Aluminum oxide recycling and material jam treatment method of electrolytic aluminum flue gas purification system

A flue gas purification system and alumina technology, applied in the field of material negative pressure recovery, to achieve reliable operation, reduce labor intensity, and improve the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

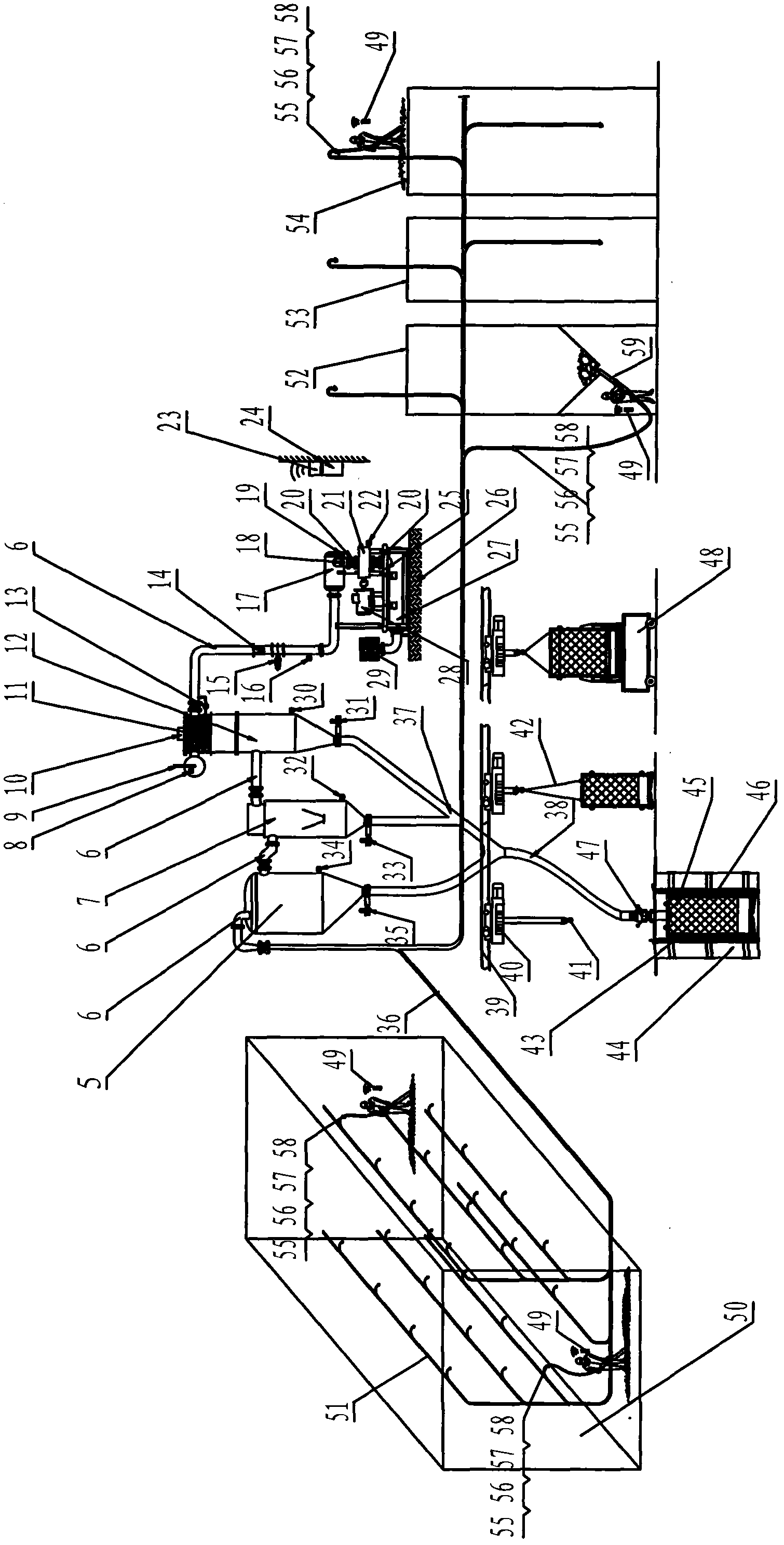

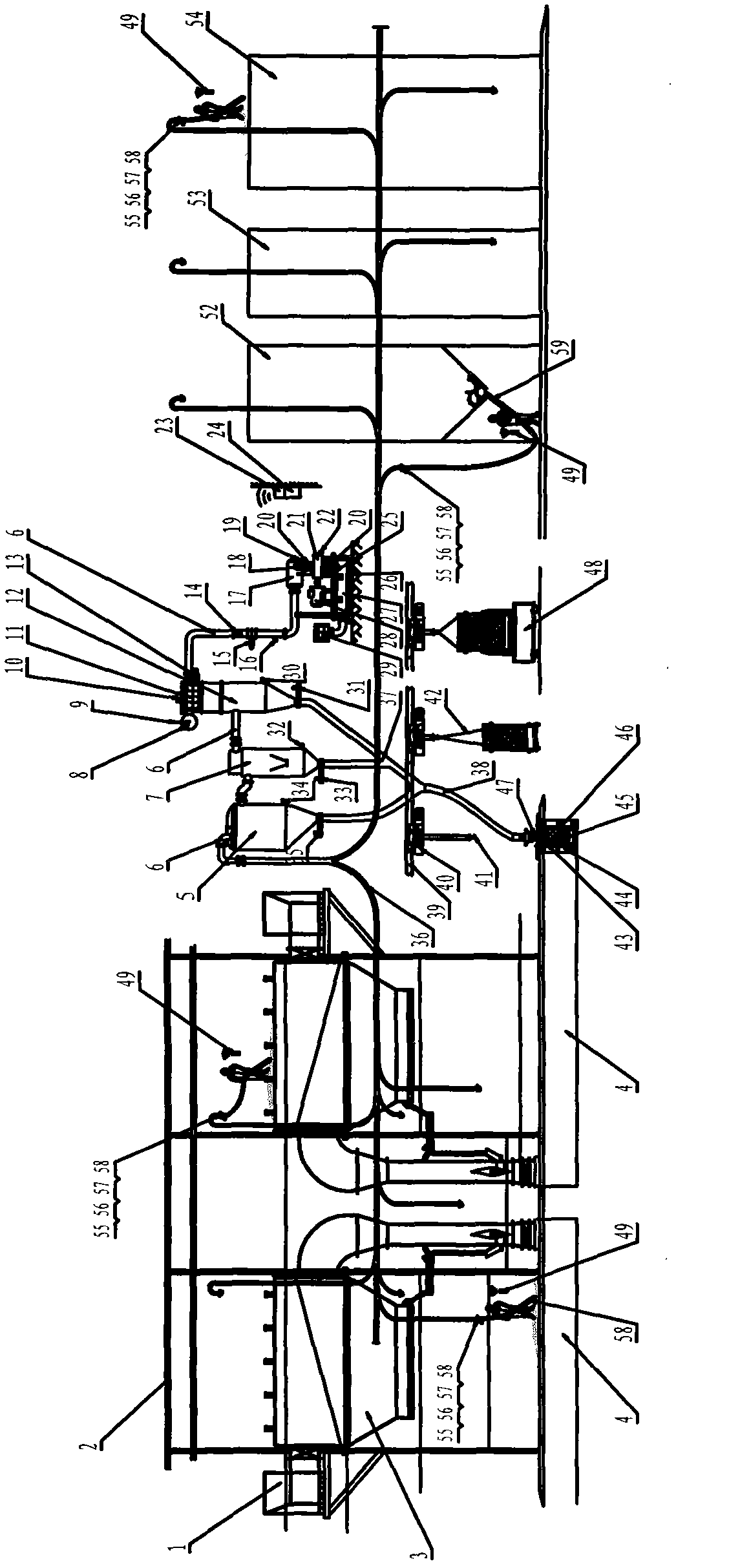

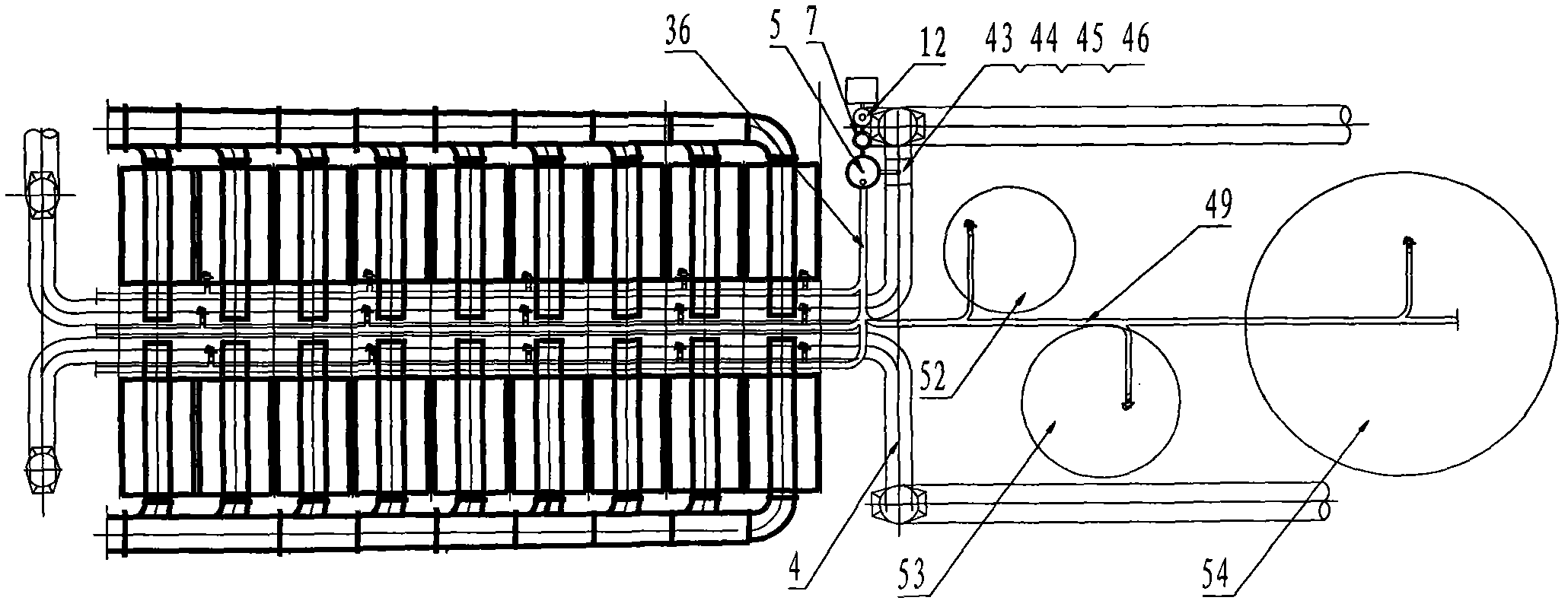

[0034] 1. Basic situation of electrolytic aluminum flue gas purification system;

[0035] Purification system process equipment configuration: 18 bag filter groups, 4 main exhaust machines, 1 6500-ton alumina storage bin, 1 1000-ton fresh alumina storage bin, 1 1200-ton fluorine-containing alumina storage bin . A set of alumina super dense phase chute.

[0036] 2. The general idea and structural arrangement of the invention

[0037] See attached figure 1 , figure 2 and image 3 Summary of the invention: The present invention provides a kind of electrolytic aluminum flue gas purification system to solve blockage, aluminum oxide recovery, contain sand and gravel sundries dirty material treatment method and device.

[0038] The general idea is: solve the blocking problem on the spot, recover alumina on the spot, and separate and treat it on the spot.

[0039] ●Fixed design, the main equipment is shielded and installed on the platform near the negative pressure flue in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com