Power transmission mechanism for wood processing machine

A technology of power transmission mechanism and processing machinery, which is applied in the direction of mechanical equipment, transmission boxes, transmission parts, etc., can solve problems such as time-consuming and laborious, cumbersome process, and influence on the performance of power transmission mechanism, so as to achieve improved stability and simple overall structure , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

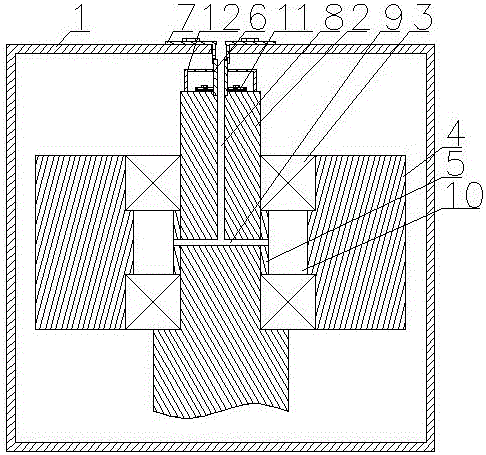

[0014] Such as figure 1 As shown, the power transmission mechanism for wood processing machinery includes a housing 1, a drive shaft 2, a bearing seat 3, a power transmission tooth 4, an oil guide assembly and a driven shaft limit assembly 12, wherein the drive shaft 2, the bearing The seat 3 and the power transmission gear 4 are both arranged in the housing 1, the bearing seat 3 is paired and arranged between the power transmission tooth 4 and the drive shaft 2, the inner ring of the bearing seat 3 cooperates with the drive shaft 2, and the outer ring of the bearing seat 3 matches the power transmission shaft 2. Transmission tooth 4 cooperates. An annular oil storage chamber 10 is formed between the drive shaft 2, the bearing housing 3 and the power transmission gear 4 in this embodiment, and the drive shaft 2 is formed with a first oil tank that is vertically arranged and whose upper opening is located at the top of the drive shaft 2. The liquid flow hole 8 and the second o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com