Mechanism for outputting power during wood processing

A technology of power and wood, applied in the direction of engine components, engine seals, mechanical equipment, etc., can solve problems such as time-consuming and laborious, cumbersome process, and influence on the performance of power transmission mechanisms, to achieve improved stability, simple overall structure, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

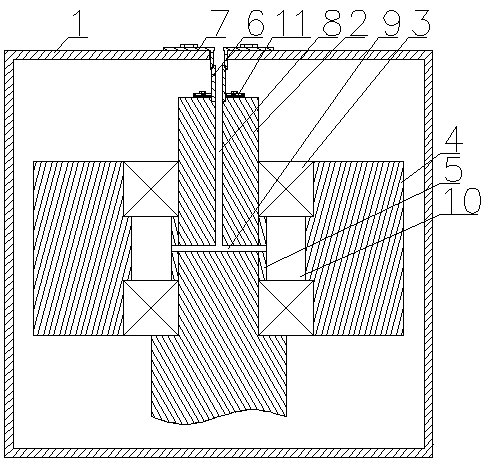

[0013] Such as figure 1 As shown, the mechanism for outputting power when processing wood includes a housing 1, a drive shaft 2, a bearing seat 3, a power transmission tooth 4 and an oil guide assembly, wherein the drive shaft 2, the bearing seat 3 and the power transmission tooth 4 are all Set in the housing 1, the bearing seat 3 is paired between the power transmission tooth 4 and the drive shaft 2, the inner ring of the bearing seat 3 cooperates with the drive shaft 2, and the outer ring of the bearing seat 3 cooperates with the power transmission tooth 4. An annular oil storage chamber 10 is formed between the drive shaft 2, the bearing housing 3 and the power transmission gear 4 in this embodiment, and the drive shaft 2 is formed with a first oil tank that is vertically arranged and whose upper opening is located at the top of the drive shaft 2. The liquid flow hole 8 and the second oil flow hole 9 which are horizontally arranged and connected to the first oil flow hole 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com