Automatic feeding mechanism for square tube puncturing machine

An automatic feeding and punching machine technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of irregular materials, difficult to arrange neatly, easy to produce deviations in punching, etc., to achieve the same spacing, arrangement Neat and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing:

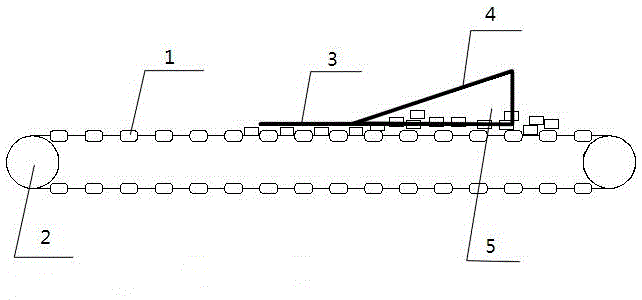

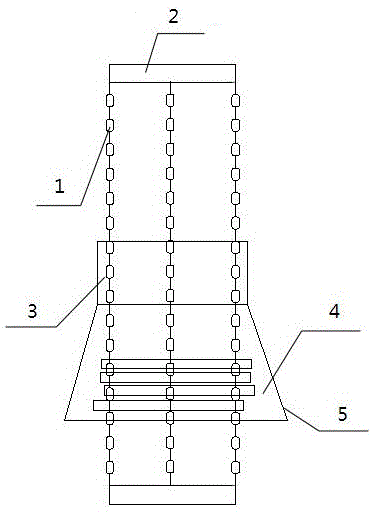

[0013] An automatic feeding mechanism for a square tube punching machine, including a chain conveyor belt and a motor. The motor drives the chain conveyor belt to rotate. It is characterized in that a horizontal baffle is set above the upper chain conveyor belt. The distance is 2mm higher than the minimum height of the square tube; a second baffle is set at the right end of the horizontal baffle, the left end of the second baffle is connected with the right end of the horizontal baffle, and the right end of the second baffle is higher than the horizontal baffle , the chain pitch is greater than the width of the square tube, the side of the chain conveyor is provided with a side baffle, the left end of the side baffle is connected to the right end of the horizontal baffle, and the distance from the right end of the side baffle to the chain conveyor is longer than the length o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com