Dynamic tension sensor

A tension sensor, dynamic technology, applied in the field of dynamic tension sensor, can solve problems such as zero drift, detection data deviation, component length usage, etc., achieve accurate detection results, eliminate the influence of detection signals, and have a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

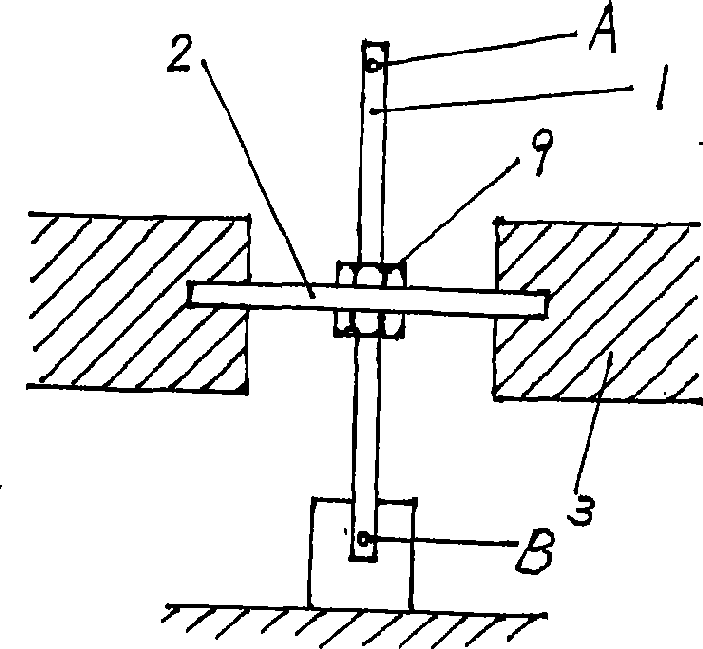

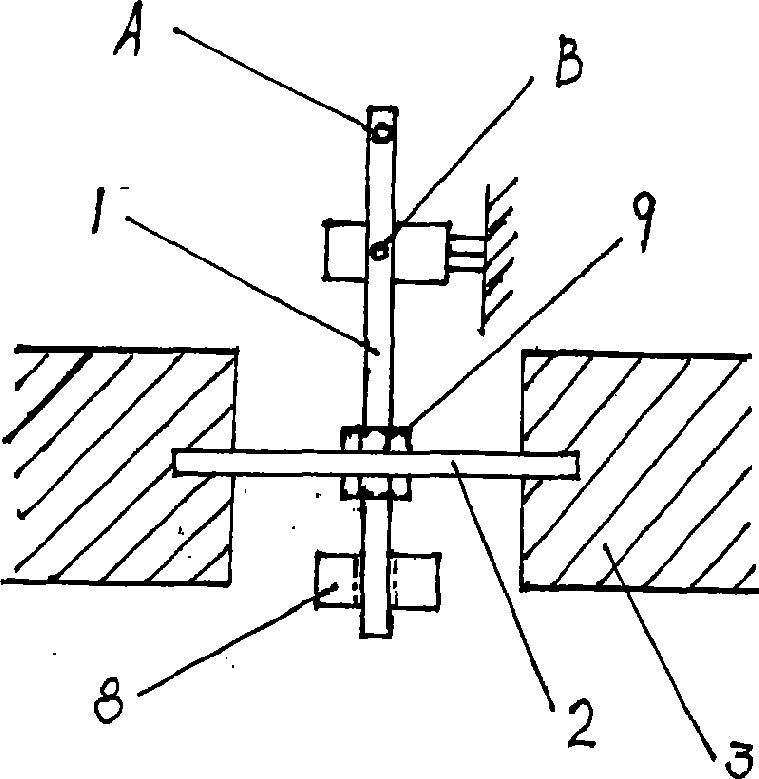

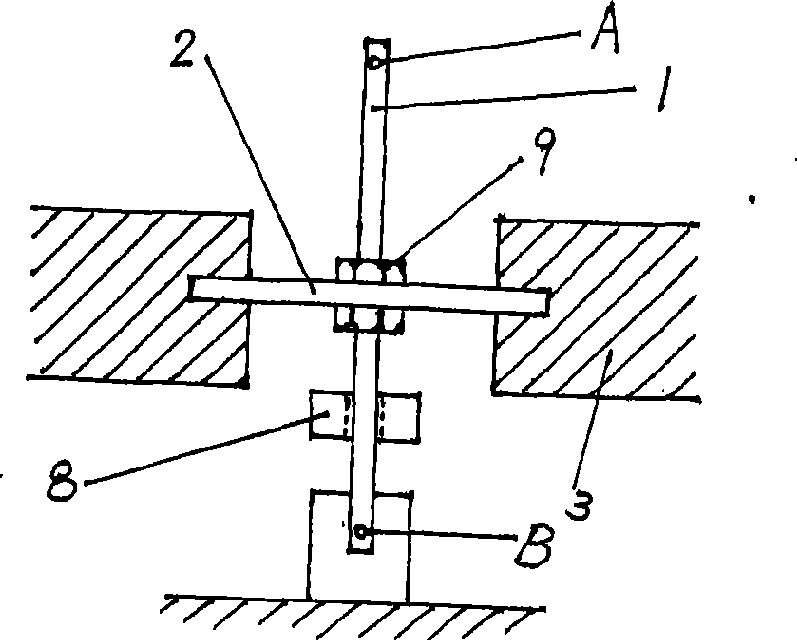

[0012] The present invention will be described in further detail below.

[0013] The elastic sheet 2 is a thin metal sheet. When elastic sheets 2 of different elastic modulus materials, different widths, different heights or different thicknesses are selected, the force-measuring range, resolution and deformation of the elastic sheet 2 can be changed, thereby achieving dynamic control. linear output and resolution requirements.

[0014] The detection end and output end on the torsion shaft 1 can be located on both sides or the same side of the elastic sheet 2. When they are located on the same side, in order to keep the two ends of the torsion shaft 1 balanced under static conditions, they can be set on the other side of the torsion shaft 1. Balance sheet 8, and balance sheet 8 can select the nut of different specifications or other components for use as required.

[0015] Changing the distance between the detection point A of the detection end and the elastic sheet can chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com