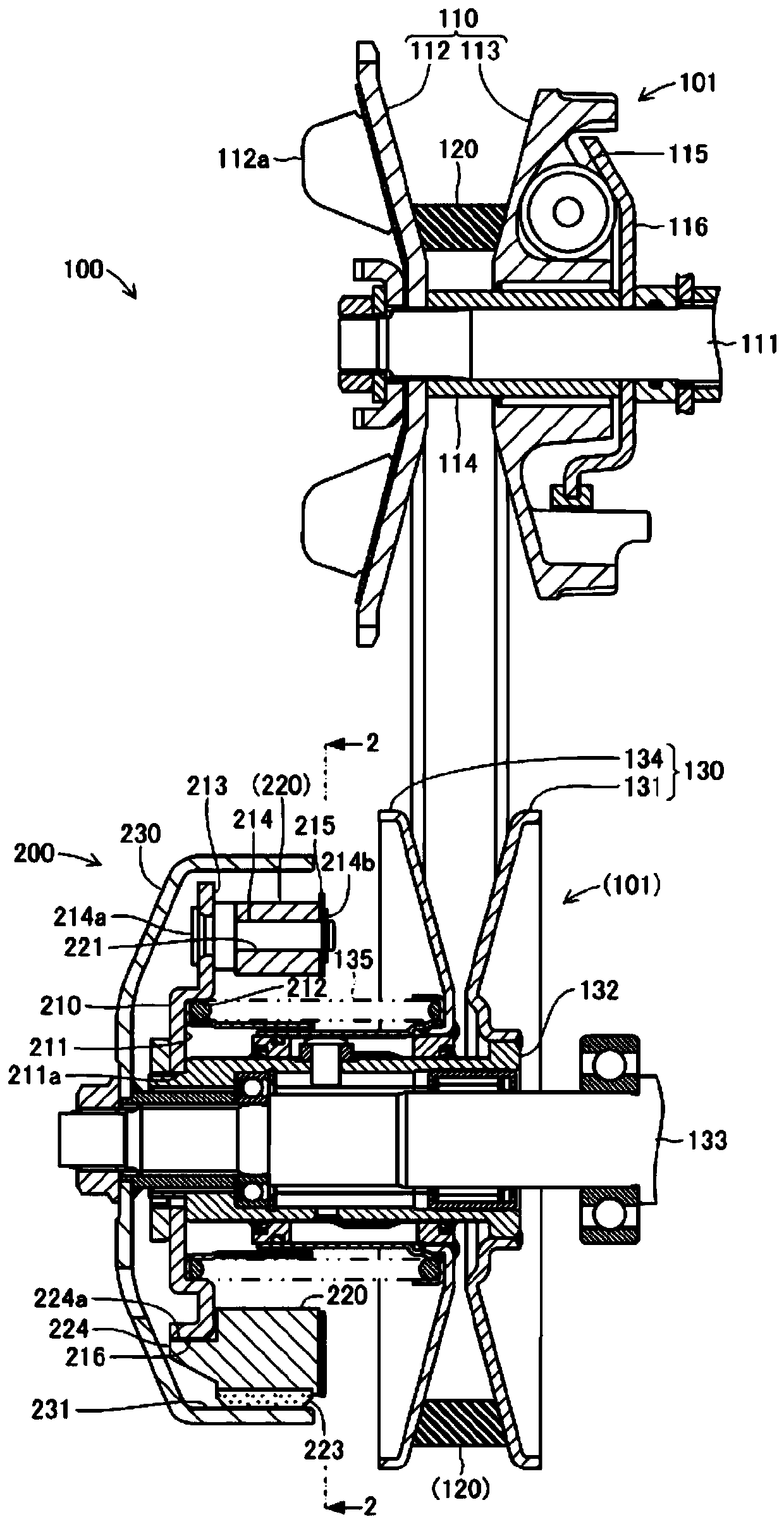

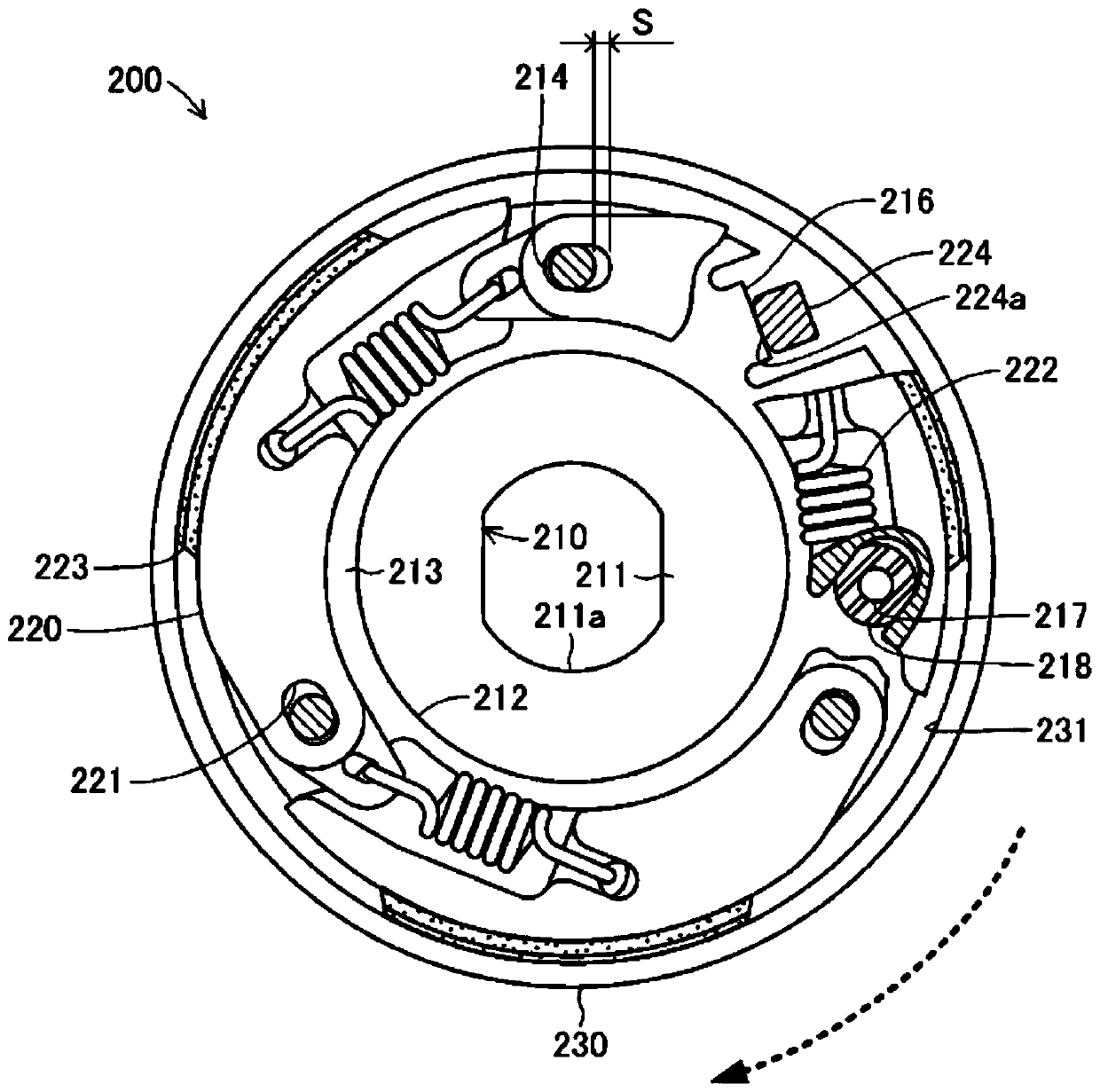

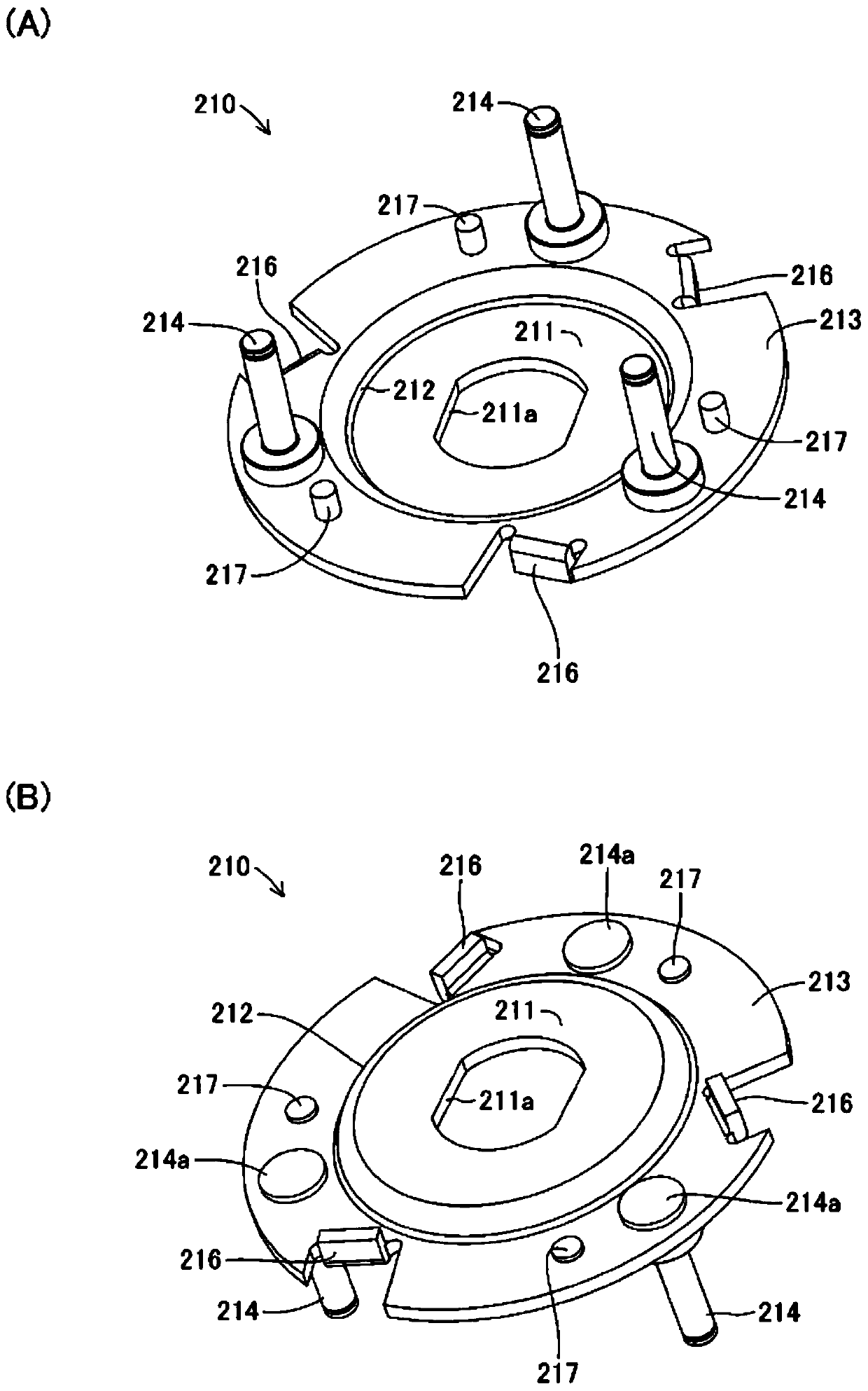

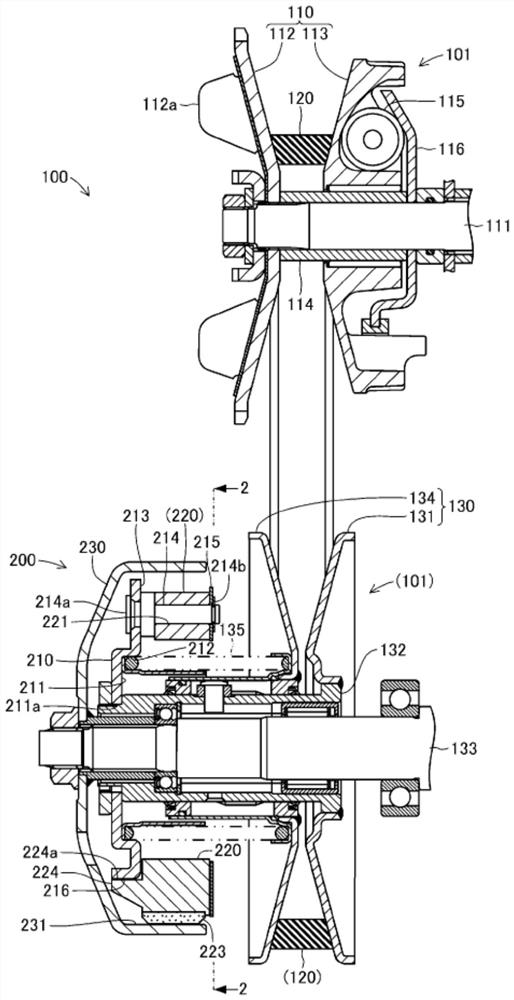

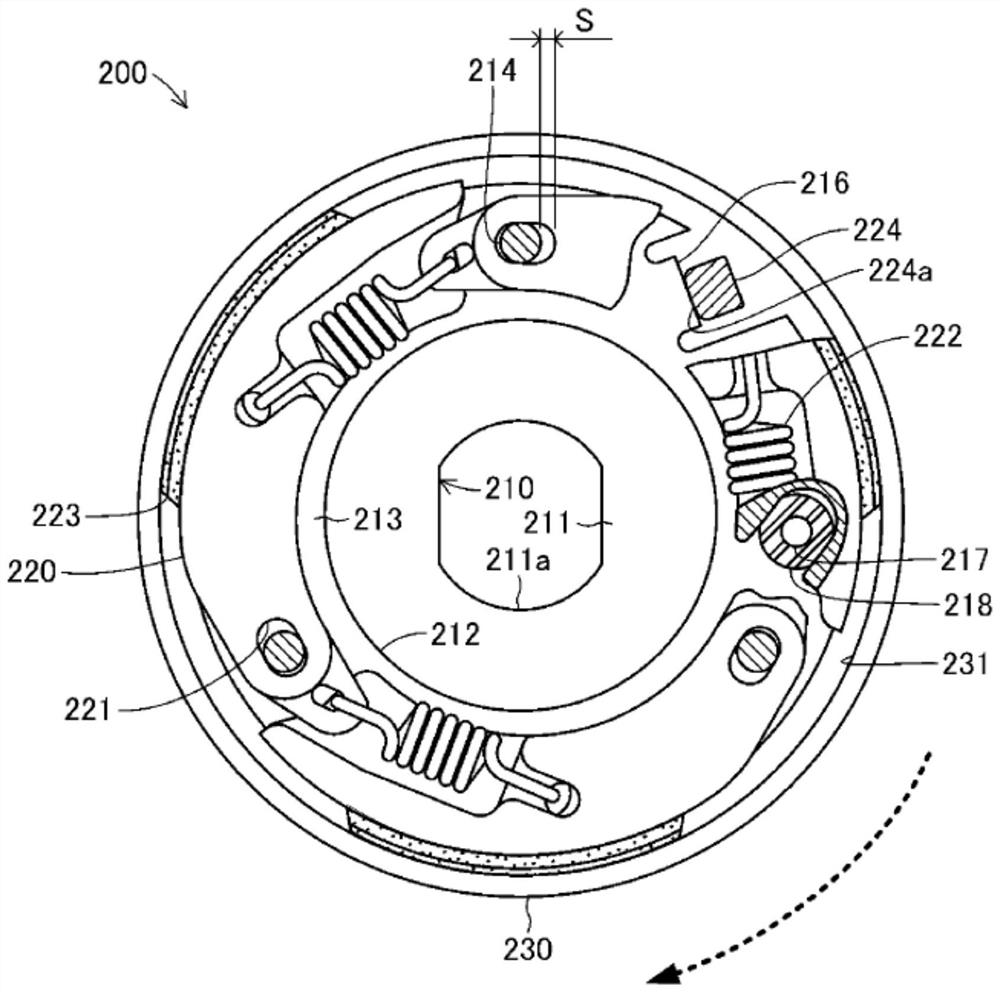

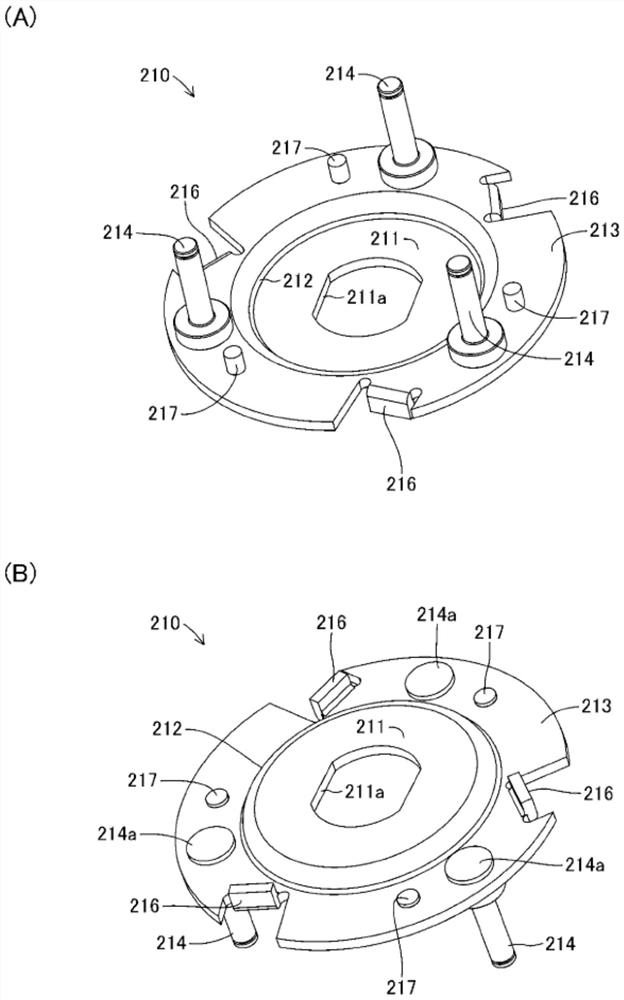

Centrifugal clutch

Provided is a centrifugal clutch capable of increasing clutch capacity by using a simple configuration. The centrifugal clutch 200 comprises a drive plate 210 that has direct rotation drive as a result of the drive force of an engine. The drive plate 210 comprises both a swing support pin 214 and a guide section 216. The swing support pin 214 is fitted into a pin sliding hole 221 formed in a clutch weight 220 and swingably supports the clutch weight 220. The guide section 216 extends inclined towards the rear and outwards, in the rotation drive direction of the drive plate 210, is formed in anotched or hole shape, and has a protruding body 224 on the clutch weight 220 being in contact therewith. The pin sliding hole 221 is formed in a long hole shape that allows displacement of the clutchweight 220 towards the rear side in the rotation drive direction of the drive plate 210. The protruding body 224 is formed protruding from the clutch weight 220.

Owner:FCC KK

centrifugal clutch

The present invention provides a centrifugal clutch capable of increasing the clutch capacity with a simple configuration. The centrifugal clutch 200 includes a drive plate 210 that is directly rotationally driven by engine driving force. The drive plate 210 includes a swing support pin 214 and a guide portion 216 , respectively. The swing support pin 214 is fitted in a pin sliding hole 221 formed in the clutch weight 220 to swingably support the clutch weight 220 . The guide portion 216 is formed in the shape of a notch or a hole and extends toward the rear and outward in the rotational driving direction of the drive plate 210 and extends obliquely, and contacts the protrusion 224 of the clutch weight 220 . The pin slide hole 221 is formed in the shape of an elongated hole allowing the displacement of the clutch weight 220 to the rear side in the rotational driving direction of the driving plate 210 . The protruding body 224 is formed by protruding from the clutch weight 220 .

Owner:FCC KK

Mechanism for outputting power during wood processing

InactiveCN108071693AEnsure slidingSimple structureEngine sealsGear lubrication/coolingDrive shaftEngineering

The invention discloses a mechanism for outputting power during wood processing. The mechanism includes a shell body, a driving shaft, a bearing seat, power transmission teeth, and an oil liquid guiding assembly, wherein the driving shaft, the bearing seat and the transmission teeth form an oil liquid storing cavity. The driving shaft is provided with a first oil liquid communicating hole and a second oil liquid communicating hole. The oil liquid guiding assembly includes a pipe-shaped driven shaft and a driven shaft fixing piece. The driven shaft fixing piece includes a positioning pipe and aring positioning table. The positioning pipe penetrates through the top of the shell body and the ring positioning table is fixed to the shell body. An inner channel of the pipe-shaped driven shaft is connected with and communicates with the positioning pipe inner channel and a first oil liquid communicating hole. The top of the side wall of the pipe-shaped driven shaft and the bottom of the sidewall of the positioning pipe form inclined surface contact. When the mechanism for outputting power is used, oil liquid is easily added to the bearing seat, and reliability and stability when the mechanism is used can be ensured accordingly.

Owner:刘应华

Glass substrate suction table, and method for processing of glass substrate

ActiveCN101959814BAvoid scratchesEnsure slidingEdge grinding machinesConveyorsHardnessTotal thickness

Disclosed is a sheet material (18) which is intended to be adhered to a glass substrate suction table for a glass substrate-processing machine. The sheet material (18) has a hardness of 90 to 95 degrees in accordance with JIS K6253 or JIS K7215, a thickness of 0.7 mm or less, and a coefficient of kinetic friction of 0.3 or less. Preferably, the sheet material (18) has a multi-layered structure composed of at least a urethane sheet material (32) and an olefin sheet material (or a nitflon sheet material) (34), and has a total thickness of 0.7 mm or less.

Owner:ASAHI GLASS CO LTD

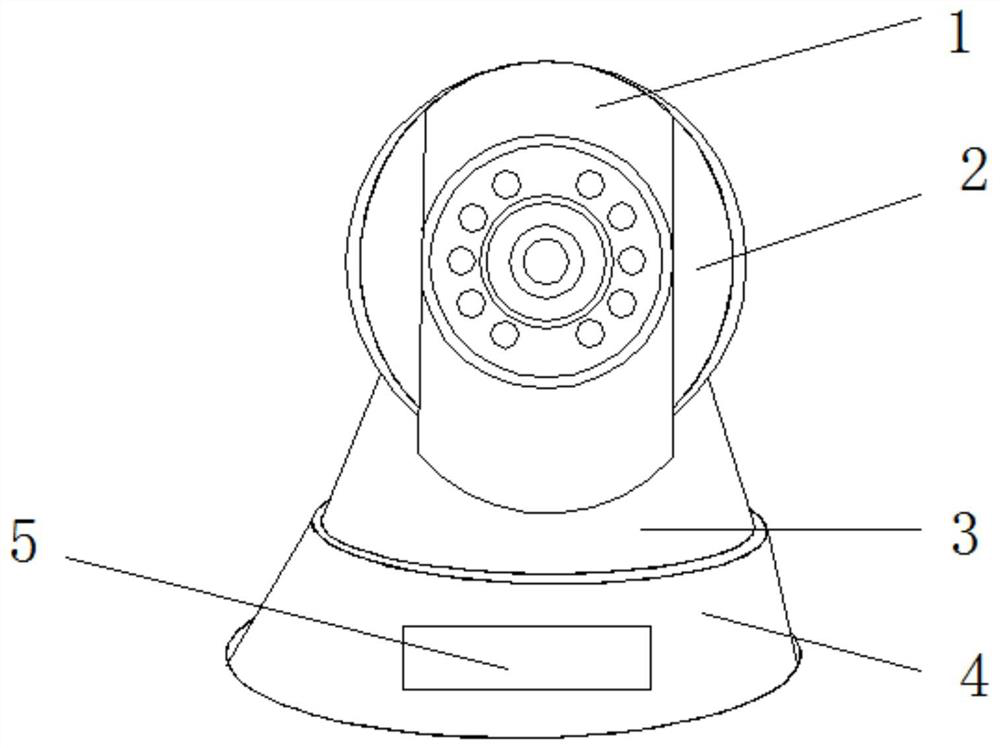

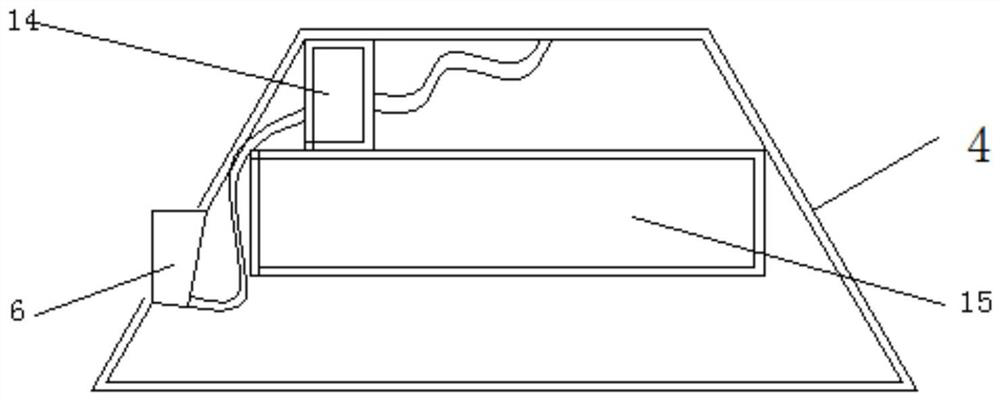

Image pickup device with scoring function

InactiveCN111654608AWith scoring functionDirection adjustmentTelevision system detailsColor television detailsMechanical engineeringImage sensor

The invention discloses an image pickup device with a scoring function. The image pickup device comprises a camera shell and a central controller, rotators are arranged at the left end and the right end of the camera shell. A waterproof connecting shell is arranged on the lower sides of the rotators; a base is connected under the waterproof connecting shell. A display screen is arranged in the middle of the base; a waterproof film is arranged on the upper surface of the camera shell, rotating rollers are arranged at the left end and the right end of the waterproof film, a focusing ring is arranged in the camera shell, a lens is arranged at the part of the focusing ring, an infrared filter is arranged at the bottom of the focusing ring, and an image sensor is arranged on the lower side of the infrared filter. The camera shell and the rotator form a rotating structure through the rotating rod, the rotator is fixedly connected with the waterproof connecting shell, and after the central controller sends a command to the direction sensor, the direction of the camera shell can be adjusted, so that an object is completely shot for systematic scoring.

Owner:广东鹄志人才服务有限公司

Power transmission mechanism for wood processing machine

InactiveCN106369150AEnsure slidingSimple structureGearboxesGear lubrication/coolingDrive shaftWood processor

The invention discloses a power transmission mechanism for a wood processing machine. The power transmission mechanism comprises a shell, a driving shaft, bearing pedestals, a power transmission gear, an oil flow guiding assembly and a driven shaft limiting assembly. The driving shaft, the bearing pedestals and the power transmission gear define an oil storage cavity. A first oil circulating hole and a second oil circulating hole are formed in the driving shaft. The oil flow guiding assembly comprises a tubular driven shaft and a driven shaft fixing piece. The driven shaft fixing piece comprises a positioning tube and an annular positioning table. The positioning tube penetrates through the top of the shell, and the annular positioning table is fixed to the shell. The upper end and the lower end of the tubular driven shaft make contact with the bottom of the positioning tube and the top of the driving shaft correspondingly. The bottom of the side wall of the positioning tube is recessed inwards to form a limiting groove. The top of the side wall of the tubular driven shaft protrudes upwards to form a joint tube, and the joint tube is embedded into the limiting groove. The driven shaft limiting assembly comprises a supporting rod and a limiting ring. The tubular driven shaft penetrates through an inner ring body of the limiting ring. When the power transmission mechanism is applied, oil can be added to the bearing pedestals conveniently, and thus reliability and stability of the power transmission mechanism during application can be guaranteed.

Owner:邹昌金

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com