Patents

Literature

101results about How to "Same spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

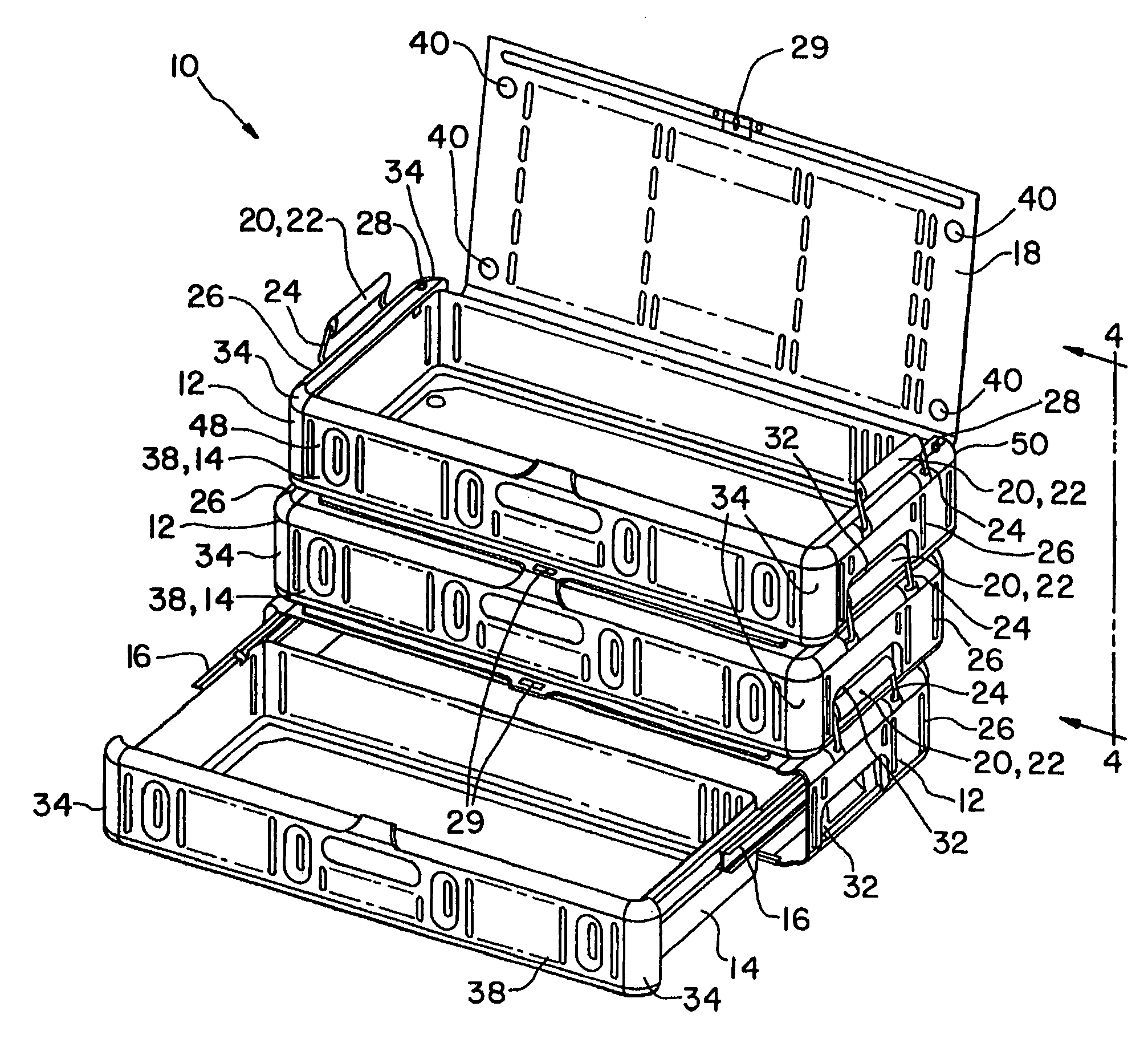

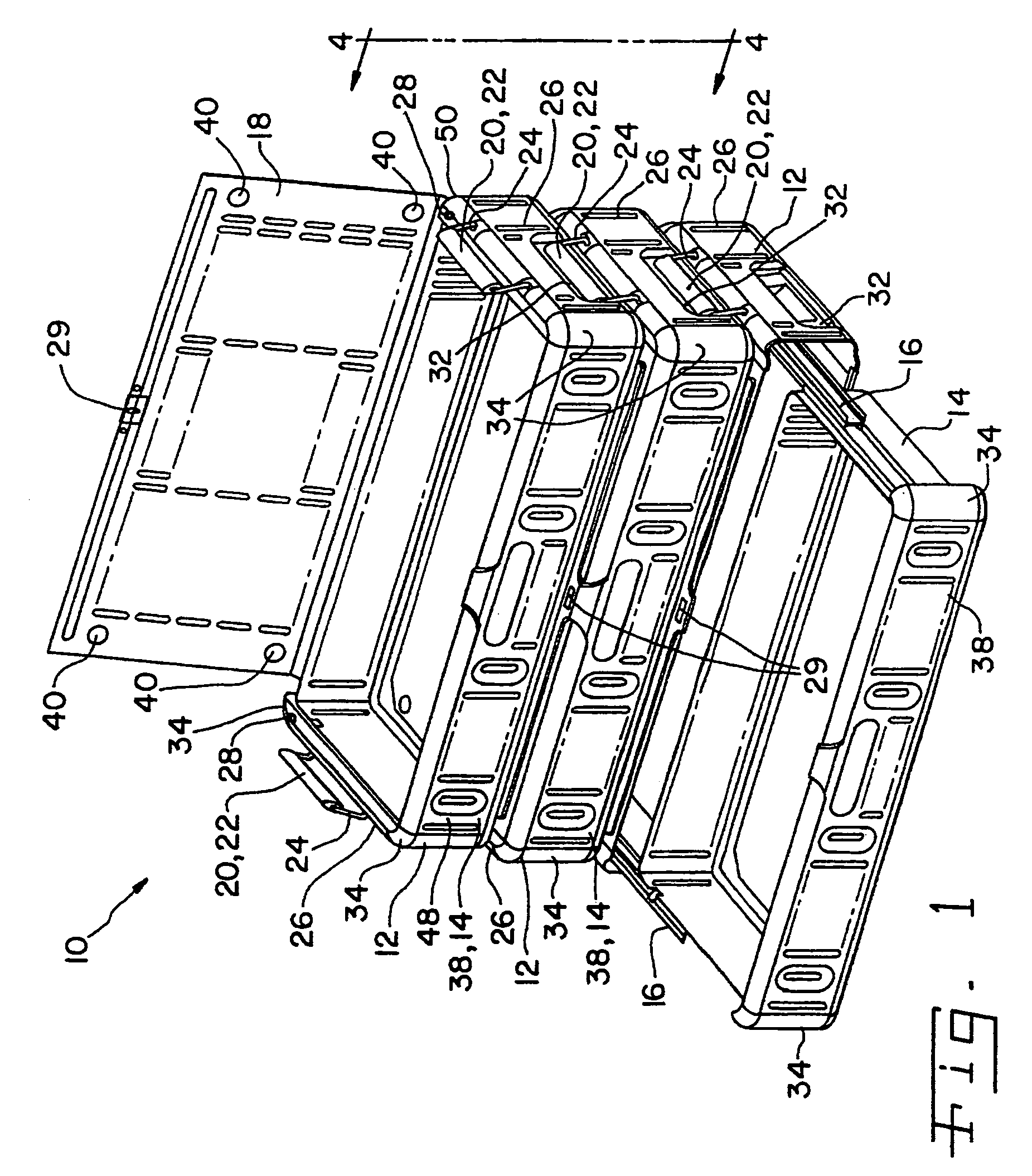

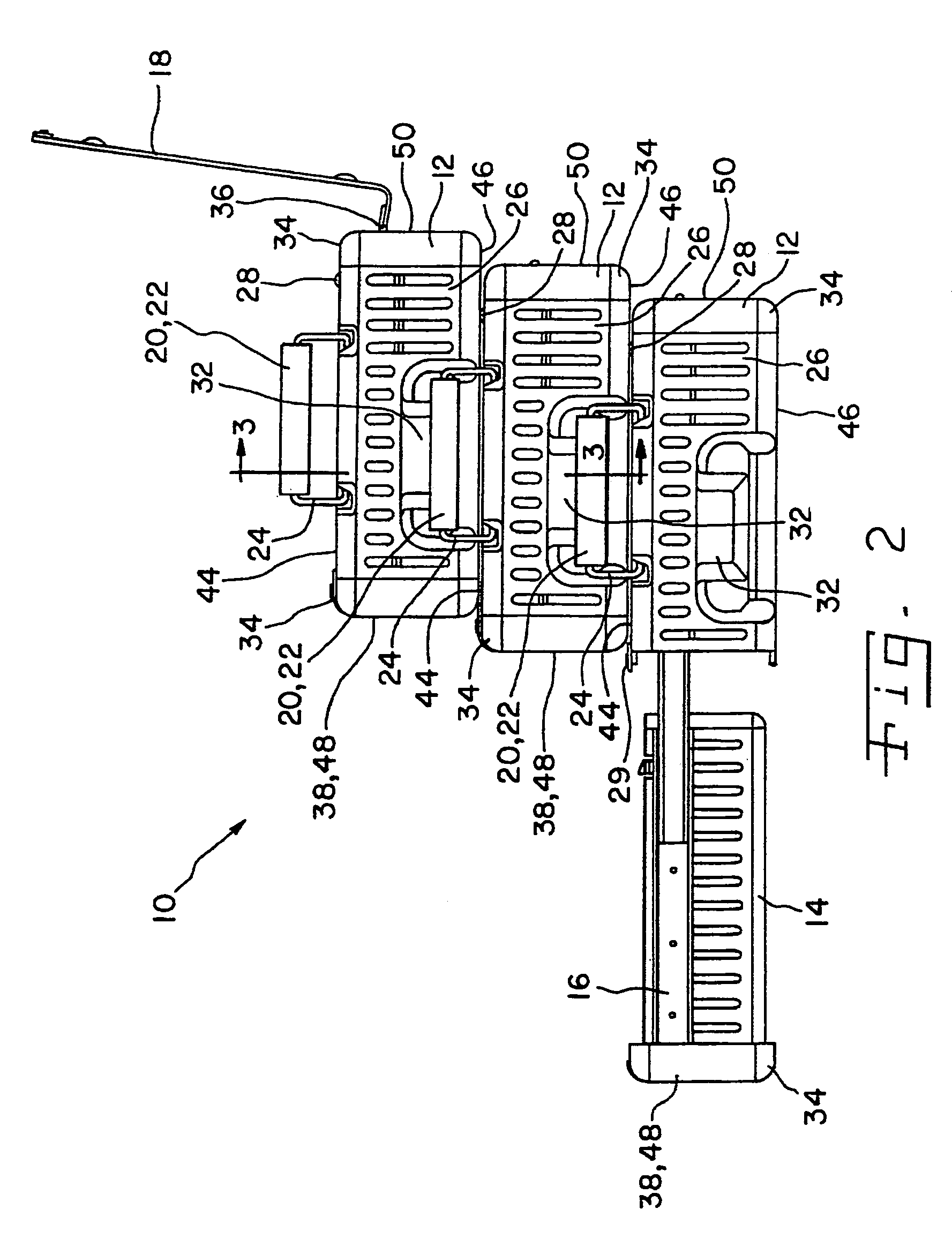

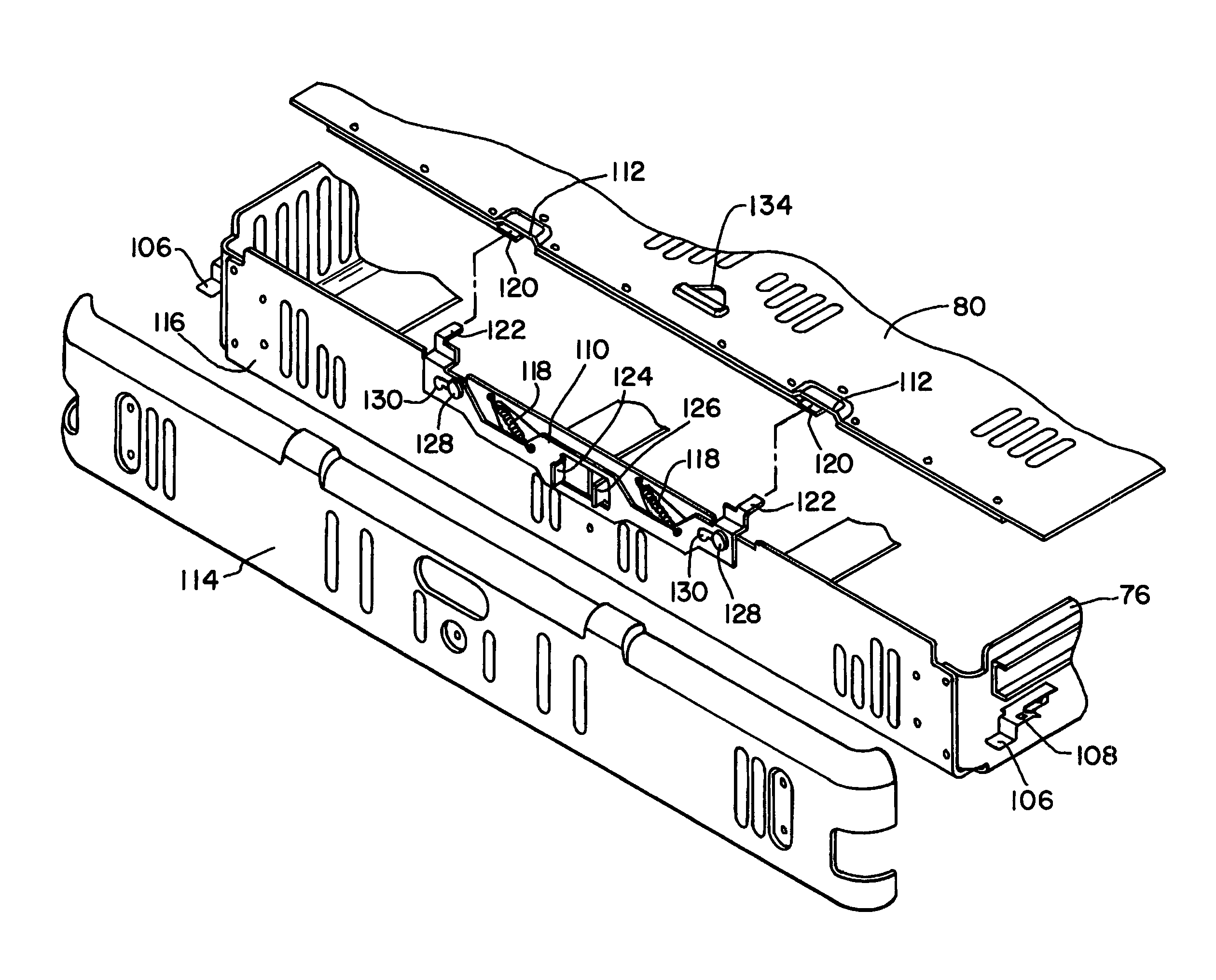

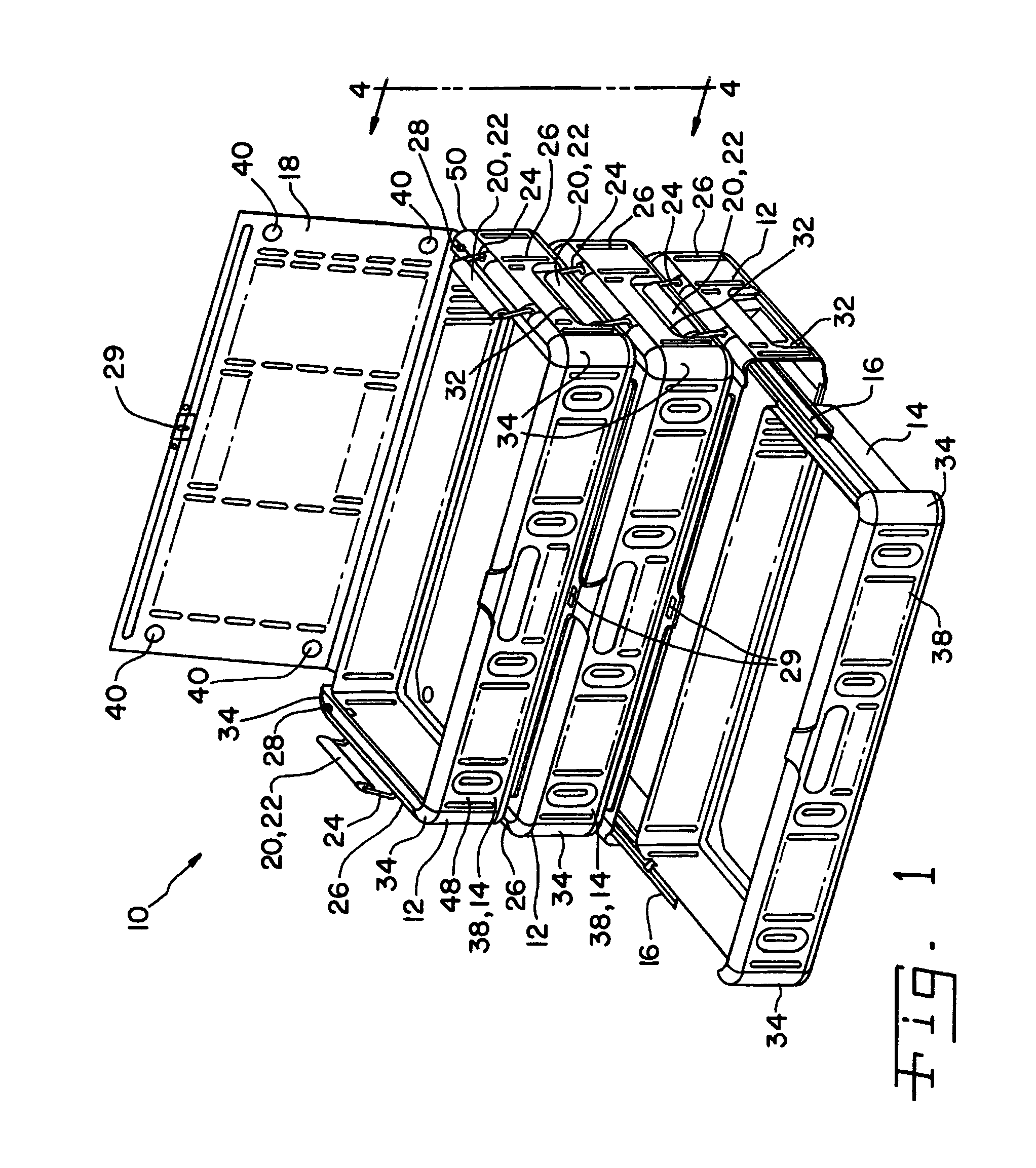

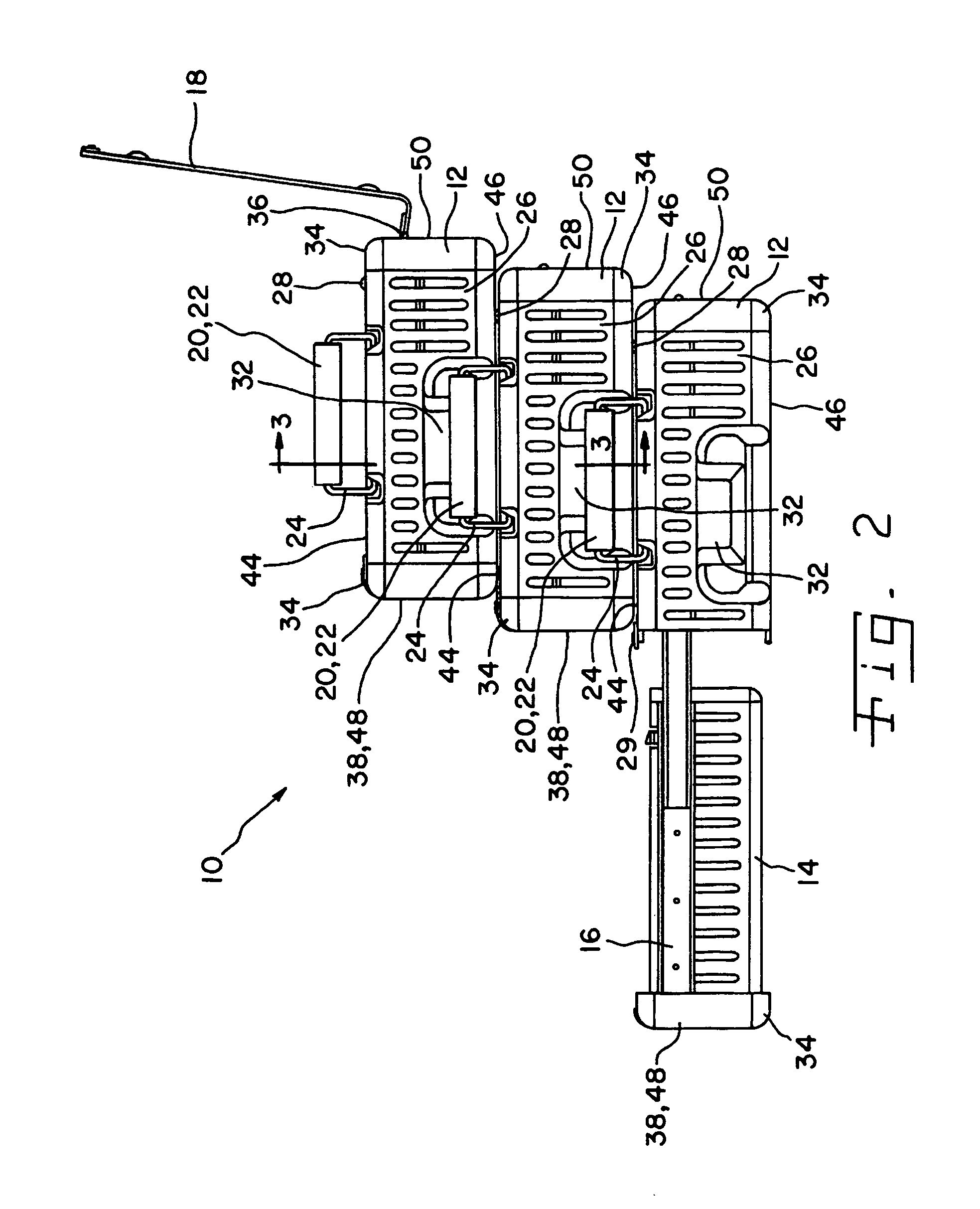

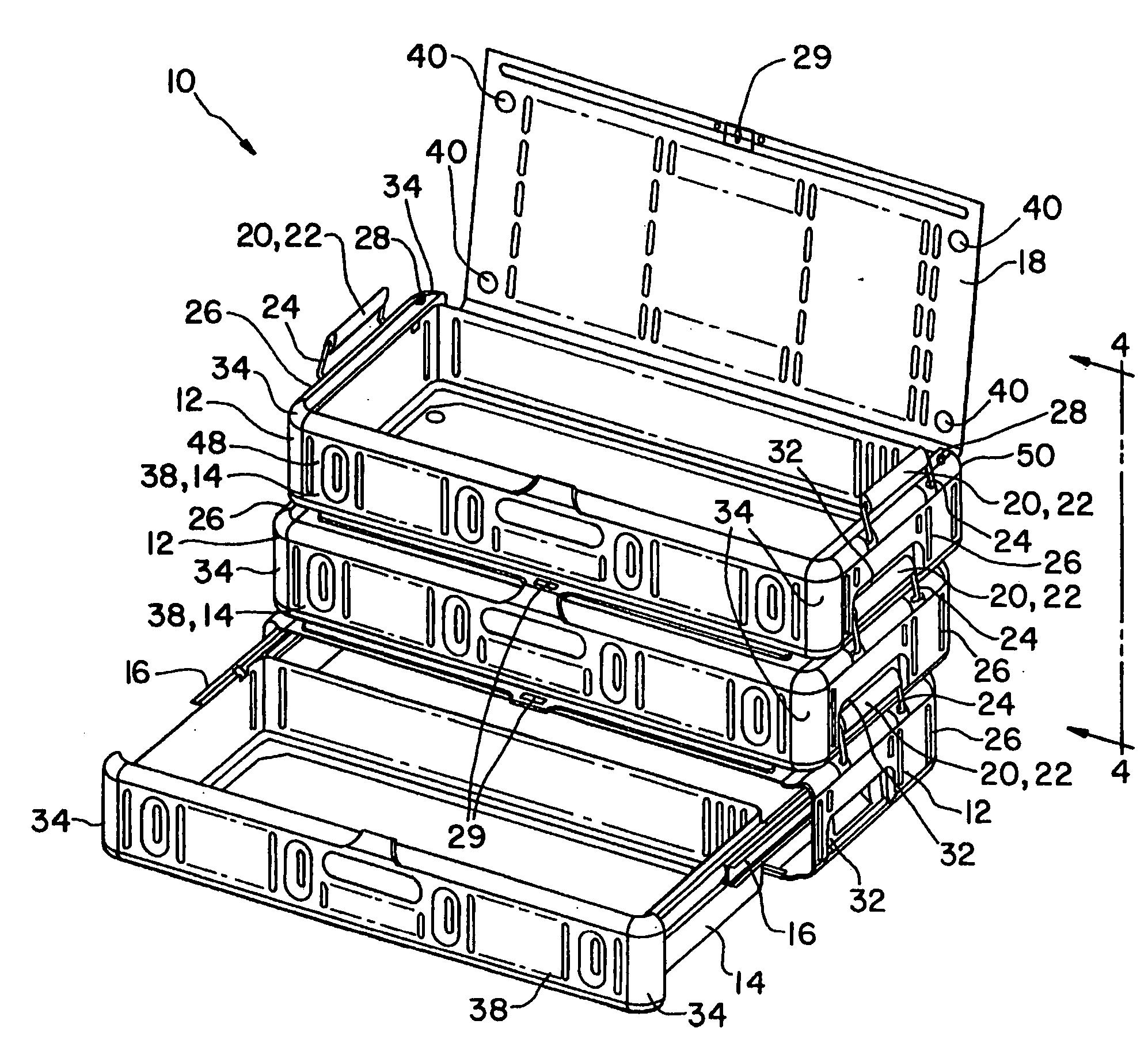

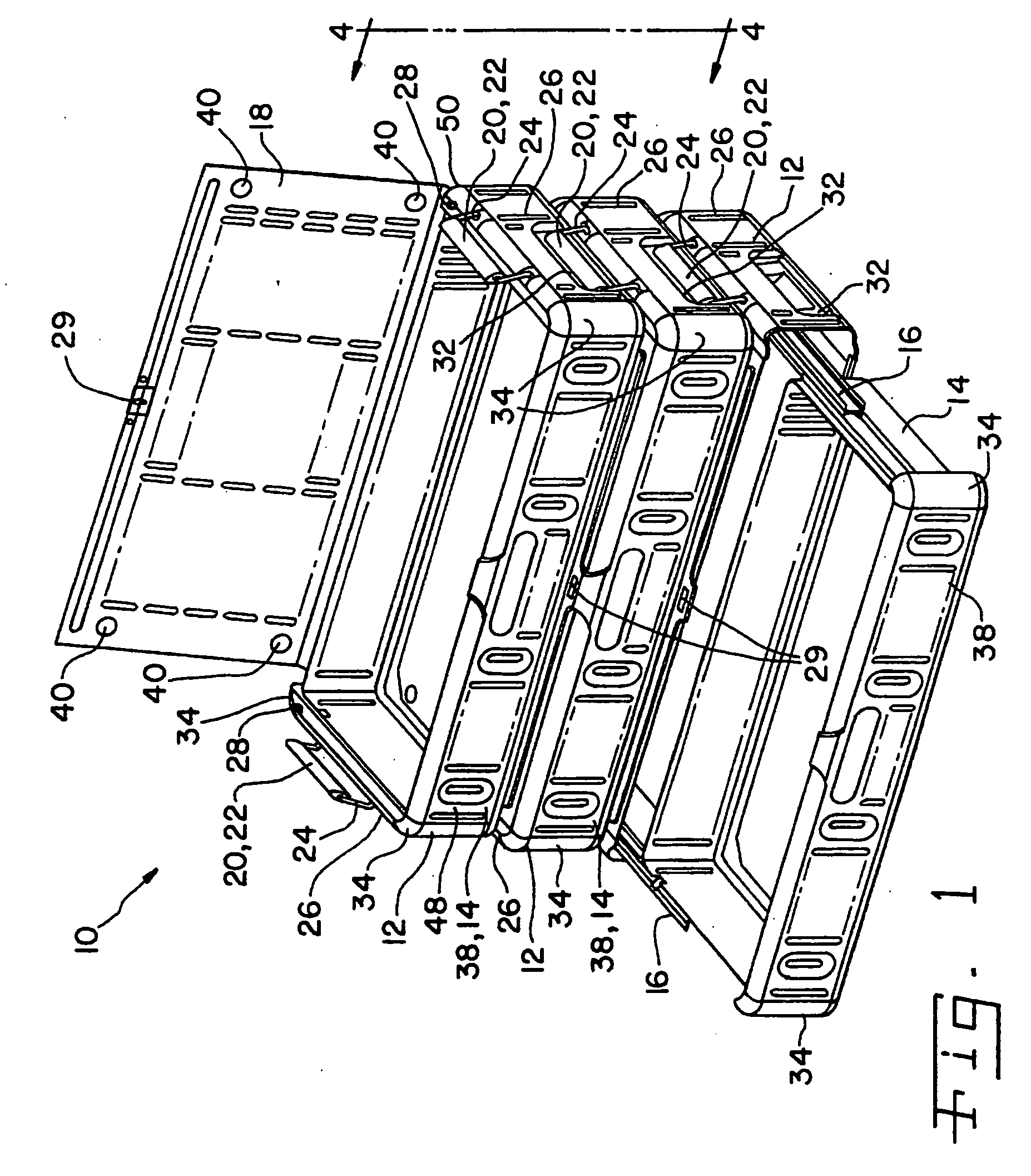

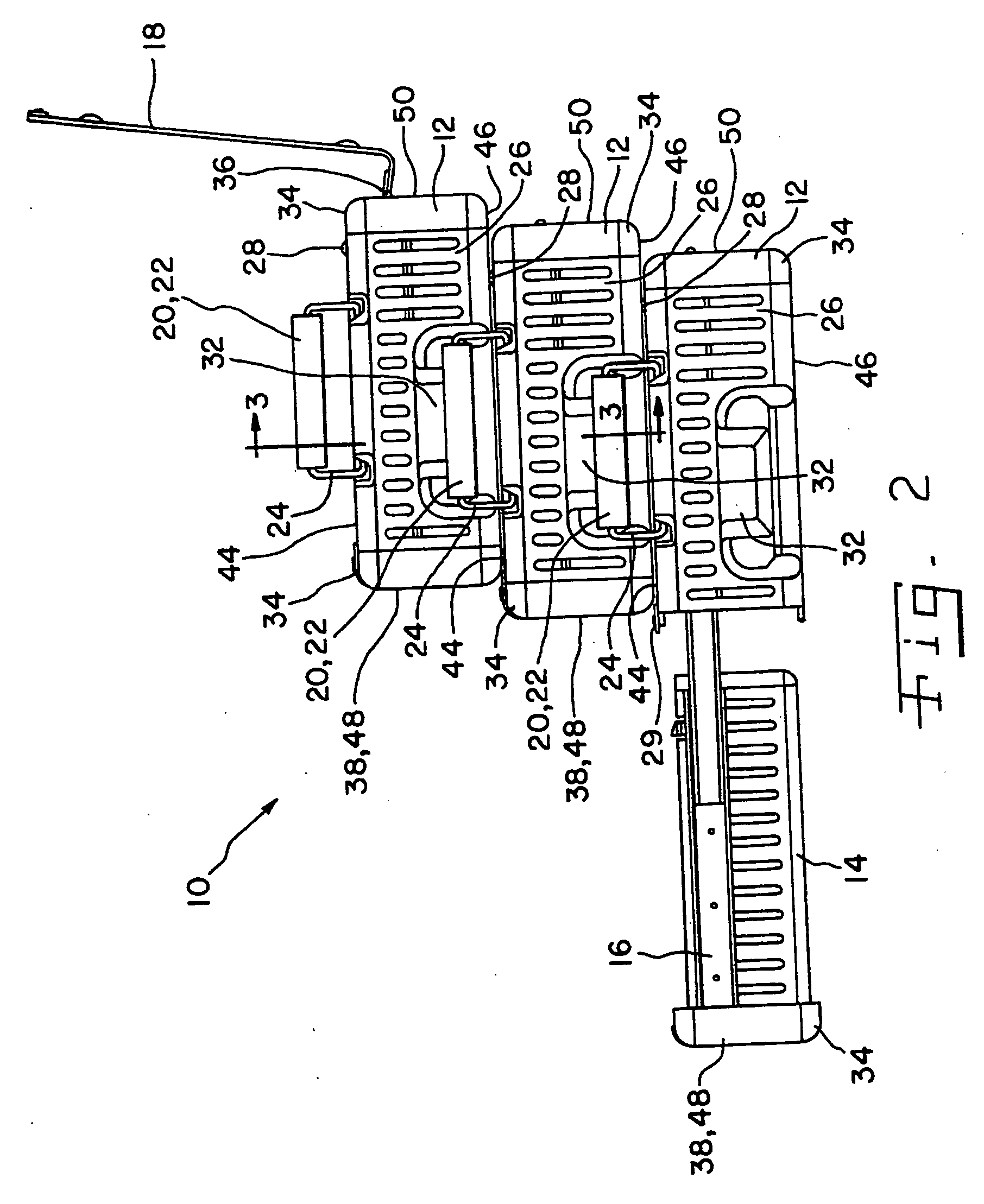

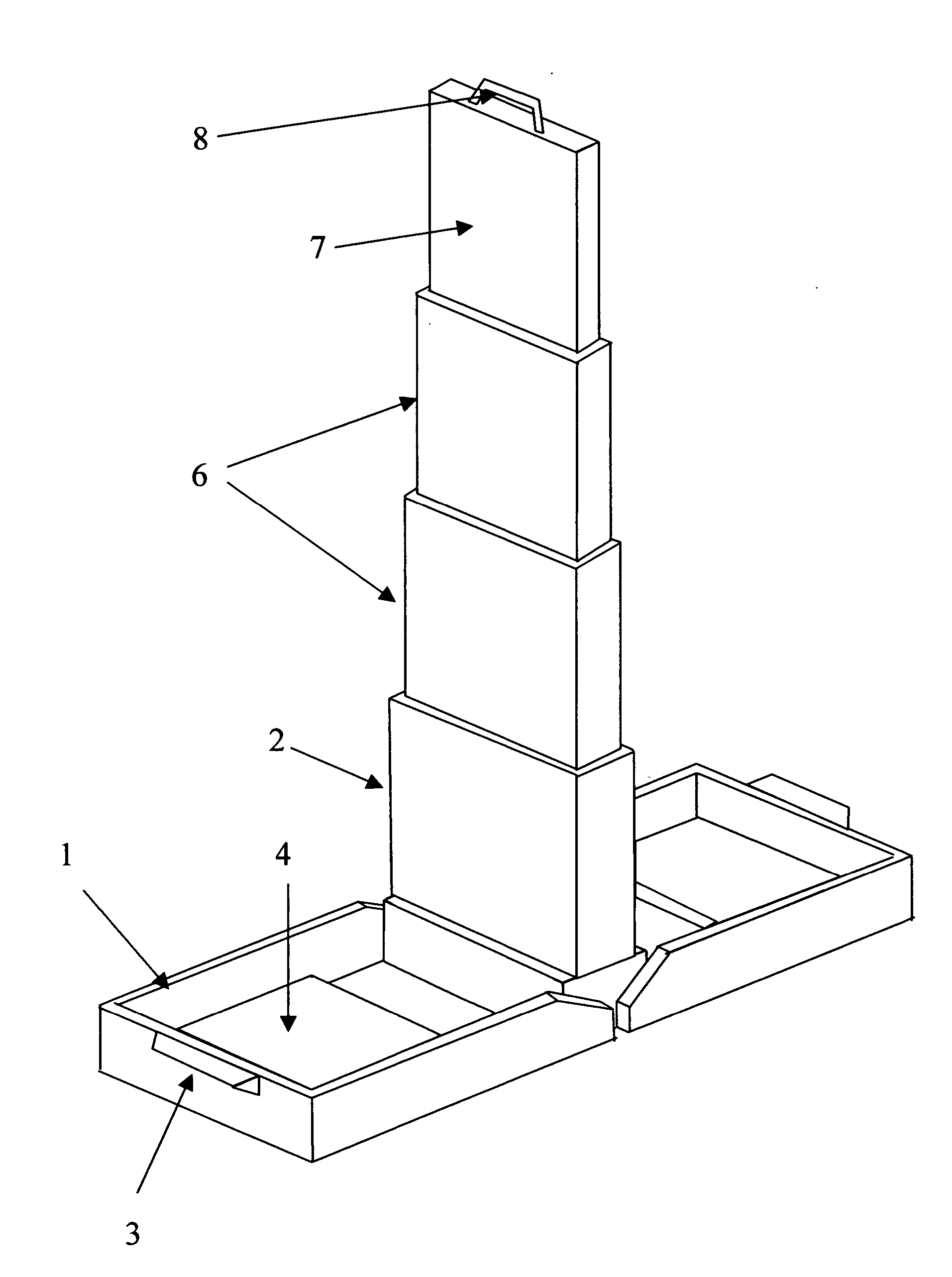

Orthopaedic instrument sterilization case

InactiveUS7523827B2OptimizationMaximize accessSurgical furnitureDispensing apparatusOrthopaedic deviceBiomedical engineering

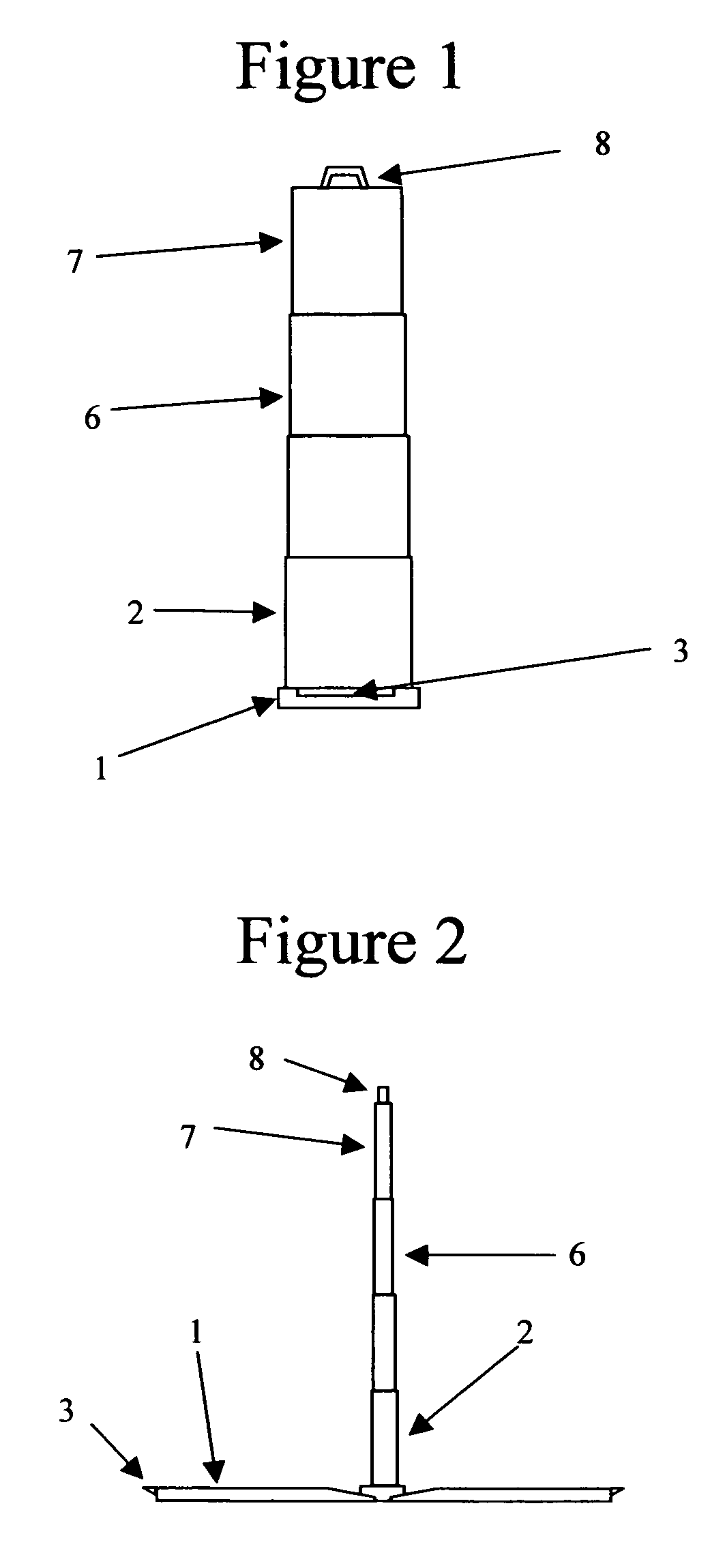

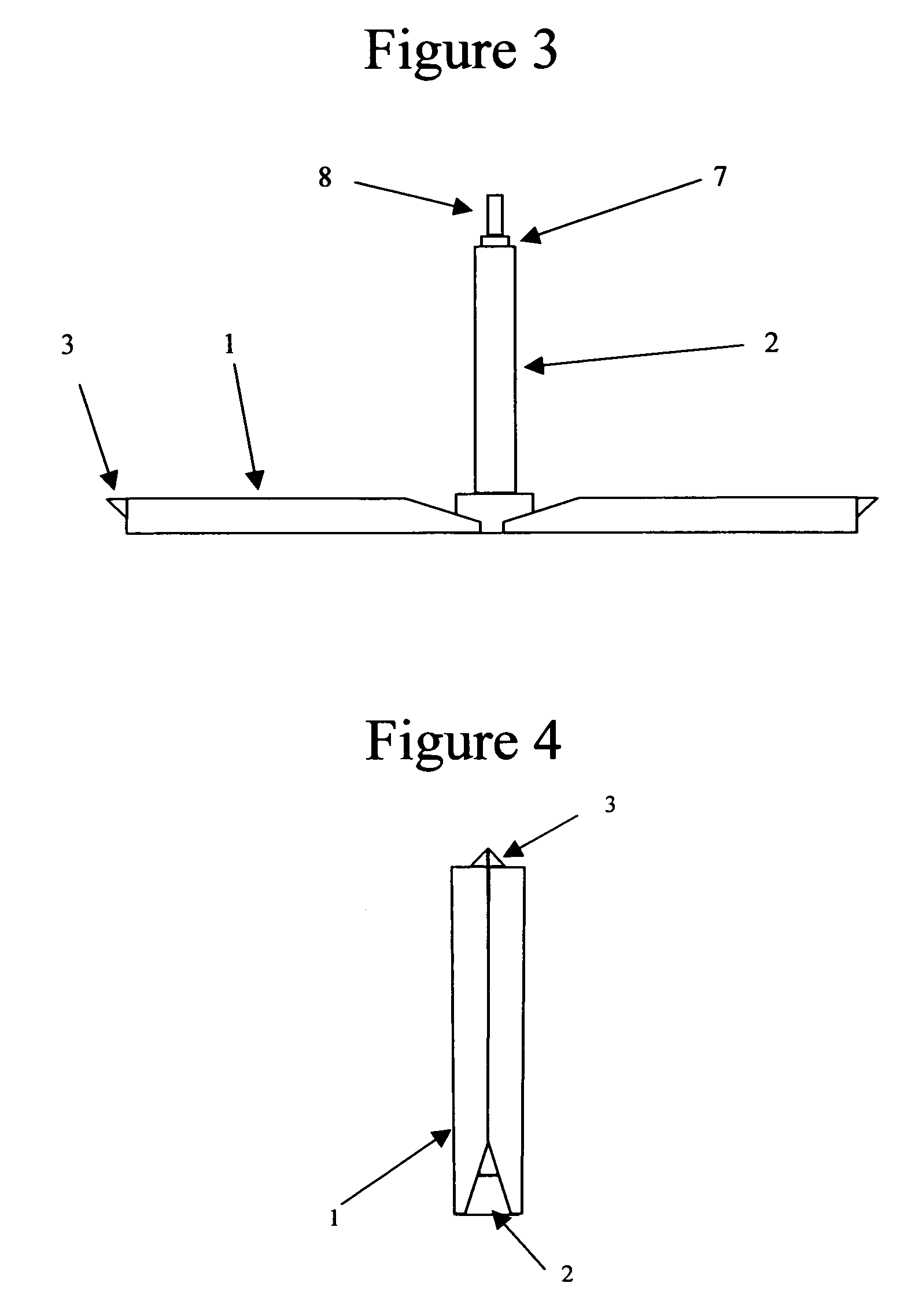

A sterilization case assembly including a plurality of sterilization cases having a first sterilization case and a second sterilization case. The second sterilization case is stacked upon the first sterilization case in a vertical direction. The second sterilization case is offset from the first sterilization case in a direction transverse to the vertical direction.

Owner:SYMMETRY MEDICAL MFG INC

Orthopaedic instrument sterilization case

InactiveUS8100281B2OptimizationMaximize accessSurgical furnitureDiagnosticsOrthopaedic deviceEngineering

A sterilization case assembly including a plurality of sterilization cases having a first sterilization case and a second sterilization case. The second sterilization case is stacked upon the first sterilization case in a vertical direction. The second sterilization case is offset from the first sterilization case in a direction transverse to the vertical direction. In another embodiment, the second sterilization case is configured for both stacking offset from the first sterilization case in a direction transverse to the vertical direction and stacking inline from the first sterilization case in a direction transverse to the vertical direction.

Owner:SYMMETRY MEDICAL MFG INC

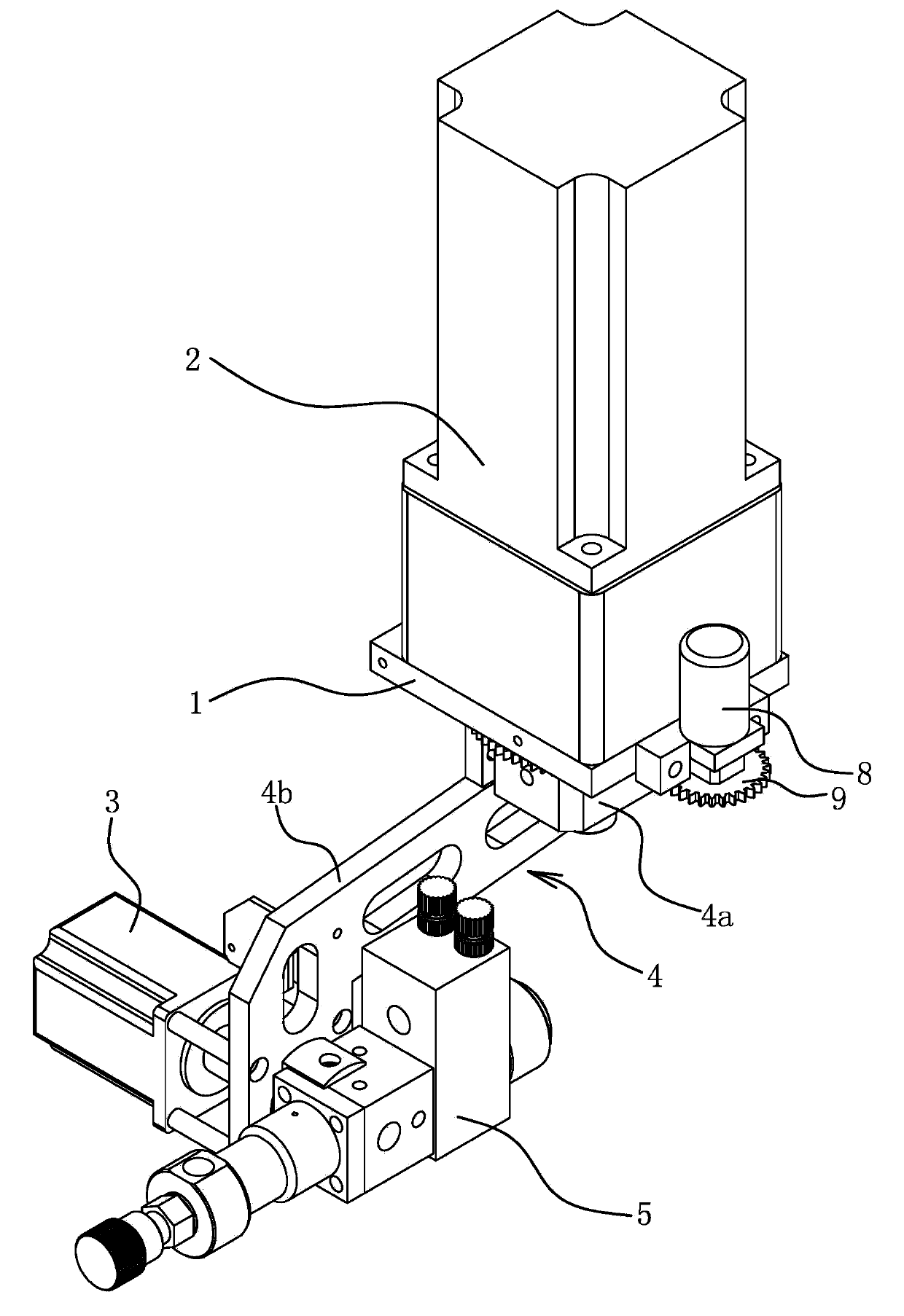

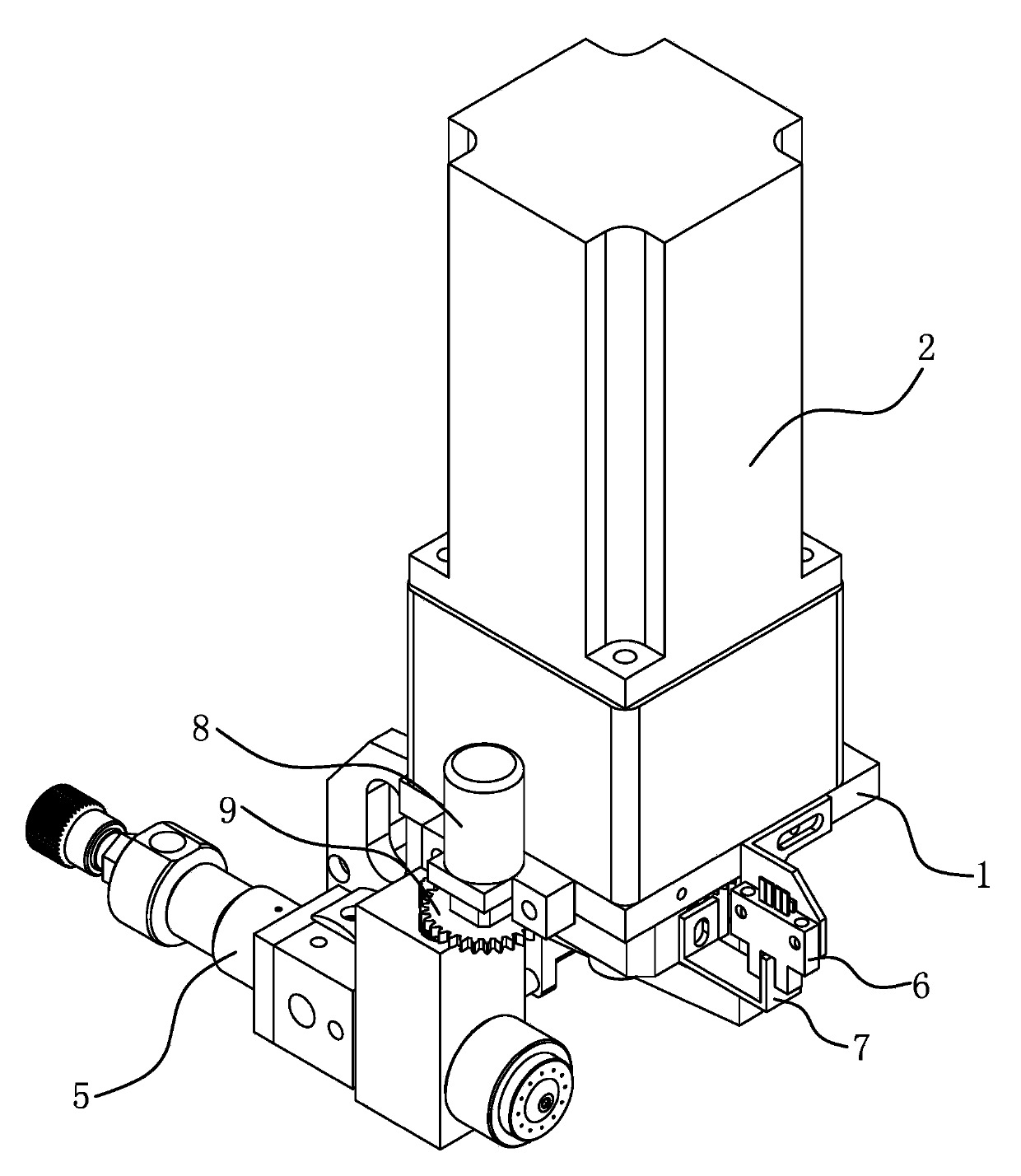

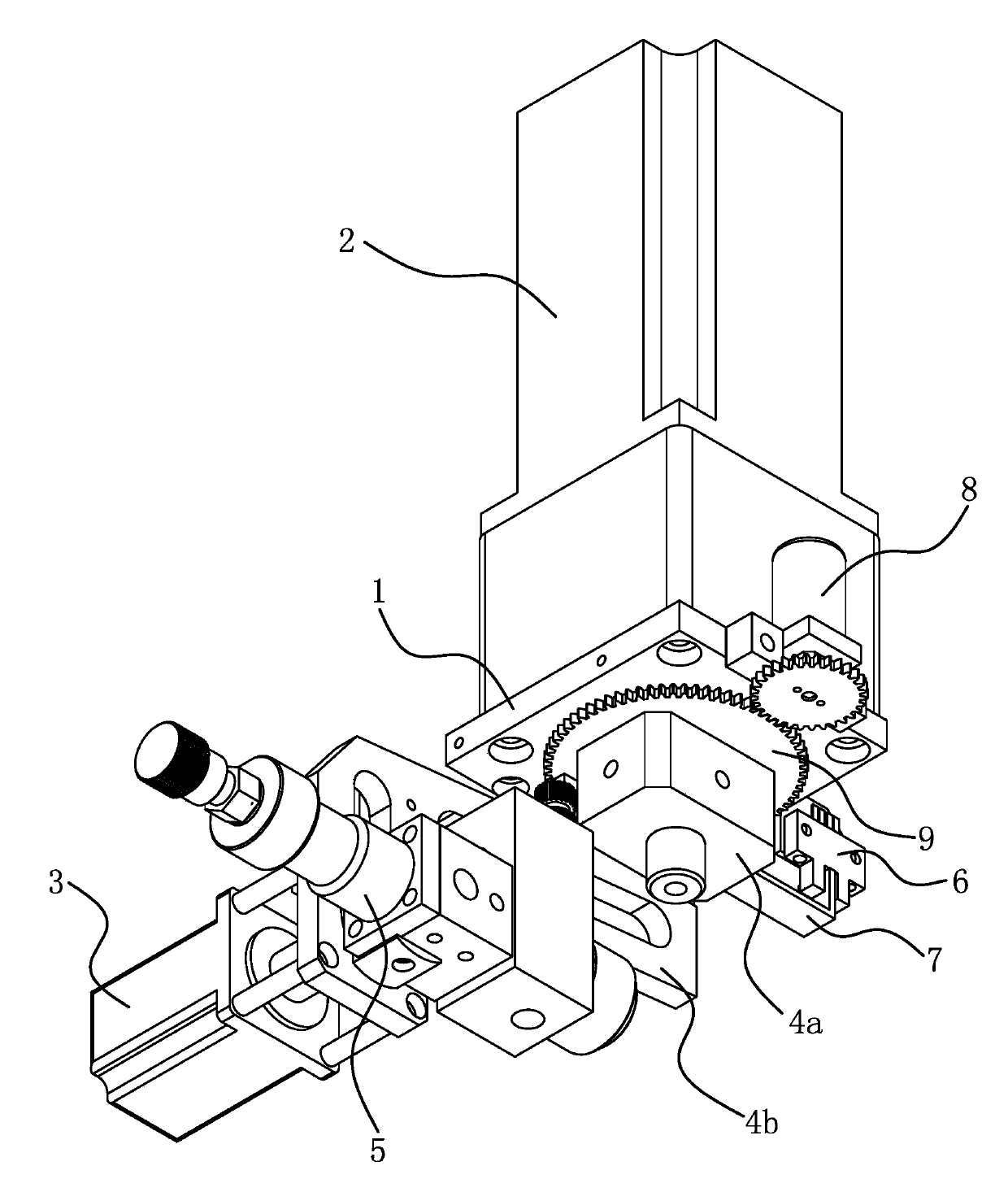

Automatic upper glue spraying component and automatic upper glue spraying machine

The invention provides an automatic upper glue spraying component and an automatic upper glue spraying machine, belongs to the technical field of operation, and solves the problem that spraying nozzles of existing glue spraying machines cannot be kept in the same direction with any positions of shoe outsoles. The automatic upper glue spraying component comprises a first motor, a glue spraying gun, a second motor and a connecting piece. A rotating shaft of the first motor and a shell of the second motor are fixedly connected through the connecting piece. The glue spraying gun is fixedly connected with a rotating shaft of the second motor. The direction of the axis of the rotating shaft of the first motor is different from that of the axis of the rotating shaft of the second motor. According to the automatic upper glue spraying component, the direction of a nozzle of the glue spraying gun and the distance between the glue spraying gun and the rotating shaft of the first motor can be adjusted, and can be automatically adjusted according to program settings during glue spraying, so that the glue spraying gun can be ensured to face to-be-sprayed points in the optimal direction, and intervals between the nozzle of the glue spraying gun and to-be-sprayed surfaces are ensured to be uniform. The automatic upper glue spraying component used for spraying glue to uppers has the advantage of improving product quality.

Owner:曹县雅天工艺品有限公司

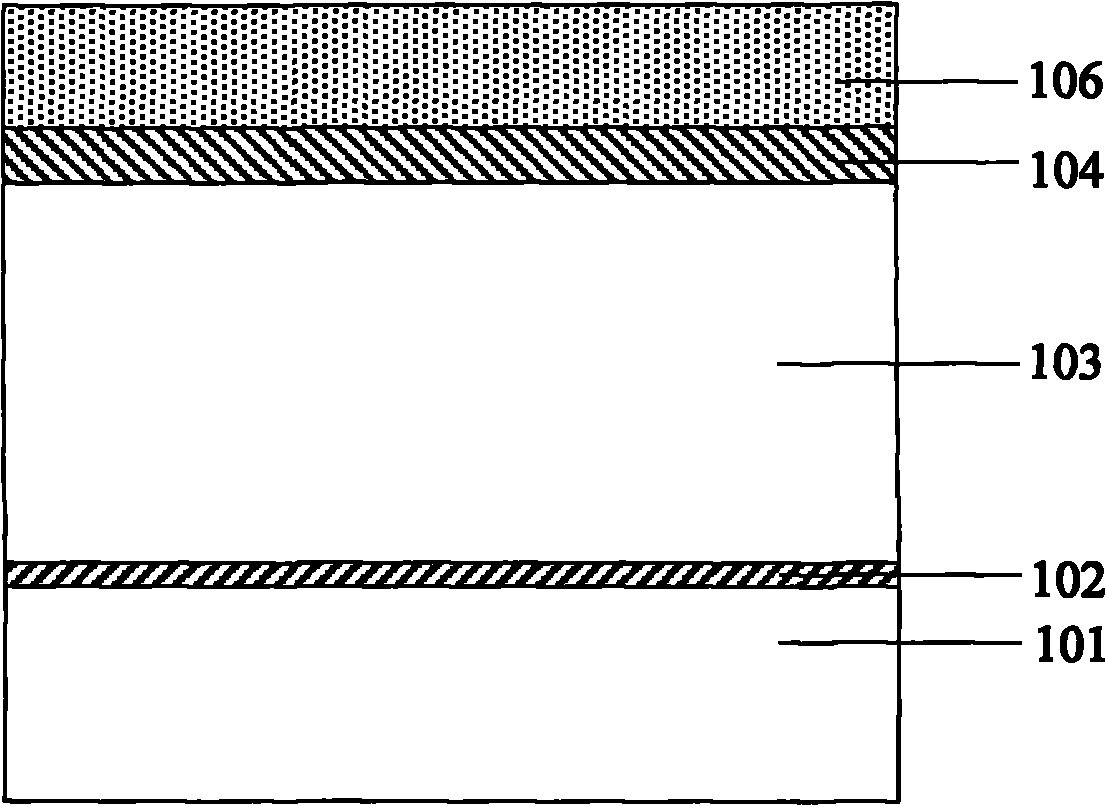

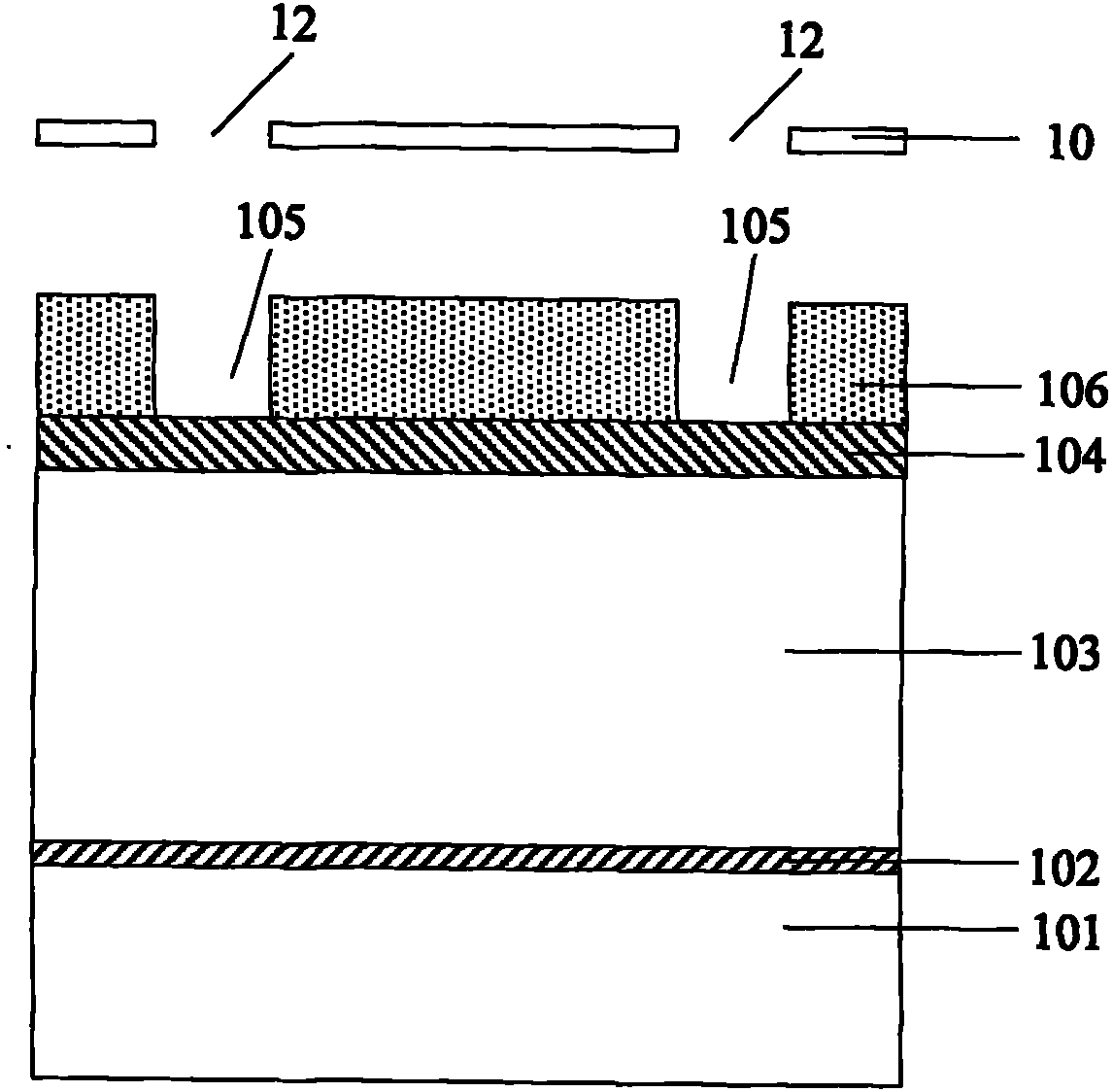

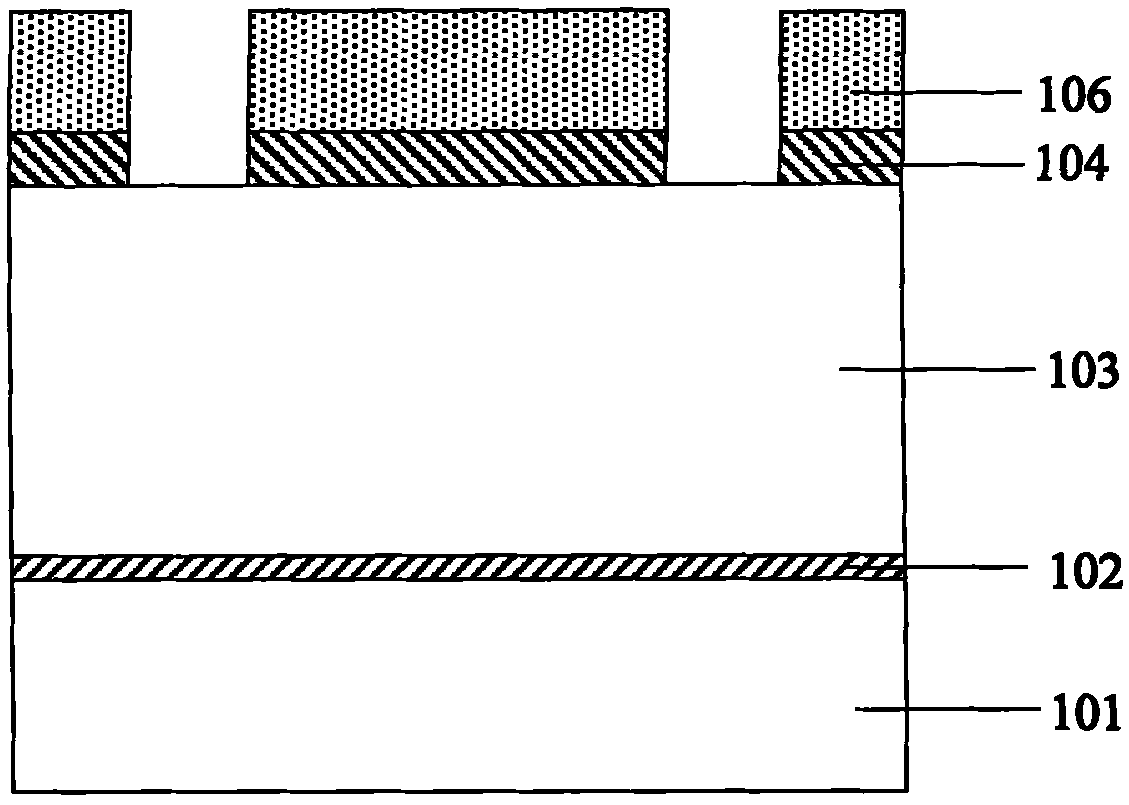

Method for forming contact hole

InactiveCN102054745AChange direction of motionSame spacingSemiconductor/solid-state device manufacturingMedia layerPhotoresist

The invention discloses a method for forming a contact hole, which comprises the following steps of: sequentially forming an insulating medium layer, a hard mask layer and a photoresist layer on a semiconductor substrate; forming the graph of a contact hole opening on the photoresist layer; by taking the photoresist layer as a mask, etching the hard mask layer along the graph of the contact hole opening so as to form the contact hole opening; removing the photoresist layer; by taking the hard mask layer as the mask, etching the insulating medium layer to a certain depth along the contact holeopening by a plasma etching process, wherein the depth is one third to three fourths of the depth of a target contact hole; determining the type of charged ions accumulated on the surface of the hardmask layer, and introducing plasmas of which the type is opposite to that of the charged ions into a reaction chamber until the charged ions are neutralized; and by taking the hard mask layer as the mask, continuing to etch the insulating medium layer until the semiconductor substrate is exposed so as to form the target contact hole. The contact holes with uniform opening width can be formed by the method.

Owner:SEMICON MFG INT (SHANGHAI) CORP

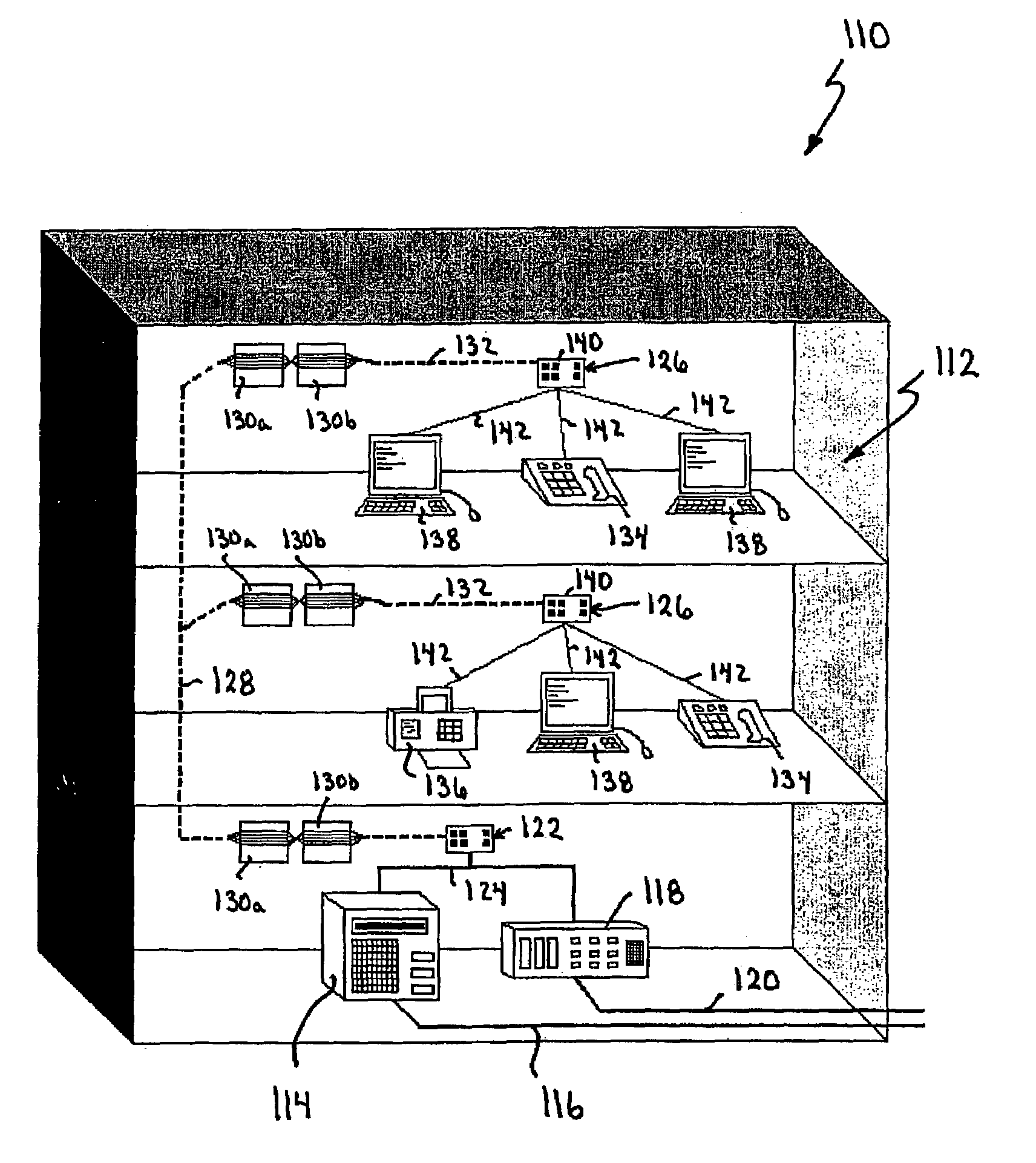

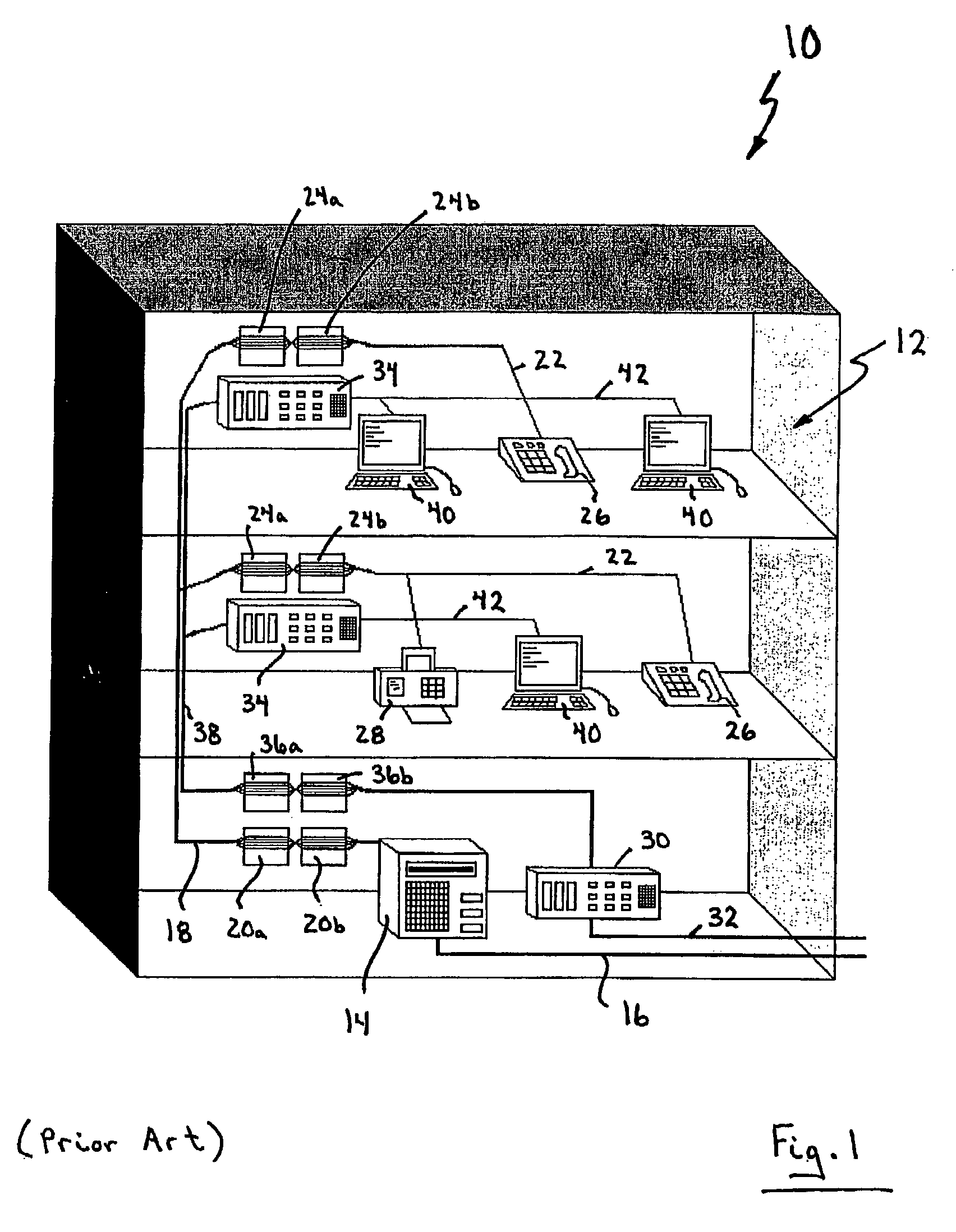

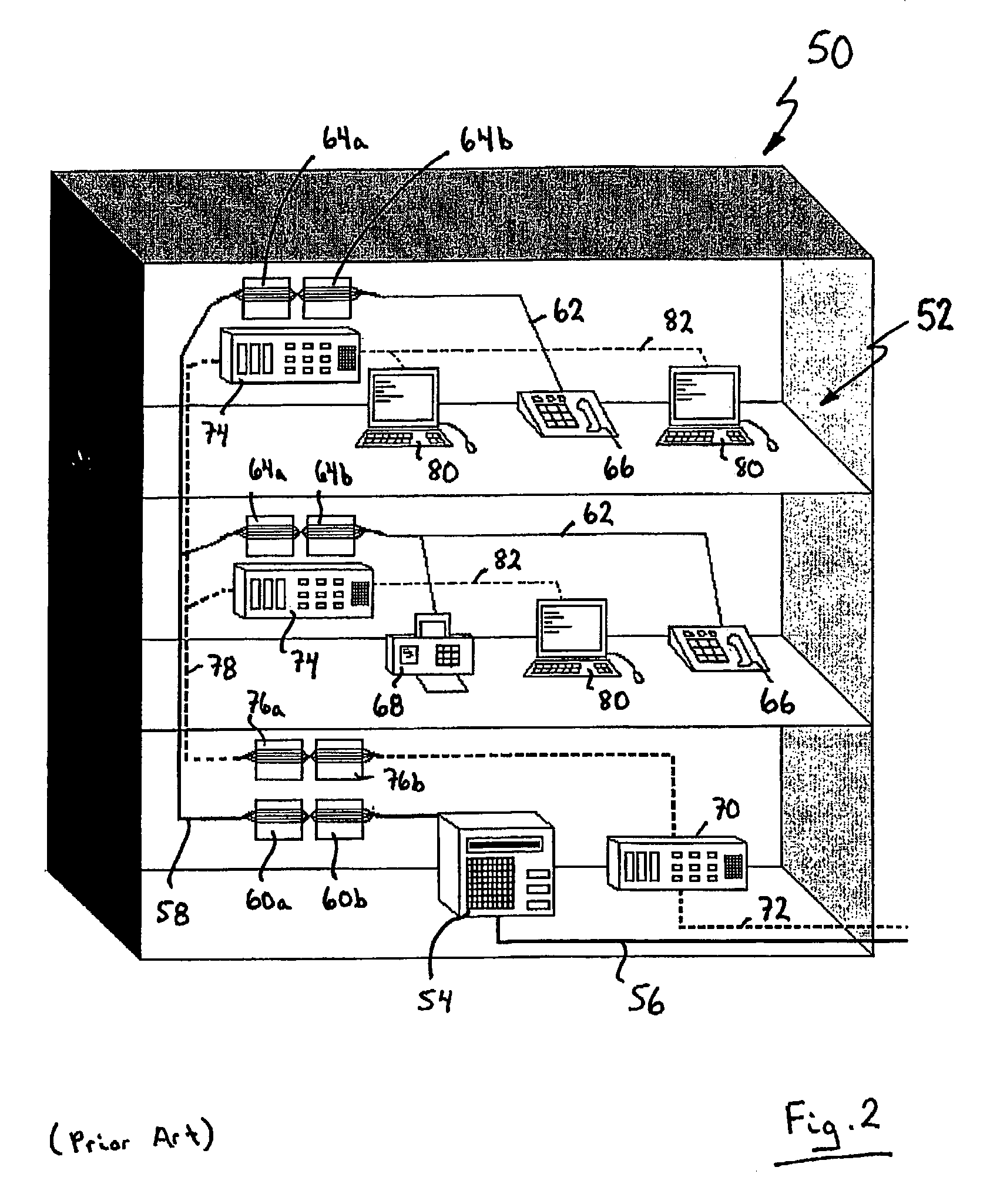

Fiber optic premise wiring system

InactiveUS7206392B2Same spacingFacilitate communicationTelephonic communicationElectromagnetic network arrangementsFiberCommunications system

A premise wiring system comprises a backend communications system including telephony capabilities and at least one communications device configured for electrical signalling. A signal conversion system acts between the backend communications system and the at least one communications system. The signal conversion system converts electrical signalling being exchanged between the at least one communications device and the backend communications system into optical signalling for transmission over a fiber optic link and reconverts the optical signalling into electrical signalling for delivery to the at least one communications device and the backend communications system.

Owner:FINGLER LARRY

Orthopaedic instrument sterilization case

InactiveUS20060191943A1Easily sterilizeMinimize footprint of systemSurgical furnitureDiagnosticsEngineeringBiomedical engineering

A sterilization case assembly including a plurality of sterilization cases having a first sterilization case and a second sterilization case. The second sterilization case is stacked upon the first sterilization case in a vertical direction. The second sterilization case is offset from the first sterilization case in a direction transverse to the vertical direction.

Owner:SYMMETRY MEDICAL MFG INC

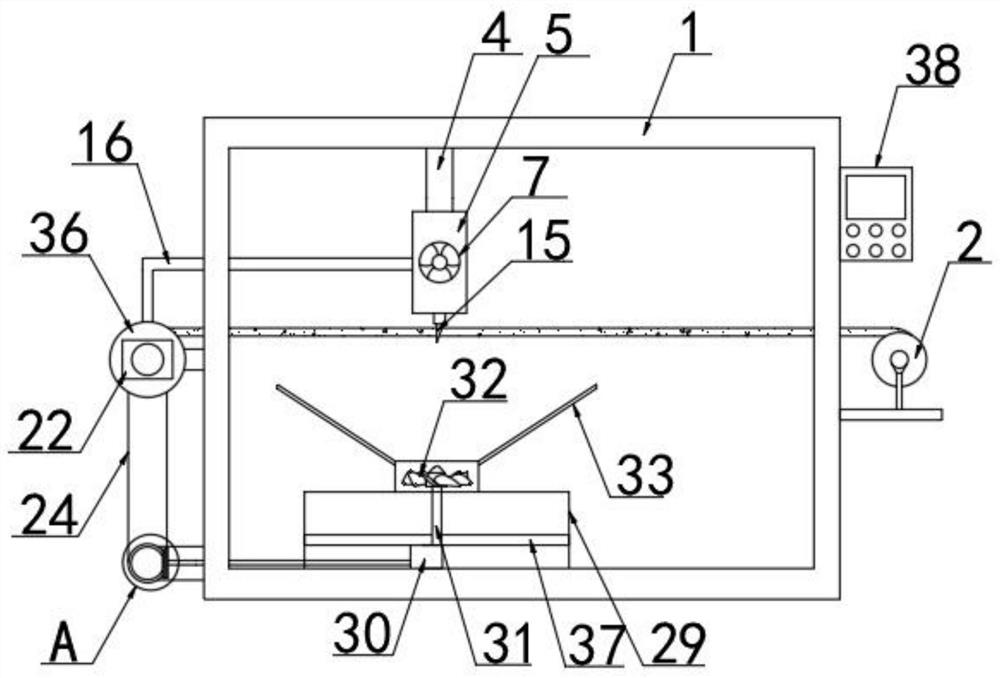

Hot press for new-type wall material production line

InactiveCN104118131AReduce distortionReduce the possibility of deformationPressesProduction lineComing out

The invention discloses a hot press for a new-type wall material production line. The hot press comprises a frame, an upper pressing plate, synchronous arms, a lower pressing plate, oil cylinders and hot pressing plates. The frame comprises an outer frame body and an inner frame body, the inner frame body is hollow, the upper pressing plate is fixed on the upper portion of the inner frame body, the synchronous arms are arranged on the two wings of the frame, the lower ends of the synchronous arms are connected with the lower pressing plate located in the inner frame body, the lower pressing plate is connected with the oil cylinders, and the hot pressing plates are arranged between the upper pressing plate and the lower pressing plate. The whole process of plate feeding, plate pressing and plate discharging is automatic, the overall structural frame is detachable, and all pressing plates can go up at the same time in the pressing plate rising process; double plates can go into and come out of the insides of the hot pressing plates, hot oil circulating grooves are also adopted, and synchronous temperature rising and even temperature distribution of the pressing plates are guaranteed. The hot press is more stable in performance and guarantees that the distances between adjacent plates are adjustable and are equal.

Owner:ZHAOYANG PNEUAMTIC HYDRAULIC MECHANICAL EQUIP JIANGSU

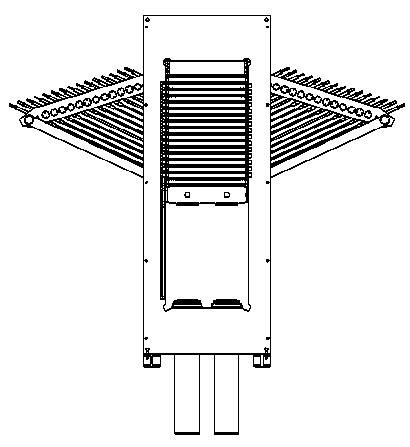

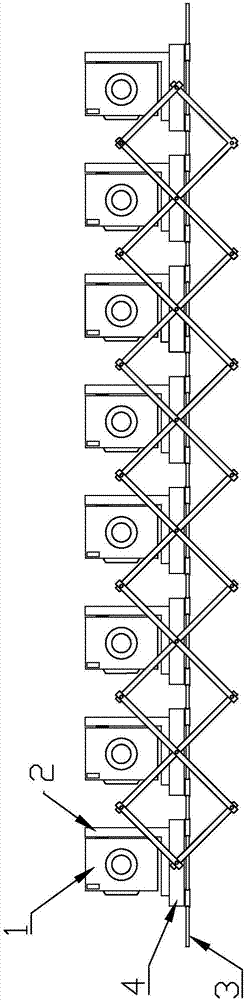

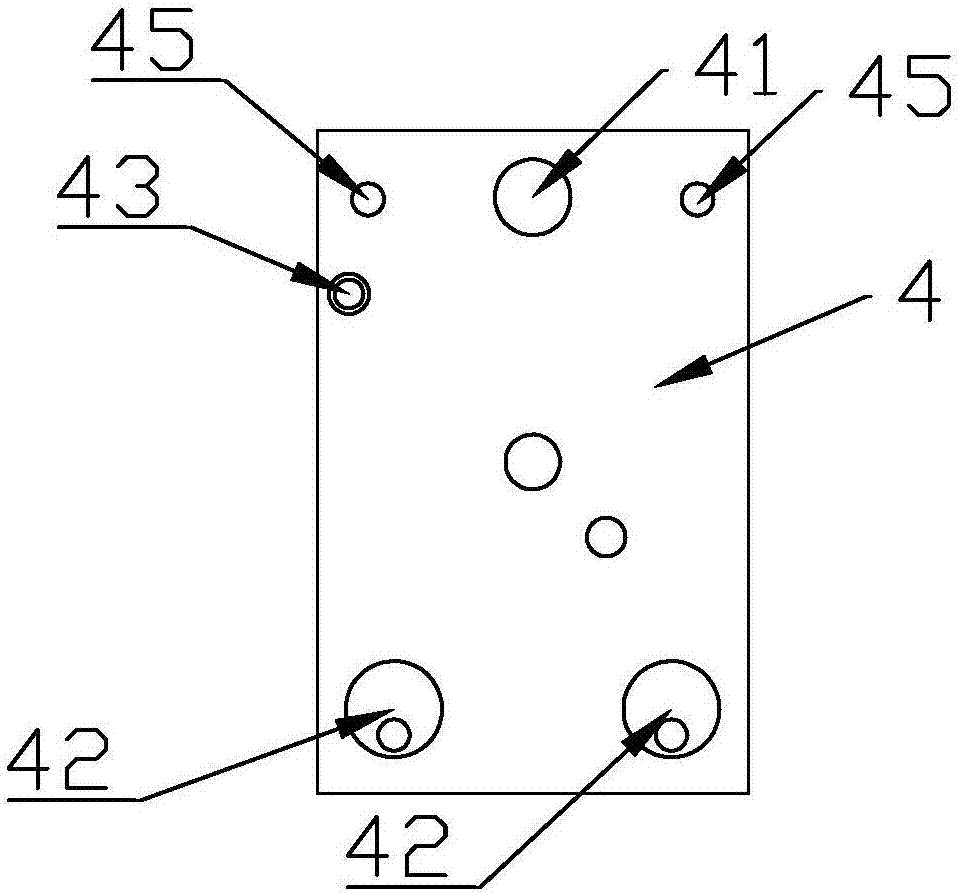

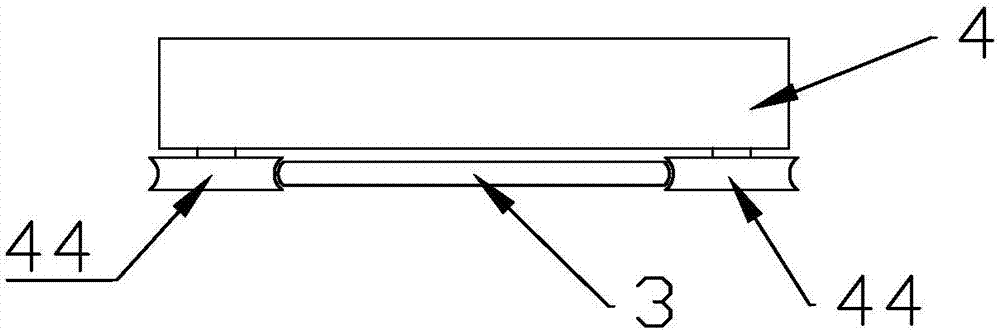

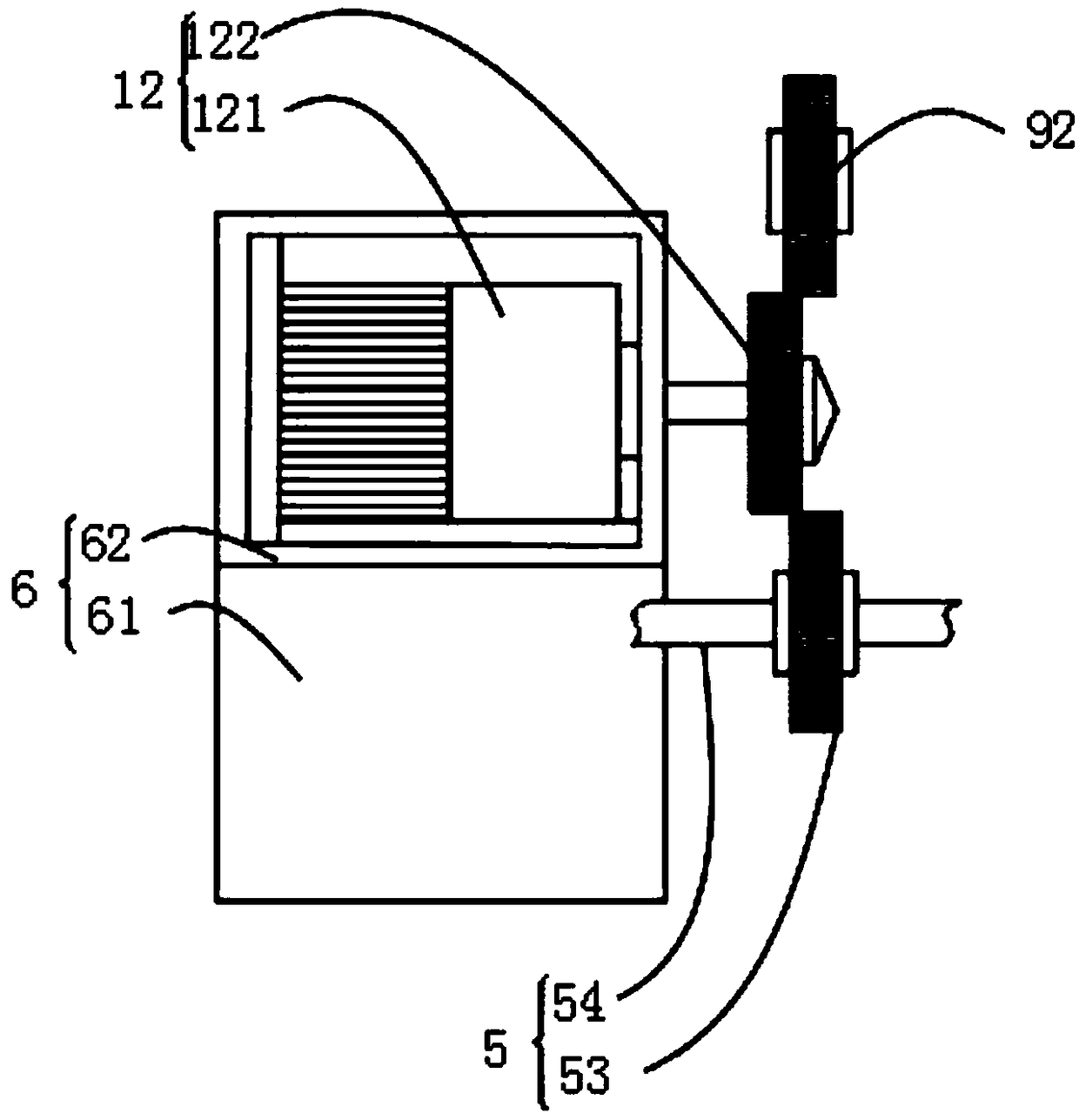

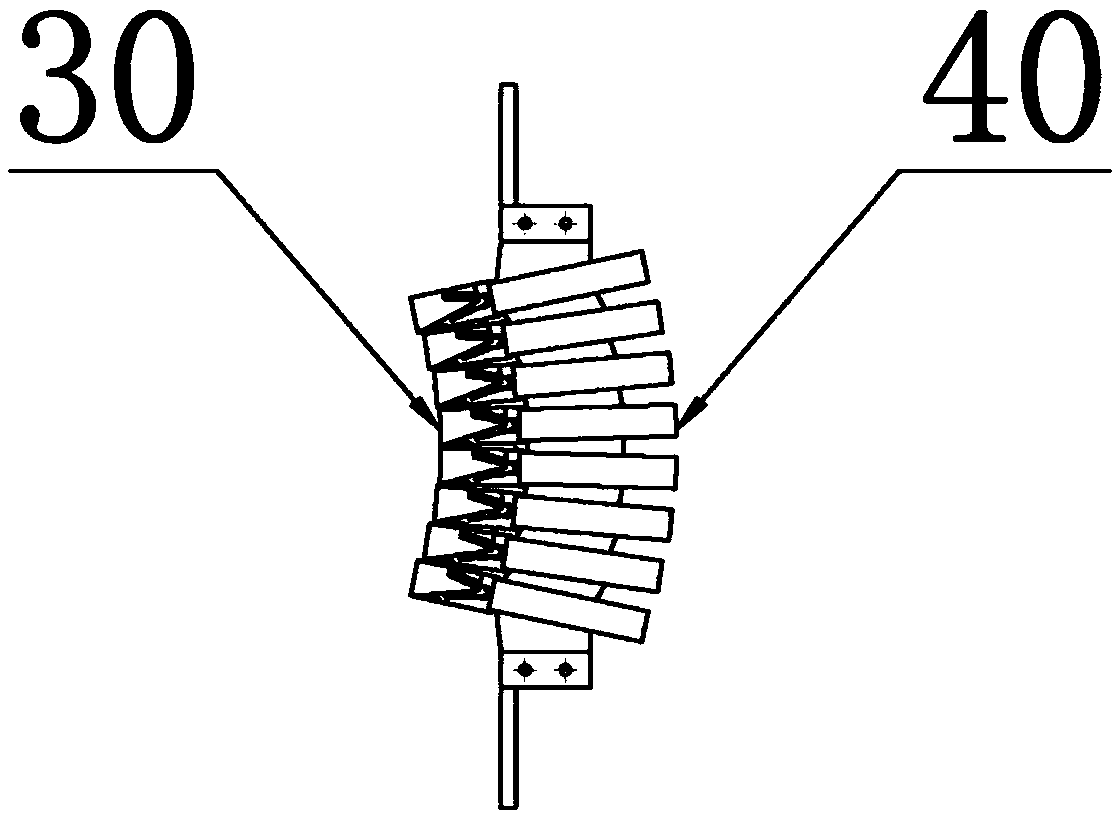

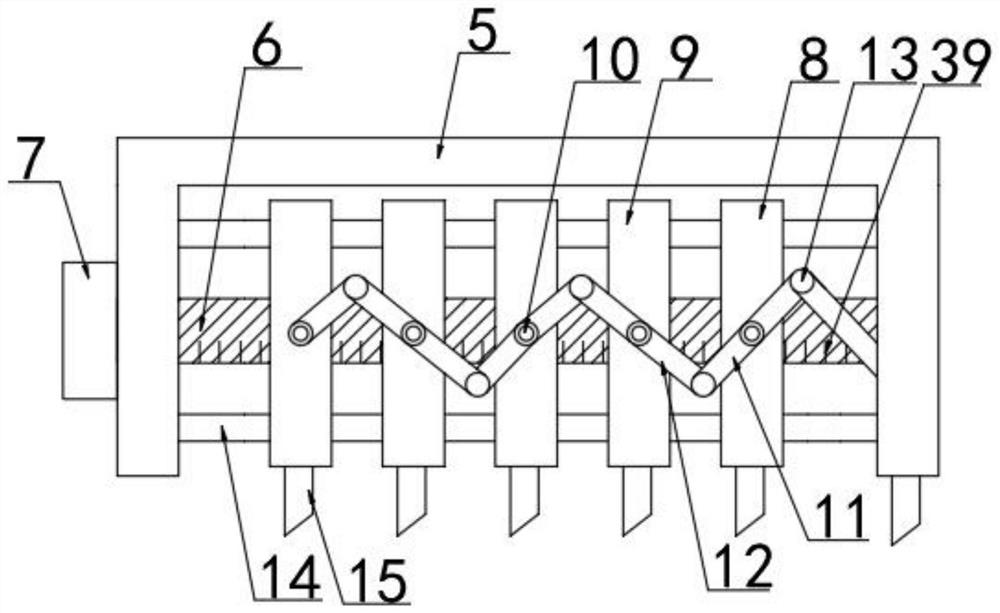

Multi-camera array shooting device with adjustable spacing

ActiveCN107995484ASame spacingSimple structurePhotovoltaic energy generationSteroscopic systemsMulti cameraEngineering

The invention discloses a multi-camera array shooting device with adjustable spacing. The multi-camera array shooting device with adjustable spacing comprises multiple cameras; each camera is arrangedon a guide rail through sliding blocks; each sliding block is provided with an X-type hinging component; each X-type hinging component comprises two hinged rods; the intersection of the hinged rods is an X-hinged point; the X-hinged point is arranged at the side surface of each sliding block; the corresponding hinged rods between two adjacent X-type hinging components are hinged; each sliding block is provided with at least a stop screw; and after each stop screw is tightly screwed, the bottom thereof is connected with the guide rail in a supporting manner. As multiple X-type hinging components are designed to compose a linkage structure, the intersection angle of the other X-type hinging components can be adjusted synchronously as long as one X-type hinging component is changed, and thespacing of each sliding block is further adjusted and same spacing of two adjacent sliding blocks is kept; as the stop screw is designed on each sliding block, all the sliding blocks can be fixed as long as two sliding blocks are fixed by the stop screws.

Owner:GUANGDONG IND TECHN COLLEGE

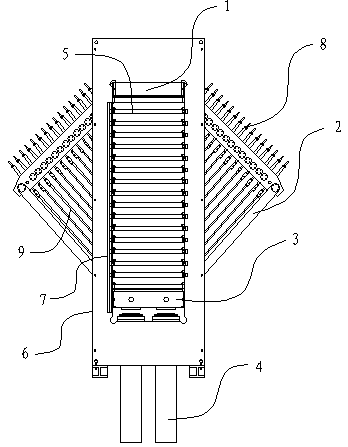

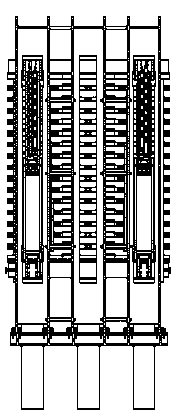

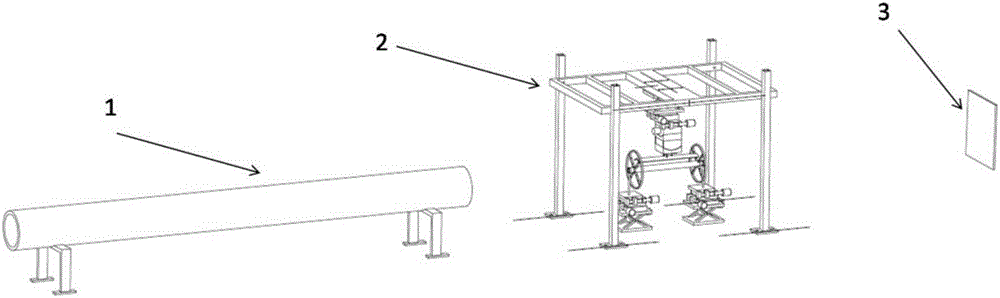

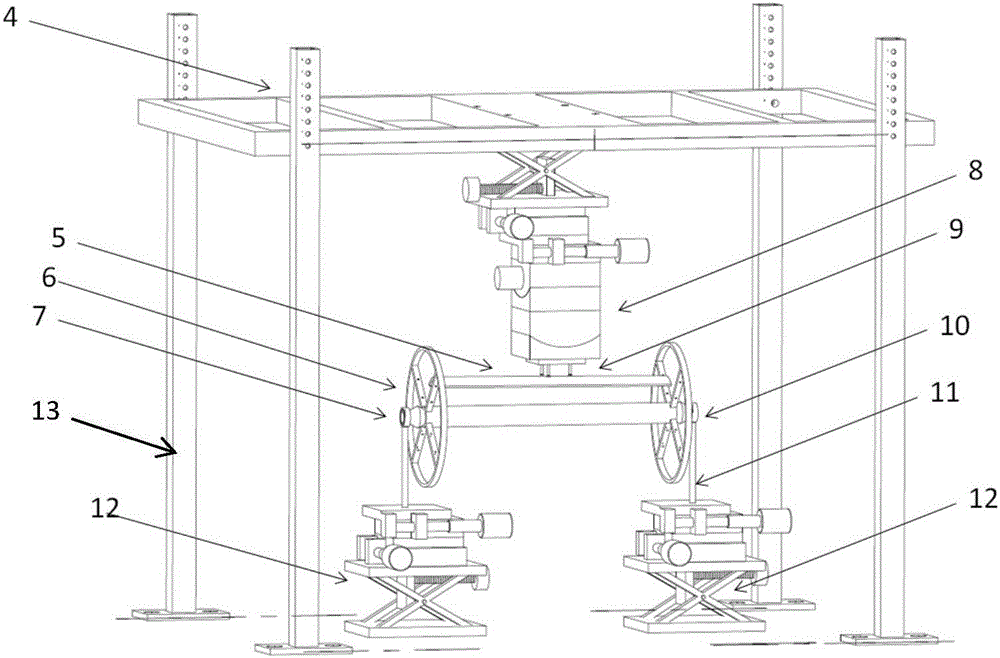

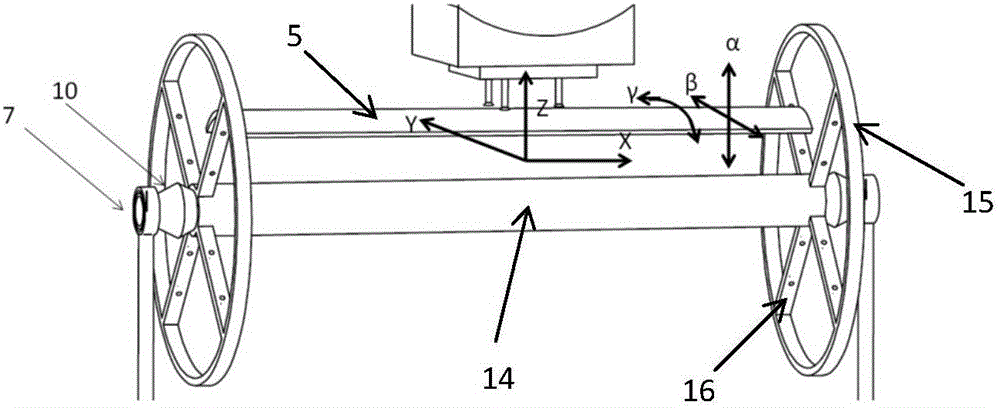

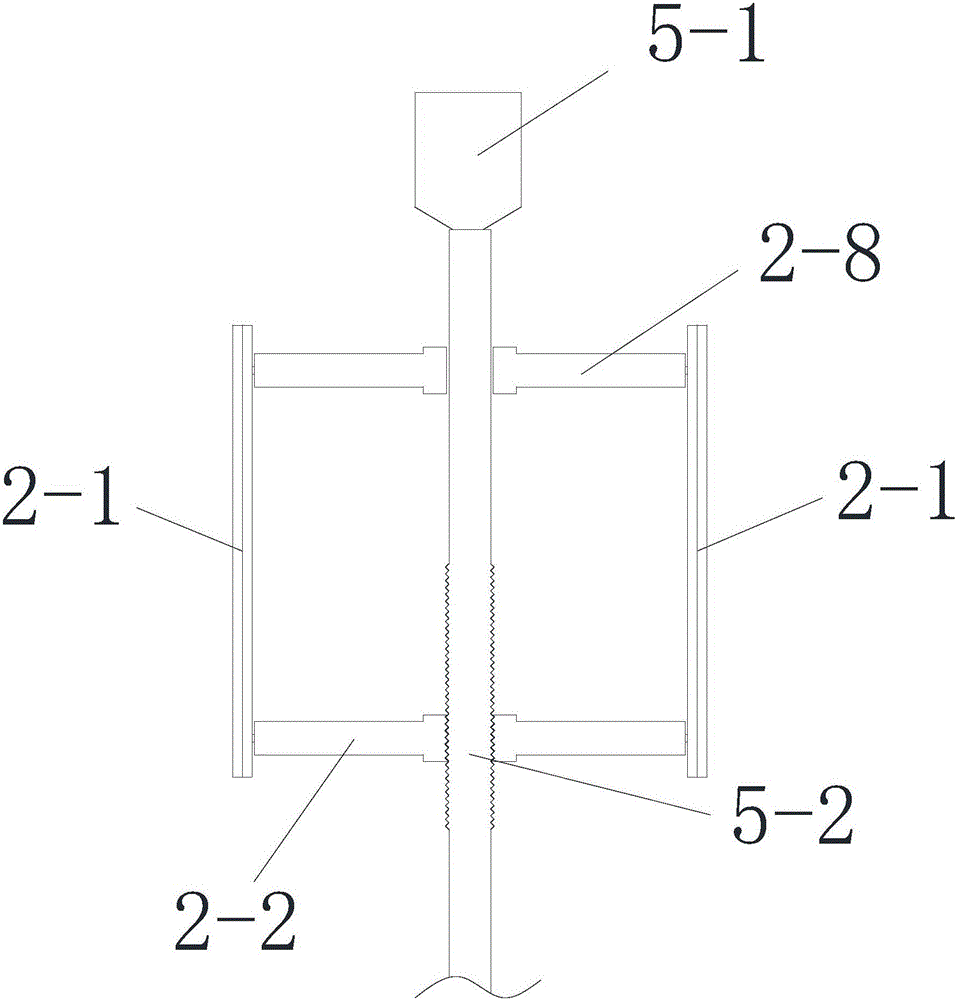

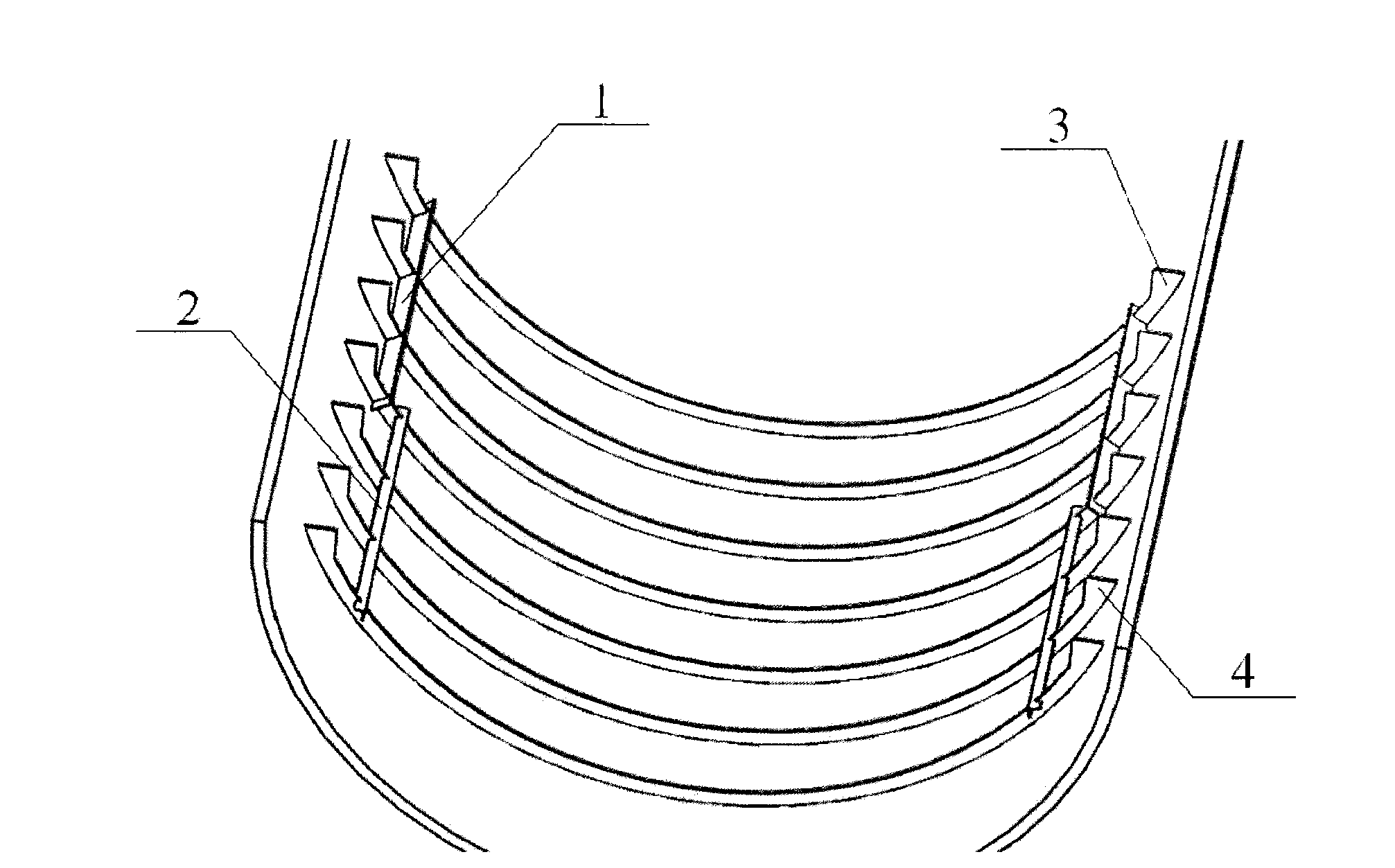

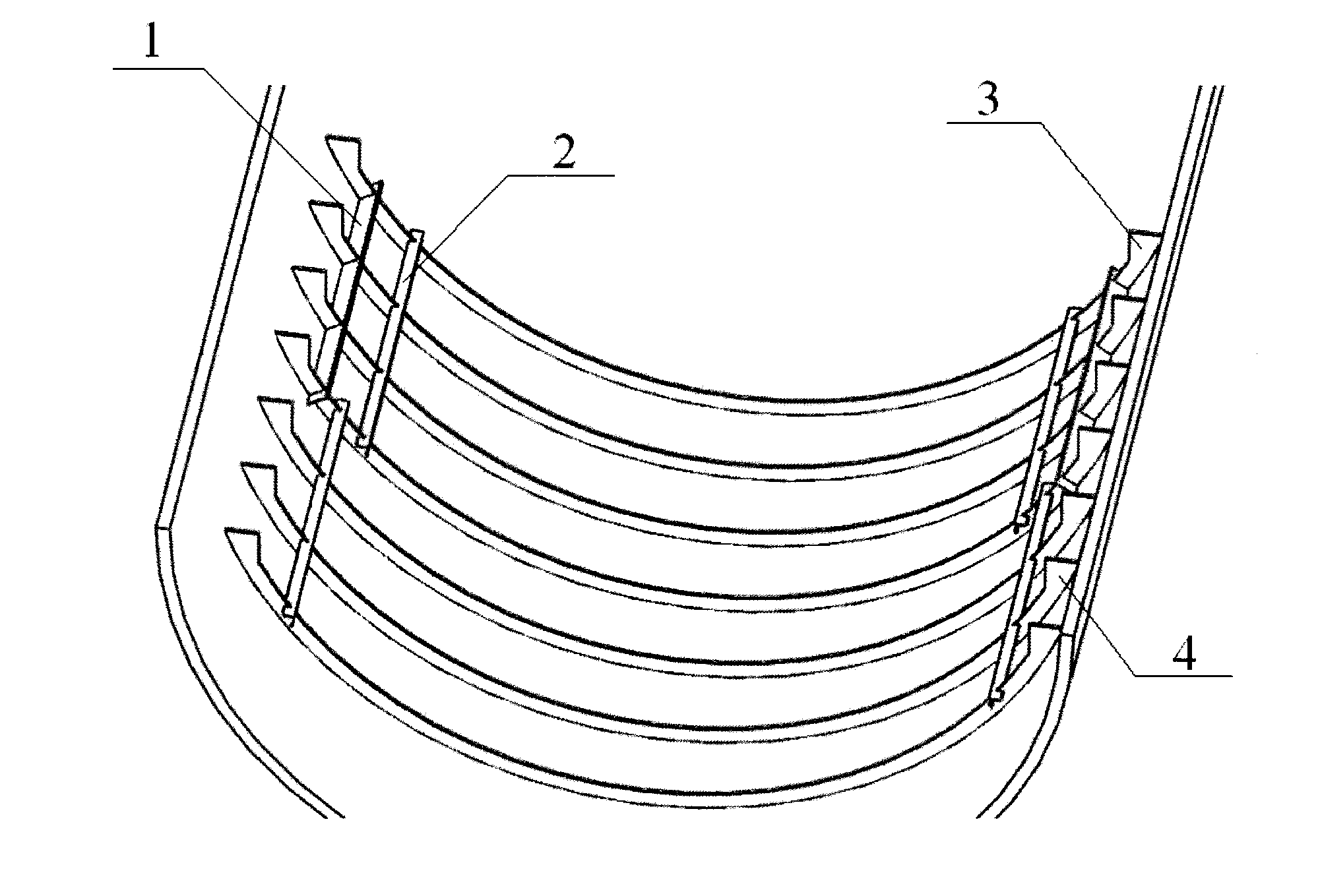

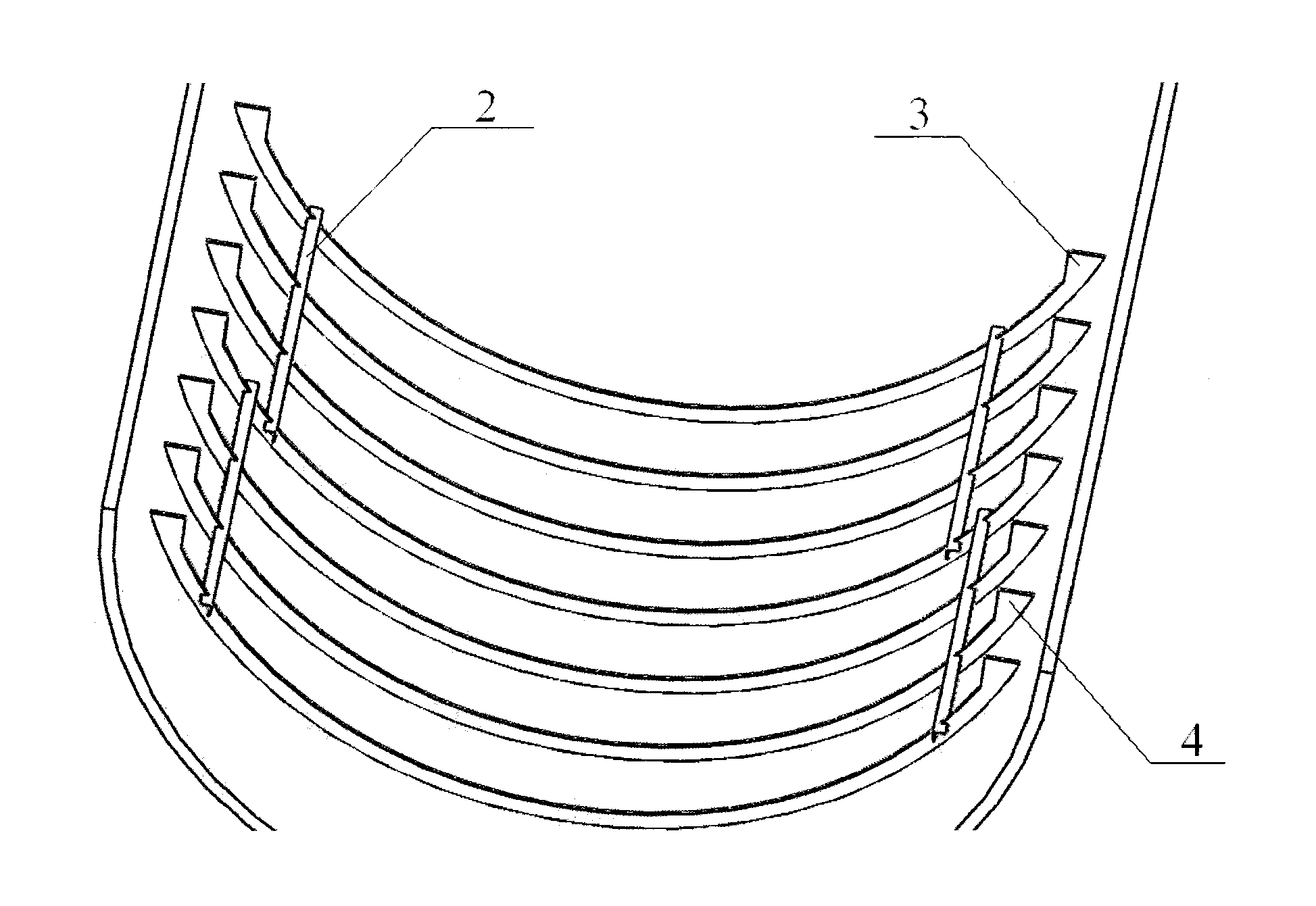

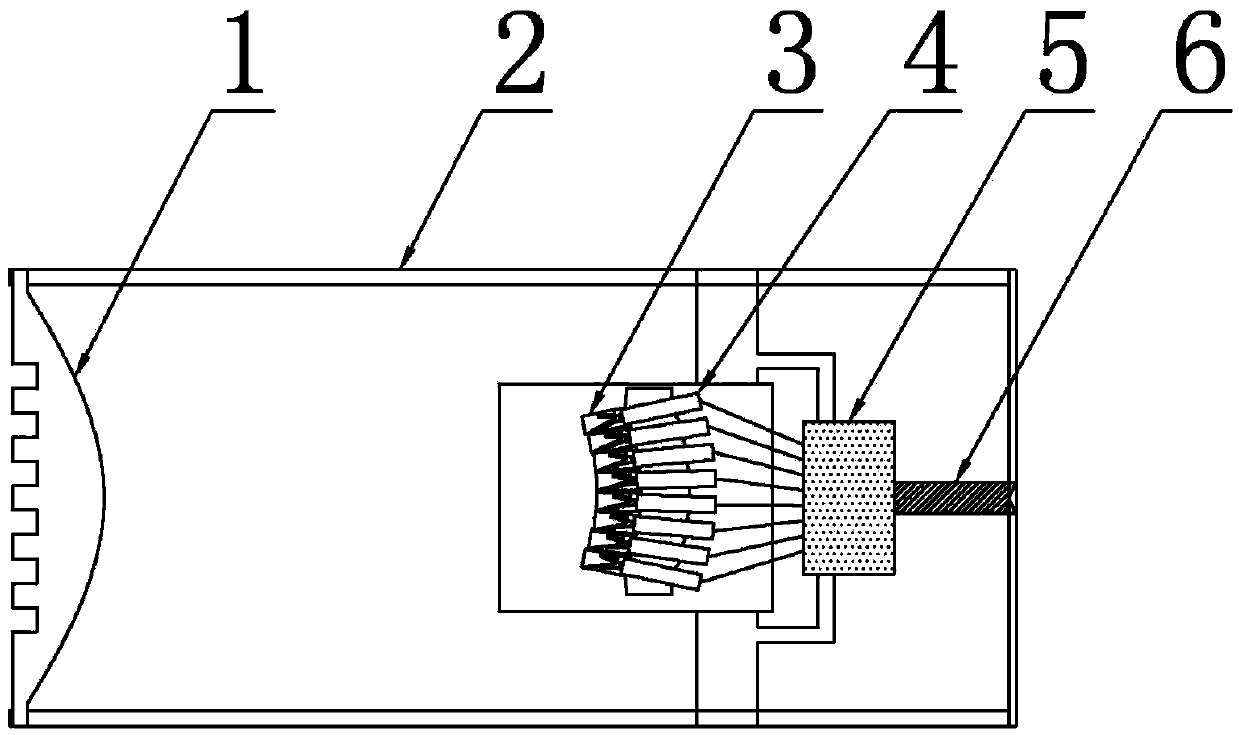

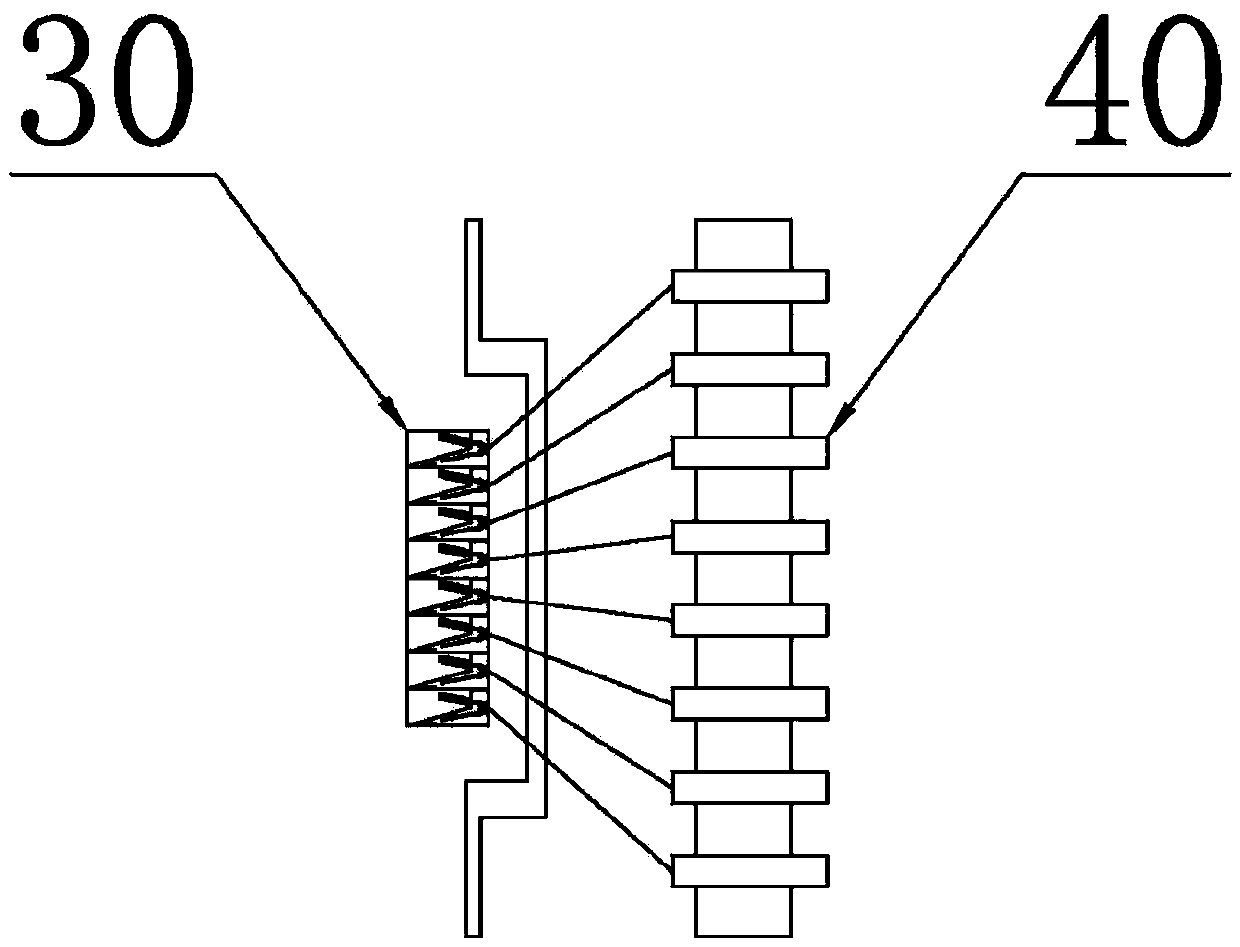

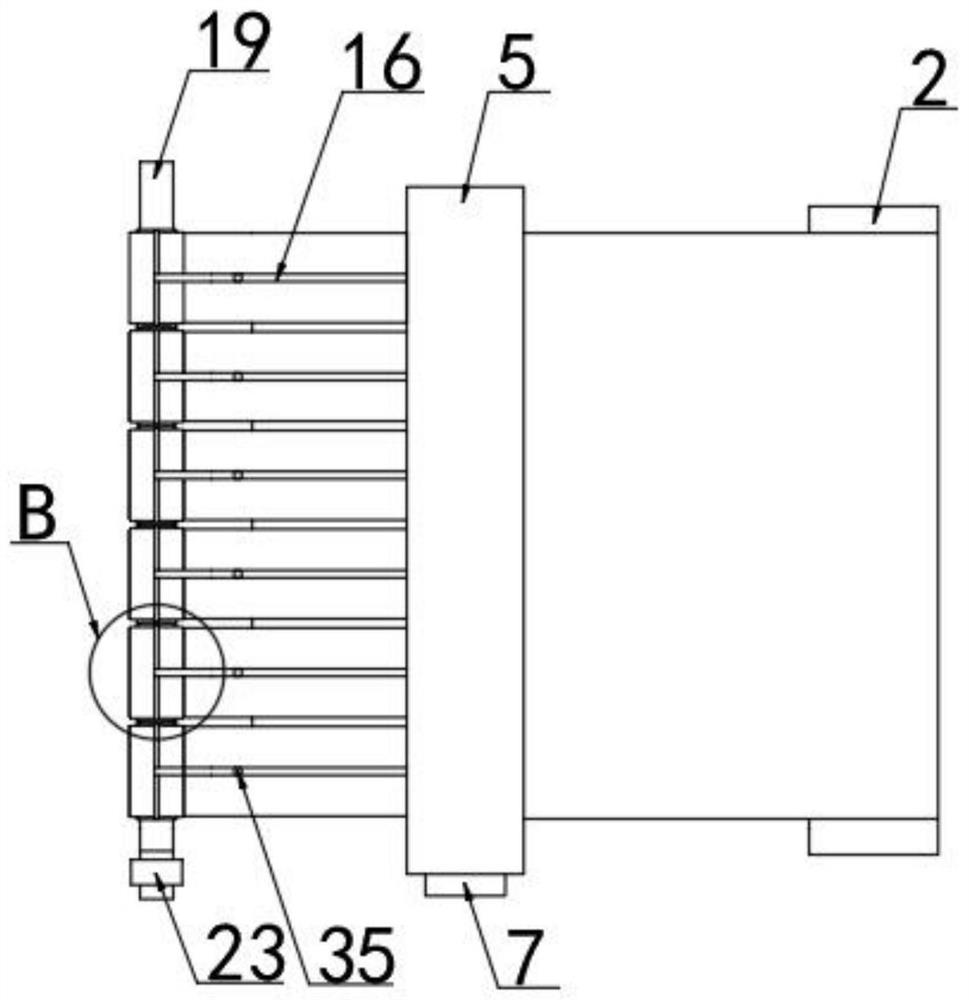

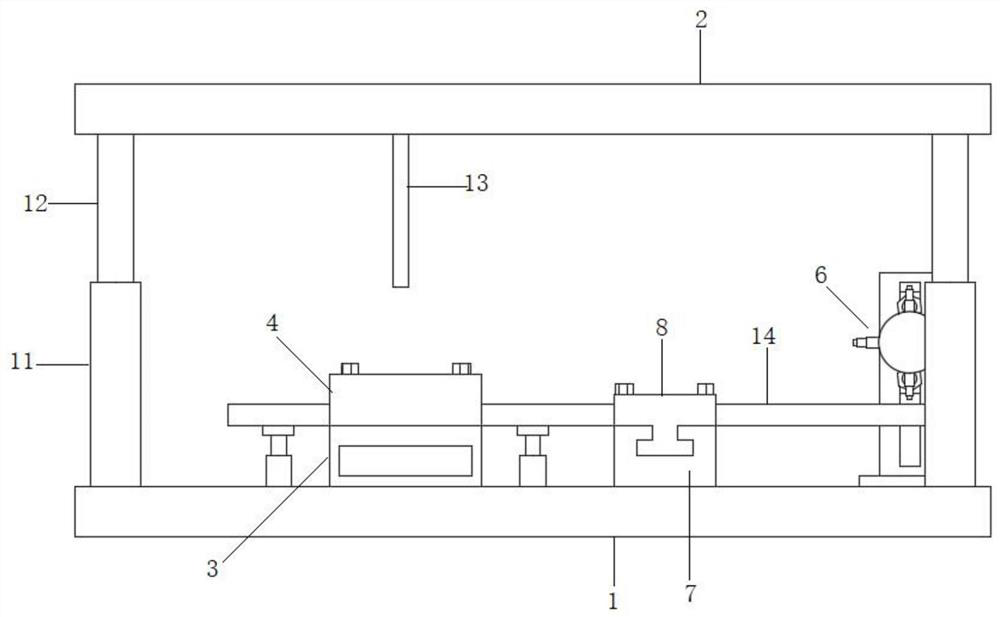

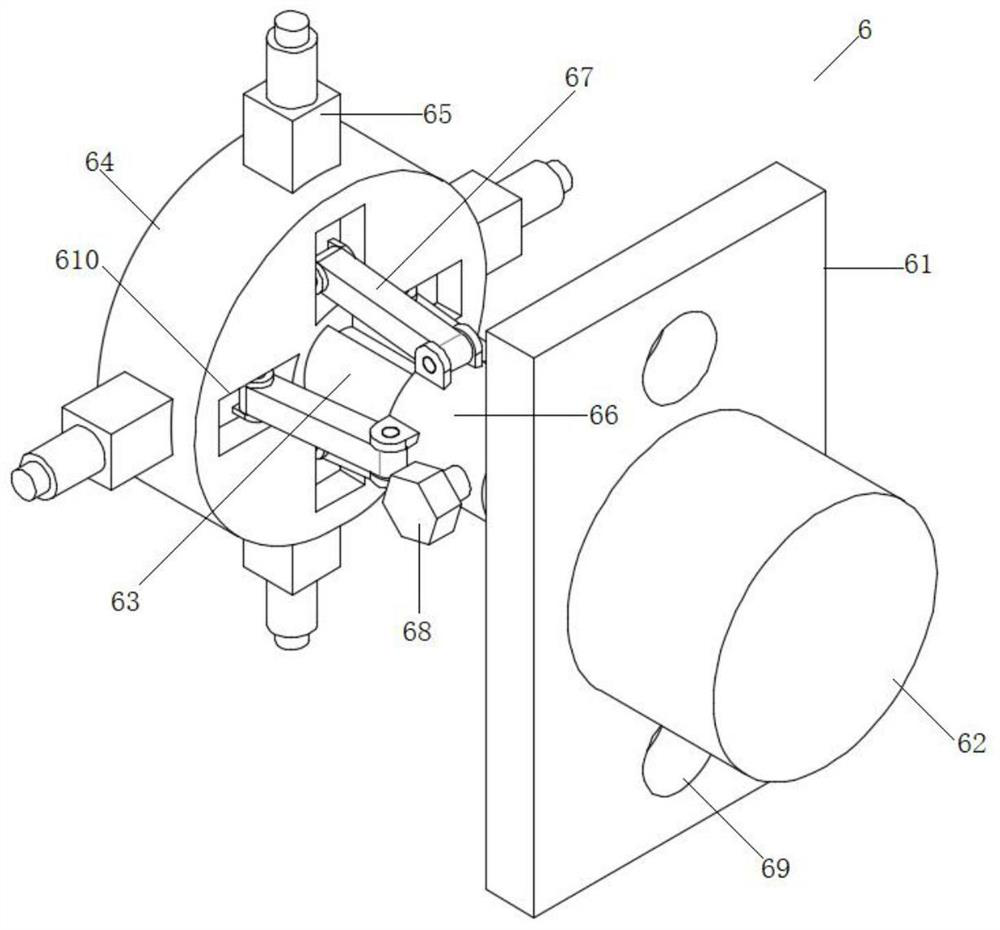

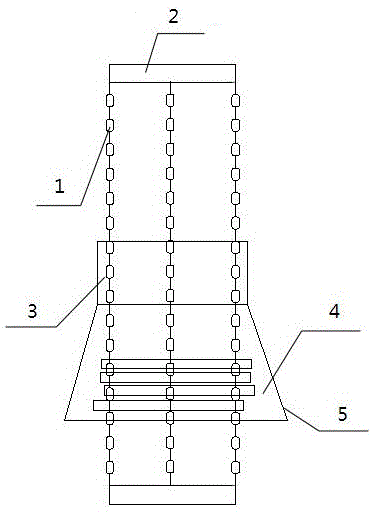

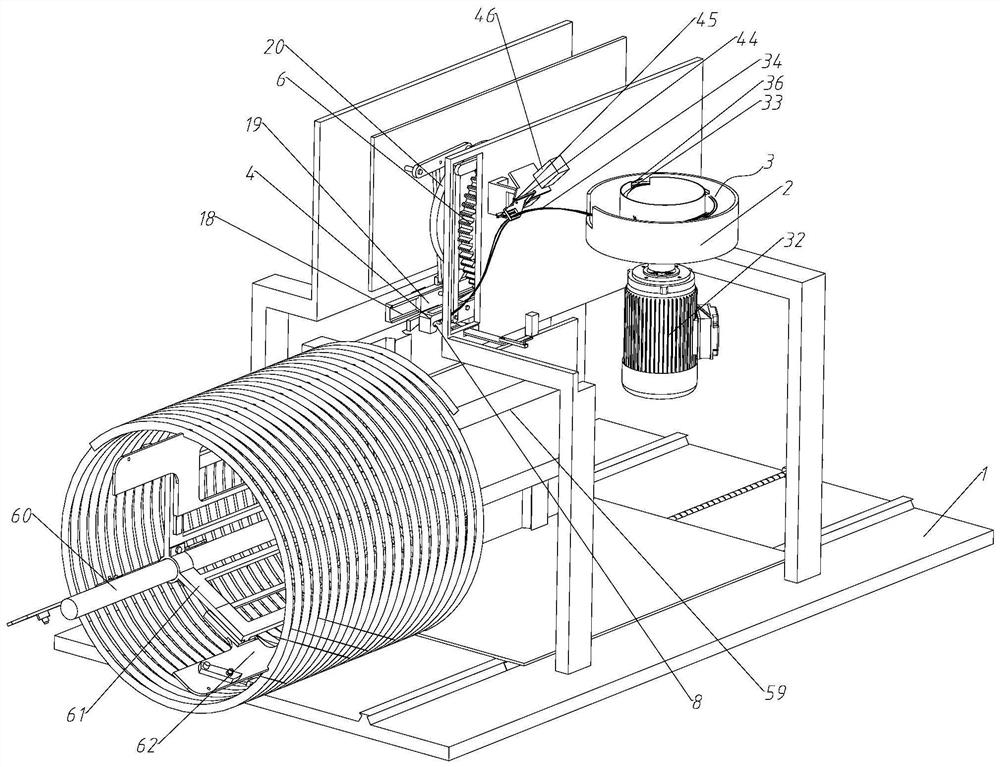

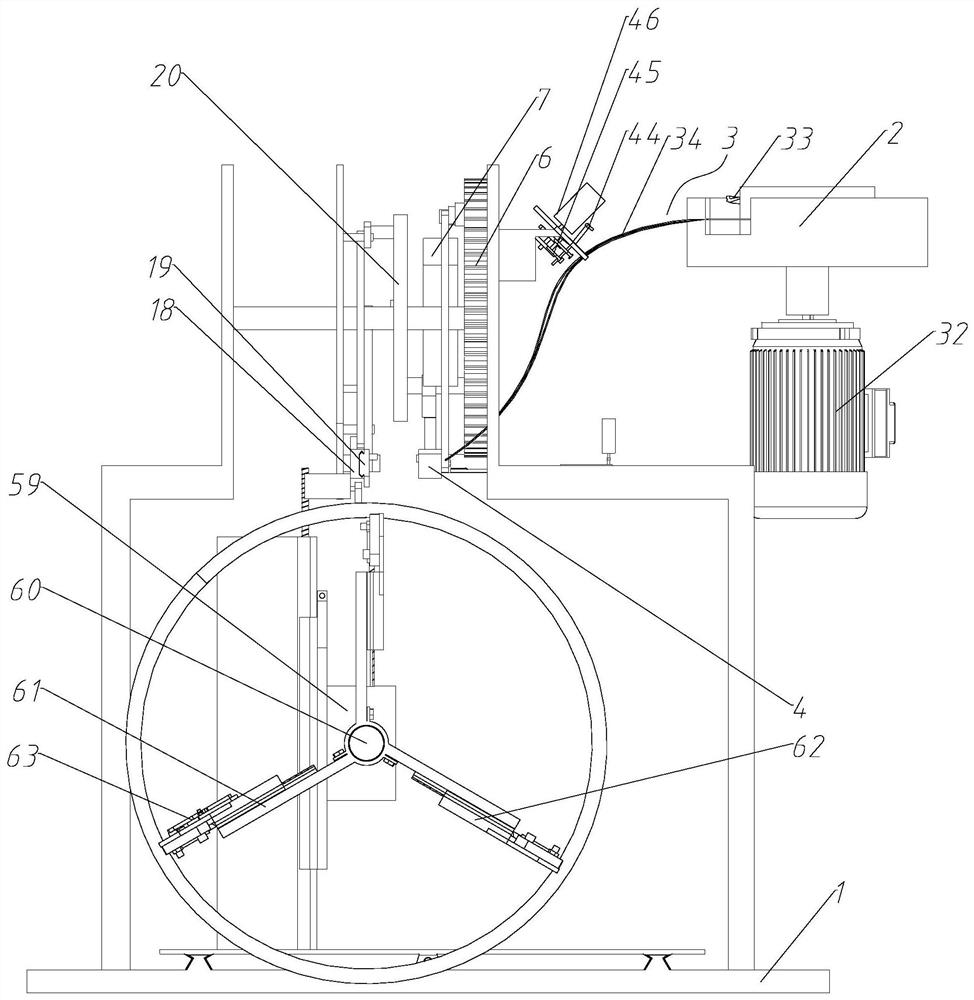

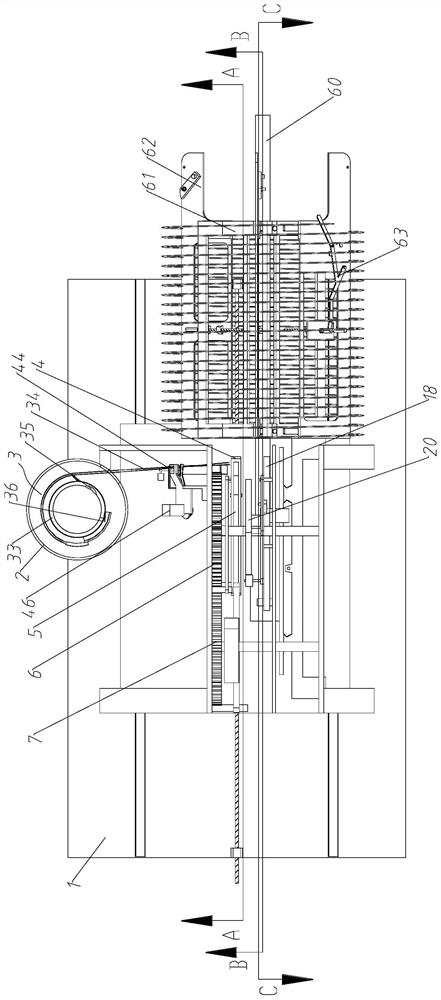

Assembling and adjusting system and method for multilayer nested X-ray focusing optical device

ActiveCN106653138AWon't hurtEasy to installHandling using diffraction/refraction/reflectionX-rayEngineering

The invention provides an assembling and adjusting system and method for a multilayer nested X-ray focusing optical device, and aims to solve a problem that an existing assembling and adjusting system causes damages for a glass lens in the assembling process because of employment of a mechanical mold and is not ideal in assembling precision. The assembling and adjusting system comprises an adjustment main system which is composed of an assembly frame, a six-dimensional adjustment device used for adjusting the attitude of a glass lens, a glass connecting column, a three-dimensional adjustment device group used for adjusting the overall attitude of the focusing optical device, two bearings respectively installed at two end parts of a central rod of the focusing optical device, two concentric devices respectively located between the bearings and a rim of the focusing optical device and long rods used for connecting the bearings and three-dimensional adjustment devices, wherein the six-dimensional adjustment device, the glass connecting column and the three-dimensional adjustment device group are sequentially arranged from top to bottom; the six-dimensional adjustment device is installed on the assembly frame in a headstand direction; and the focusing optical device to be assembled and adjusted is fixed between the glass connecting column and the three-dimensional adjustment device group. The assembling and adjusting system is convenient to assemble and adjust and high in assembling and adjusting precision, and does not damage the lens.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

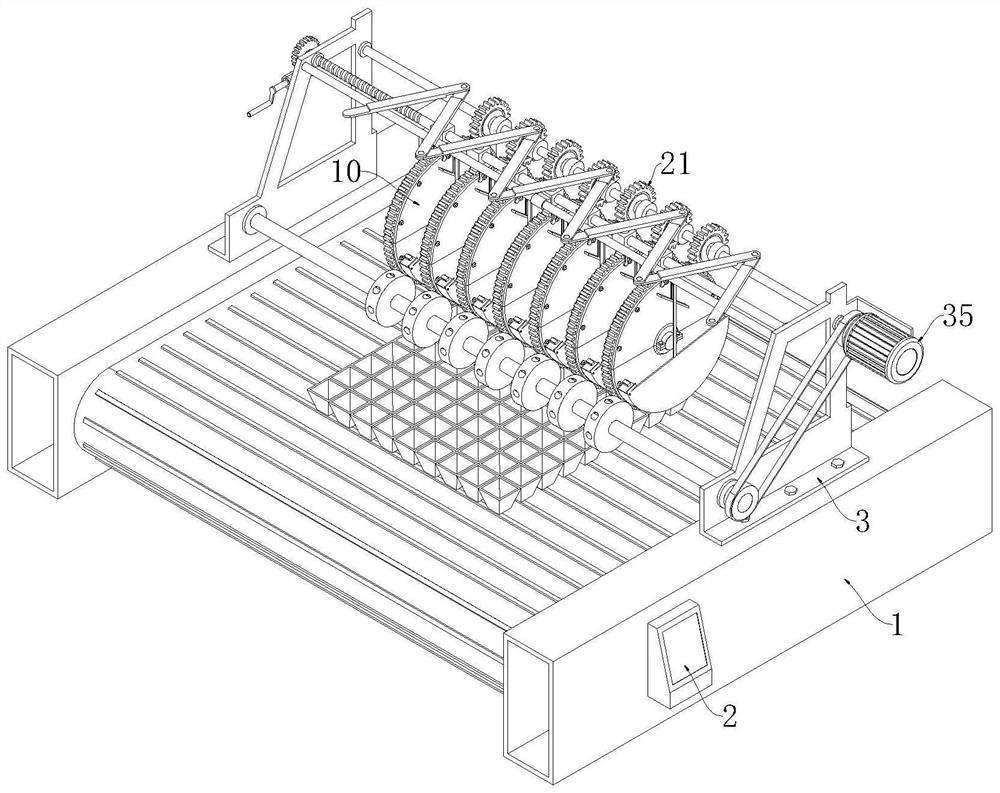

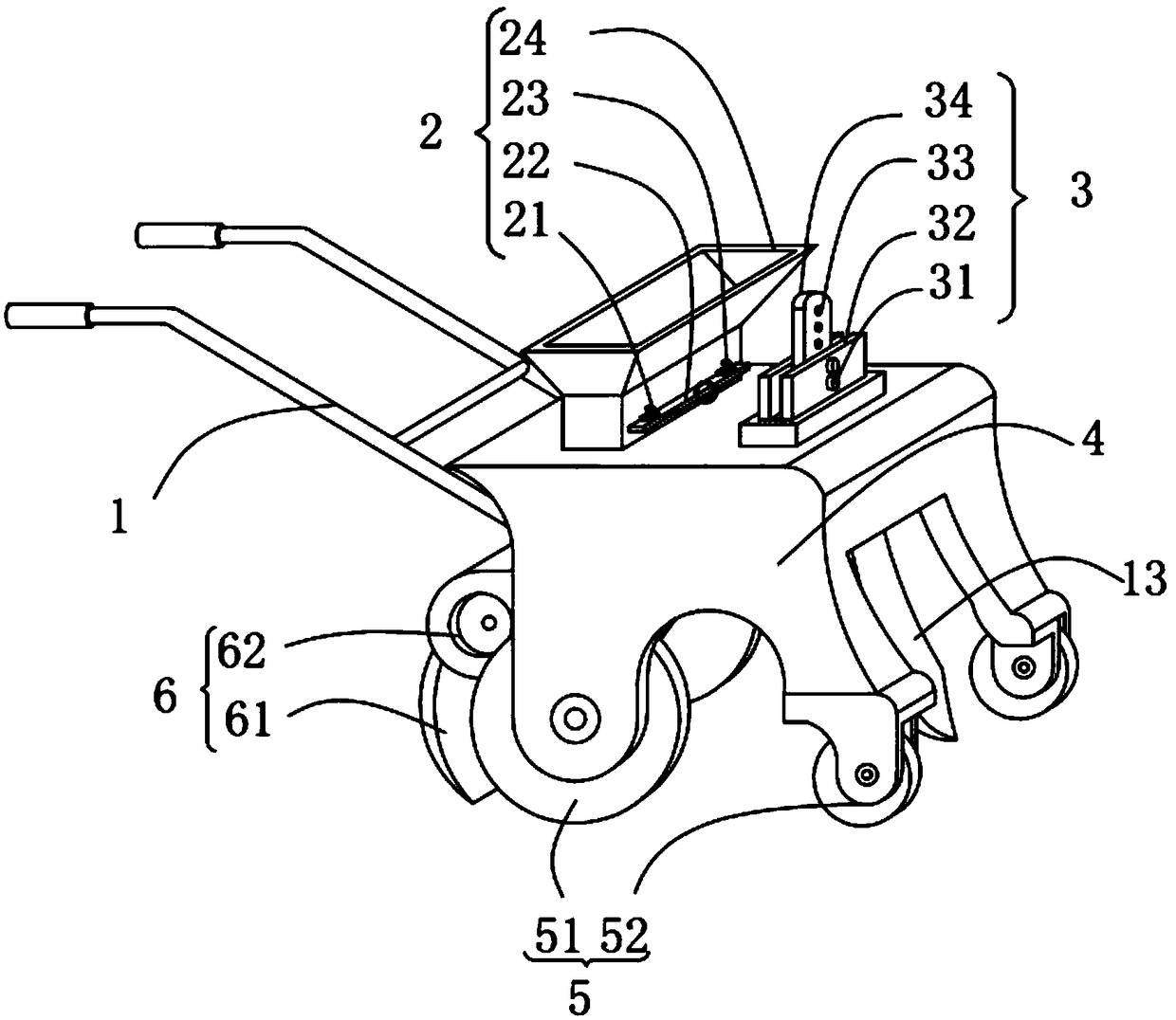

Intelligent agricultural seeding machine

InactiveCN114342607AAvoid easy cloggingNot easy to cause blockageSeed depositing seeder partsSingle grain seedersAgricultural scienceAgricultural engineering

The invention discloses an intelligent agricultural seeding machine which comprises a conveying device and a PLC, the top of the conveying device is fixedly connected with two racks, a plurality of seeding parts distributed in the axial direction are arranged on a guide shaft, and an adjusting part for adjusting the distance between every two adjacent seeding parts is arranged between the two racks. According to the device, the driving piece drives the rotating disc assembly to rotate, the suction head sucks seeds and moves the seeds to pass through the first check block and the second check block, the seeds move back and forth on the suction head under the blocking effect of the two check blocks, therefore, redundant seeds are separated from the suction head due to extrusion, the two check blocks extrude the seeds from the upper direction and the lower direction respectively, and the seeds are separated from the suction head. And the suction head covers half of the area of the air inlet end of the suction head, so that the device can effectively remove the seeds which are adsorbed on the suction head and have smaller particle sizes, the effects of saving the seeds and reducing the cost are achieved, and the normal development and growth of the seeds are facilitated.

Owner:王少平 +2

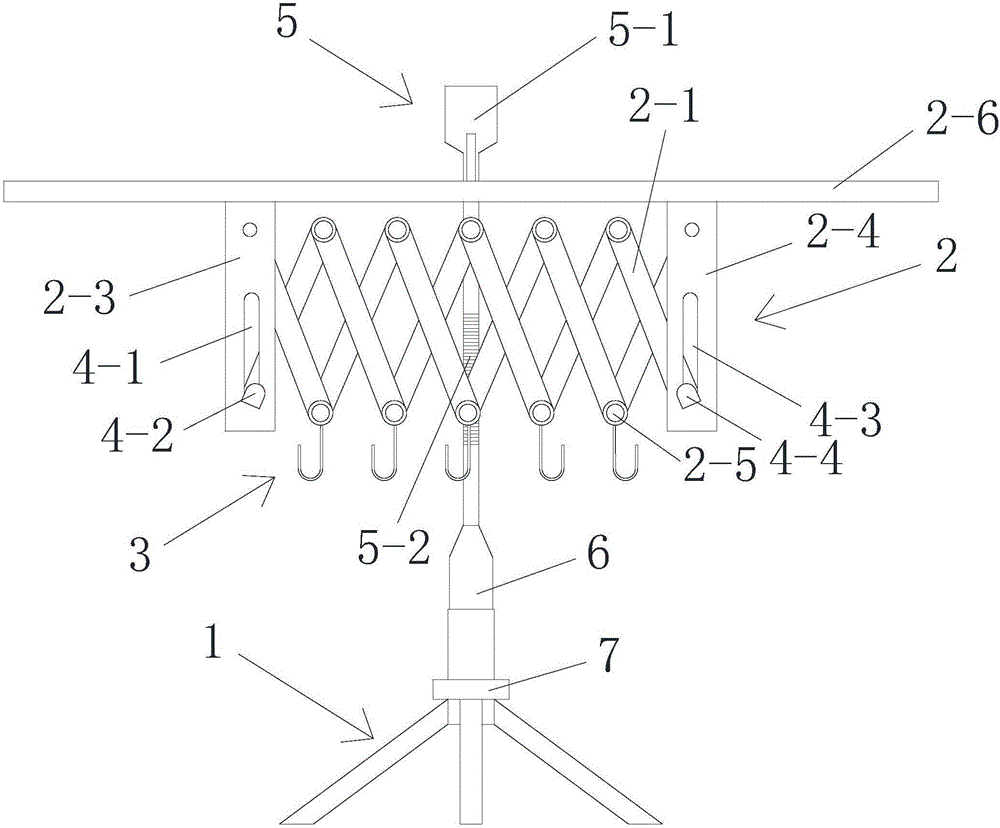

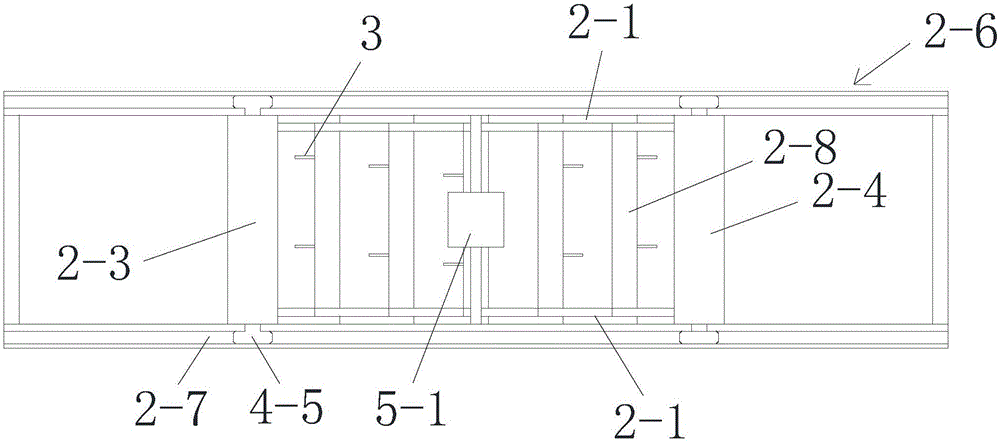

Floor reinforcing steel bar laying device

ActiveCN105863271AImprove construction efficiencyReduce labor costsBuilding material handlingFloor slabEngineering

The invention relates to a floor reinforcing steel bar laying device. The floor reinforcing steel bar laying device comprises a base, a horizontal frame which is arranged on the base and extends and retracts along the horizontal direction and a plurality of reinforcing steel bar hook sets which are fixedly arranged on the horizontal frame and are distributed at intervals along the extending-retracting direction of the horizontal frame, wherein each reinforcing steel bar hook set comprises more than or equal to two reinforcing steel bar hook sets which are arranged at intervals. The invention aims at providing a floor reinforcing steel bar laying device which can effectively improving floor reinforcing steel bar laying construction quality and efficiency. The floor reinforcing steel bar laying device has the advantages that the reinforcing steel bar hook sets distributed at intervals are arranged, and a retractable horizontal frame is used for adjusting distribution position of the reinforcing steel bar hook sets, so that large-area reinforcing steel bar layout can be completed by one time, workers do no need to bend down to put reinforcing steel bars one by one, floor reinforcing steel bar laying construction quality is greatly improved, and labor cost is greatly saved. A shear-fork type structure is adopted for controlling extension and retraction of the horizontal frame, same intervals between the reinforcing steel bar hook sets can be guaranteed, and reinforcing steel bar location accuracy is improved.

Owner:CSCEC STRAIT CONSTR & DEV

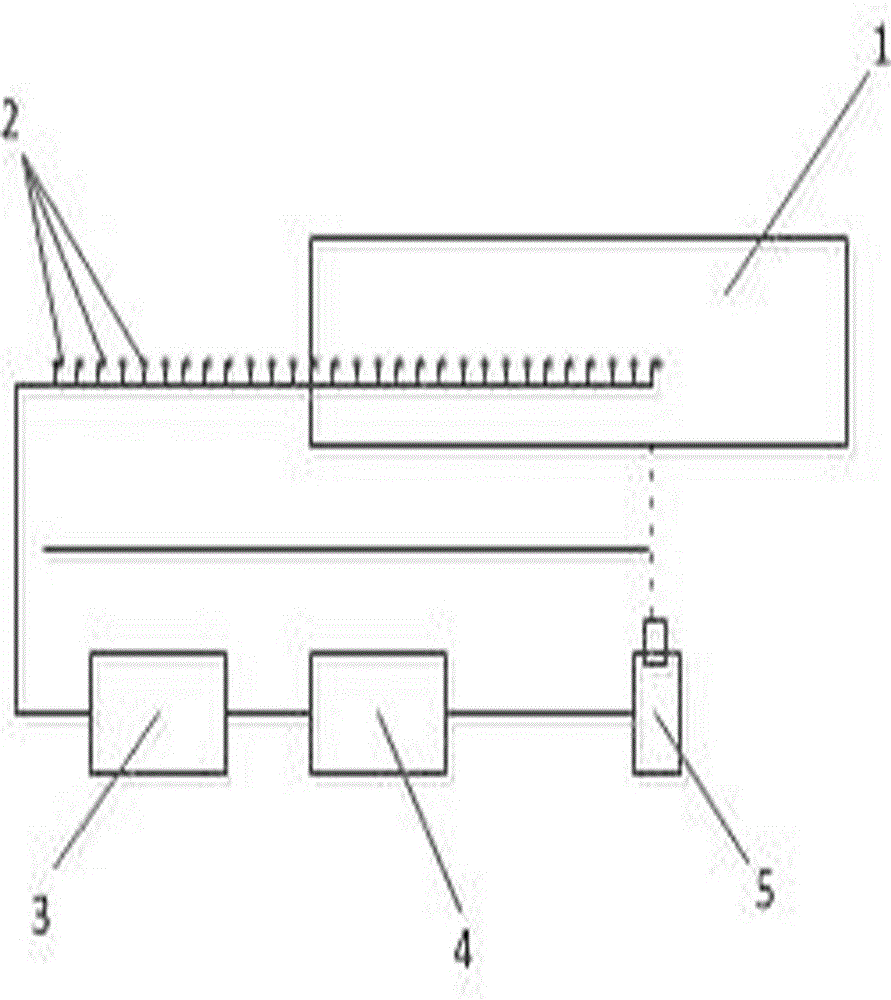

Method and device for acquiring standard images of non-uniform velocity moving objects

InactiveCN104660999ASame spacingIncrease viewing widthTelevision system detailsColor television detailsEngineeringLaser sensor

The invention discloses a method and a device for acquiring standard images of non-uniform velocity moving objects. In a region in which the photographing position, as a start position, of a three-line array CCD camera extends toward one side by a distance, laser sensors which are arranged at equal intervals are used for dividing the region into a plurality of equal intervals; the distance between the three-line array CCD camera and the surface of an object passing through the region is adjusted according to the intervals of the laser sensors and the focal length of the three-line array CCD camera, so that the imaging range of the three-line array CCD camera is equal to the intervals among the laser sensors; the three-line array CCD camera is controlled by signals generated by a moving object passing the region by sequentially blocking the laser sensors to intermittently acquire images of the moving object, and image data are transmitted to a computer to form continuous and uninterrupted standard images. The device is easy to operate; the laser sensors are utilized for directly triggering the three-line array camera to photograph without adjusting the photographing frequency of the camera, so that the scanning leakage phenomenon can be prevented effectively.

Owner:洛阳灵翔计算机科技发展有限公司

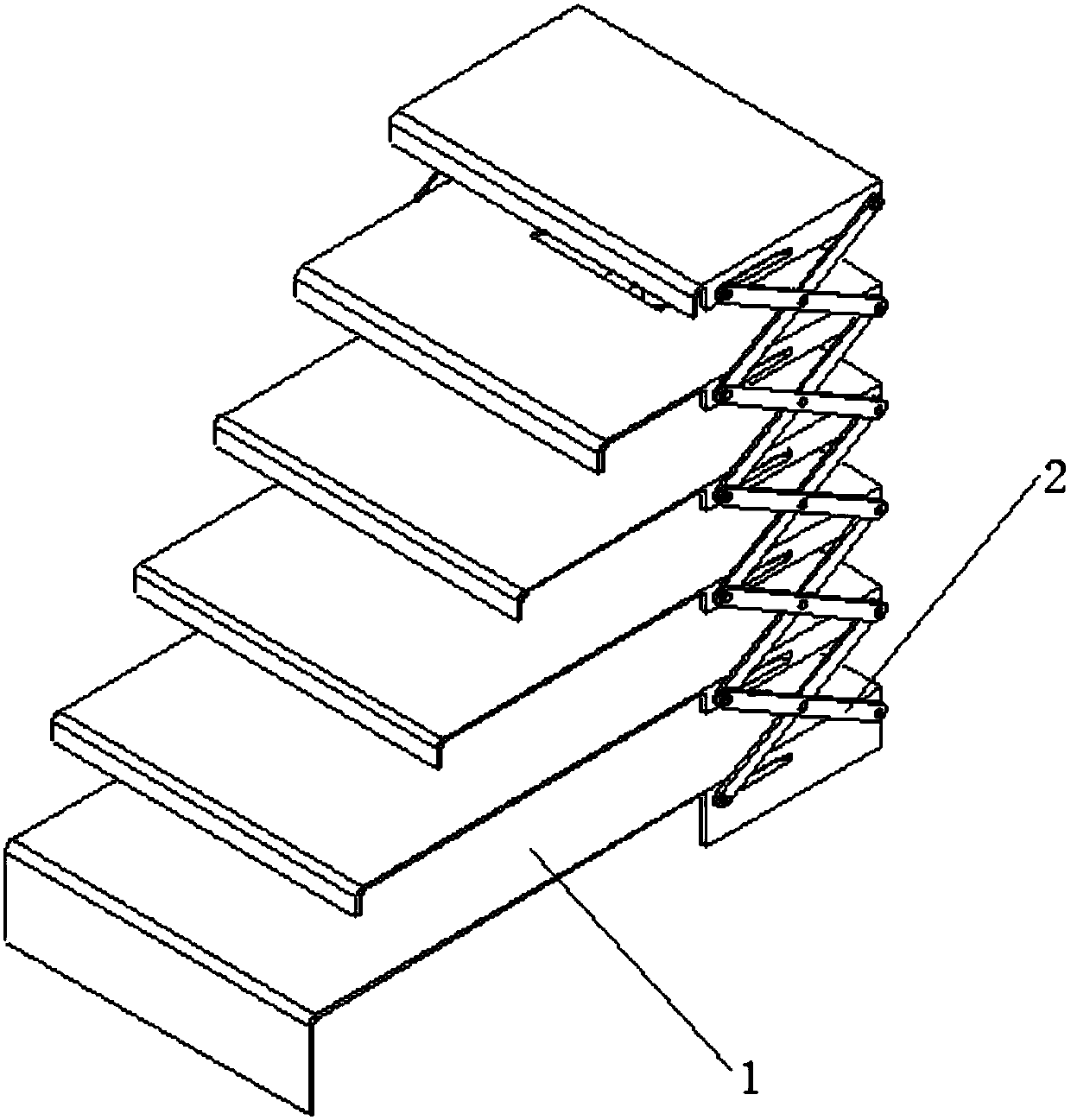

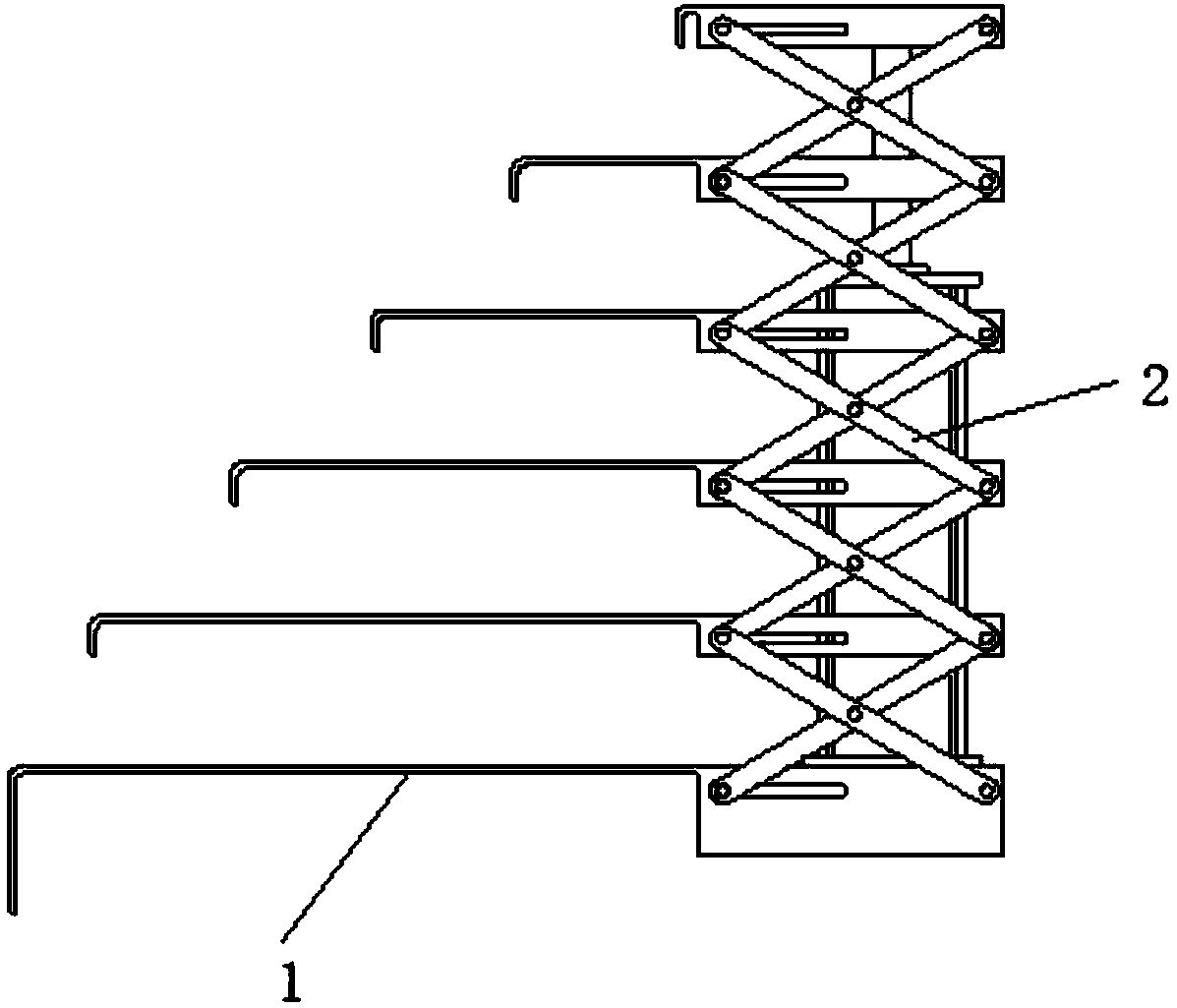

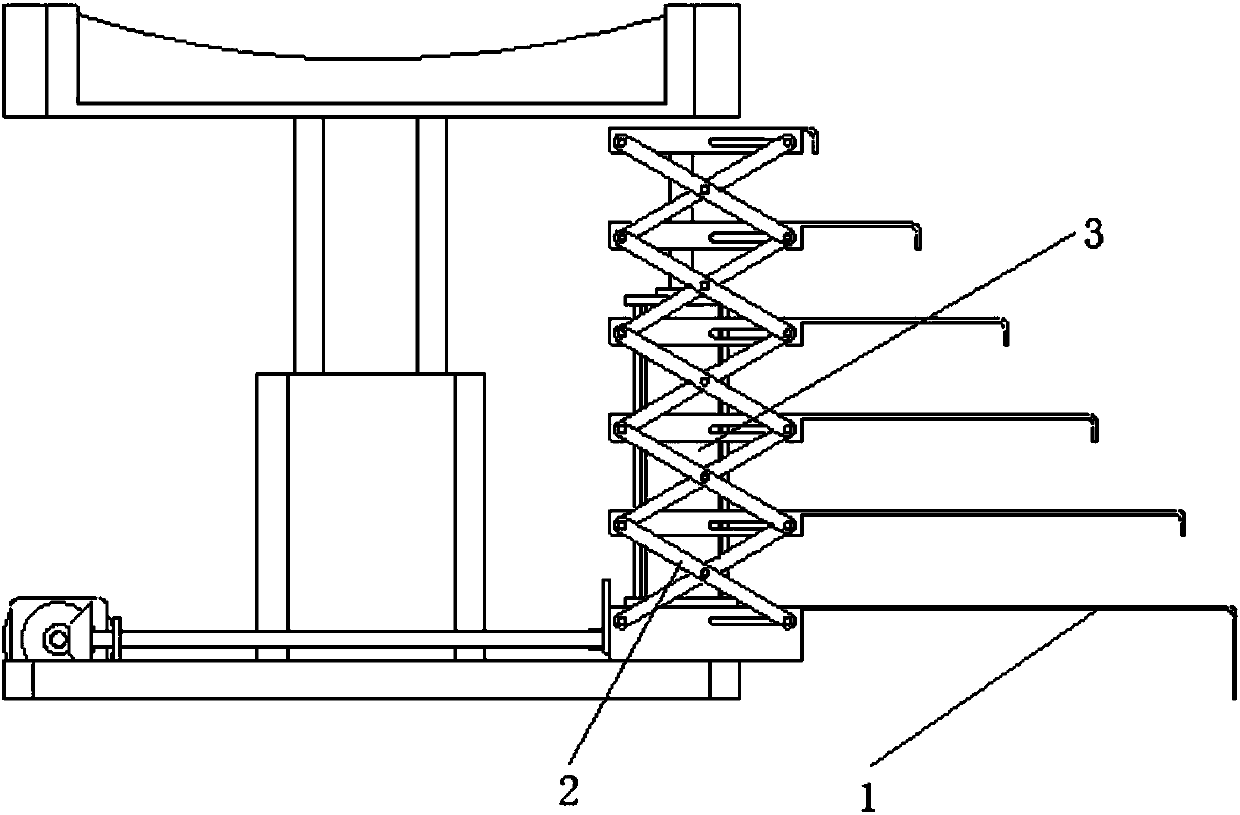

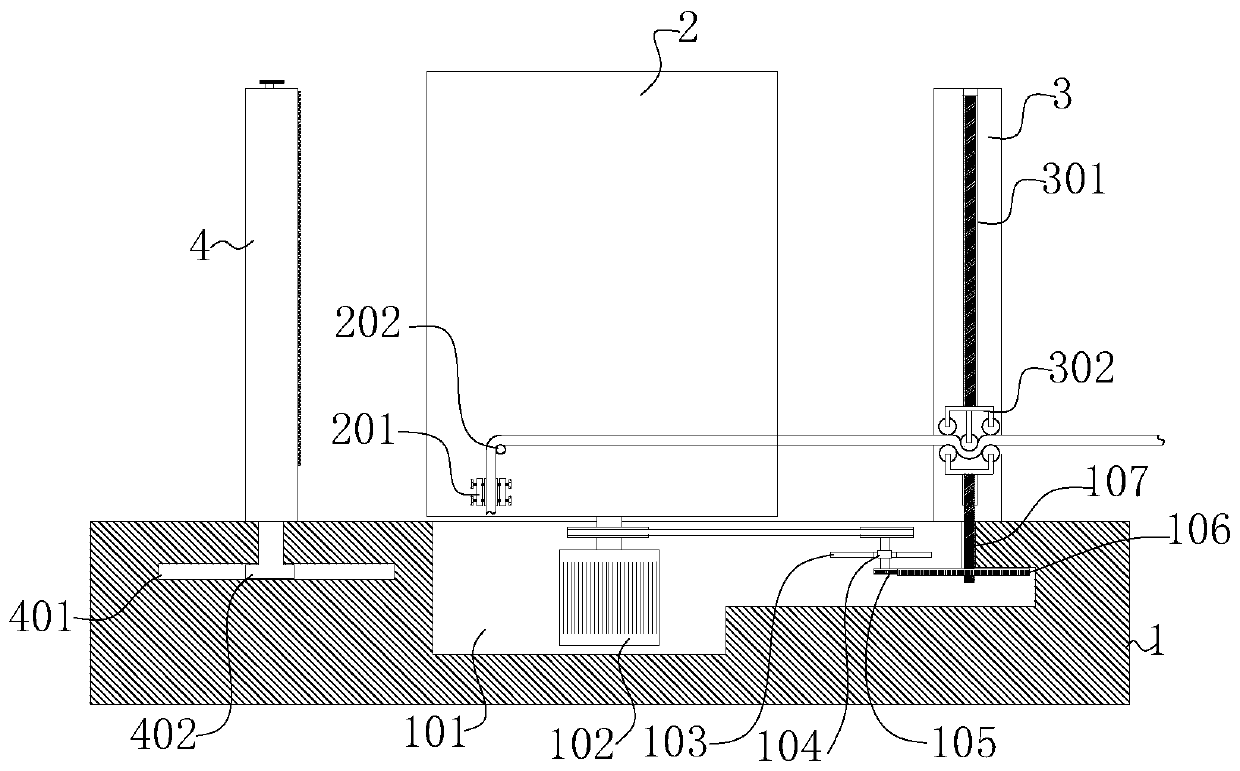

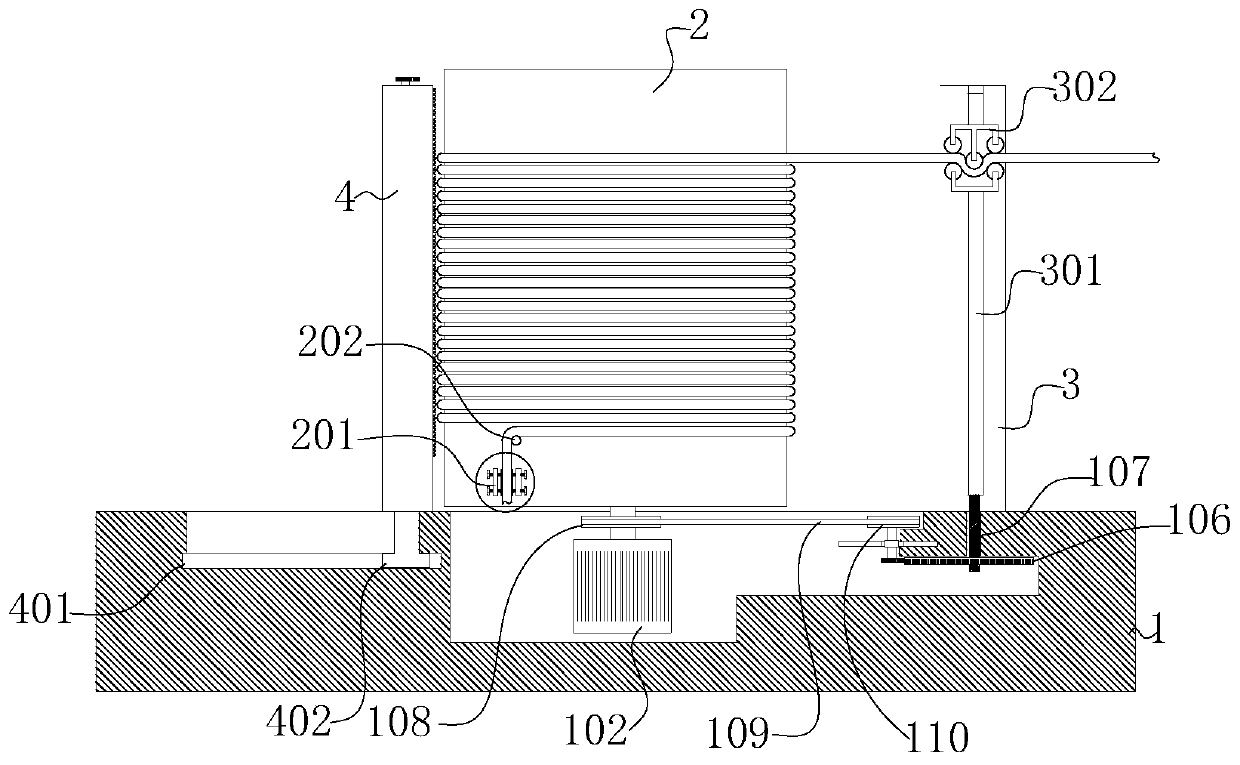

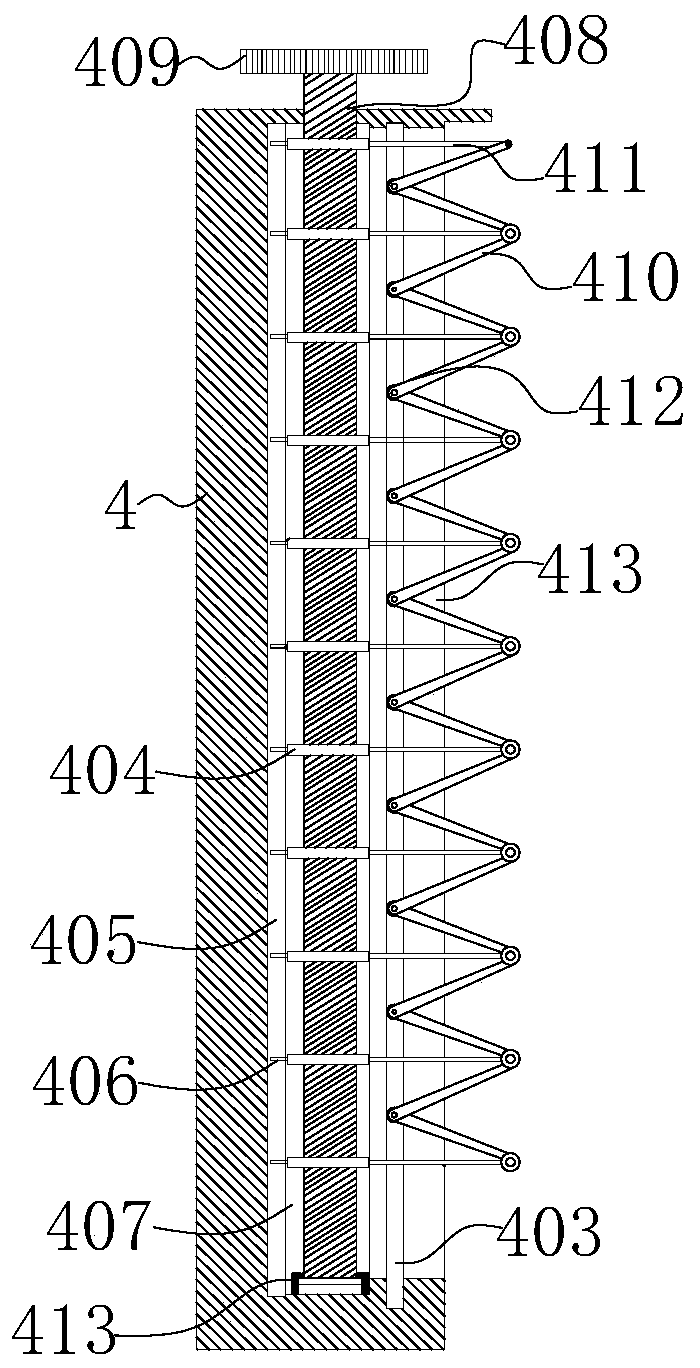

Foldable ladder for CT (computed tomography) examination couch

PendingCN108042150ASolve the problems that are prone to failure and affect the service life of CT examination bedSolve the service lifePatient positioning for diagnosticsComputerised tomographsEngineeringCt examination

The invention discloses a foldable ladder for a CT (computed tomography) examination couch, and belongs to the technical field of medical apparatus and instruments. The foldable ladder comprises a plurality of levels of steps. The multiple levels of steps are parallelly arranged, cross connecting rod groups are symmetrically arranged on two sides of each step and comprise a plurality of connectingrods which are hinged to one another in a cross manner, parallelogram structures are formed by the connecting rods which are hinged to one another in the cross manner, a horizontal vertex of each parallelogram structure is hinged to one of the multiple levels of steps, another horizontal vertex of each parallelogram structure is slidably connected with the step among the multiple levels of steps,and the every two corresponding horizontal vertexes are hinged points of the hinged ends of the two corresponding connecting rods. The foldable ladder has the advantages that the heights of the stepsmounted on the cross connecting rod groups can be adjusted by the cross connecting rod groups, identical distances between the multiple levels of steps can be guaranteed, patients can conveniently get on and out of the CT examination couch, and the problems of easy faults of examination couches and influence on the service lives of the CT examination couches due to the fact that the CT examination couches need to continuously ascend and descend during examination in the prior art can be solved; the examination time can be saved, and the examination efficiency can be improved.

Owner:SECOND AFFILIATED HOSPITAL OF XIAN MEDICAL UNIV

Manufacturing method of transformer coil

ActiveCN110534336AIncreased versatilityDifferent ascent speedInductances/transformers/magnets manufactureEngineeringElectrical conductor

The invention discloses a manufacturing method of a transformer coil, and relates to the technical field of electrical equipment. The manufacturing method comprises the following steps: S1, material preparation: preparing a flat conductor, coating the surface of the flat conductor with paint and insulating two adjacent flat conductors when in contact; S2, spiral winding: fixing one end of the flatconductor prepared in the step S1 to the bottom end of an inner core mold; and winding the flat conductor around the inner core mold to form a spiral structure through rotation of the inner core mold; and S3, tightness adjustment: tightening the wound flat conductor to make the formed spiral structure more compact when the flat conductor in the step S2 is wound on the inner core mold,. Accordingto the manufacturing method, the changeover gears with different diameters are changed and changed rotating gears are normally meshed with the second gear so that the distance between the two adjacentturns of each produced coil is identical after the coil turns of the device are changed.

Owner:湖南利航电子有限公司

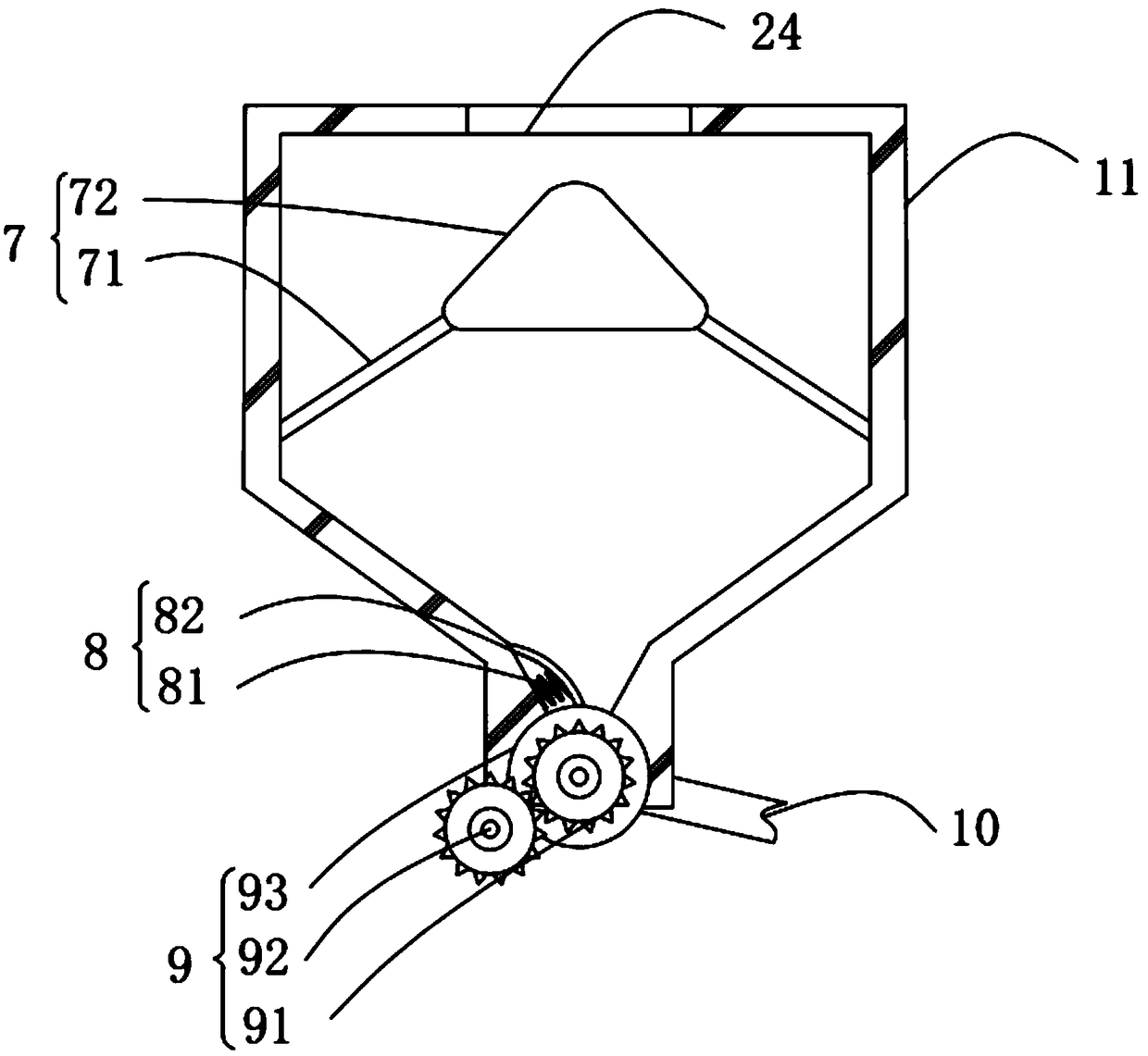

Peanut planting method

The invention relates to the field of peanut planting technology, in particular to a peanut cultivation method, wherein the a blocking mechanism is installed inside the body of a peanut seeder, and the peanuts fall into the inside of the body and fall onto the surface of the blocking mechanism, and the peanuts slide into the inside of the body on the surface of the blocking mechanism, peanuts don't collide with each other to prevent the peanuts from being damaged; the bottom end of a discharging box is equipped with an anti-blocking mechanism, which is in contact with the anti-blocking mechanism during the rotation of the first discharging mechanism to make the anti-blocking mechanism move up and down, so that the peanuts located on the side wall of the anti-blocking mechanism can move into the inner part of the first discharging mechanism, achieving the same spacing of the peanuts planted; a lifting mechanism is slidingly connected with the body, and controls the movement of the lifting mechanism inside the body to control the distance between the bottom end of the ditcher and the bottom of the body, thereby controlling the ditching depth of the ditcher.

Owner:许美凤

Enhanced retractable safety marker

InactiveUS20060127176A1Easy to placeImprove the immunityTraffic signalsRoad signsDesign standardStructural stability

An enhanced retractable safety marker is a device designed to provide motorists with advance warning of disabled vehicles and / or work zone areas. The device has been designed to withstand reasonable winds through the use of two base supports, several retractable horizontal stabilizers that fit through slots on the base supports and a series of retractable vertical risers. The retractable vertical risers allow for the device to easily expand to height consistent with traffic engineering design standards when in operation and then compact when it is in storage. The two base supports in combination with the retractable horizontal stabilizers are designed not only to provide the necessary structural stability but to also open and close about the retractable vertical risers thus providing for additional compactness. The shape of the vertical risers may either be rectangular, elliptical, square of circular depending on application and may have reflective decals affixed to them to correspond with standard traffic control design.

Owner:TIPALDO JOHN M

Method for guaranteeing mounting accuracy of tray internal part support ring of pressure container

ActiveCN102794143AControl deformationSame spacingChemical/physical/physico-chemical processesPosition angleEngineering

The invention discloses a method for guaranteeing the mounting accuracy of a tray internal part support ring of a pressure container. The method comprises the following steps of: I, clamping the two ends of adjacent support rings through the clamp slots on two measurement clamp plates; II, clamping the support rings clamped by the clamp slots on the measurement clamp plates by use of a clamp slot on the positioning angle steel; III, fixing the support rings and the positioning angle steel together to form a support ring group; IV, removing the measurement clamp plates; V, if the support rings are continuously fixed, performing steps VI and VII; otherwise, mounting the support rings fixed together on a tray, performing heat treatment and removing all positioning angle steel to finish the mounting; VI, clamping the outermost support ring of the support ring group by use of one clamp slot at one end of the measurement clamp plate, and placing new support rings into other clamp slots on the measurement clamp plate one by one; and VII, repeating the steps II to V. The method disclosed by the invention has the characteristics of high support ring assembly speed, short manufacturing period, easiness in guarantee of flatness and space and the like.

Owner:SHANGHAI BOILER WORKS

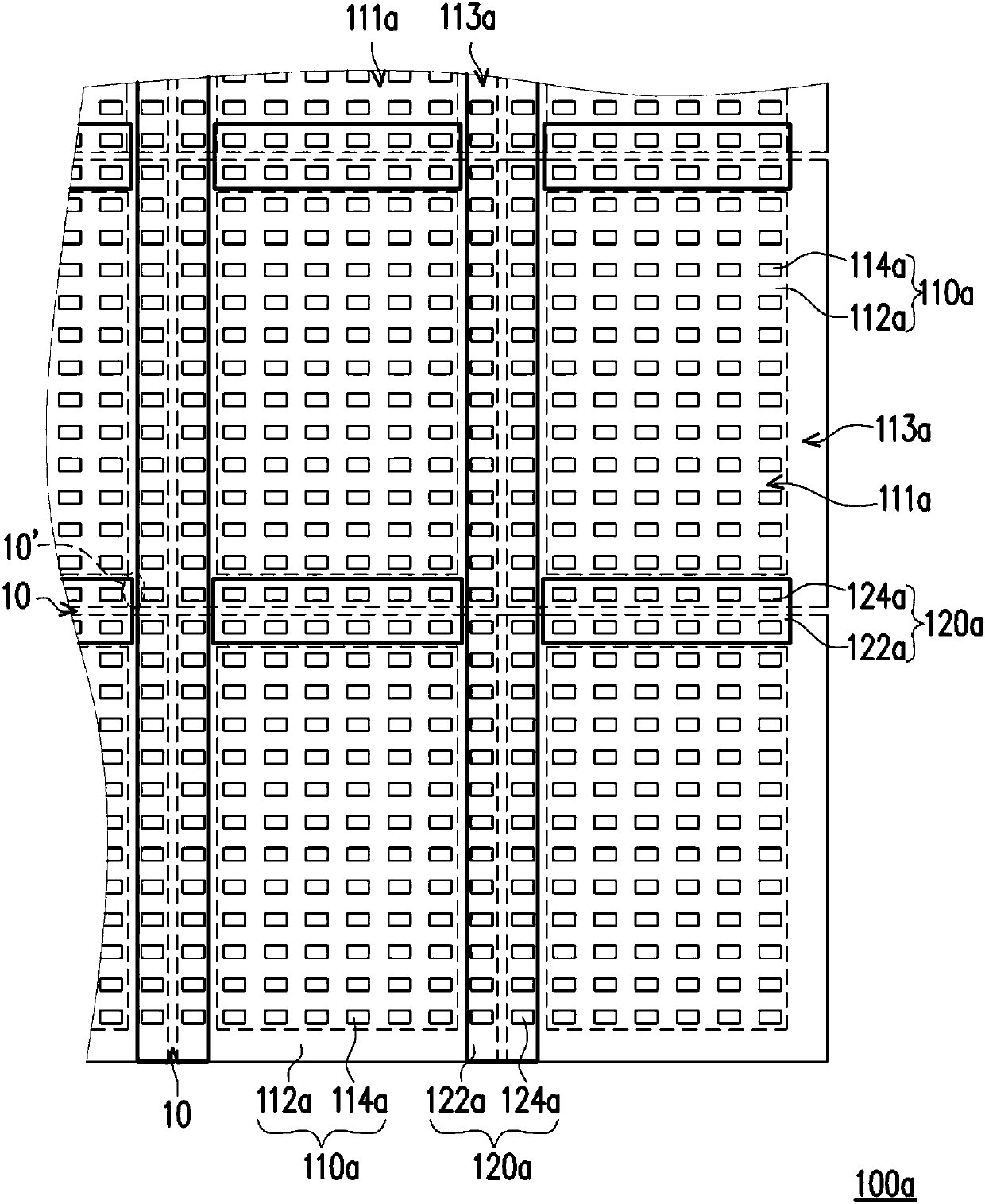

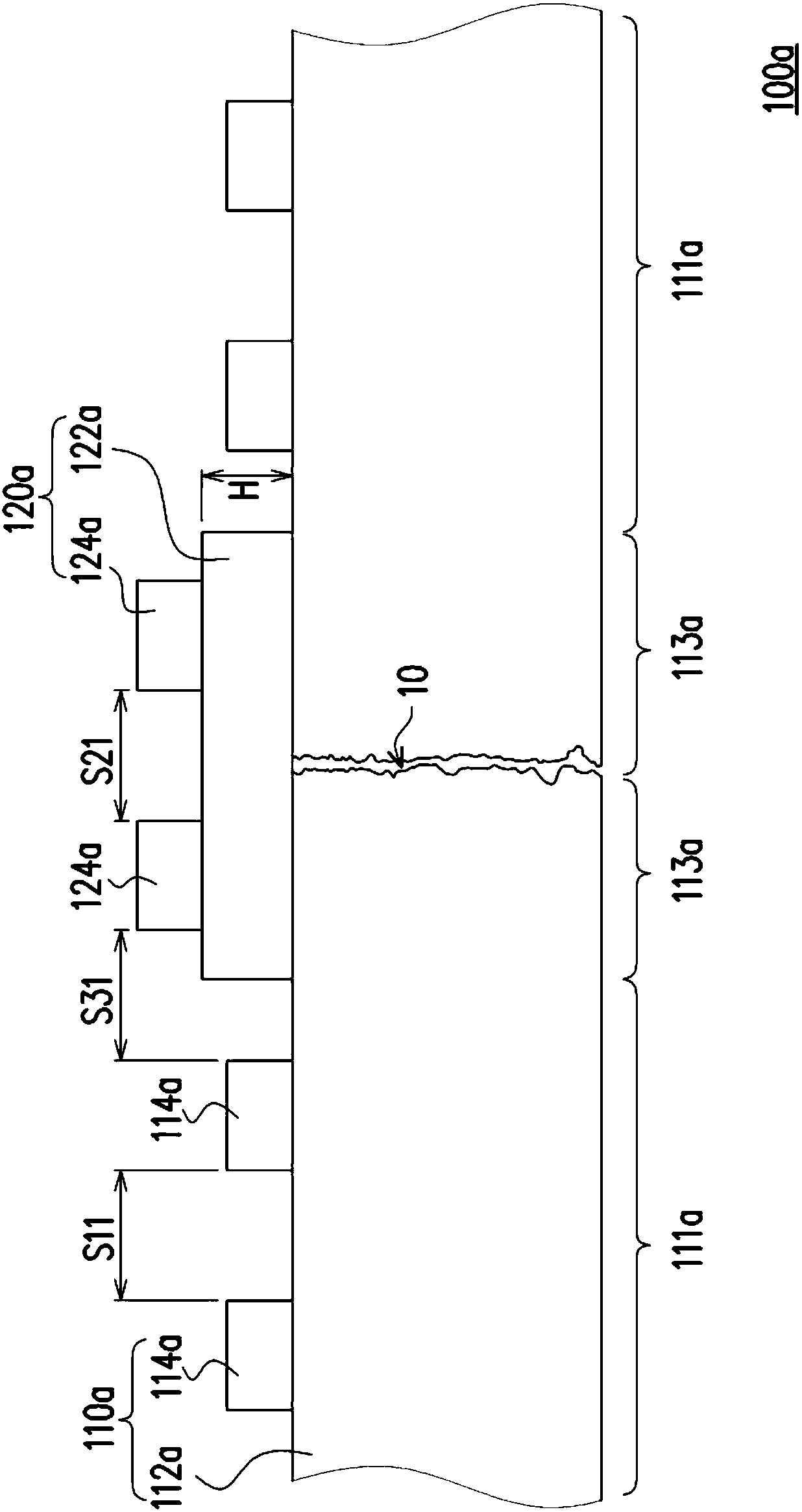

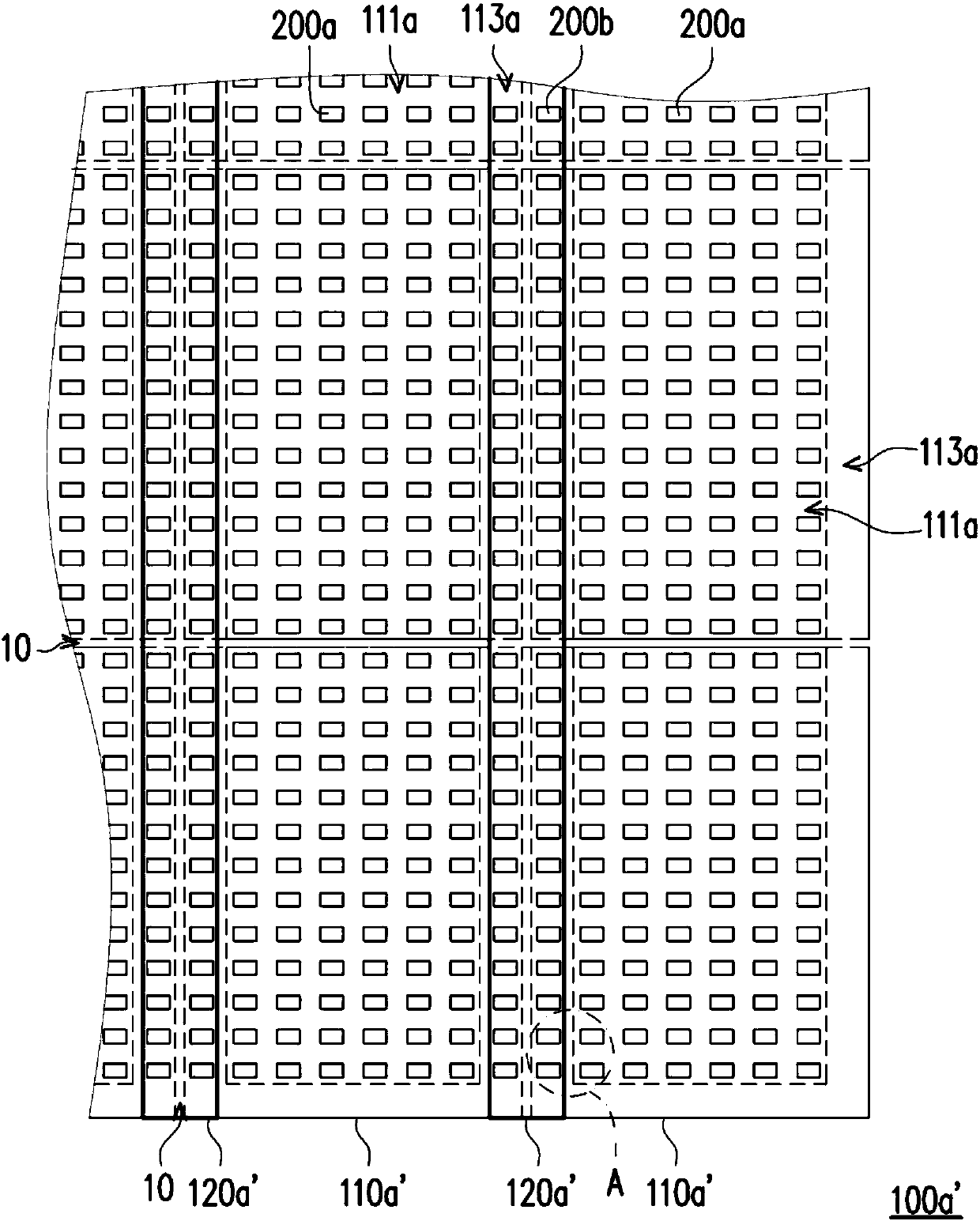

Light emitting diode display

PendingCN109728021AImprove display qualityImprove continuitySolid-state devicesIdentification meansLED displayDisplay device

A light emitting diode display includes a plurality of display units and a plurality of auxiliary display units. The display units are arranged in an array and connected with one another. Each displayunit has a component configuration area, a peripheral area around the component configuration area, and a plurality of first light emitting elements configured in the component configuration area andarranged in an array. Each auxiliary display unit is configured on the peripheral areas of any two adjacent display units. Each auxiliary display unit includes an auxiliary substrate and a pluralityof second light emitting elements arranged in an array. The second light emitting elements are arranged on the auxiliary substrates and are at a horizontal height different from that of the first light emitting elements. Each auxiliary substrate bridges two adjacent display units.

Owner:PLAYNITRIDE

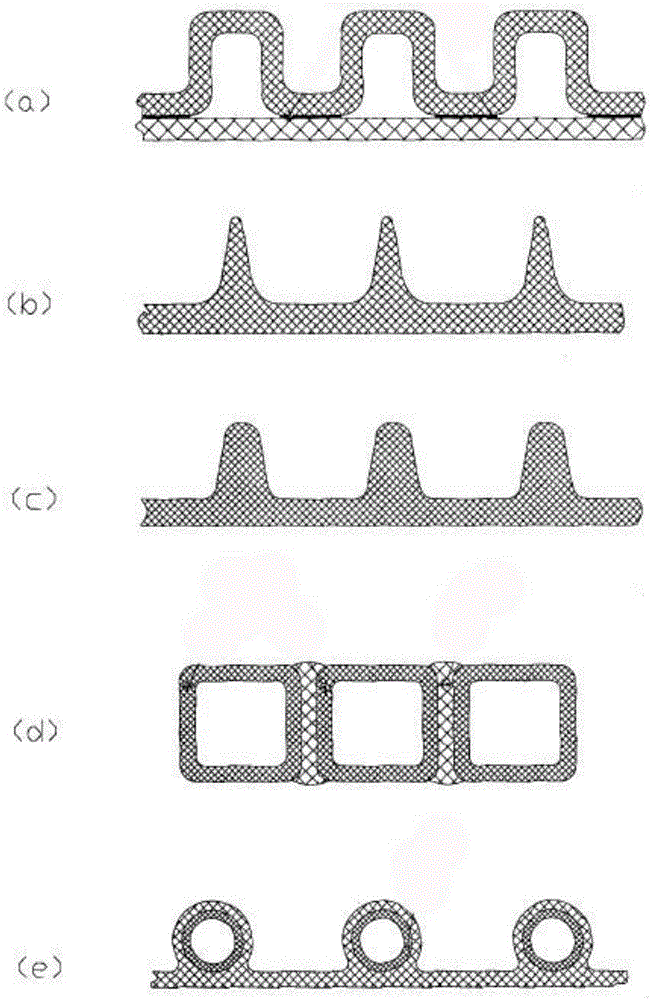

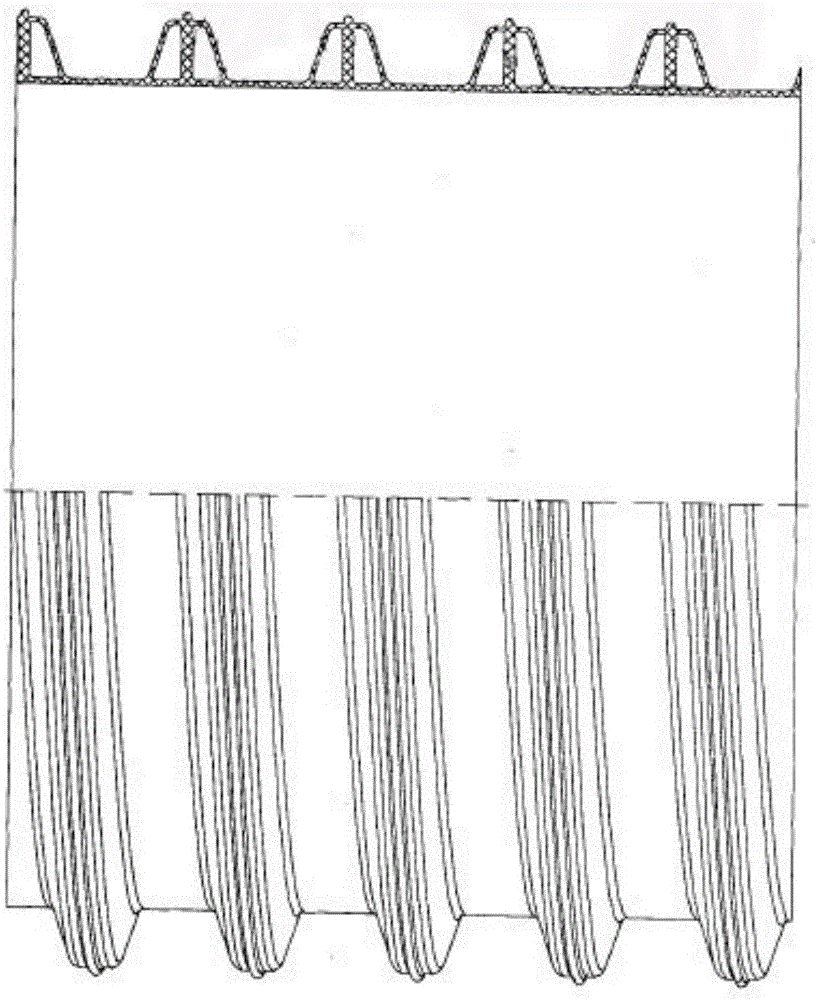

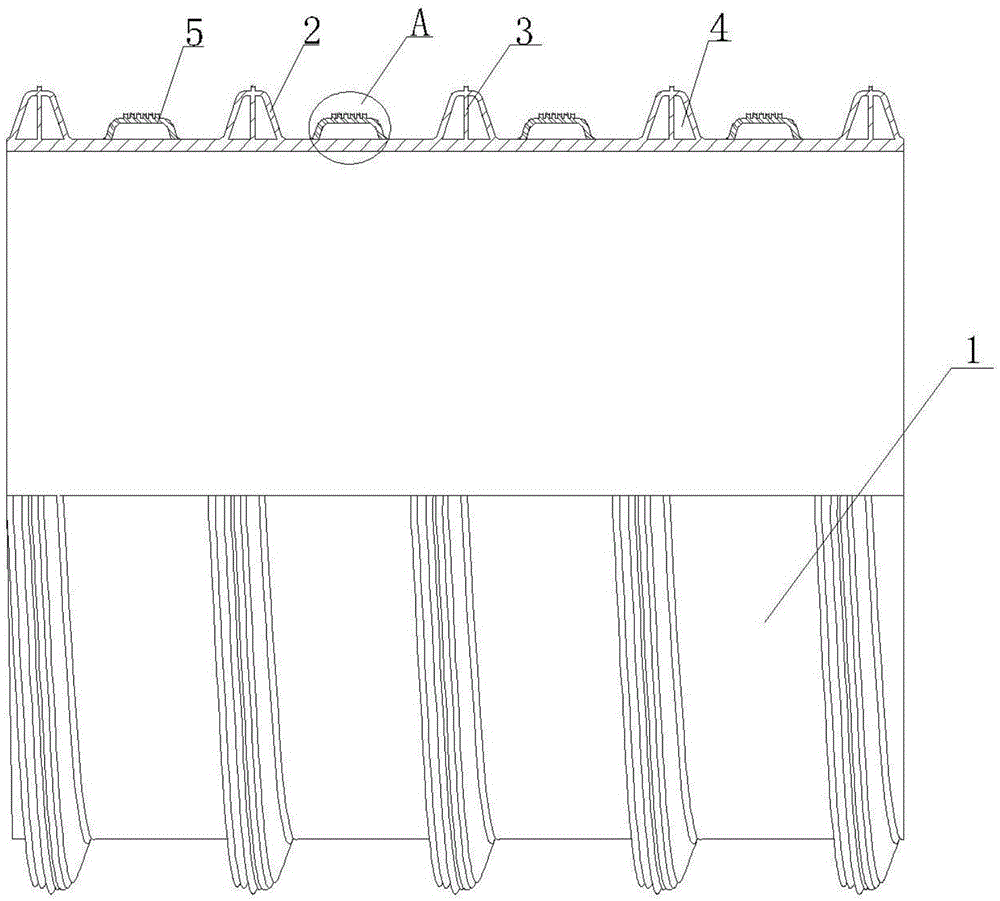

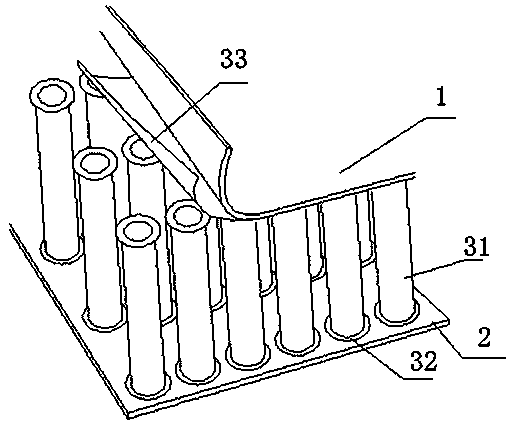

Inner fin and outer rib reinforced corrugated pipe

ActiveCN105526436AStrong resistance to deformationIncreased ring stiffnessFlexible pipesEngineeringHelix

The invention relates to a corrugated pipe and in particular relates to an inner fin and outer rib reinforced corrugated pipe that breaks through the thinking pattern limitations in the industry and is effectively improved in pressure resistance and deformation resistance thereof. The inner fin and outer rib reinforced corrugated pipe comprises a cylindrical-surface pipe body 1 and helical surrounds 2 that helically surround the pipe body; a reinforcing inner fin 3 perpendicular to a pipe wall is contained in the helical surrounds 2 and divides the helical surrounds 2 into two parallel hollow cavities 4; a transverse reinforcing rib 5 is further arranged between every two adjacent helical surrounds 2; each transverse reinforcing rib 5 is mounted on the cylindrical-surface pipe body 1 and provided with threads on a surface thereof; due to such a structure that the transverse reinforcing rib is further arranged between every two adjacent helical surrounds and each transverse reinforcing rib is mounted on the cylindrical-surface pipe body and provided with threads on the surface thereof, the whole cylindrical-surface pipe body is covered with the helical surrounds and the transverse reinforcing ribs, such that the whole inner fin and outer rib reinforced corrugated pipe is still capable of keeping good ring stiffness under pressures or vibrations, and meanwhile, is better in anti-deformation capability.

Owner:江阴市康乐塑胶有限公司

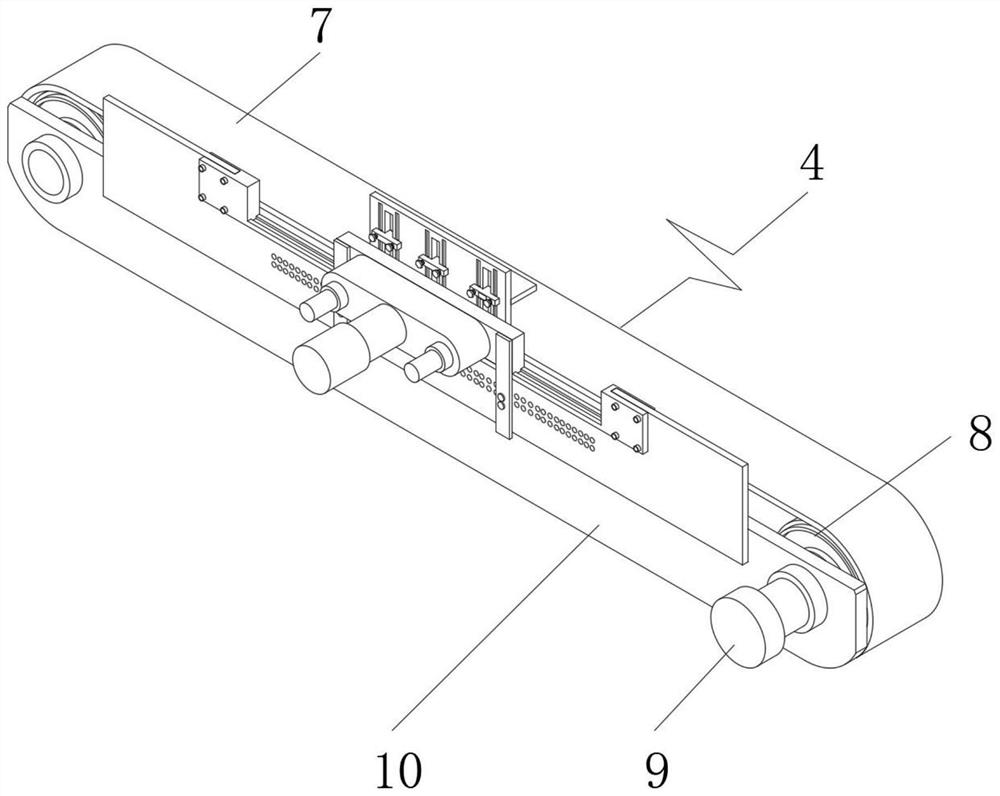

Portable millimeter wave passive focal plane imaging system

InactiveCN105371962AHighly integratedReduce volumeRadiation pyrometryAntenna supports/mountingsSignal conditioning circuitsRadiometer

The invention provides a portable millimeter wave passive focal plane imaging system. The portable millimeter wave passive focal plane imaging system comprises a cylinder of which one end is equipped with a lens antenna, wherein the cylinder is internally fixed with a focal plane feed source array opposite to the lens antenna, the focal plane feed source array is connected with a radiometer reception set, the radiometer reception set is connected with a signal conditioning circuit, and the signal conditioning circuit is connected with a switching circuit having a signal output port and a power supply input port. The portable millimeter wave passive focal plane imaging system has properties of small volume and light weight, can be held by a single person to scan a target scene for imaging and can realize millimeter wave imaging of building and ground vehicle targets all day long.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Non-woven fabric production splitting machine with automatic positioning function

The invention discloses a non-woven fabric production splitting machine with an automatic positioning function. The machine comprises a working rack; a feeding roller is arranged on one side of the working rack; a plurality of receiving rollers are arranged on the side, away from the feeding roller, of the working rack; a supporting rod is fixedly arranged at the top end of the working rack; a U-shaped supporting frame is fixedly arranged at the bottom end of the supporting rod; a slitting adjusting mechanism is arranged on the inner side of the U-shaped supporting frame; and a dust suction mechanism is arranged at the bottom end of the working rack. According to the non-woven fabric slitting machine, slitting cutters and a discharging roller can be adjusted at the same time, and it can beguaranteed that the distances between the multiple slitting cutters and the discharging roller are the same, so that errors generated during non-woven fabric slitting can be reduced, wrinkles generated during winding of a non-woven fabric by the discharging roller can be avoided, and the use by people is facilitated; when a driving motor drives the receiving rollers to perform winding, dust suction fan blades can be driven to suck waste floccules generated during non-woven fabric slitting into a collecting box, so that the situation that the waste floccules are inhaled into the human body toharm human health is avoided.

Owner:智程无纺布(江苏)有限公司

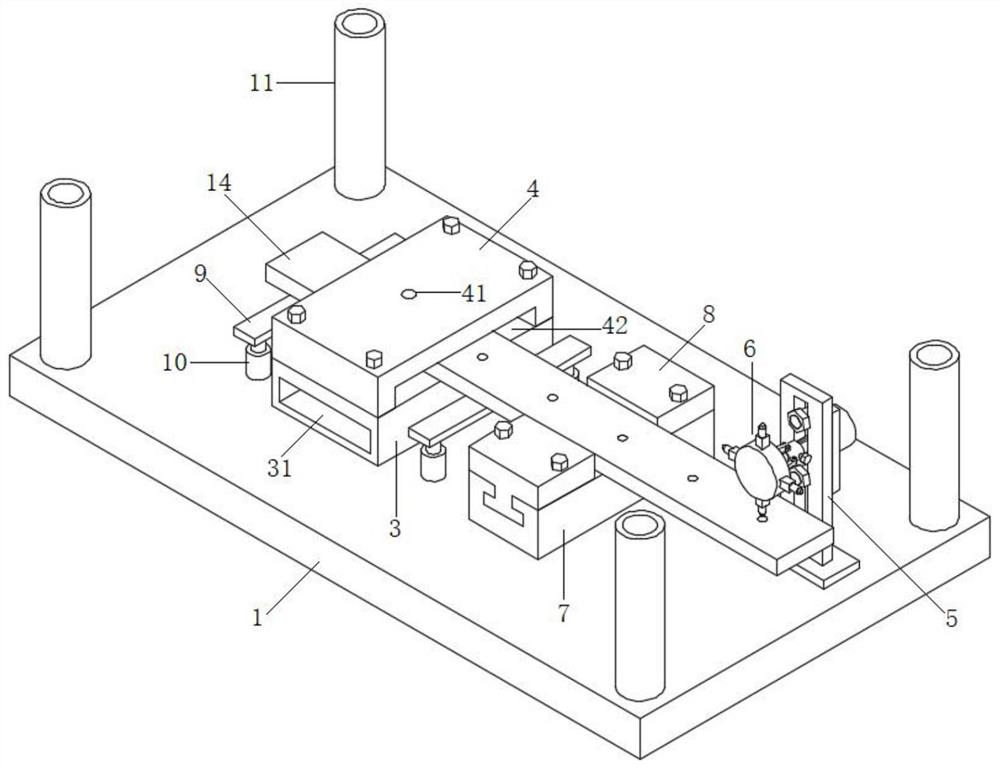

Continuous stamping and punching die for plates

InactiveCN113102607AImprove drilling efficiencyImprove drilling accuracyPerforating toolsMetal-working feeding devicesStampingElectric machinery

The invention discloses a continuous stamping and punching die for plates, and relates to the technical field of stamping dies. The continuous stamping and punching die comprises a lower die and an upper die, a punching base is fixedly connected to the lower die, a punching table is fixedly connected to the punching base, a channel for the plates to penetrate through is arranged between the punching base and the punching table, a through hole is formed in the punching table, and a punching rod is fixedly connected to the lower surface of the upper die; the lower die is fixedly connected with a vertical plate, and the vertical plate is fixedly connected with a driving device used for driving the plates to move; the driving device comprises a connecting plate, a motor is fixedly connected to the connecting plate, a rotating shaft is fixedly connected to the motor, a rotating disc is fixedly connected to the end of the rotating shaft, and a plurality of driving rods are evenly arranged on the circumferential side face of the rotating disc. The driving device is arranged on the lower die and can automatically drive the plates to move, so that the punching efficiency of the plates is improved, the punching precision of the plates is improved, and it is guaranteed that the distances between adjacent holes are the same.

Owner:HEFEI ZHENGTE MACHINERY CO LTD

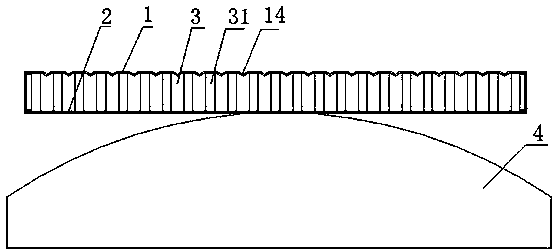

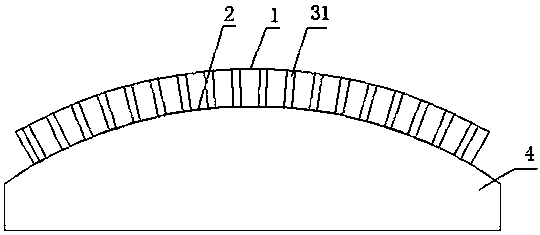

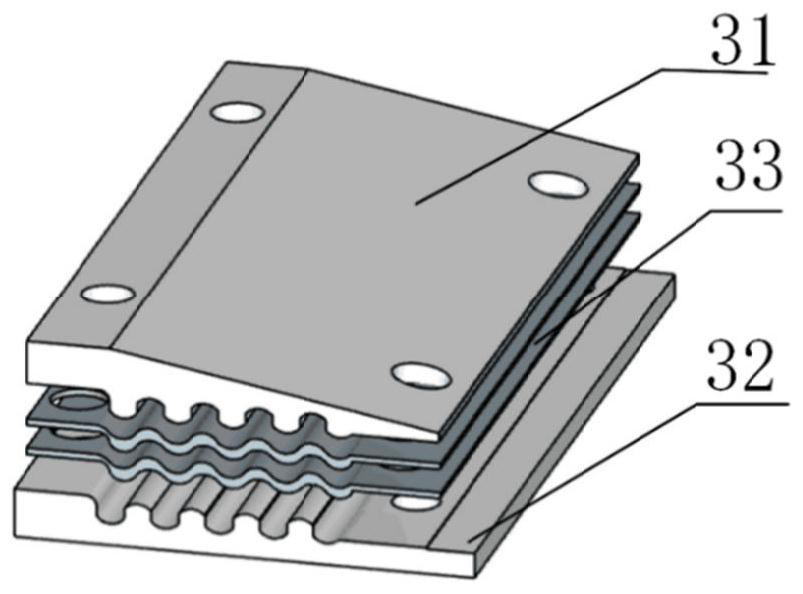

Arc-shaped brazing sandwich panel forming method

ActiveCN108080476ASame spacingGuaranteed StrengthShaping toolsSoldering apparatusStructural stabilitySandwich panel

The invention provides an arc-shaped brazing sandwich panel forming method. The method involves a first panel, a second panel and a sandwich layer arranged between the first panel and the second panel. A plurality of grooves are preset in one of the panels. After brazing, a sandwich panel is put on a die, and an arc-shaped brazing sandwich panel can be formed by means of heating and / or pressurizing. By adoption of the arc-shaped brazing sandwich panel forming method, on one hand, the effect that the distance between the first panel and the second panel is the same or basically the same can beguaranteed, and the precision and flatness after deformation are also guaranteed; and on the other hand, the deformed strength and structural stability of the sandwich panel can be ensured.

Owner:张跃

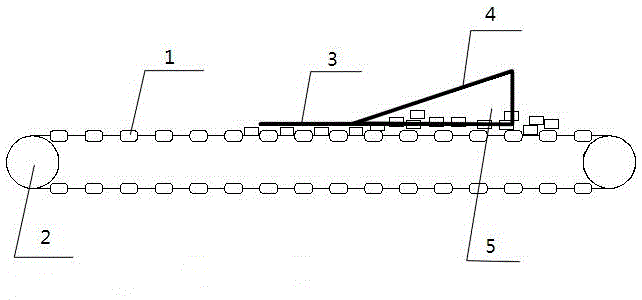

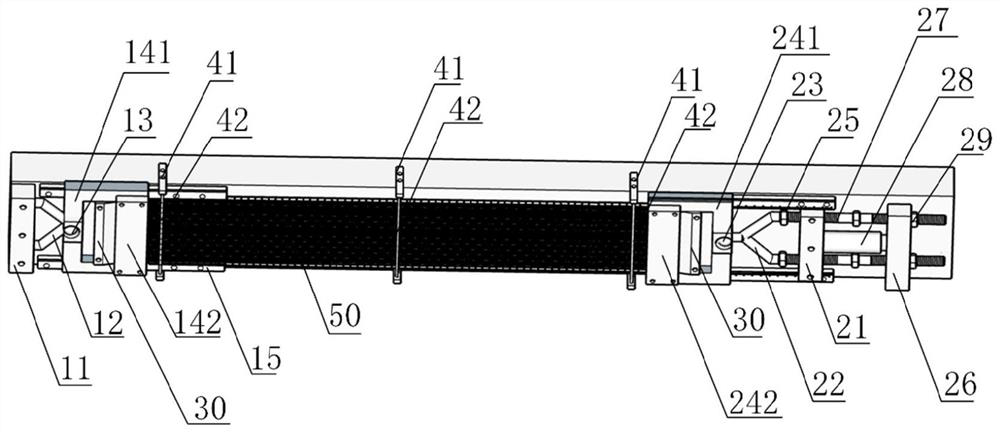

Automatic feeding mechanism for square tube puncturing machine

InactiveCN105057488AOrderly rowsSame spacingMetal-working feeding devicesPositioning devicesMotor driveEngineering

The invention provides an automatic feeding mechanism for a square tube puncturing machine, and the automatic feeding mechanism arranges materials regularly. In order to solve the technical issue, the following technical scheme is adopted by the automatic feeding mechanism for the square tube puncturing machine: the automatic feeding mechanism for the square tube puncturing machine comprises a chain conveyer belt and motors, and the motors drive the chain conveyer belt to rotate; the automatic feeding mechanism for the square tube puncturing machine is characterized in that a horizontal baffle plate is arranged on the upper layer of the chain conveyer belt, and the distance between the horizontal baffle plate and horizontal chain links of the chain conveyer belt is 2 mm higher than the minimum height of square tubes; a second baffle plate is arranged at the right end of the horizontal baffle plate; the left end of the second baffle plate is connected with the right end of the horizontal baffle plate, and the right end of the second baffle plate is higher than the horizontal baffle plate. The automatic feeding mechanism for the square tube puncturing machine has the beneficial effects that the square tubes are embedded in the chain links under the action of the force of the chain conveyer belt to be conveyed; the effect of arranging the square tubes is achieved; the square tubes are arranged regularly with same distances, and manual work is saved.

Owner:苏州金牛精密机械有限公司

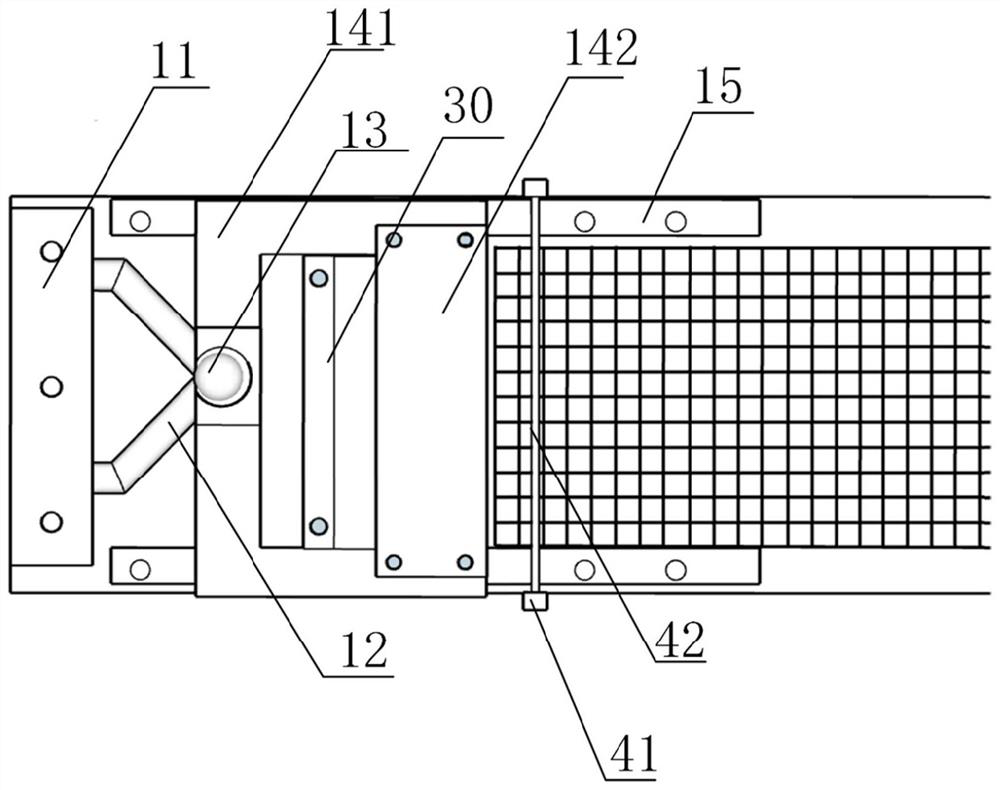

TRC prestress implementation device and construction method for reinforcing RC component by using TRC prestress implementation device

ActiveCN111794519AStrong anchoring forceAvoid cutsBuilding repairsBuilding reinforcementsFiberStructural engineering

The invention discloses a TRC prestress implementation device and a construction method for reinforcing an RC component by using the TRC prestress implementation device. The TRC prestress implementation device comprises an anchoring mechanism, a tensioning mechanism, a plurality of layered positioning mechanisms and a fiber net clamp; the anchoring mechanism comprises a first anchoring crosspiece,a first centering mechanism and a first self-locking box; the tensioning mechanism comprises a second anchoring crosspiece, a second centering mechanism, a second self-locking box and a tensioning driving assembly; the fiber net clamp is wedge-shaped and comprises a clamp cover plate and a clamp bottom plate which are detachably connected; and the plurality of layered positioning mechanisms are uniformly distributed between the anchoring mechanism and the tensioning mechanism and are used for equidistantly distributing each layer of fiber net in the plurality of layers of fiber nets. According to the TRC prestress implementation device and the construction method for reinforcing the RC component by using the TRC prestress implementation device, prestress application to the plurality of layers of fiber nets can be completed on a construction site without large complex equipment, RC component reinforcement through the prestress TRC is achieved, the whole implementation device is simple,the process flow is concise, construction is convenient, popularization is easy, and the device and the construction method have good application prospects and economic value in the field of engineering reinforcement.

Owner:HOHAI UNIV

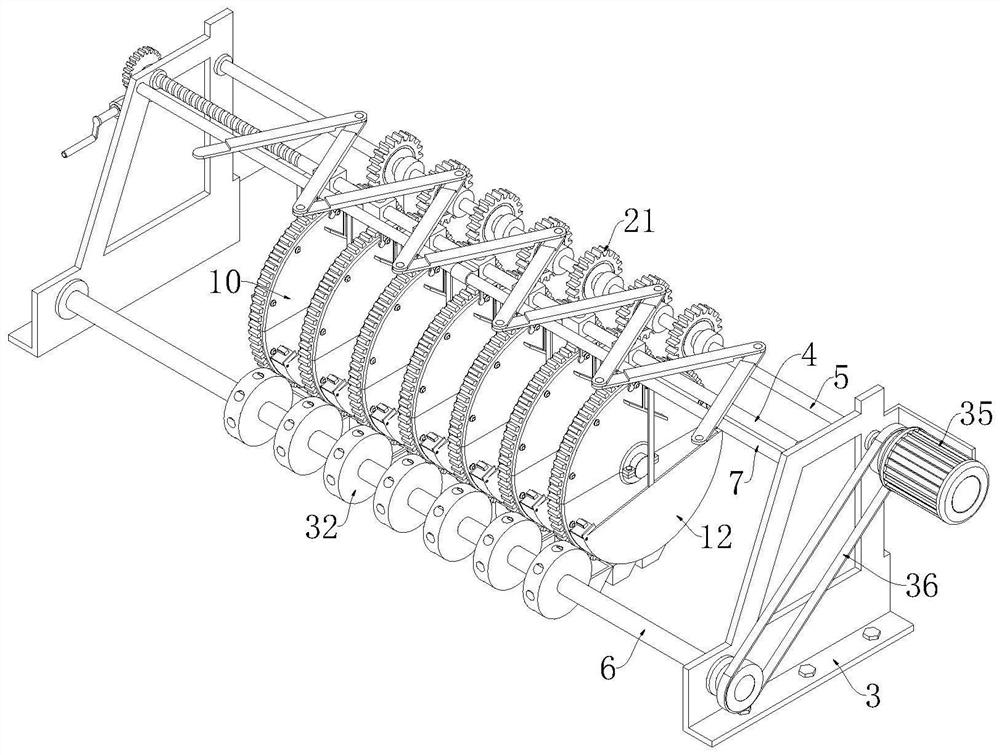

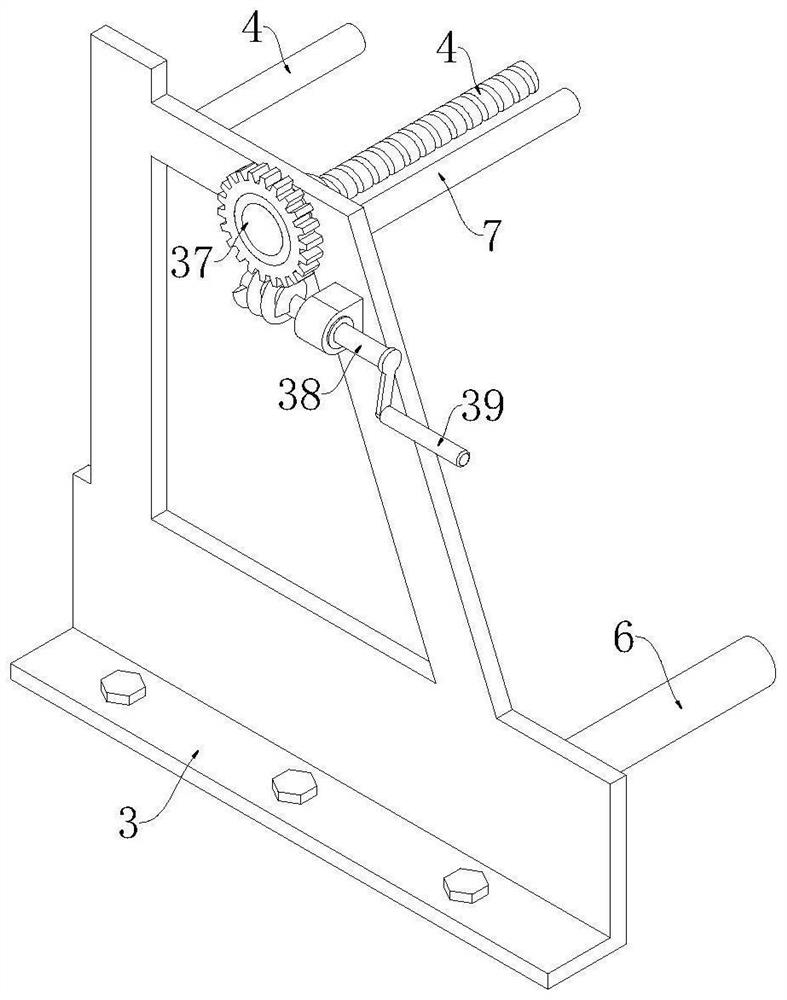

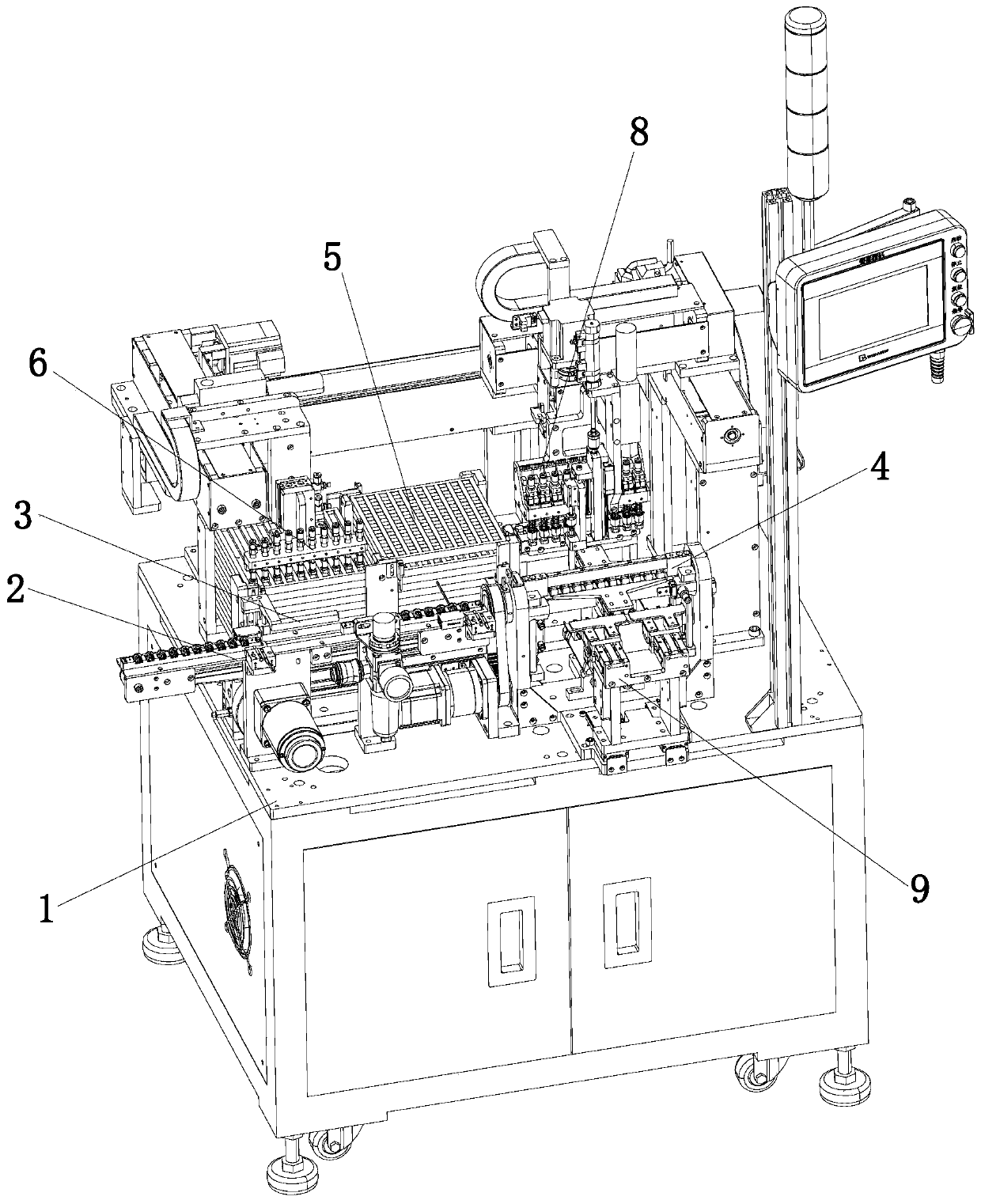

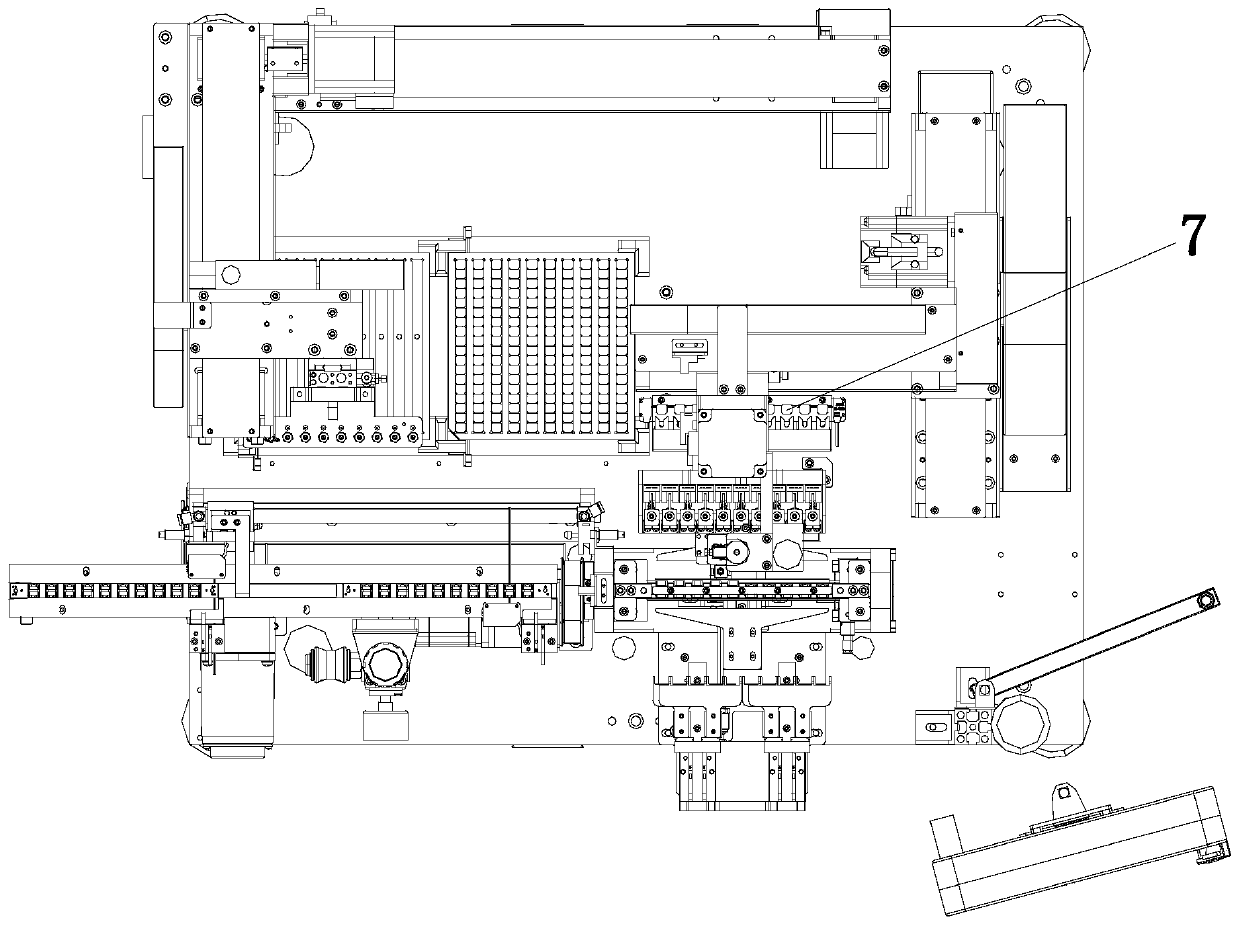

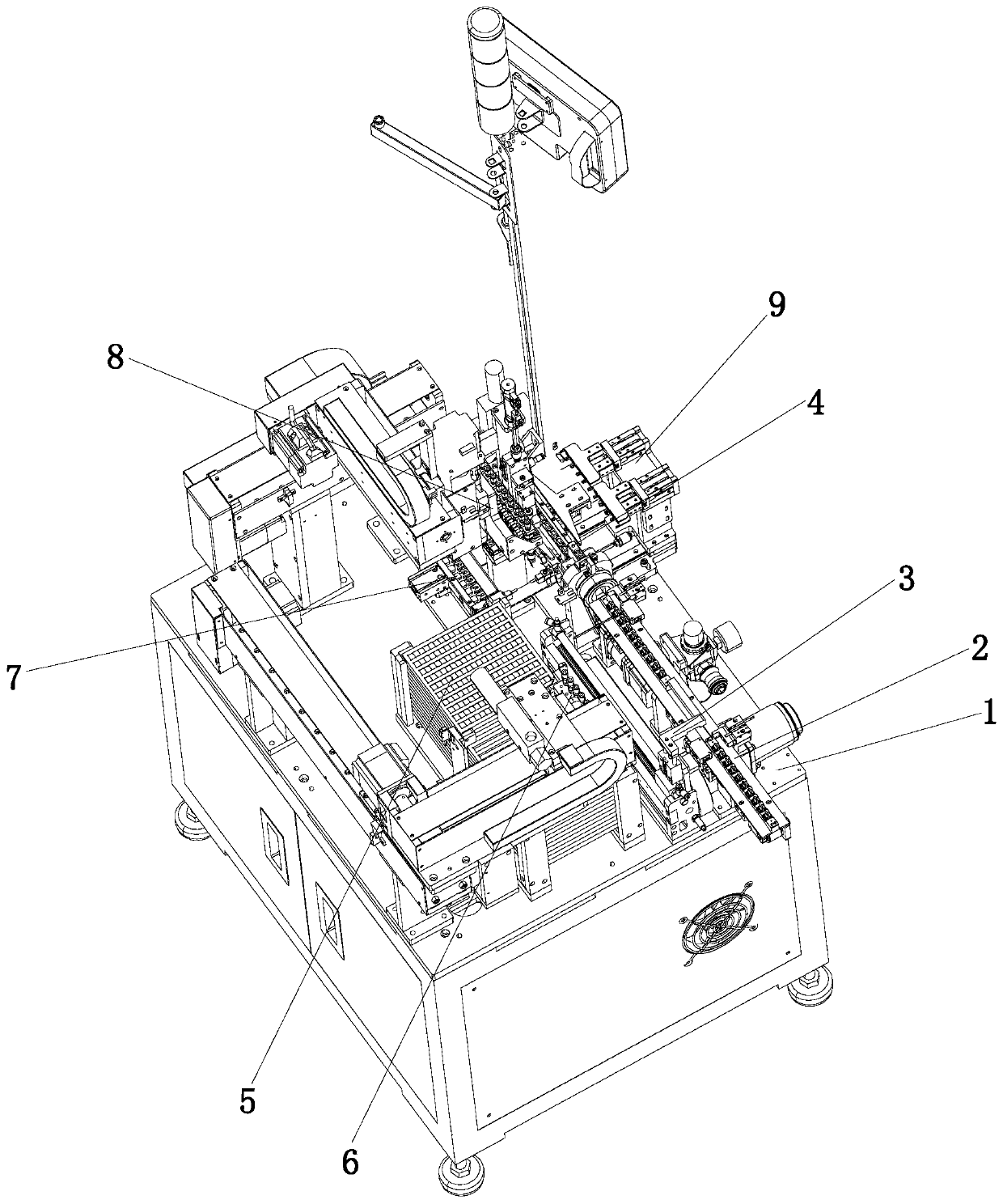

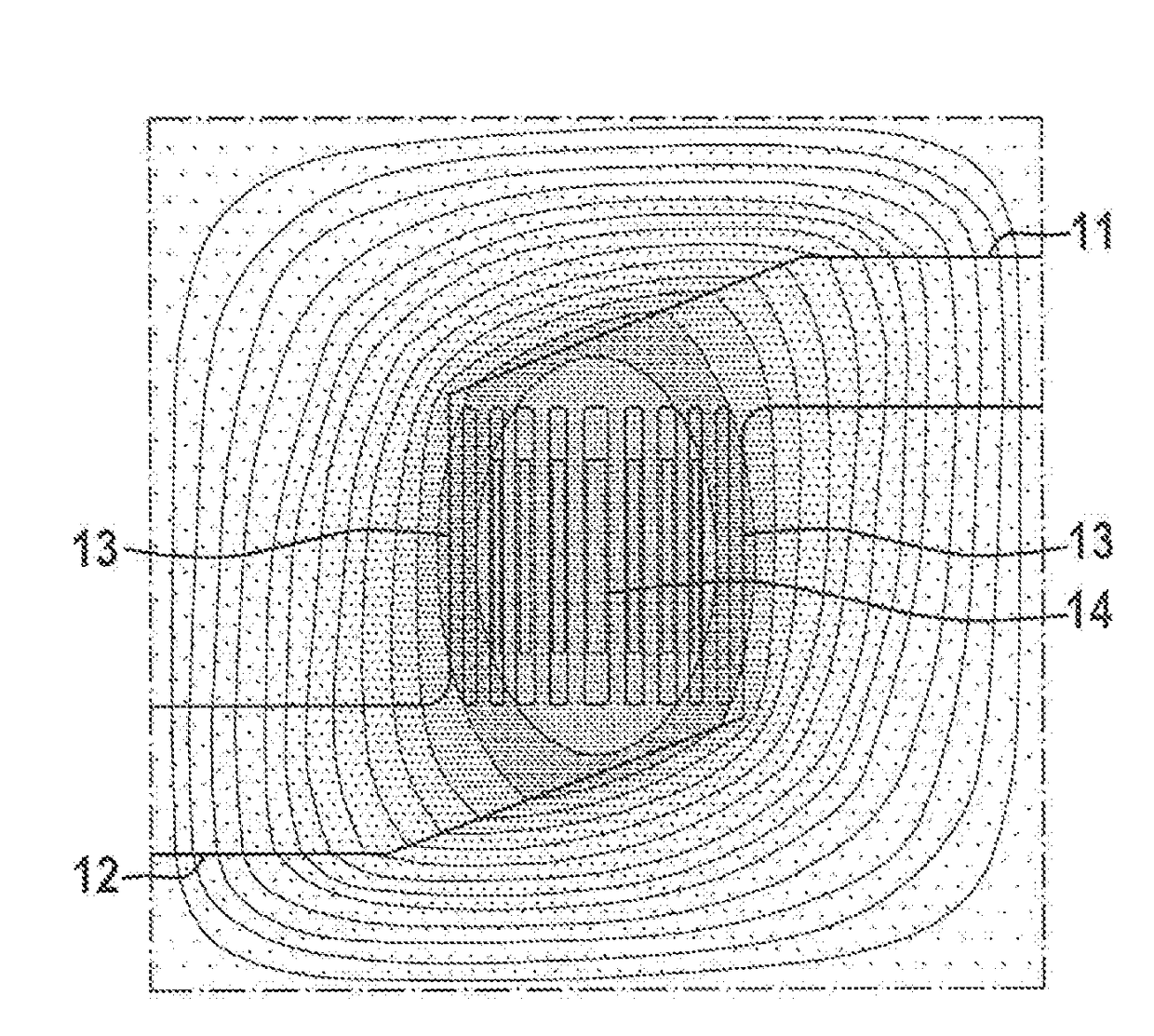

Magnetic core assembling machine

PendingCN110931240ANot easy to scratchImprove work efficiencyInductances/transformers/magnets manufactureEngineeringMechanical equipment

The invention provides a magnetic core assembling machine, and belongs to the technical field of mechanical equipment, the assembling machine comprises a machine shell, a feeding belt mechanism, a jigscraping mechanism, a rotary assembling mechanism, a material ejecting disc mechanism, a carrying mechanism, a correcting mechanism, a three-axis assembling mechanism and a correcting mechanism. Thefeeding belt mechanism is arranged at the top of the machine shell. The scraping jig mechanism is arranged at the rear end of the feeding belt mechanism; the rotary assembling mechanism is arranged atthe right end of the feeding belt mechanism; the material ejecting disc mechanism is arranged at the rear end of the scraping jig mechanism; the carrying mechanism is arranged beside the material ejecting disc mechanism. The correcting mechanism is arranged at the right end of the material ejecting disc mechanism; the three-axis assembling mechanism is arranged above the correcting mechanism, thecorrecting mechanism is arranged at the front end of the rotary assembling mechanism, and the problems that when an existing magnetic core assembly machine is used, only one magnetic core can be assembled at a time, the working efficiency is low, coils are prone to being scratched by the magnetic cores, and poor voltage resistance is caused are solved.

Owner:东莞市镕泰自动化设备有限公司

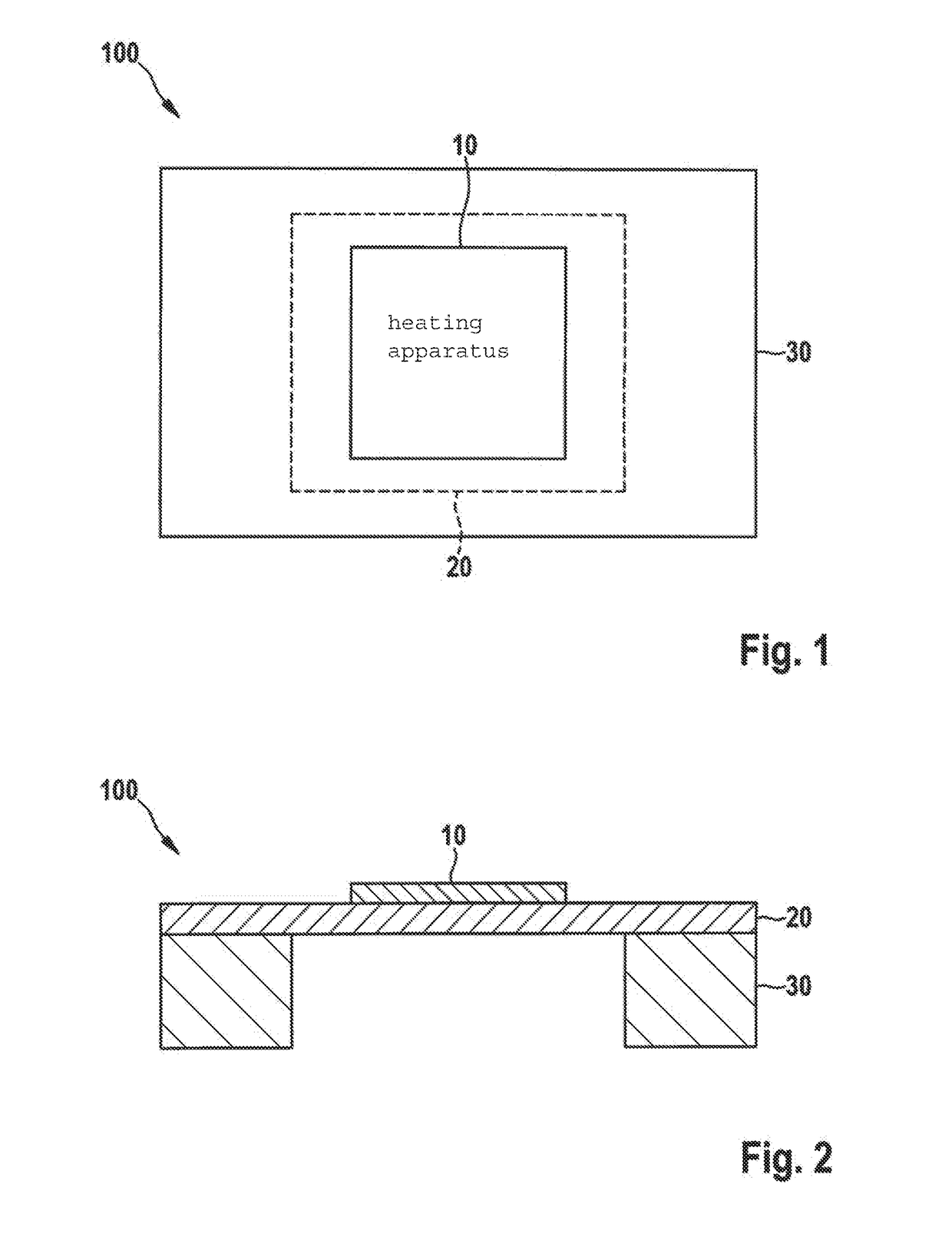

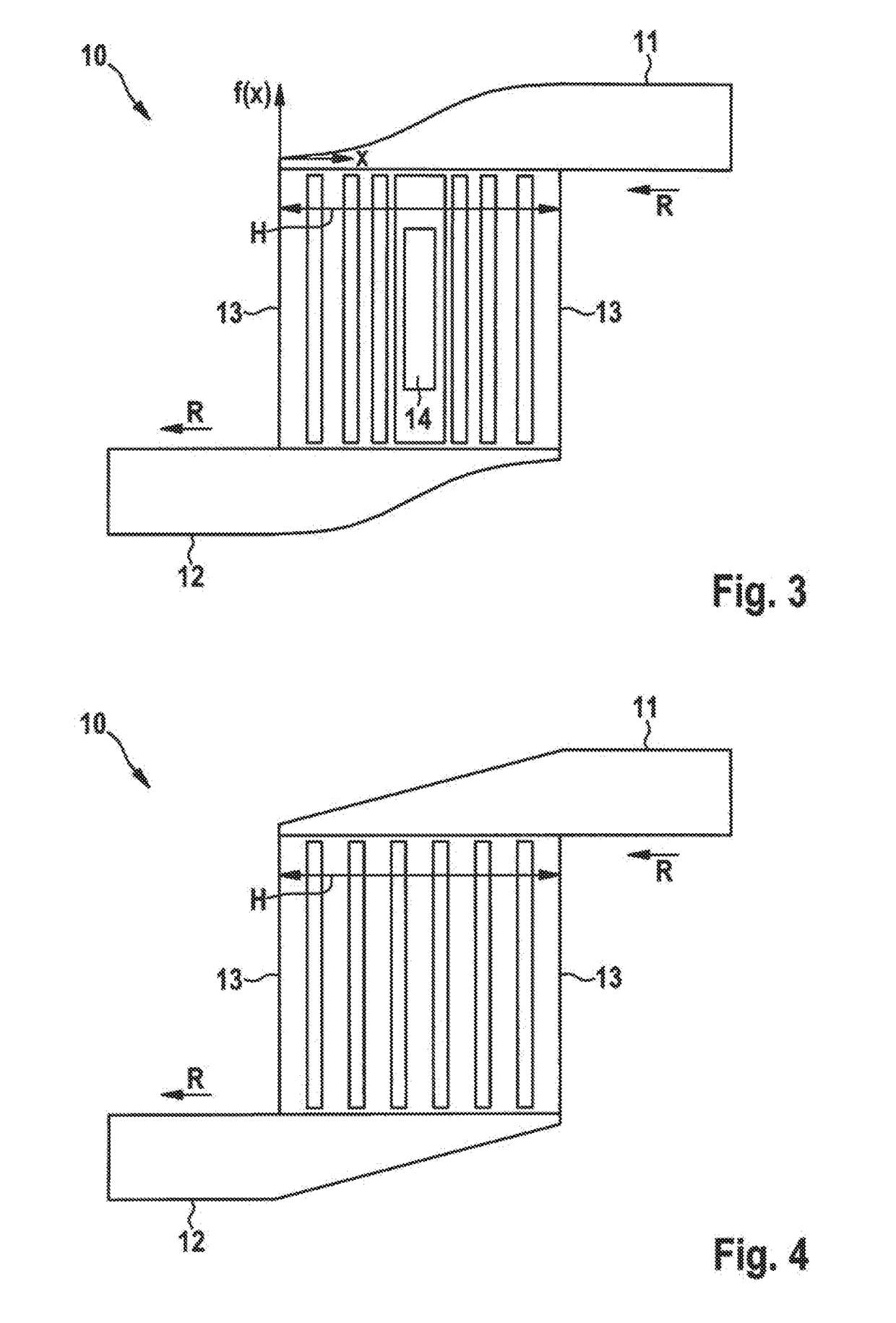

Heating apparatus for a MEMS sensor

ActiveUS20170129768A1Increase widthReduce widthAnalysing gaseous mixturesHeating element materialsPower flowEngineering

A heating apparatus for a MEMS sensor, comprising a metallic supply lead element for electric current; a metallic return lead element for electric current; and a defined number of metallic heating elements configured between the supply lead element and the return lead element, a substantially constant electrical current density being configurable in the supply lead element, in the return lead element, and in the heating elements.

Owner:ROBERT BOSCH GMBH

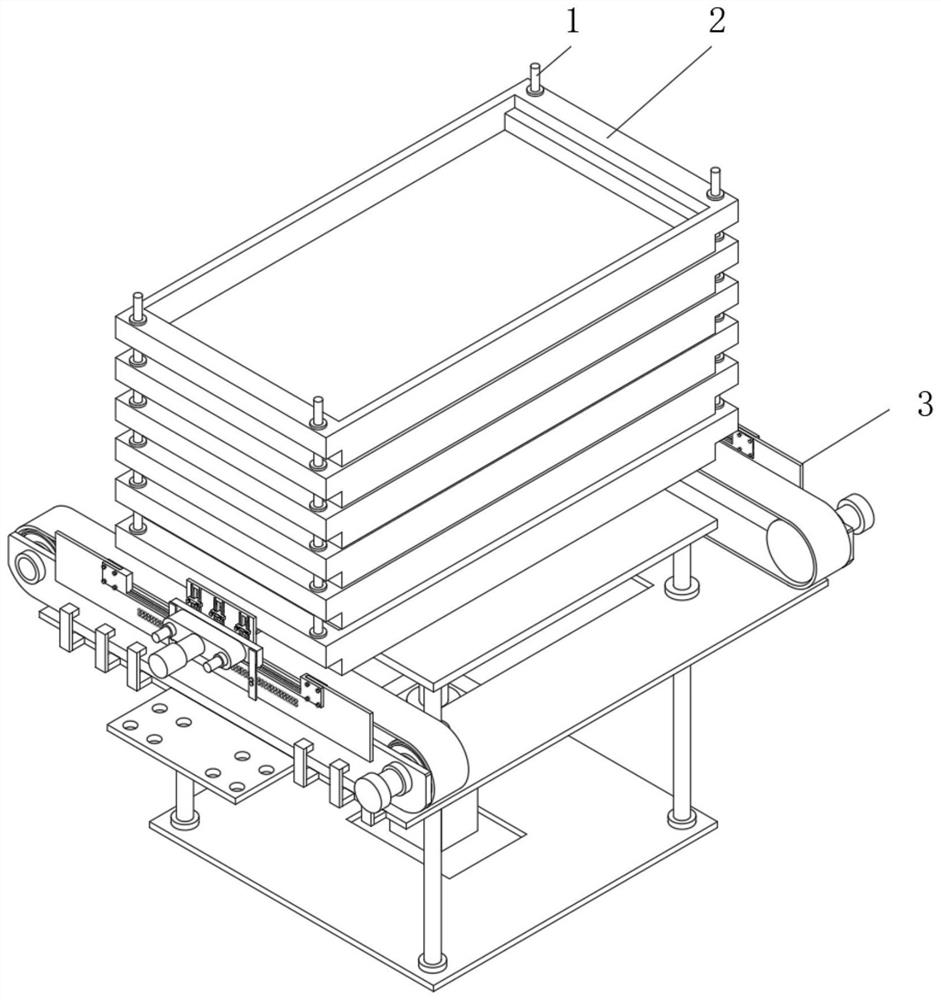

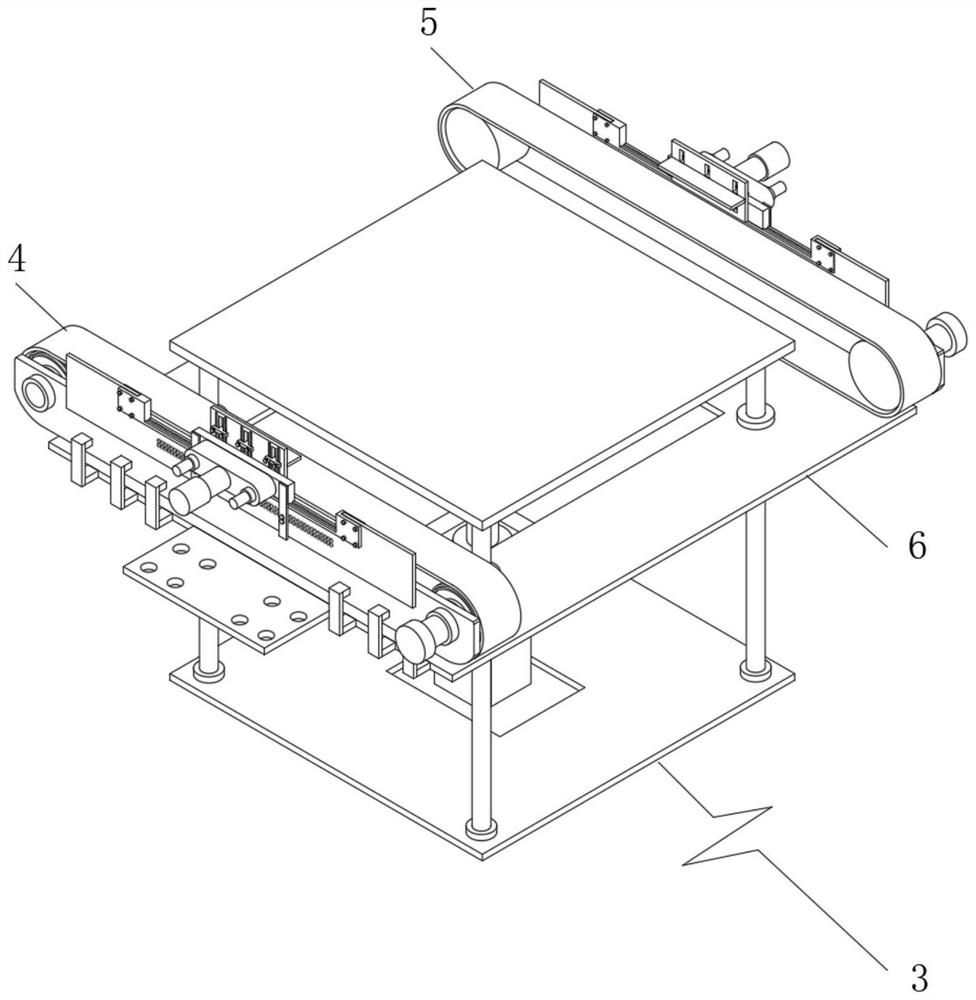

Automatic tray separating and conveying device

ActiveCN112499279ASame spacingQuick detach useDe-stacking articlesHydraulic cylinderElectric control

The invention discloses an automatic tray separating and conveying device which comprises trays and a separating mechanism, wherein the trays are stacked above the separating mechanism; supporting columns are symmetrically and fixedly mounted at the two ends of each tray, and the trays are inserted into slot holes in the bottoms of the trays through the supporting columns to be stacked; and the separating mechanism comprises a first blocking conveying main body, a second blocking conveying main body and a supporting device. In the using process, lifting of the supporting plate is controlled through a main electric control hydraulic cylinder, and transverse stretching and retracting of a supporting blocking plate is controlled through an auxiliary electric control hydraulic cylinder to workin a coordinated and matched mode, so that stacked trays are separated to a conveyor belt one by one from the lower portion to be conveyed, and spacing between the trays separated and conveyed on theconveyor belt is guaranteed to be the same, and thus, the trays stacked together can be rapidly separated and used, time and labor are saved, and the separated trays are equidistant and convenient touse.

Owner:SHANDONG BIHAI MASCH TECH CO LTD

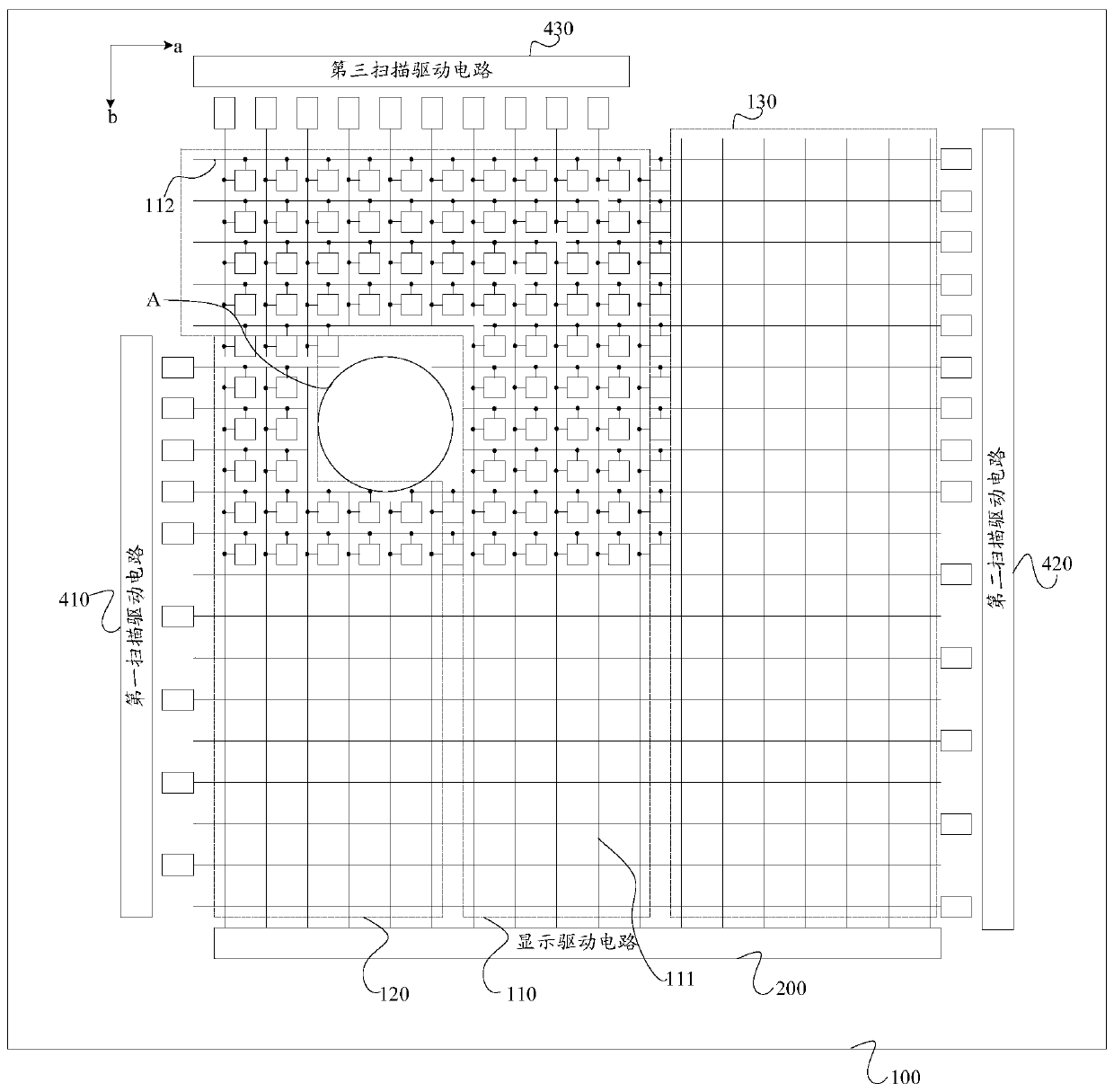

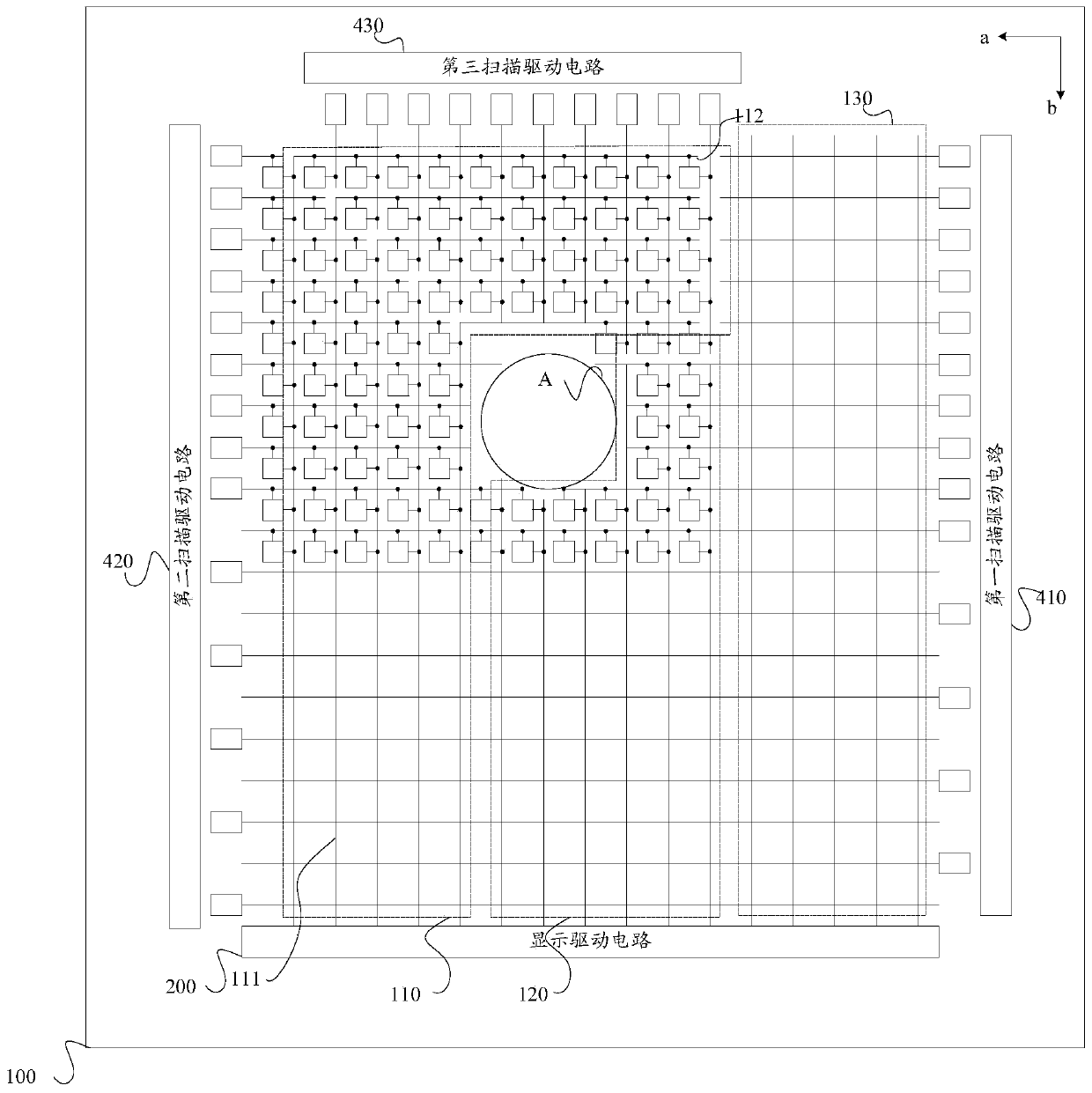

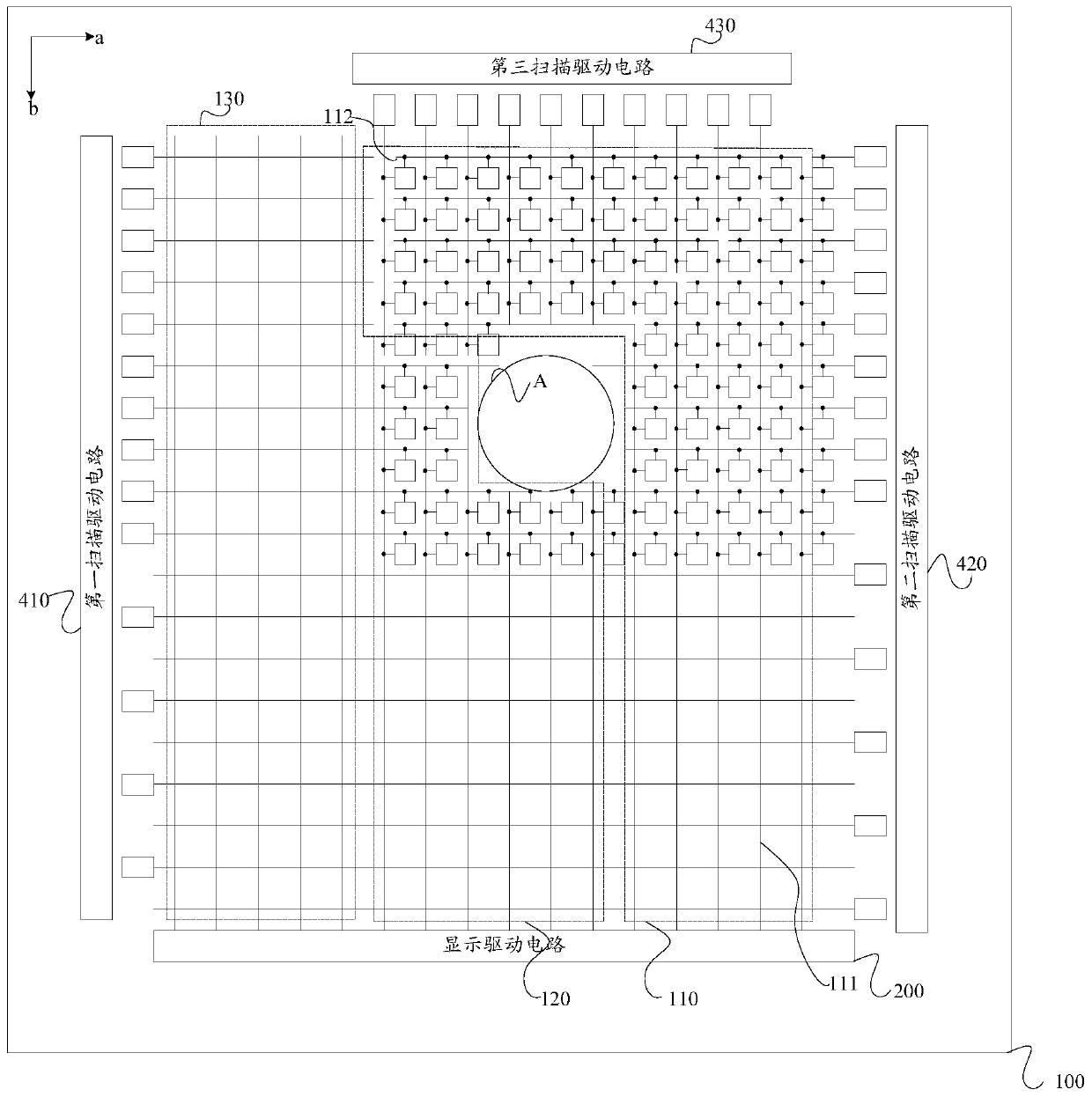

Array substrate and driving method thereof, display panel and display device

ActiveCN109739058AAvoid crosstalkAvoid settingStatic indicating devicesSolid-state devicesDisplay deviceEngineering

The invention discloses an array substrate and a driving method thereof, a display panel and a display device. By changing a wiring way of data lines on the periphery of a hole digging area, the datalines on the periphery of the hole digging area are divided into first data lines and second data lines, the first data lines are changed into an L-shaped wiring mode, namely the first data lines aredivided into first branches extending in a second direction and second branches extending in a first direction, and meanwhile, in order to avoid the phenomenon that the second branches of the first data lines are mutually crossed with the second data lines to cause signal interference, the second data lines extending in the second direction are stopped at the second branches to form certain separation distances with the second branches, and accordingly a problem of mutual crosstalk of data signals is avoided. The wiring way of the data lines on the periphery of the hole digging area is changed, so that signal lines with small intervals at a frame of the hole digging area can be avoided, and thus more severe coupling problems produced in a charging process can be decreased, and the color cast problem under a condition of heavy load pictures can be avoided.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Automatic buckle machine for blade barbed wire

The invention relates to the technical field of barbed wire assembly equipment, and provides an automatic buckle machine for a blade barbed wire. The automatic buckle machine comprises a base, whereina buckle delivery device, an intermittent buckle conveying device, a quantitative wire separation device, a locking device and a barbed wire bearing frame are additionally arranged on the base; the buckle delivery device comprises an upper buckle plate and a rail connected with the upper buckle plate; the intermittent buckle conveying device is arranged on the base and located at one side of therail; the locking device and the quantitative wire separation device are sequentially arranged at the tail end of the rail; the barbed wire bearing frame is arranged below the quantitative wire separation device and the locking device; the locking device comprises a first caliper lever, a second caliper lever, a first driving device and a second driving device, the first caliper lever is hinged tothe second caliper lever, the first caliper lever is hinged to the base, and the first driving device and the second driving device are arranged on the base; the first caliper lever swings around a hinge point on the base through the first driving device; and the second caliper lever is meshed with the first caliper lever through the second driving device. Through the technical scheme, the problems that in the prior art, manual installation of the blade barbed wire is low in efficiency, and a potential safety hazard exists in installation are solved.

Owner:石家庄市东春机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com