Polyolefin resin composition comprising different rubber components for insulating electric cables

A polyolefin resin and composition technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of reduced flexibility, low thermal deformation temperature, difficult construction and installation, etc., and achieves excellent low-temperature impact strength, mechanical Excellent physical properties and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

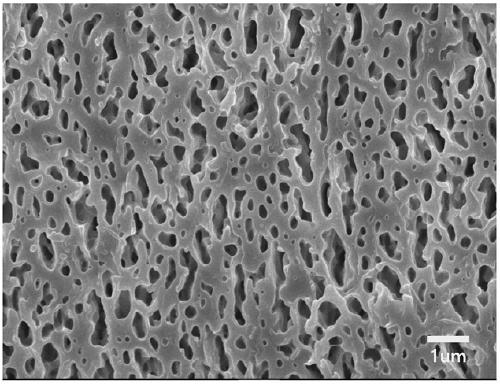

Image

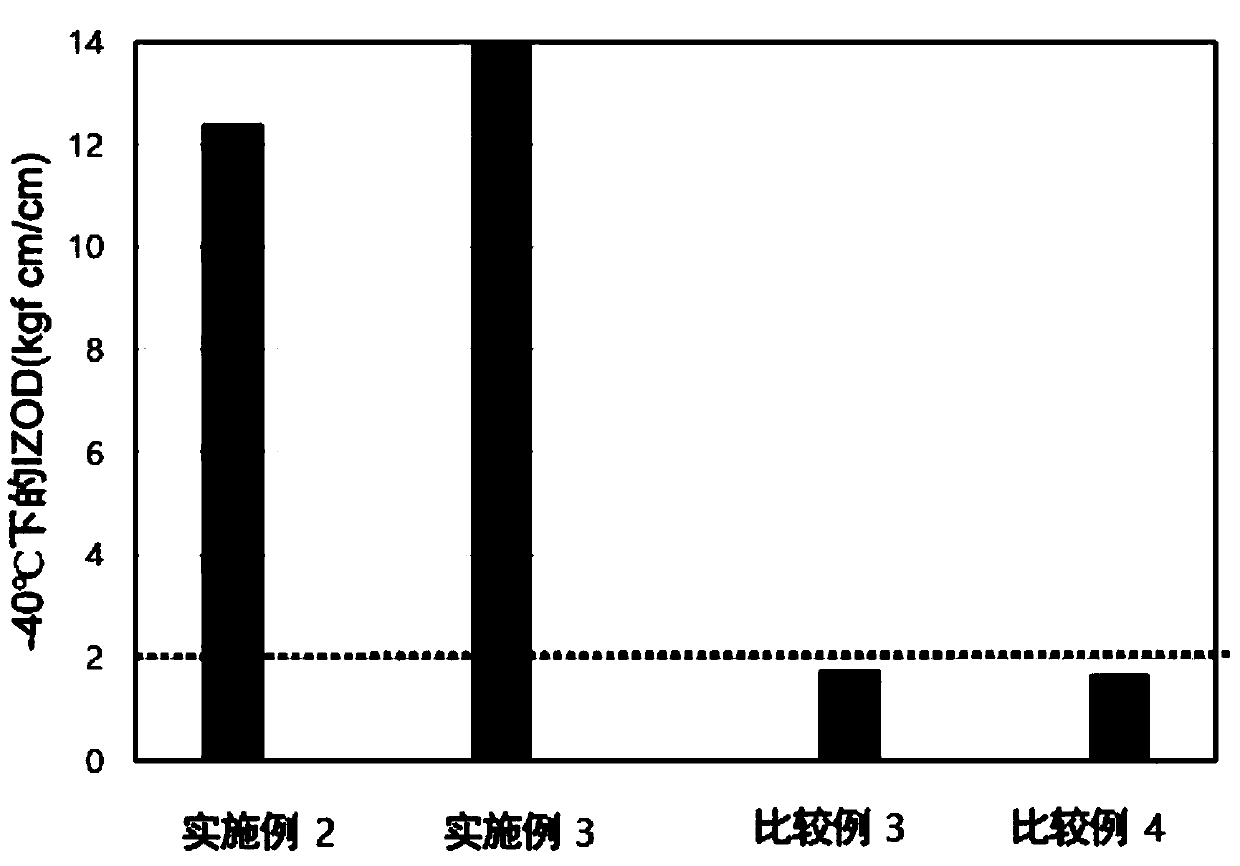

Examples

Embodiment 1

[0081] (A) 74.8% by weight of polyolefin resin A1; (B) 10% by weight of rubber copolymer resin B1; (C) 15% by weight of rubber copolymer resin C1; and 0.2% by weight A polyolefin resin composition composed of antioxidants and neutralizers.

[0082] Mix the above three polyolefin resins (A), (B) and (C) with antioxidants and neutralizers in a Henschel mixer (SSM-75) for 30 minutes, and then mix them at 230° C. , melt-extruded through a twin-screw extruder PLATEK (TEK-30), and granulated by a granulator. The pellets of the resin composition thus prepared were injection-molded into test pieces specified in ASTM No. 4 using a 150-ton injection molding machine (Selexte 150).

Embodiment 2~4 and comparative example 1~6

[0084] A composition was prepared by the same method as in Example 1, except that the kind and content of resins constituting the composition were changed as shown in Table 1 below. The numbers described in the following Table 1 represent the content on a weight % basis.

[0085] [Table 1]

[0086]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com