Method for guaranteeing mounting accuracy of tray internal part support ring of pressure container

A technology for pressure vessels and installation accuracy, which is applied in chemical instruments and methods, chemical/physical/physical-chemical processes, chemical/physical processes, etc. It can solve the problem that the distance between support rings is difficult to meet the requirements, achieve flatness and improve assembly Speed, the effect of shortening the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

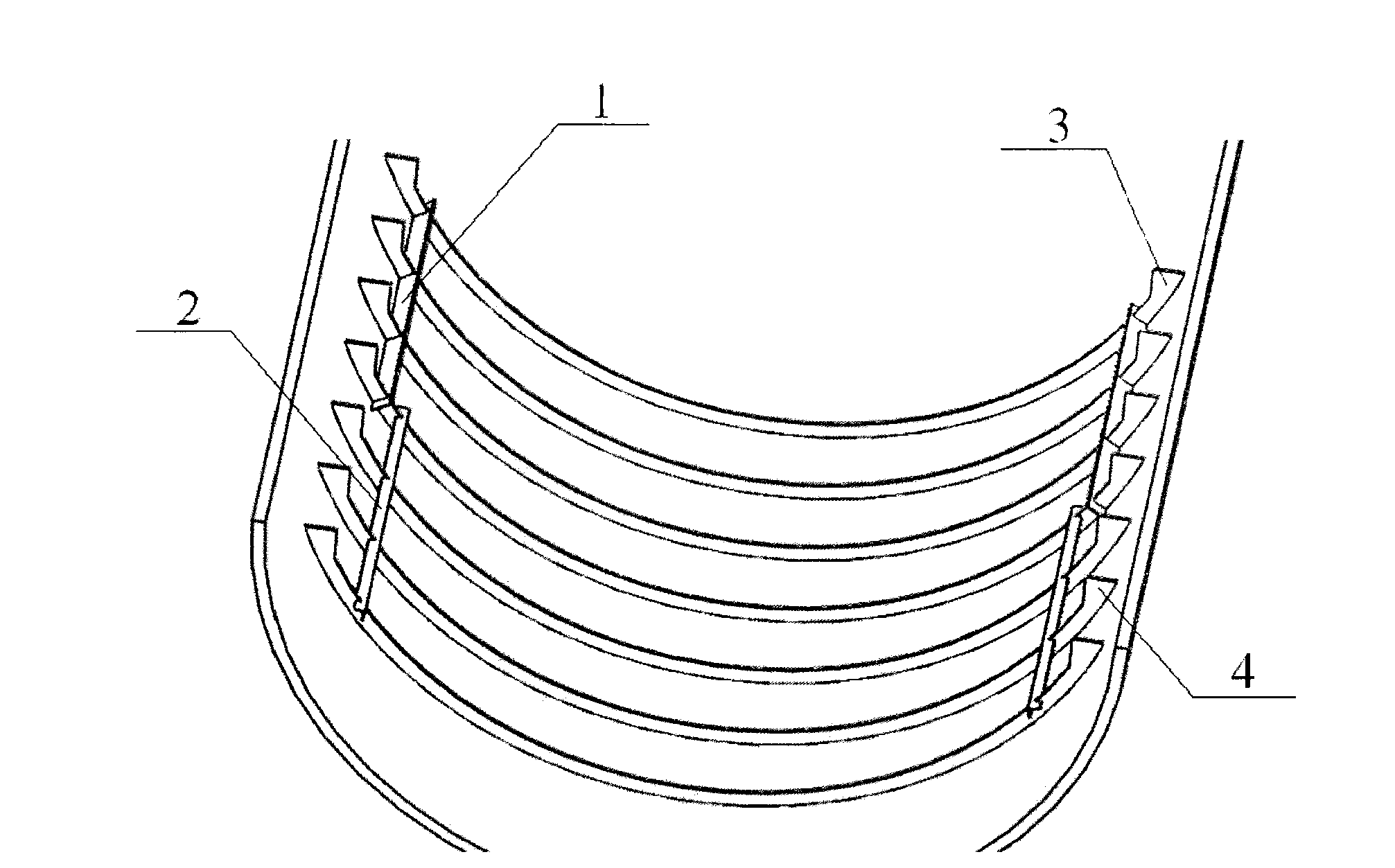

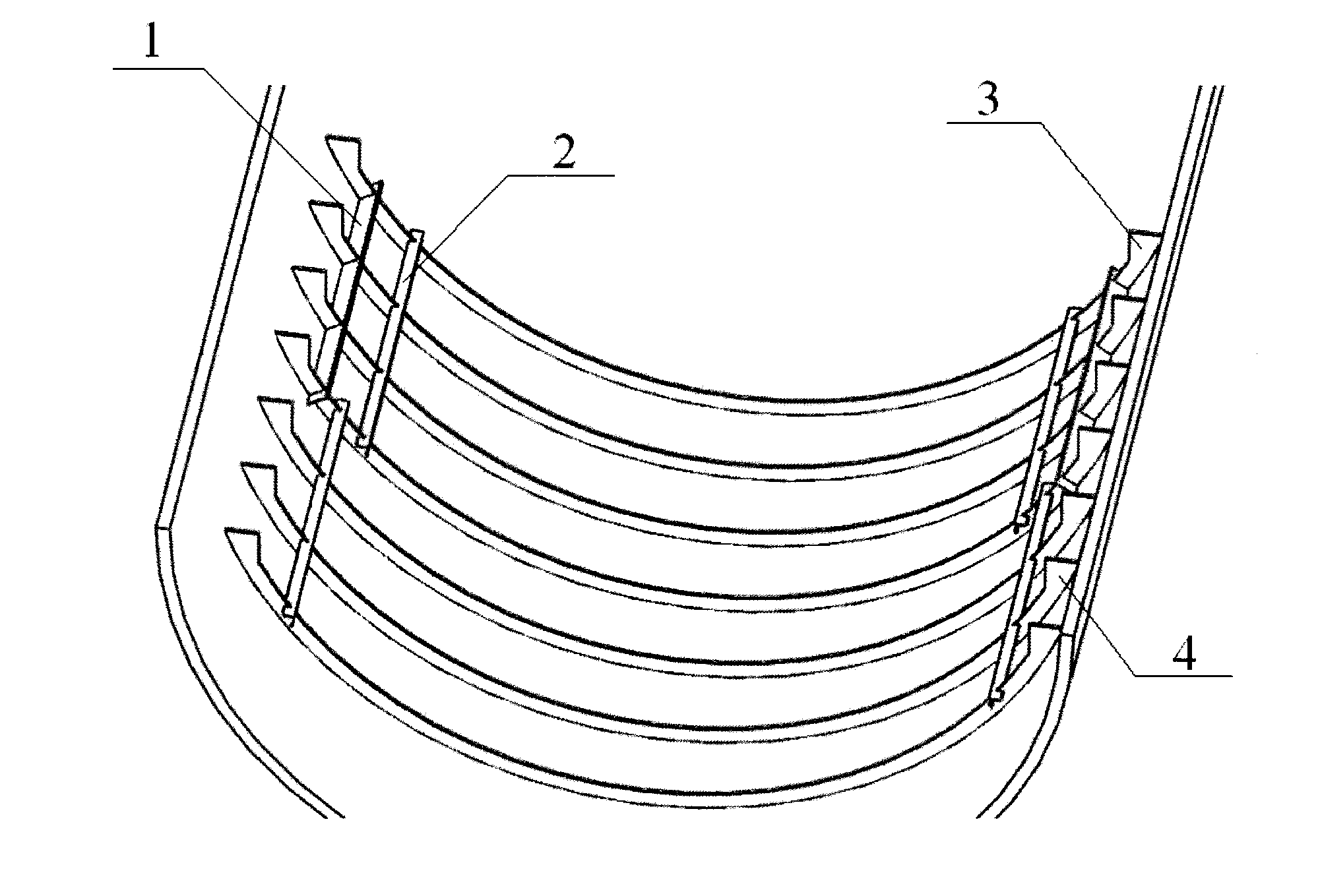

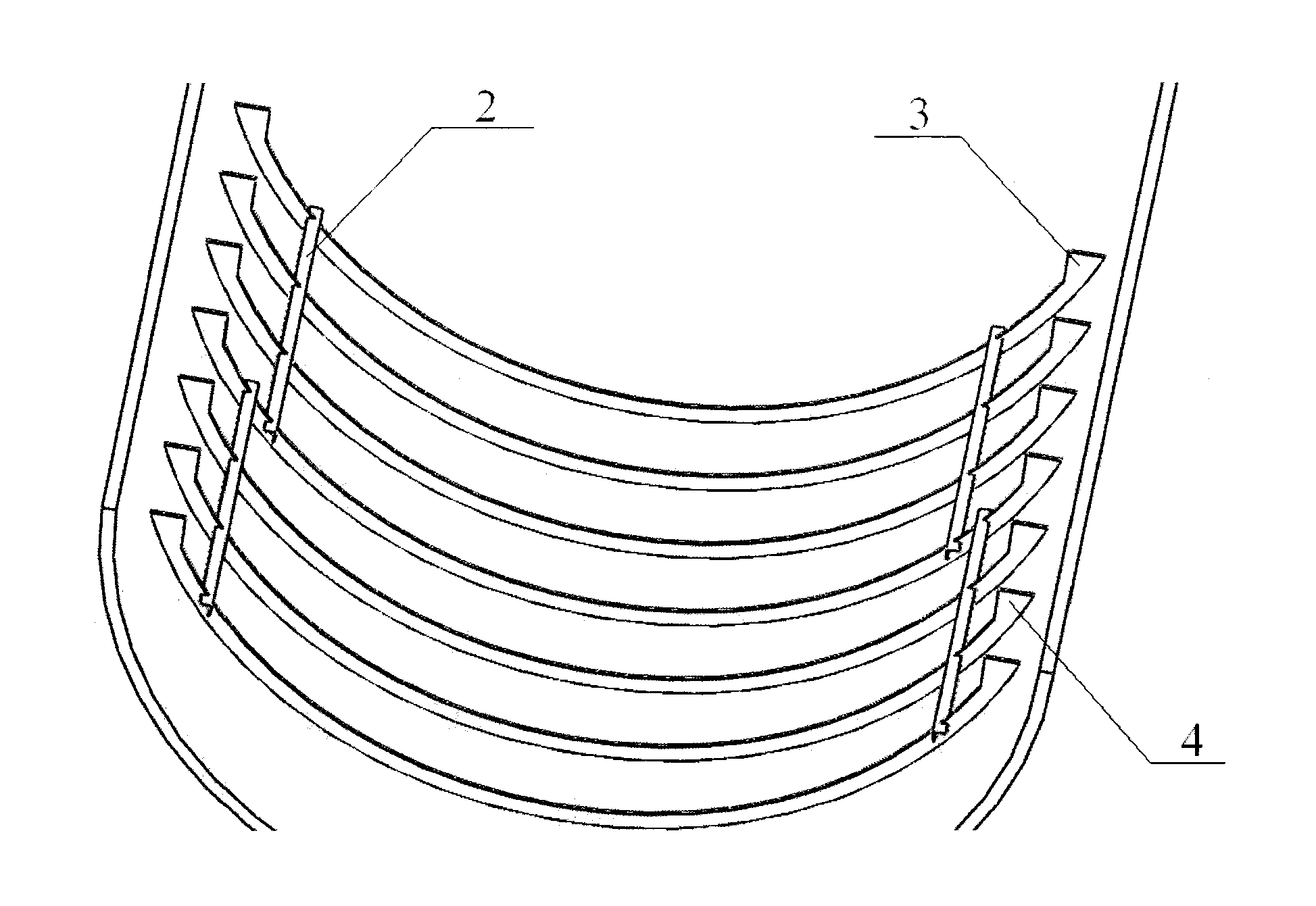

[0023] The invention is a method for ensuring the installation accuracy of the supporting ring of the inner part of the pressure vessel tray, such as Figure 1 ~ Figure 3 shown, including the following steps:

[0024] Step 1: Simultaneously clamp both ends of the supporting ring 3 of the adjacent layer through the slots on the two measuring clamps 1;

[0025] Step 2: Use the slot on the positioning angle 2 to clamp the support ring 3 that was previously clamped by the slot on the measuring clamp 1;

[0026] Step 3: Fix the support ring 3 and the positioning angle steel 2 together by spot welding to form the support ring group 4;

[0027] Step 4: Remove the measuring clamp 1 from the support ring 3;

[0028] Step 5: If you want to continue to fix the support ring 3, proceed to steps 6 and 7; otherwise, install the fixed support ring 3 on the tower tray, remove all the positioning angle steel 2 after heat treatment, and the installation is completed.

[0029] Step 6: Clamp a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com