Milk-containing drink and milk composition having reduced milk serum protein content

A whey protein and milk-containing beverage technology, which is applied in the field of milk compositions and milk-containing beverages with reduced whey protein content, can solve problems such as deterioration and insufficient, and achieve the effect of preventing flavor deterioration and refreshing taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Using milk-containing coffee beverages, the reasons for the unique creaminess of milk-containing beverages after pasteurization are discussed. In order to investigate the cause, as shown in Table 1 below, coffee beverage samples excluding various raw materials were prepared. Glycerin fatty acid esters and sucrose fatty acid esters are used as emulsifiers.

[0065] Table 1

[0066] Table 1 Coffee beverage (prototype sample)

[0067]

[0068] (○··with addition, ×··without addition)

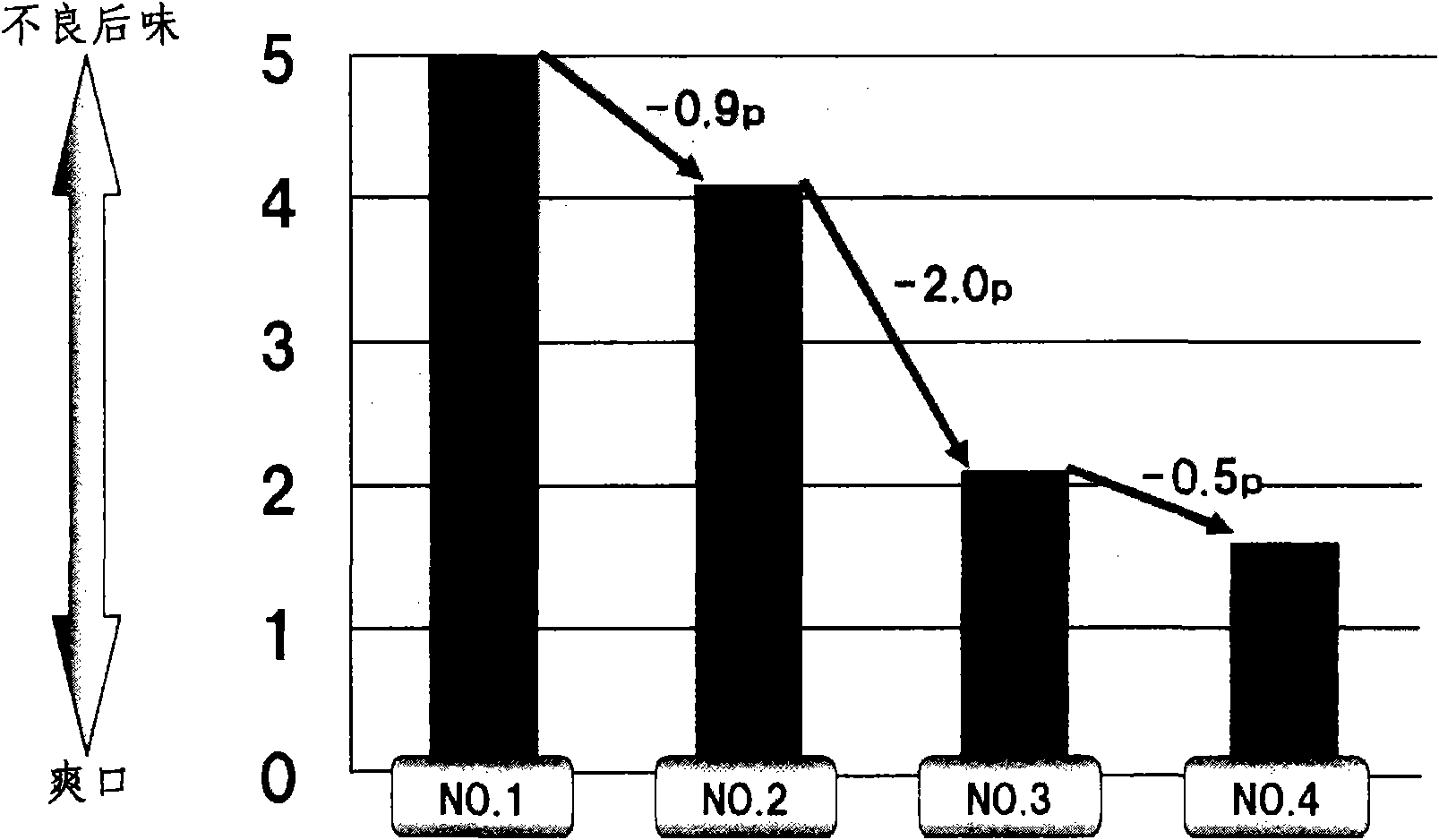

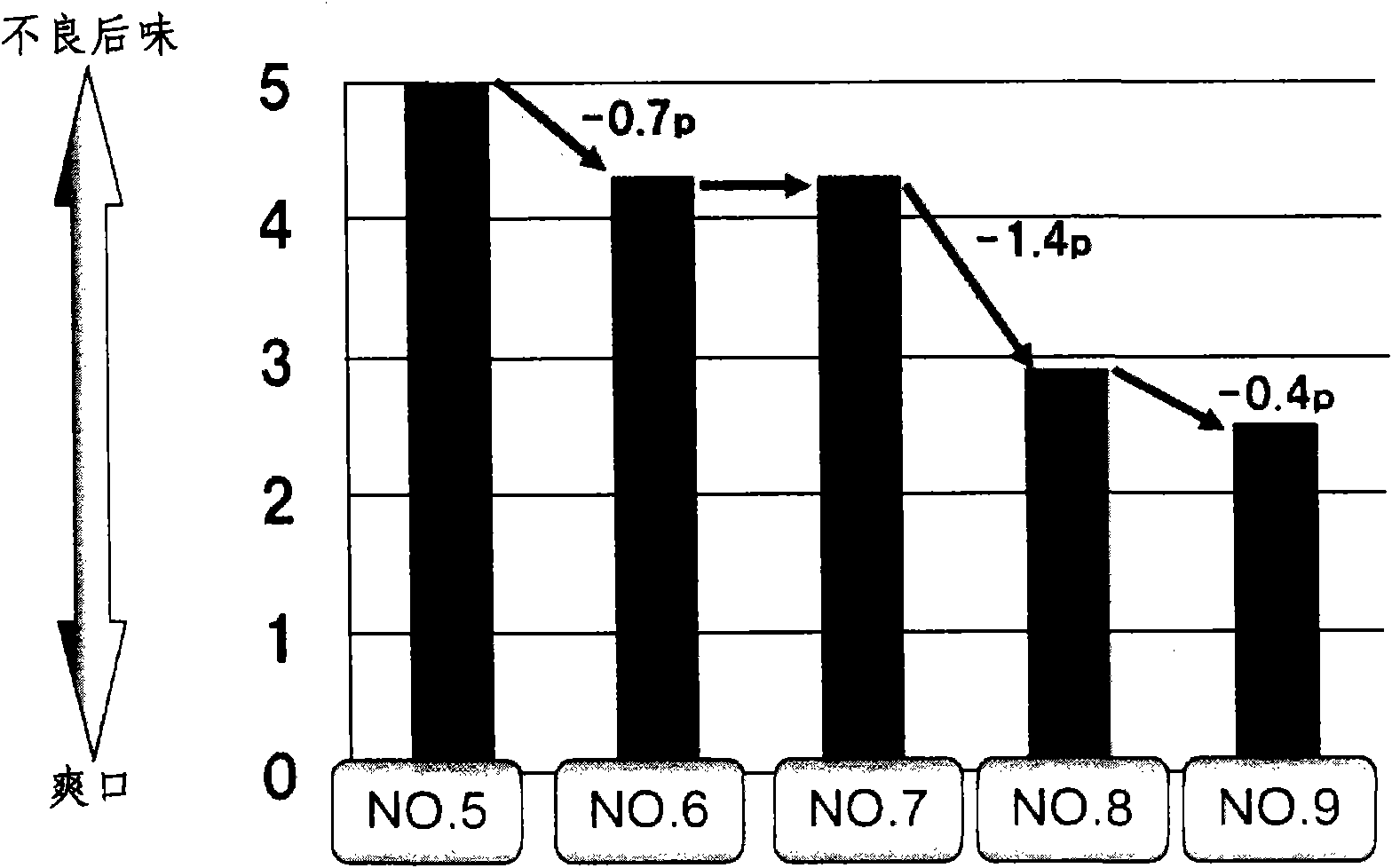

[0069] After these samples were heat-sterilized, five sensory panelists conducted a sensory evaluation through a blind test. Carry out 5 grades of evaluations for bad aftertaste, with the worst aftertaste as 5 points and carry out scoring, represent 5 average marks ( figure 1 ).

[0070] exist figure 1 Among them, reducing milk (sample No. 2 to NO. 3) improved the aroma the most, and it is known that milk contributes the most to the aroma change after pasteurization. It can be seen ...

Embodiment 2

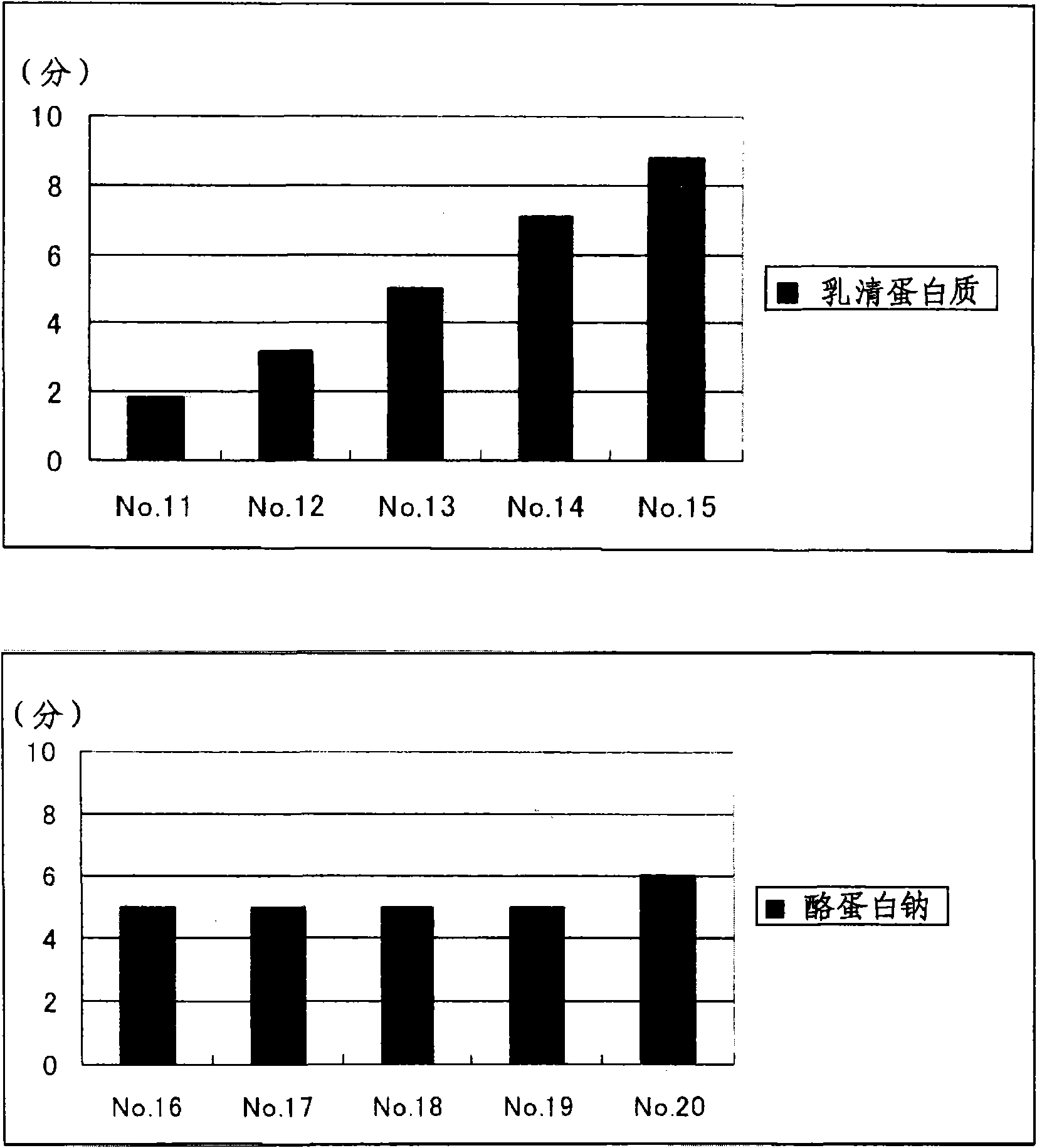

[0090]Each component was mixed with the composition shown in Table 5, 100 times the water of the whole raw material was added, it homogenized in water, and the milk composition A, B was obtained. Extract 20 g of roasted and ground coffee beans with pure water at 90°C, add an appropriate amount of baking soda (sodium bicarbonate) and an emulsifier, and 70 g of sugar to the obtained coffee extract, and add the milk to the milk composition at 3.0% by mass of the fixed milk For substance A or B, adjust the total amount to 1000ml with pure water, homogenize the obtained sample solution, fill it into a 190g tank, heat-sterilize it (125°C, 20 minutes), and use milk composition A to obtain Sample A, sample B was obtained using milk composition B. The bad aftertaste was evaluated on five levels, and the worst aftertaste was scored as five points, and the fragrance evaluation was performed in the same manner as in Example 1. The results are also shown in Table 5. It is known that the ...

Embodiment 3

[0095] Milk protein, fresh cream, and lactose were dissolved in 90° C. pure water to obtain milk compositions (1) to (6). In each composition, the ratio of the whey protein in the whole milk protein was changed as shown in Table 6. Next, an appropriate amount of baking soda (sodium bicarbonate), an emulsifier, and 60 g of sugar were added to the coffee extract obtained by extracting 30 g of roasted and ground coffee beans with pure water at 90° C., and the milk solids were 3.0% by mass and added to the milk composition. Any one of the substances (1) to (6), the total amount was adjusted to 1000ml with pure water, and the obtained sample solution was homogenized, filled into a 190g tank, and heat sterilized (125°C, 20 minutes), samples (1) to (6) respectively corresponding to milk compositions (1) to (6) were obtained. In addition, the mass of the whole milk protein in a drink was fixed (0.78 mass %). Table 6 also shows the results of flavor evaluation of samples (1) to (6). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com