Guidewire

A wire and coil technology that is applied to the field of wires with a lubricated surface, which can solve the problems of reduced wire operability, blood vessel perforation, and cracks, and achieve the effects of ensuring softness, ensuring slidability, and improving slidability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] First, 2 g of polyvinyl alcohol and 1 g of water-soluble carbodiimide were dissolved in 106 ml of dimethylformamide as a solvent to prepare a hydrophilic coating solution (solution A).

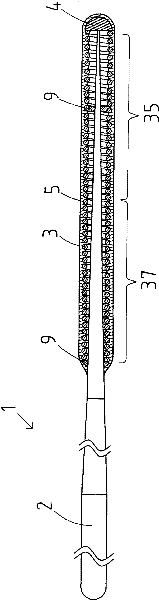

[0108] Next, put figure 1 In the shown wire, the leading end portion made of Sn—Ag and the coil member made of SUS316 (SUS316, stainless steel) were immersed in the solution A.

[0109] Next, drying was performed at 120° C. for 2 hours in a drying oven to remove dimethylformamide as a solvent, and a crosslinking reaction by water-soluble carbodiimide proceeded.

[0110] Thereby, a conductive wire covered with a hydrophilic paint having a thickness of 1 μm whose degree of crosslinking decreases from the coil member side toward the surface side of the hydrophilic paint is obtained, and figure 1 wires described in.

Embodiment 2

[0112] First, from 2-methyl-2-acrylic acid-2-(phosphonooxy) ethyl ester (Axidhoshokishimetakrilet) having a phosphoric acid group in the monomer unit (trade name: Hosuma-Muni Chemical Co., Ltd. 2 g of the polymer constituted by production) was dissolved in 100 ml of water as a solvent to prepare a solution B having a tie layer component.

[0113] Next, 0.5 g of sodium hyaluronate and 1 g of water-soluble carbodiimide were dissolved in 100 ml of water as a solvent to prepare a solution of a hydrophilic coating material (solution C).

[0114] Next, using a vacuum ultraviolet ray irradiation device (manufactured by ゥゥオオデォテディコラングタル), the leading end portion of the same lead wire and the coil member as in Example 1 were irradiated with UV at 172 nm for 5 minutes in air.

[0115] Next, the UV-irradiated portion was immersed in solution B, and then dried in a drying oven at 120° C. for 2 hours to remove the solvent and form a connection layer on the surface of the coil member and the...

Embodiment 3

[0118] First, a solution B composed of the same components as in Example 2 was prepared.

[0119] Next, 2 g of polyvinyl alcohol and 1 g of water-soluble carbodiimide were dissolved in 100 ml of water as a solvent to prepare solution D as a hydrophilic coating material for the lower layer.

[0120] Next, 0.5 g of sodium hyaluronate and 3 g of carboxymethylcellulose were dissolved in 100 ml of water as a solvent to prepare a solution E of a hydrophilic coating material as an upper layer.

[0121] Next, under the same conditions as in Example 2, UV irradiation was performed on the front end portion of the same lead wire as in Example 1 and the coil member.

[0122] Next, this UV-irradiated portion was soaked in solution B containing the connection layer components, and then dried in a drying oven at 120° C. for 30 minutes to remove the solvent, thereby forming a connection between the coil member and the surface of the leading end portion. layer.

[0123] Next, the part where ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com