Screw dowel for fastening rails

A type of pin and screw technology, applied in the field of railway sleepers or ballastless tracks, can solve problems such as damage to sleepers, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

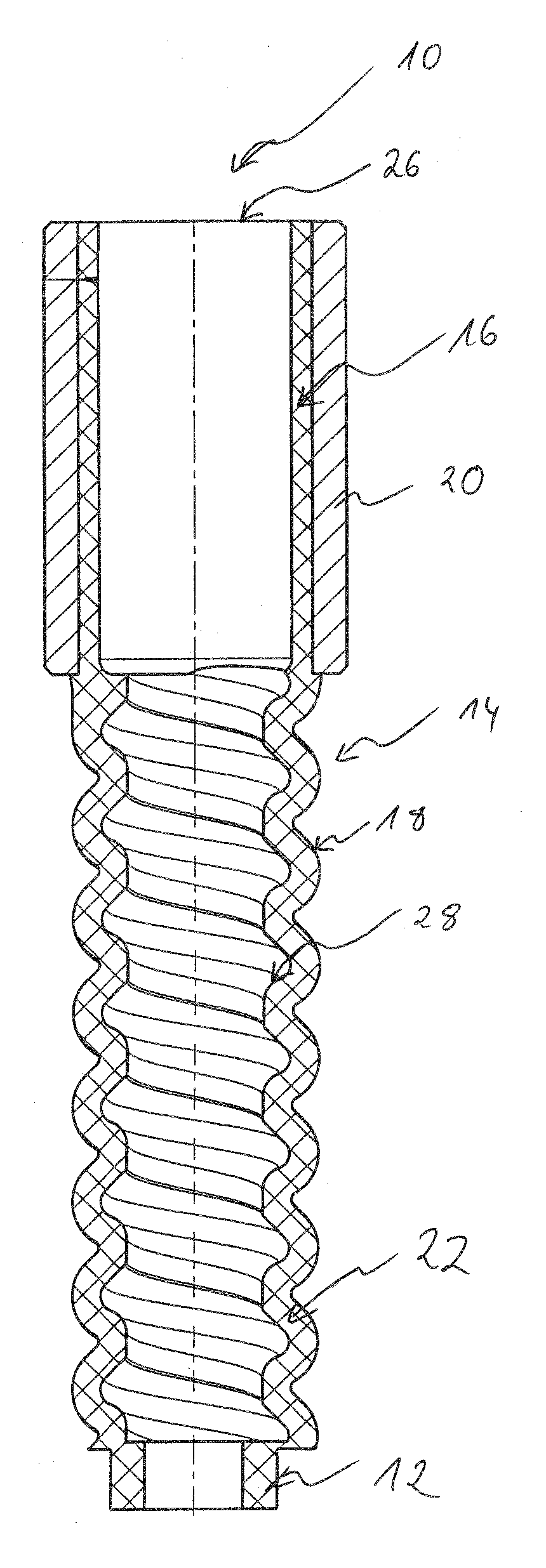

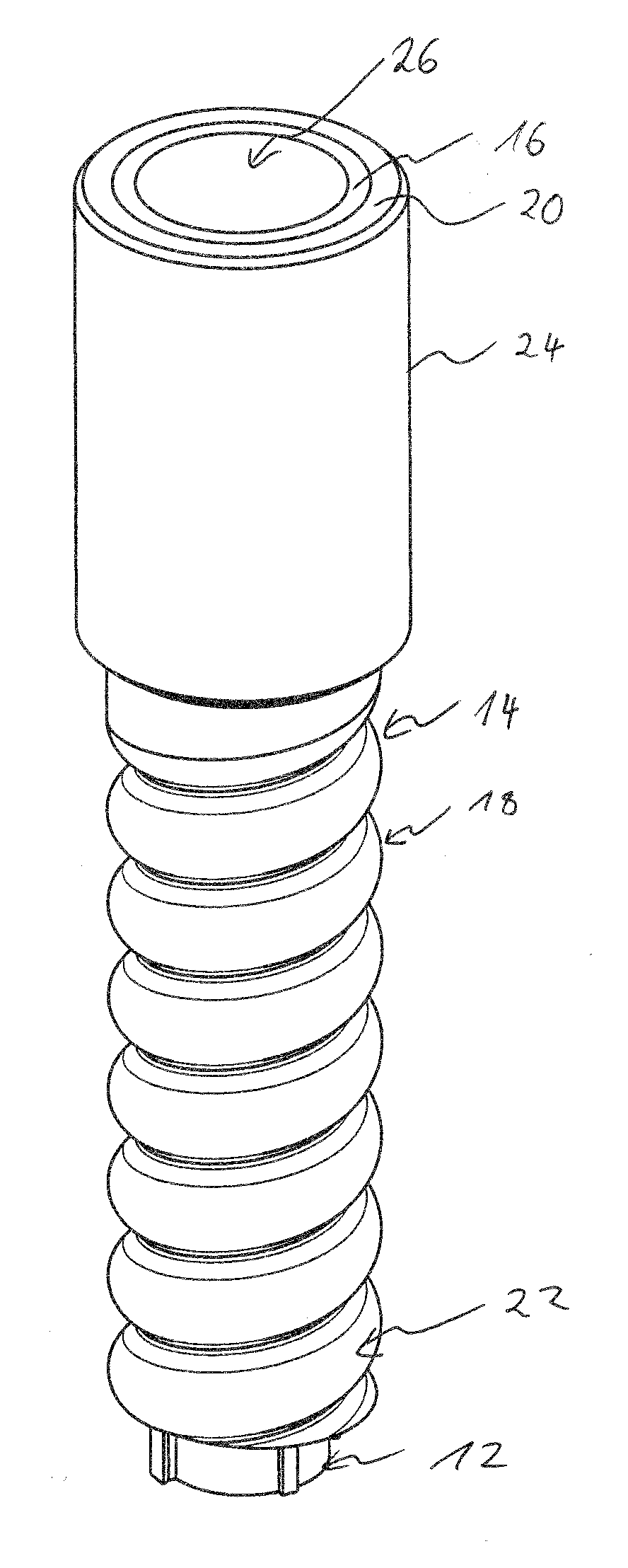

[0022] figure 1 The helical pin 10 shown in is composed of a base body 22 made of plastic material and consists of an upper part 16 without an external thread, with an external thread 18 located outside said helical pin 10 and located inside said helical pin The middle portion 14 of the internal thread 28, and the lower portion 12 constitute. The internal thread can also be a circular thread, but differs from the external thread 18 with respect to the flanks and pitch.

[0023] The upper part 16 is substantially cylindrical and is integrally formed with the threaded part 14 and the lower part 12 . On the periphery of the lower part 12 there may be provided form-fitting elements in the form of ribs extending longitudinally along the helical pin, which can be provided after the concrete blocks of the railway sleeper or ballastless track have been poured around the helical pin. Radial twisting of the helical pin relative to the surrounding concrete material is prevented or at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com