Arc-shaped brazing sandwich panel forming method

A forming method and panel technology, applied in forming tools, welding equipment, manufacturing tools, etc., can solve problems such as inconsistent spacing between upper and lower panels, inaccurate pressing, and poor compression resistance, and achieve accurate and flat deformation, simplified process, and accurate deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

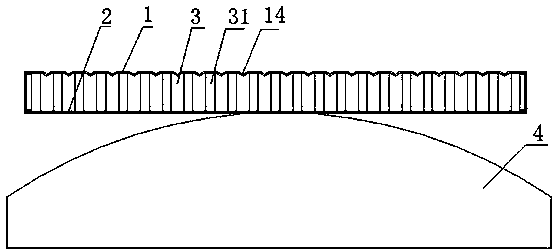

[0039] Such as figure 1 Shown: a method for forming an arc-shaped brazing sandwich panel, including a first panel 1, a second panel 2 and a sandwich layer 3, and the sandwich layer 3 is arranged between the first panel 1 and the second panel 2 to form A sandwich panel with a planar structure; the first panel 1 is provided with several grooves 14 arranged at intervals, and the second panel 2 is a smooth panel without grooves.

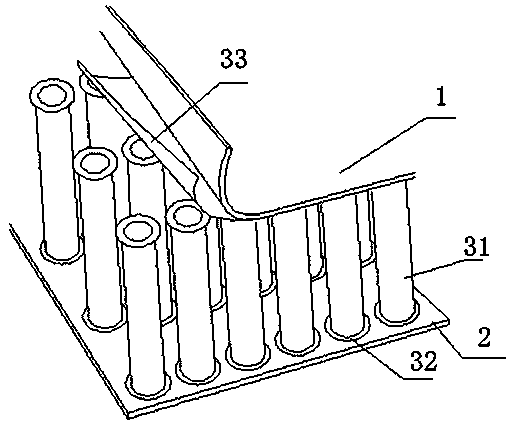

[0040] Specifically, such as figure 2 As shown: the sandwich layer 3 includes a plurality of hollow tubes 31 , and a brazing layer is provided between the hollow tubes 31 and the first panel 1 and the second panel 2 . The two ends of the hollow tube 31 are provided with flanges 32, which are turned out into a circular structure. The flange 32 of the hollow tube 31 is connected to the first panel 1 and the second panel 2 by soldering 33 . The cross section of the hollow tube 31 is circular, and the hollow tube 31 is a hollow cylindrical tube. A plura...

Embodiment 2

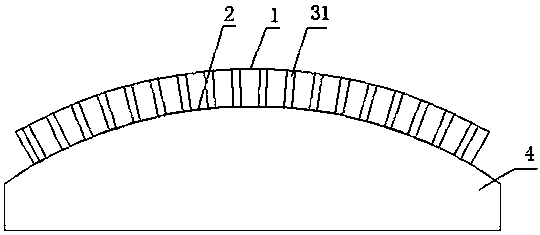

[0047] Such as Figure 4 and Figure 5Shown: the difference with embodiment 1 is that the molding process of making the sandwich panel into a curved sandwich panel comprises the following steps:

[0048] S2-1: Place the sandwich panel between the upper mold 5 and the lower mold 4 of the arc structure.

[0049] Specifically, the shape of the contact surface of the upper mold 5 and the lower mold 4 in contact with the sandwich panel is the same as the target shape of the required deformation of the sandwich panel. Among them, the second panel 2 is in contact with the lower mold 4, and the first panel 1 is in contact with the upper mold 5. In this way, during the thermal deformation process, an upward force will be generated, and the upper mold 5 will also generate a downward force on the first panel 1. bending force.

[0050] S2-2: The sandwich panels are heated so that the grooves are elongated, and the first panel and the second panel are thermally deformed into a desired s...

Embodiment 3

[0053] Such as Figure 6 Shown: The difference from Embodiment 1 is that the first panel 1' is a smooth panel without grooves, and the second panel 2' is provided with several grooves 14' arranged at intervals. The cross-sectional shape of the groove 14' is trapezoidal, i.e. forms a corrugated board structure.

[0054] Such as Figure 7 Shown: The molding process of sandwich panels to make curved sandwich panels includes the following steps:

[0055] S3-1: Put the sandwich panel on the rolling equipment 6 .

[0056] Specifically, the rolling equipment 6 includes a transmission mechanism 61 and at least one set of upper rollers 62 located above the transmission mechanism and lower rollers 63 located at the bottom of the transmission mechanism, the sandwich panel is placed on the transmission mechanism and positioned on the upper rollers 62 and the lower roller 63 , the first panel 1 ′ faces the upper roller 62 , and the second panel 2 ′ faces the lower roller 63 .

[0057] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com