Method for adhering face brick of building

A decorative brick and construction technology, applied in the direction of construction, building construction, etc., can solve problems such as low water absorption and engineering quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

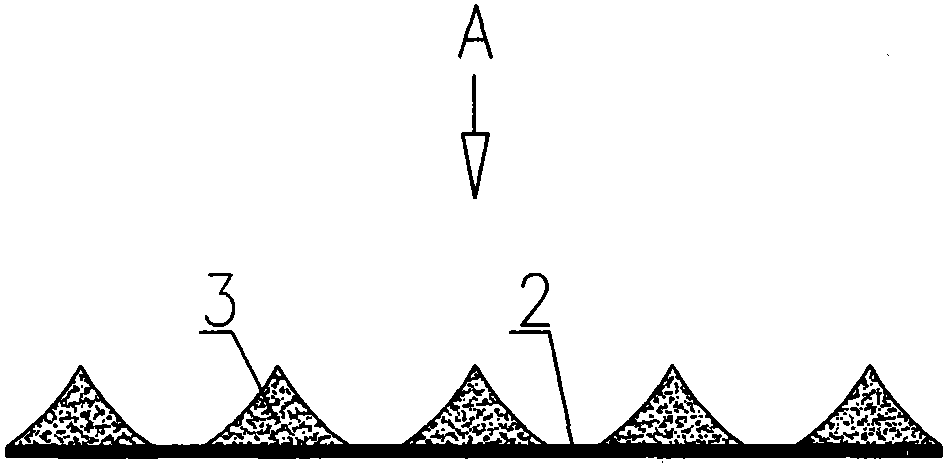

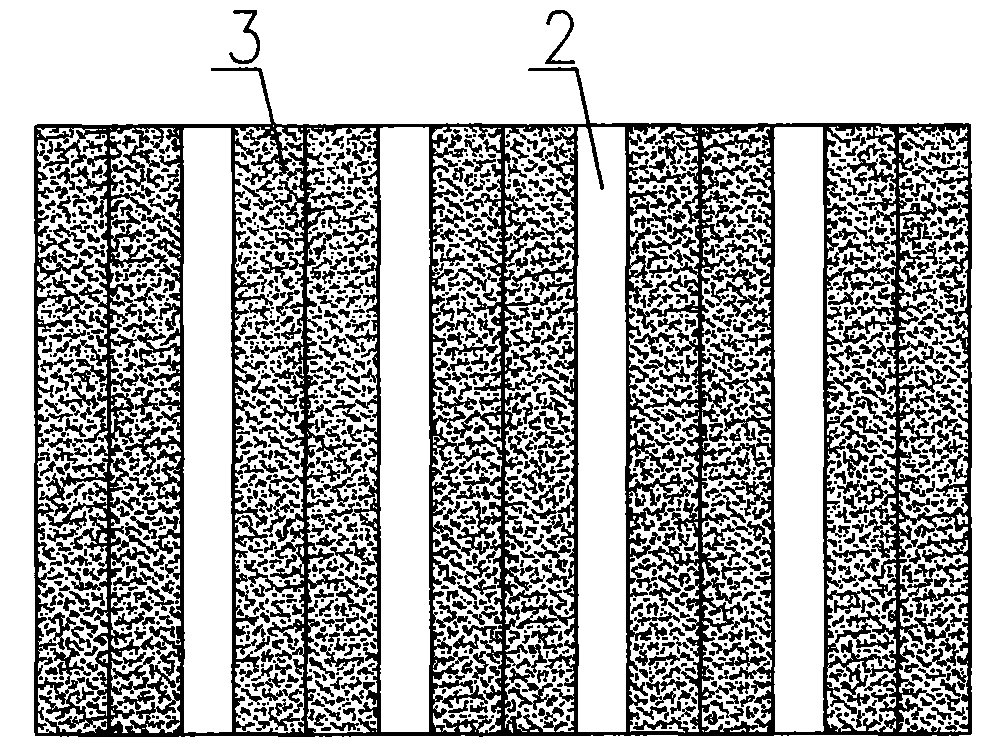

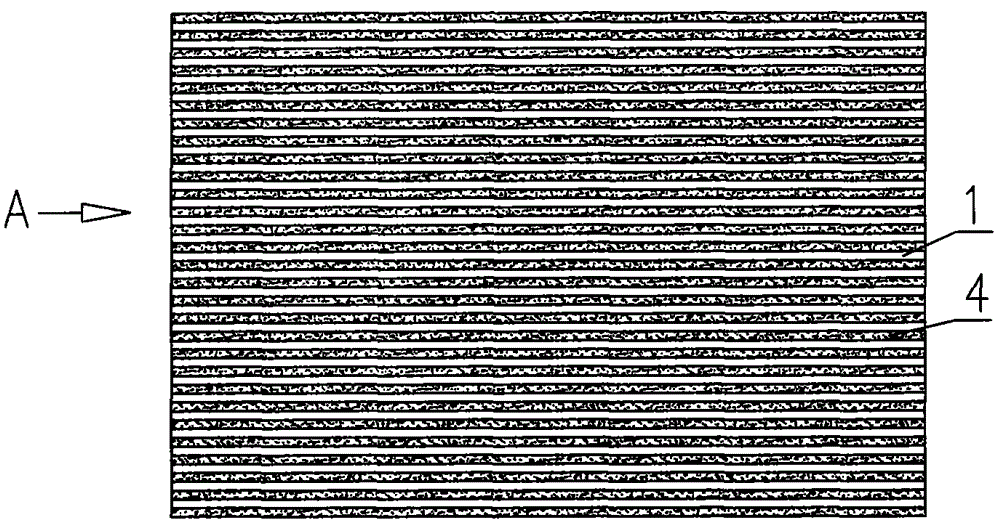

[0015] First clean up the surface of the wall base (1) and the back of the decorative brick (2), and then use an iron trowel to fully coat the pre-prepared bonding material on the wall base (1), and the application area can be larger. Press the bonding material into a ditch shape on the back of the facing brick (2) (see figure 1 , figure 2 ), the bonding material (3) in the shape of each furrow is basically perpendicular to the ground; the height of the furrow is 20-80mm; the width of the bottom of the furrow is 80-100mm; Certainly. Then use a sawtooth trowel to comb the bonding material on the base of the wall horizontally, so that the bonding material on the surface of the base of the wall forms a strip-shaped structure bonding material layer (4) (see image 3 , Figure 4 ), the combed tooth-shaped bonding material should be parallel to the ground. Then press the decorative brick with the adhesive material in the shape of the ditch on the back to the wall base that has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com