Thermoplastic elastomer composition and use thereof

A technology of thermoplastic elastomer and composition, which is applied in the field of olefin-based thermoplastic elastomer composition, can solve problems such as corner adhesion without mentioning, and achieve the effect of excellent low-temperature impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

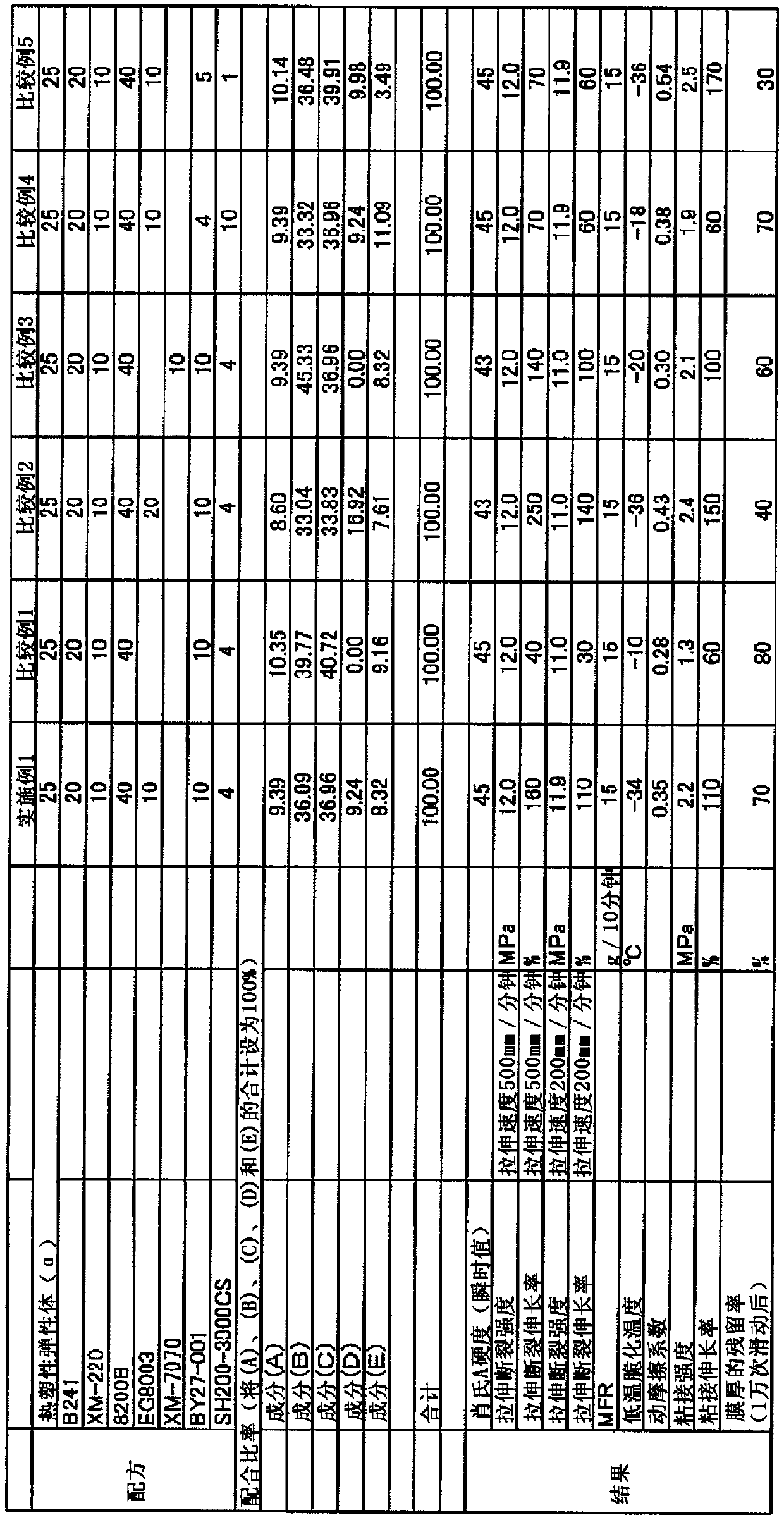

Examples

Embodiment 1

[0144] (1) Production of thermoplastic elastomer (α) containing ethylene-α-olefin-non-conjugated polyene copolymer (A)

[0145] Using a Henschel mixer, Mitsui EPT (trademark) 3072EPM (ethylene-propylene-ENB copolymer manufactured by Mitsui Chemicals Co., Ltd.) (catalogue value : ethylene content 64% by mass, ENB content 5.4% by mass; molar conversion value (total of ethylene and propylene is 100 mol%): ethylene content 75.8 mol%, propylene content 24.2 mol%; oil extension amount 40 parts by mass; iodine Value 11.5) 140 parts by mass of polypropylene-based resin (trade name: Prime Polypro E-200GP, manufactured by Prime Polymer Co., Ltd., homopolymer type, MFR (230°C, 21.2 N) 2.0g / 10min, density 0.90g / cm 3 ) 40 parts by mass, 0.3 parts by mass of organic peroxide (1,3-bis(tert-butylperoxyisopropyl)benzene) as a crosslinking agent, 0.3 parts by mass of divinylbenzene as a crosslinking auxiliary agent, As an antioxidant, 0.20 parts by mass of phenolic antioxidant (trade name: IR...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com