Valve device

A valve device, bearing bushing technology, applied in valve device, lift valve, shaft installation and other directions, can solve the problems of wear and tear of switching action obstacles, reduced productivity, increased cost, etc., to suppress or prevent sliding noise or wear, production. The effect of improved performance and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

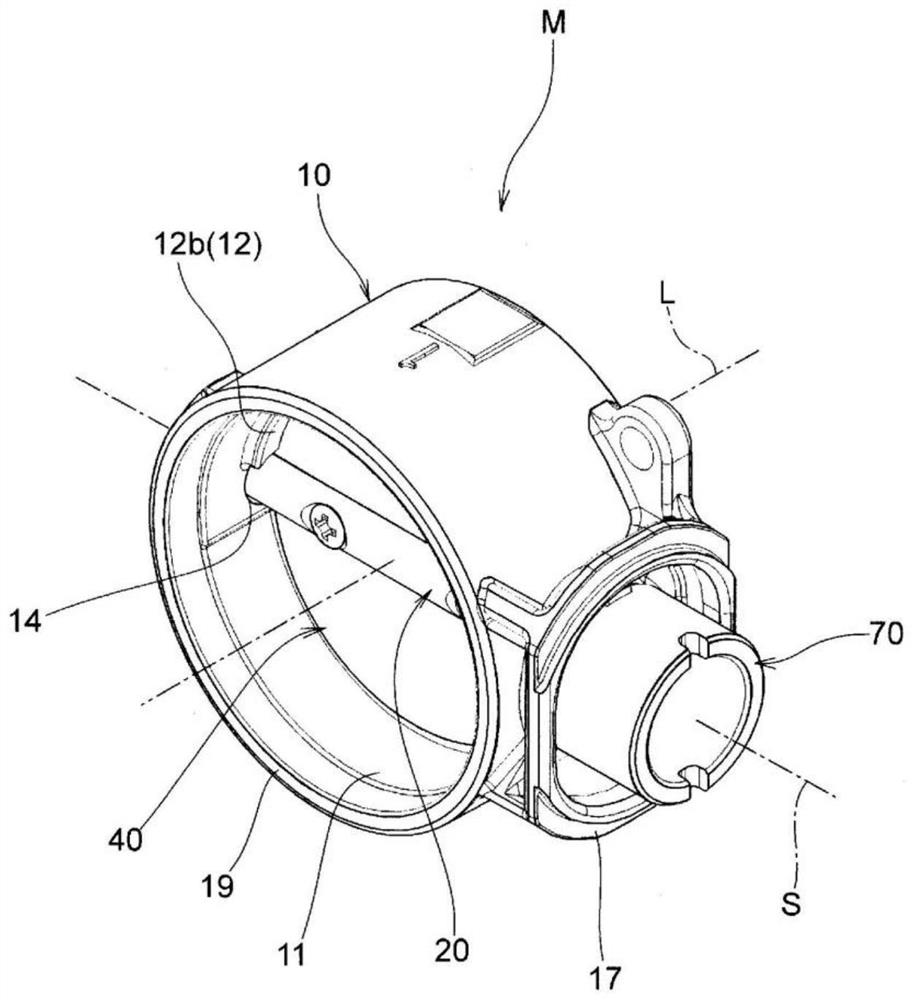

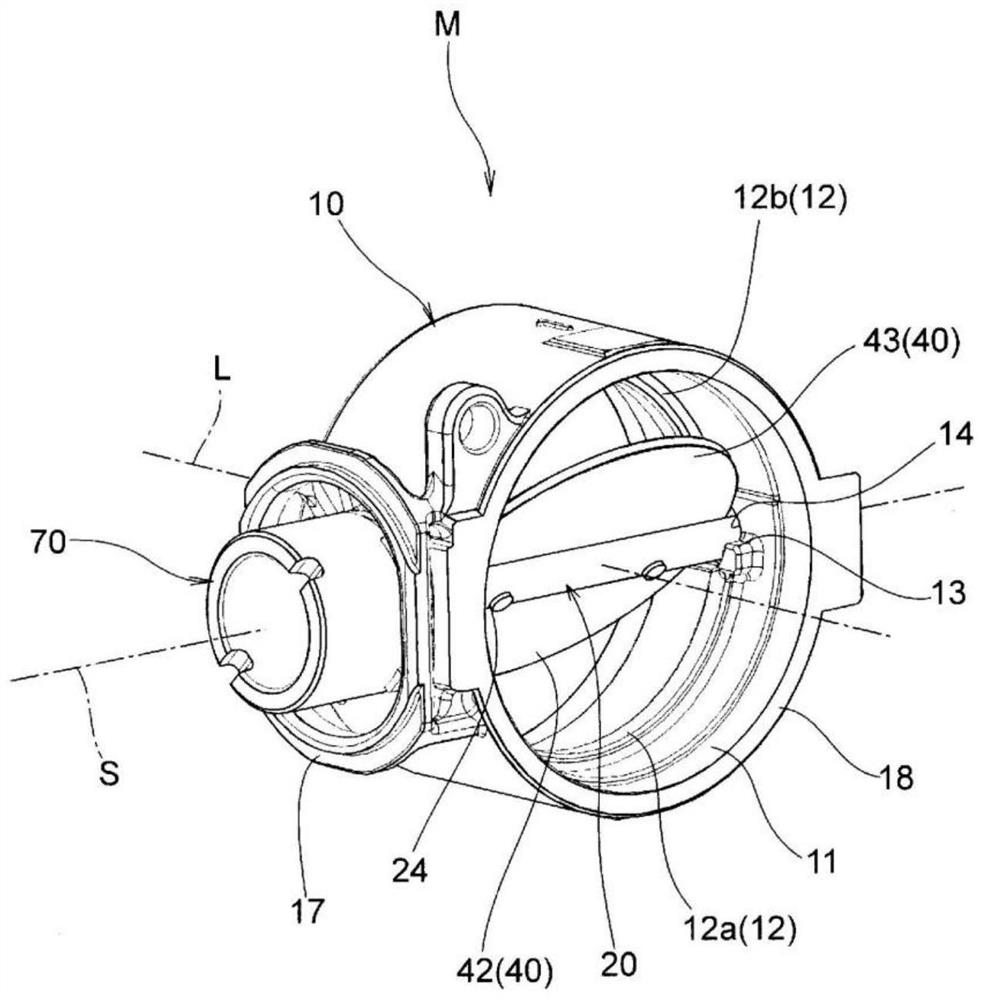

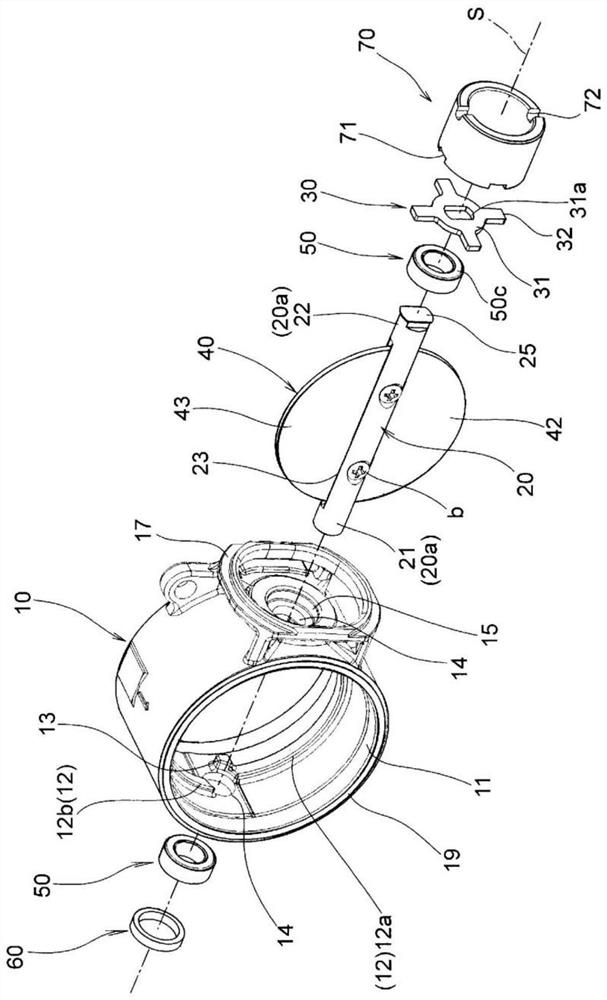

[0059] An embodiment of the valve device M such as Figure 1 to Figure 4 As shown, it includes a body 10 , a shaft 20 defining an axis S, a plate 30 , a valve core 40 , two bearing bushes 50 , a cover 60 , and a connecting member 70 .

[0060] The main body 10 is made of metal materials such as stainless steel and iron, and is cast by, for example, a dewaxing method. part 13, two shaft holes 14 through which the shaft 20 passes, two fitting holes 15 for fitting the bearing bush 50, fitting parts 16 for fitting the cover 60, the flange part 17, the first connecting part 18, The second connecting part 19 .

[0061] The passage 11 is formed in the form of a cylindrical passage having a circular cross-section with a certain inner diameter at the center on the center line L. As shown in FIG.

[0062] The seal portion 12 includes a first seal portion 12 a and a second seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com