Master cylinder

A master cylinder and cylinder technology, applied in the direction of hydraulic brake transmission, etc., can solve the problems of affecting sliding performance and poor seating performance, and achieve the effect of ensuring sliding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

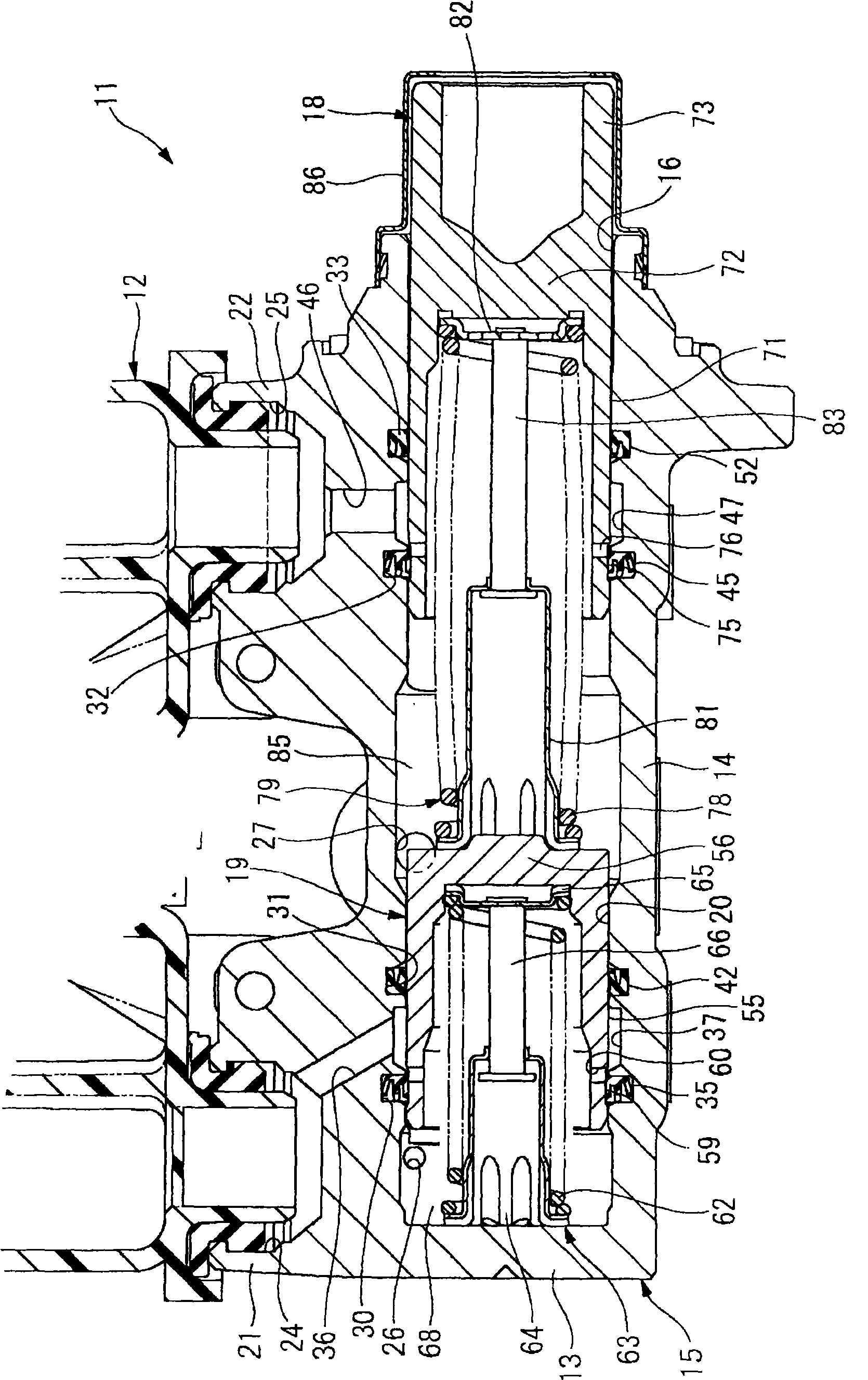

[0030] A master cylinder according to a first embodiment of the present invention will be described below with reference to the drawings.

[0031] figure 1 Reference numeral 11 in the figure represents the master cylinder of this embodiment that generates the brake hydraulic pressure by using the force corresponding to the amount of brake pedal operation introduced through the brake booster not shown in the figure. The master cylinder 11 is equipped with a The fluid storage tank 12 for draining the brake fluid.

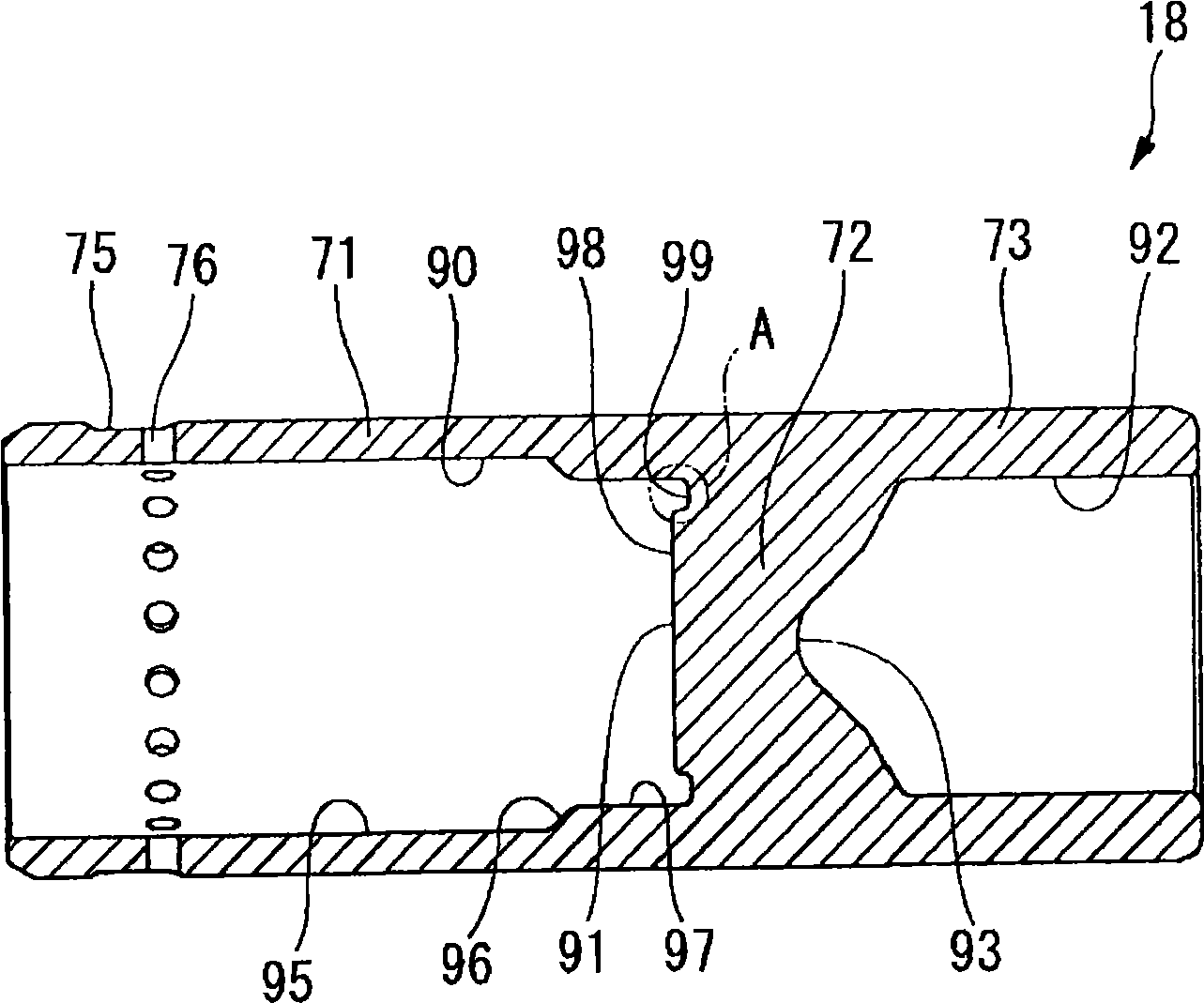

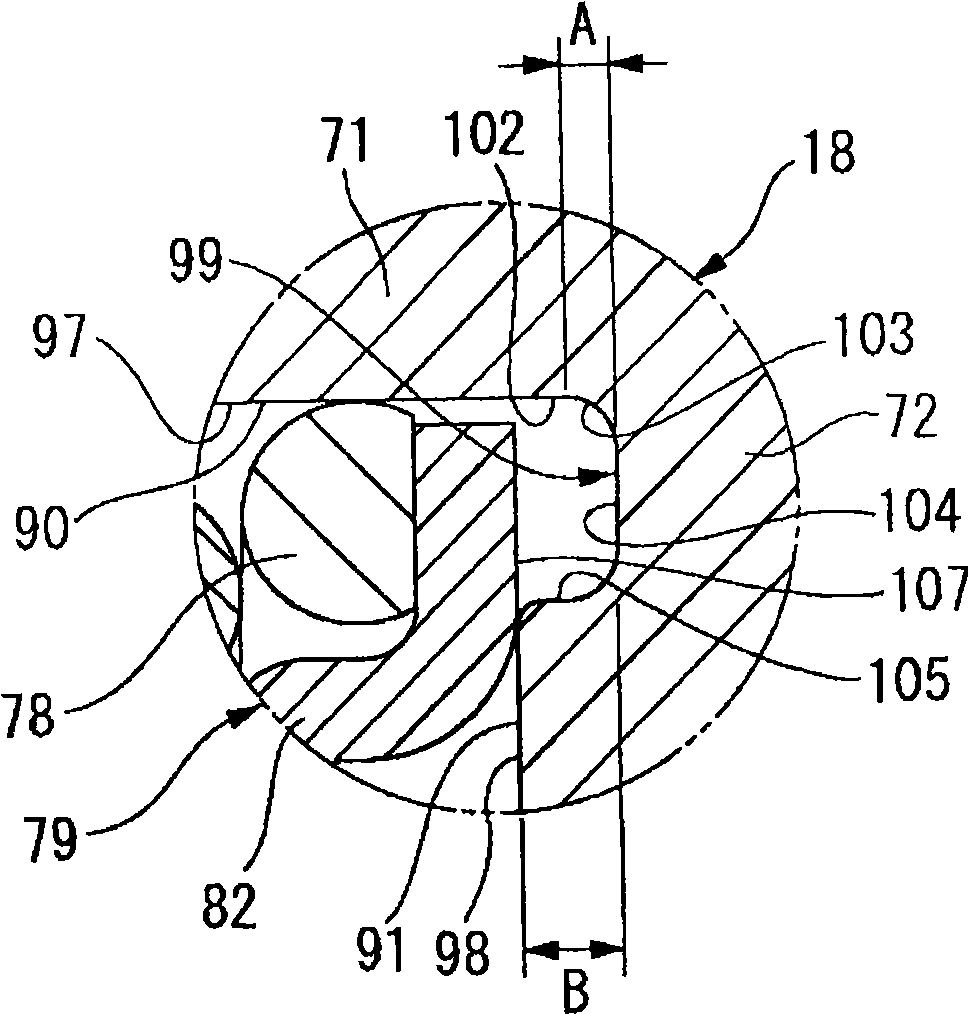

[0032] The master cylinder 11 is in series, and has: a cylinder body 15, which is processed from one material into a bottomed cylindrical shape with a bottom 13 and a cylindrical portion 14, and is arranged on the vehicle in a transverse posture; a primary piston 18, which can is slidably inserted into the opening 16 side of the cylinder body 15 ; The primary piston 18 and the secondary piston 19 are slidably guided along a sliding inner diameter portion 20 having a...

no. 2 example

[0062] Refer to the following side Figure 7 ~ Figure 10 A master cylinder according to a second embodiment of the present invention will be described centering on differences from the first embodiment. The parts that are the same as those in the first embodiment are given the same names and the same symbols, and their descriptions are omitted.

[0063] Such as Figure 7 As shown, the shape of a part of the primary piston 18 and the spring assembly 79 pressing it in the second embodiment are different from those of the first embodiment.

[0064] In the spring assembly 79 of the second embodiment, the partially provided end retainer 120 accommodated in the inner cylindrical portion 71 of the first-stage piston 18 is, for example, Figure 8 As shown, it includes: a flat disc portion 123, a joint hole 121 penetrating the axial direction is formed in the center, and peripheral holes 122 penetrating the axial direction are formed at many places (four places) around the joint hole...

no. 3 example 1

[0076] The following side mainly refers to Figure 11 to Figure 14 A master cylinder according to a third embodiment of the present invention will be described focusing on differences from the first embodiment. The parts that are the same as those in the first embodiment are given the same names and the same symbols, and their descriptions are omitted.

[0077] Such as Figure 11 As shown, the shape of a part of the primary piston 18 and the spring assembly 79 pressing it in the third embodiment are different from those in the first embodiment.

[0078] The spring assembly 79 of the third embodiment includes: a retainer 131 with a short axial length abutting against the bottom 56 of the secondary piston 19 , a retainer 132 with a long axial length abutting against the bottom 72 of the primary piston 18 , One end portion is fixed to the short holder 131 and supports the shaft member 133 slidably within a predetermined range by the long holder 132 . Thus, in the spring assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com