Method for preparing acrylonitrile-butadiene-styrene copolymer for instrument panel

A styrene copolymer and acrylonitrile technology is applied in the field of preparing acrylonitrile-butadiene-styrene copolymer for instrument panels, which can solve the problems of low impact strength of ABS resin, and achieve enhanced impact strength, cost reduction, High mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

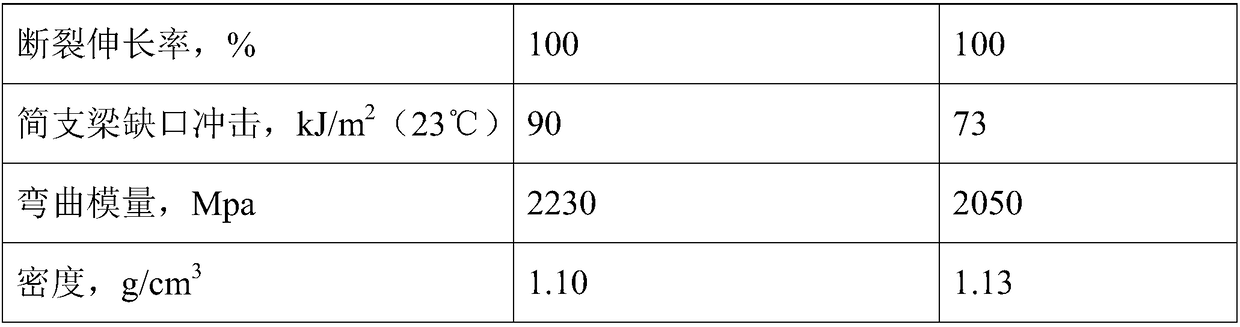

Examples

Embodiment 1

[0019] An acrylonitrile-butadiene-styrene copolymer preparation method for instrument panels includes the following steps:

[0020] S1. Mix 10g zeolite powder compound, 10g potassium titanate whiskers, 4g heavy calcium carbonate, 16g nano talc, 6g EPDM rubber, 4g sodium lauryl sulfate, 2g oxidized polyethylene wax, and heat up Stir at 90°C for 8 min, at a stirring speed of 5800r / min, to obtain premix b;

[0021] The zeolite powder composite was prepared by the following process: After pulverizing 20g of zeolite powder, adding 30g of rosin-modified phenolic resin, heating to 70℃ and stirring for 40min, continuing to add 6g of epoxy soybean oil modified phenolic resin, heating to 170℃ and stirring for 15min, Obtain a zeolite powder composite;

[0022] S2. Mix 120g of acrylonitrile-butadiene-styrene copolymer and 30g of polyvinyl chloride, heat up to 145°C and stir for 10min at a stirring speed of 2400r / min, then add 15g of premix b and 4g of tert-butyl peroxide Hydrogen, 2g1,1-bis-(t...

Embodiment 2

[0024] An acrylonitrile-butadiene-styrene copolymer preparation method for instrument panels includes the following steps:

[0025] S1. Mix 20g zeolite powder compound, 6g potassium titanate whiskers, 8g heavy calcium carbonate, 8g nano talc, 14g EPDM rubber, 2g sodium lauryl sulfate, 4g oxidized polyethylene wax, and heat up Stir at 80°C for 16 min, at a stirring speed of 5200r / min, to obtain premix b;

[0026] The zeolite powder composite was prepared by the following process: After pulverizing 40g of zeolite powder, adding 20g of rosin-modified phenolic resin, heating to 90℃ and stirring for 30min, continuing to add 12g of epoxy soybean oil modified phenolic resin, heating to 140℃ and stirring for 25min, Obtain a zeolite powder composite;

[0027] S2. Mix 80g of acrylonitrile-butadiene-styrene copolymer and 40g of polyvinyl chloride, heat up to 135℃ and stir for 20min at a stirring speed of 2000r / min, then add 25g of premix b and 2g of tert-butyl peroxide Hydrogen, 4g1,1-bis-(te...

Embodiment 3

[0029] An acrylonitrile-butadiene-styrene copolymer preparation method for instrument panels includes the following steps:

[0030] S1. Mix 12g of zeolite powder composite, 9g of potassium titanate whiskers, 5g of heavy calcium carbonate, 14g of nano talc, 8g of EPDM, 3.5g of sodium lauryl sulfate, and 2.5g of oxidized polyethylene wax , The temperature was raised to 88°C and stirred for 10 min, and the stirring speed was 5600r / min to obtain the premix b;

[0031] The zeolite powder composite is prepared by the following process: after 25g of zeolite powder is pulverized, 28g of rosin modified phenolic resin is added, the temperature is raised to 75°C and stirred for 37min, and 8g of epoxy soybean oil modified phenolic resin is continuously added, and the temperature is raised to 160°C and stirred for 18min. Obtain a zeolite powder composite;

[0032] S2. Mix 110g acrylonitrile-butadiene-styrene copolymer and 33g polyvinyl chloride, heat up to 142°C and stir for 12min at a stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com