Fluorine-resin sealing ring

A sealing ring and resin-made technology, which is applied in the sealing of engines, gaseous chemical plating, coating, etc., can solve problems such as welding, coating film melting, and fluororesin fixation, and achieve excellent sliding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

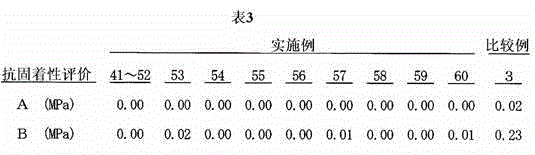

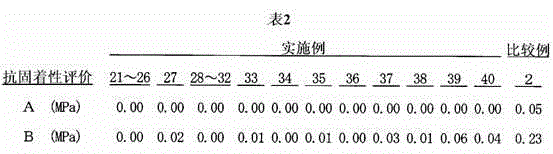

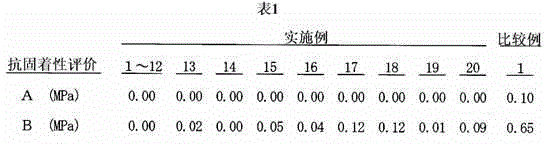

Examples

Embodiment 1

[0061] PTFE (Asahi Glass product G163) 68% by weight, glass fiber (Nitto Industries, Ltd. product CSX-3J-451S) 30% by weight and oil coke (Chuetsu Black Lead Industrial product, average particle size 20 μm) 2% by weight were mixed with a mixer Finally, compression molding was performed at 10 to 20 MPa using a compression molding machine, and then calcined in a calciner at a temperature above the melting point to produce a cube-shaped (4×4×4 mm) test piece.

[0062] The obtained test piece was placed on the lower electrode in a vacuum chamber of a low-pressure plasma processing apparatus, and the vacuum chamber was evacuated to a degree of vacuum of 10 Pa. Argon gas is introduced at the point when the vacuum degree is reached, and while the pressure in the vacuum chamber is maintained at about 60 Pa, a high-frequency power supply with a frequency of 13.56 MHz is used to supply 200 W of power to the upper electrode for 10 minutes, and the argon gas is plasma Bulkization for plas...

Embodiment 2

[0068] In Example 1, two kinds of anti-sticking evaluations were performed using a test piece in which the PTFE surfaces on which the amorphous carbon film was formed were superimposed on each other and clamped with a jig.

Embodiment 3

[0070] In Example 1, two kinds of anti-sticking evaluations were performed on the test piece on which the amorphous carbon film was formed by changing the plasma CVD treatment using acetylene gas to 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com