Toughening agent, PVC pipe material and preparation method of PVC pipe material

A PVC pipe and toughening agent technology, applied in the field of toughening agent, PVC pipe material and its preparation, can solve the problems of brittle cracking and poor impact resistance at low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

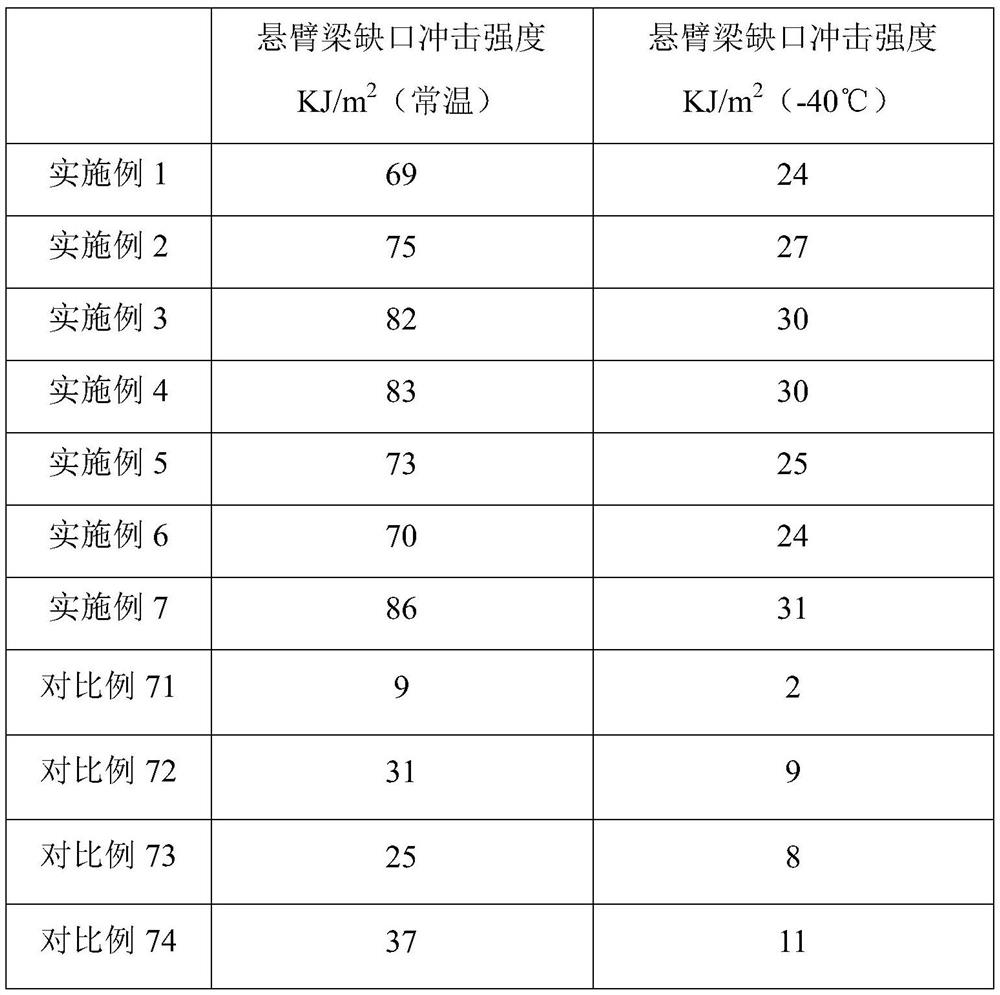

Examples

Embodiment 1

[0027] According to parts by weight, 100 parts of polyvinyl chloride, 10 parts of acrylonitrile-butadiene-styrene copolymer, 5 parts of maleic anhydride grafted polyethylene, toughening agent (mass ratio is 3:1 low density polyethylene and nitrile rubber) 10 parts, 1 part of chlorinated polyethylene, 0.5 part of antioxidant 1098, 0.5 part of antioxidant 168, 1 part of zinc stearate was placed in the mixer at room temperature and mixed for 1 minute, and the mixing speed was 150 rpm / minute. Add the mixed raw materials into a twin-screw extruder, melt and extrude and granulate to obtain a PVC pipe material, wherein the temperature of the first zone of the twin-screw extruder is 160°C, and the temperature of the second zone is 170°C , the temperature of the third zone is 180°C, the temperature of the fourth zone is 210°C, the temperature of the fifth zone is 210°C, the temperature of the sixth zone is 210°C, and the speed is 300rpm.

Embodiment 2

[0029] According to parts by weight, 100 parts of polyvinyl chloride, 20 parts of acrylonitrile-butadiene-styrene copolymer, 6 parts of maleic anhydride grafted polyethylene, toughening agent (mass ratio is 3:1 low density polyethylene and nitrile rubber) 12 parts, 5 parts of chlorinated polyethylene, 2 parts of antioxidant 1098, 2 parts of antioxidant 168, 5 parts of zinc stearate were placed in mixer and mixed at room temperature for 2 minutes, mixing speed 180 rpm minute. Add the mixed raw materials into the twin-screw extruder, melt and extrude and granulate to obtain PVC pipe material, wherein the temperature of the first zone of the twin-screw extruder is 170°C, and the temperature of the second zone is 180°C , the temperature of the third zone is 200°C, the temperature of the fourth zone is 220°C, the temperature of the fifth zone is 220°C, the temperature of the sixth zone is 220°C, and the speed is 500rpm.

Embodiment 3

[0031] 100 parts by weight of polyvinyl chloride, 12 parts of acrylonitrile-butadiene-styrene copolymer, 8 parts of maleic anhydride grafted polyethylene, toughening agent (mass ratio is 3:1 low density polyethylene and 14 parts of nitrile rubber), 3 parts of chlorinated polyethylene, 1 part of antioxidant 1098, 2 parts of antioxidant 168, and 3 parts of zinc stearate were placed in a mixer at room temperature and mixed for 2 minutes at a mixing speed of 170 rpm . Add the mixed raw materials into a twin-screw extruder, melt and extrude and granulate to obtain PVC pipe material, wherein the temperature of the first zone of the twin-screw extruder is 170°C, and the temperature of the second zone is 190°C , the temperature of the third zone is 180°C, the temperature of the fourth zone is 210°C, the temperature of the fifth zone is 220°C, the temperature of the sixth zone is 220°C, and the speed is 500rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com