BOPP film and preparation method thereof

A technology of thin film and nano-titanium dioxide, which is applied in the field of plastic film, can solve the problems of insufficient antibacterial and antibacterial performance, achieve good smooth effect, ensure sliding performance, change sliding and anti-sticking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0052] Prepare antibacterial polypropylene pellets, it may further comprise the steps:

[0053] S1, put polypropylene and polyhexamethyleneguanidine hydrochloride into a high-speed mixer and stir well;

[0054] S2, melting and extruding the mixture into granules through a twin-screw extruder, the granulation temperature is 220° C., and the rotation speed is 350 rpm;

[0055] S3, drying the extruded pellets in a constant temperature oven at 90° C. for 3 hours to obtain antibacterial polypropylene pellets.

preparation example 2

[0057] Preparation of loaded zinc sulfate nano-titanium dioxide fibers comprises the following steps:

[0058] S1, put the saturated solution of zinc sulfate and nano-titanium dioxide fibers into the reaction kettle, and heat at 300°C for 10 hours;

[0059] S2, cooled to room temperature, washed 3 times with distilled water;

[0060] S3, put it in an oven, and dry it at 80° C. for 8 hours.

Embodiment 1

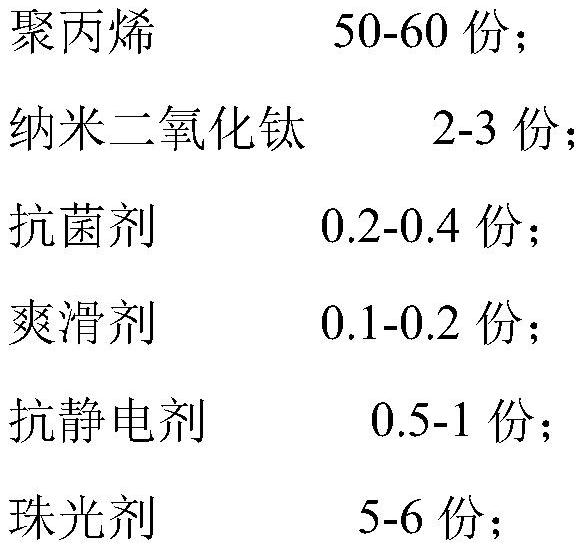

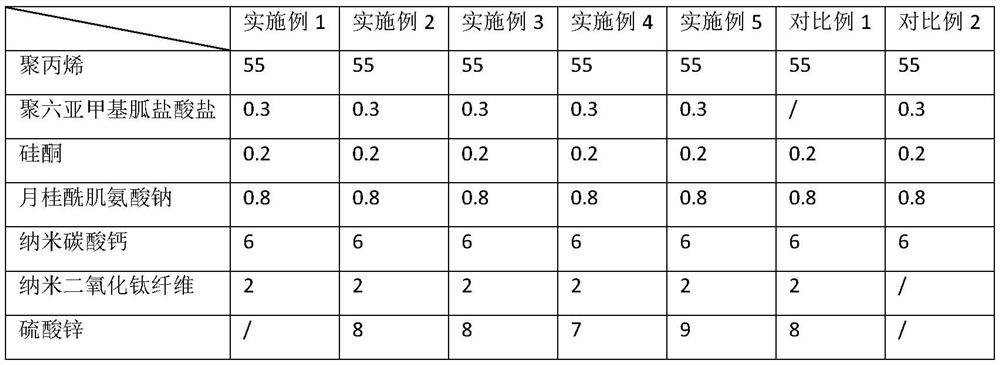

[0063] A kind of BOPP film, comprises surface layer, core layer and bottom layer, by weight, and the raw material composition of core layer is as shown in table 1.

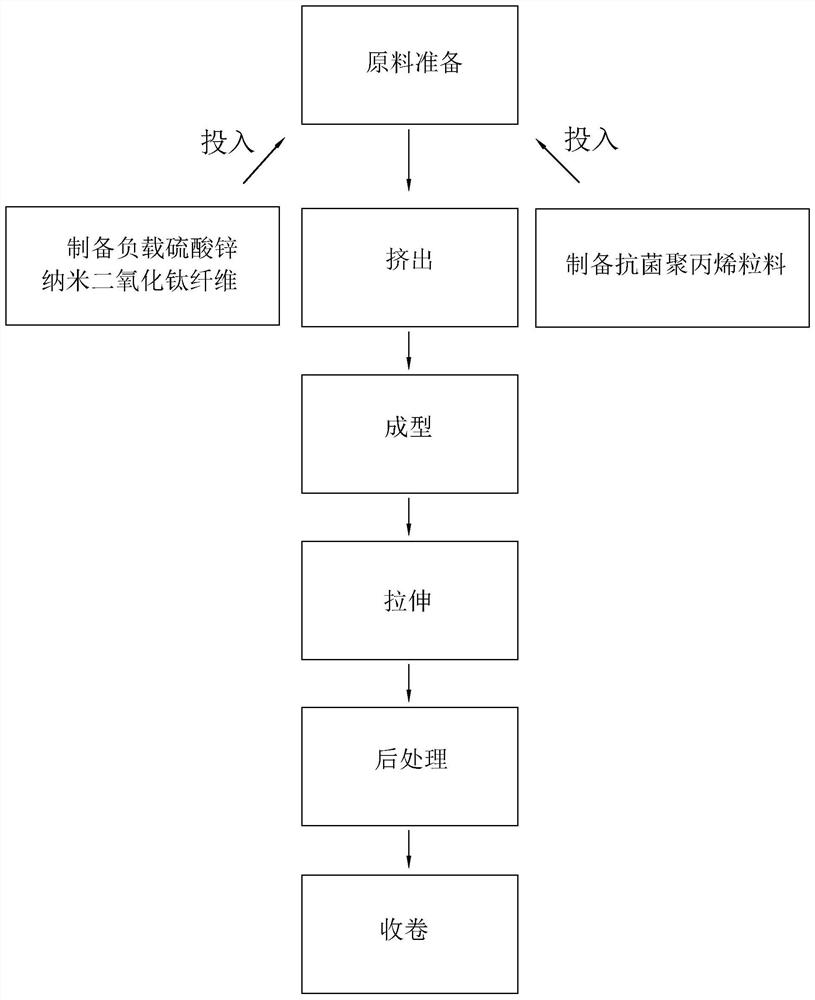

[0064] The preparation method of BOPP film comprises the following steps:

[0065] S1, raw material preparation: prepare antibacterial polypropylene pellets by mixing polypropylene and polyhexamethyleneguanidine hydrochloride;

[0066] S2, Extrusion: Take antibacterial polypropylene pellets, nano-titanium dioxide fibers, silicone, sodium lauroyl amate, and nano-calcium carbonate, and extrude on an extruder at 220°C to obtain a core layer, and simultaneously prepare a surface layer and a bottom layer;

[0067] S3, forming: pass the surface layer, core layer and bottom layer through a three-layer co-extrusion film head, pass through a salivating machine at 230°C, and cool and form through a cooling system at 20°C;

[0068] S4, Stretching: stretch the film longitudinally at 110°C, with a stretching ratio of 6.5 time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com