Bone screw for providing dynamic tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

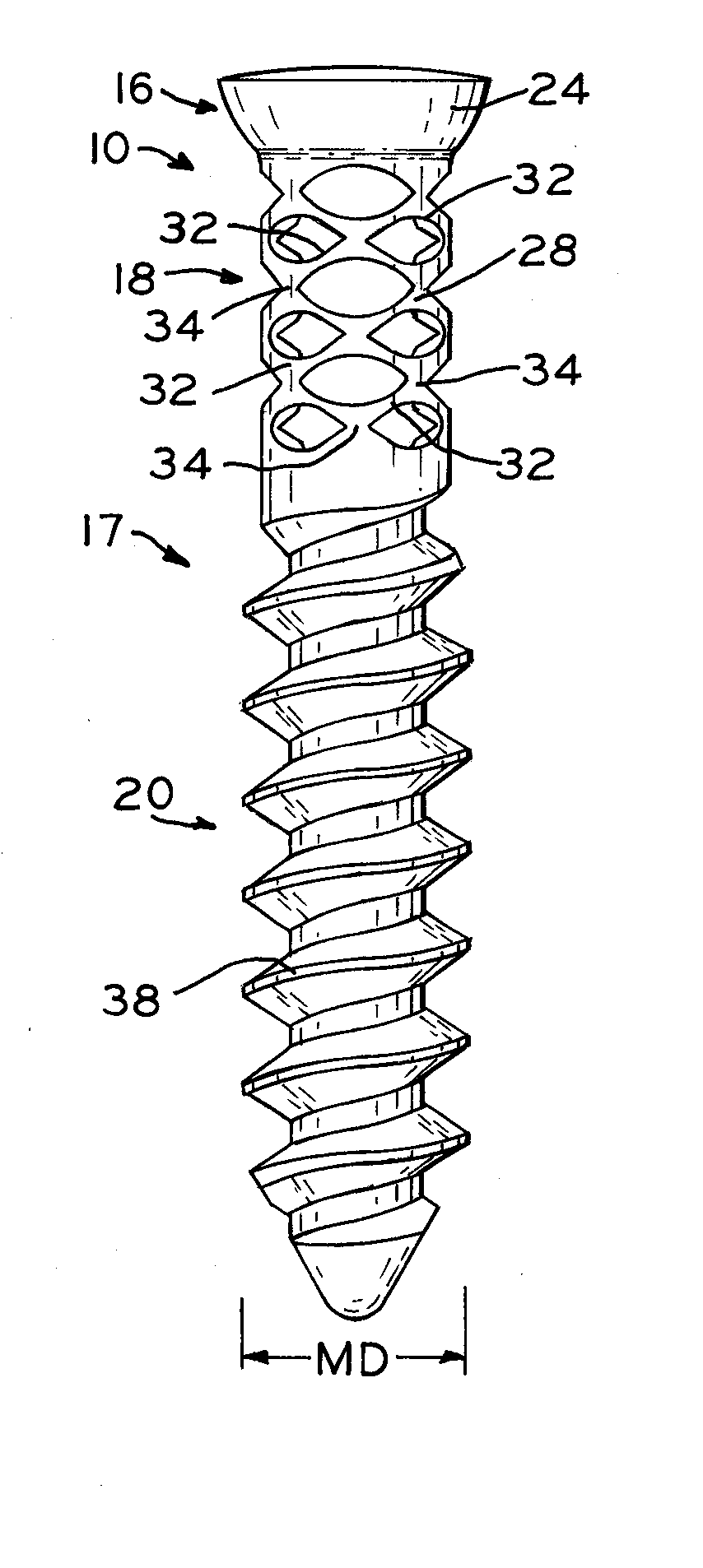

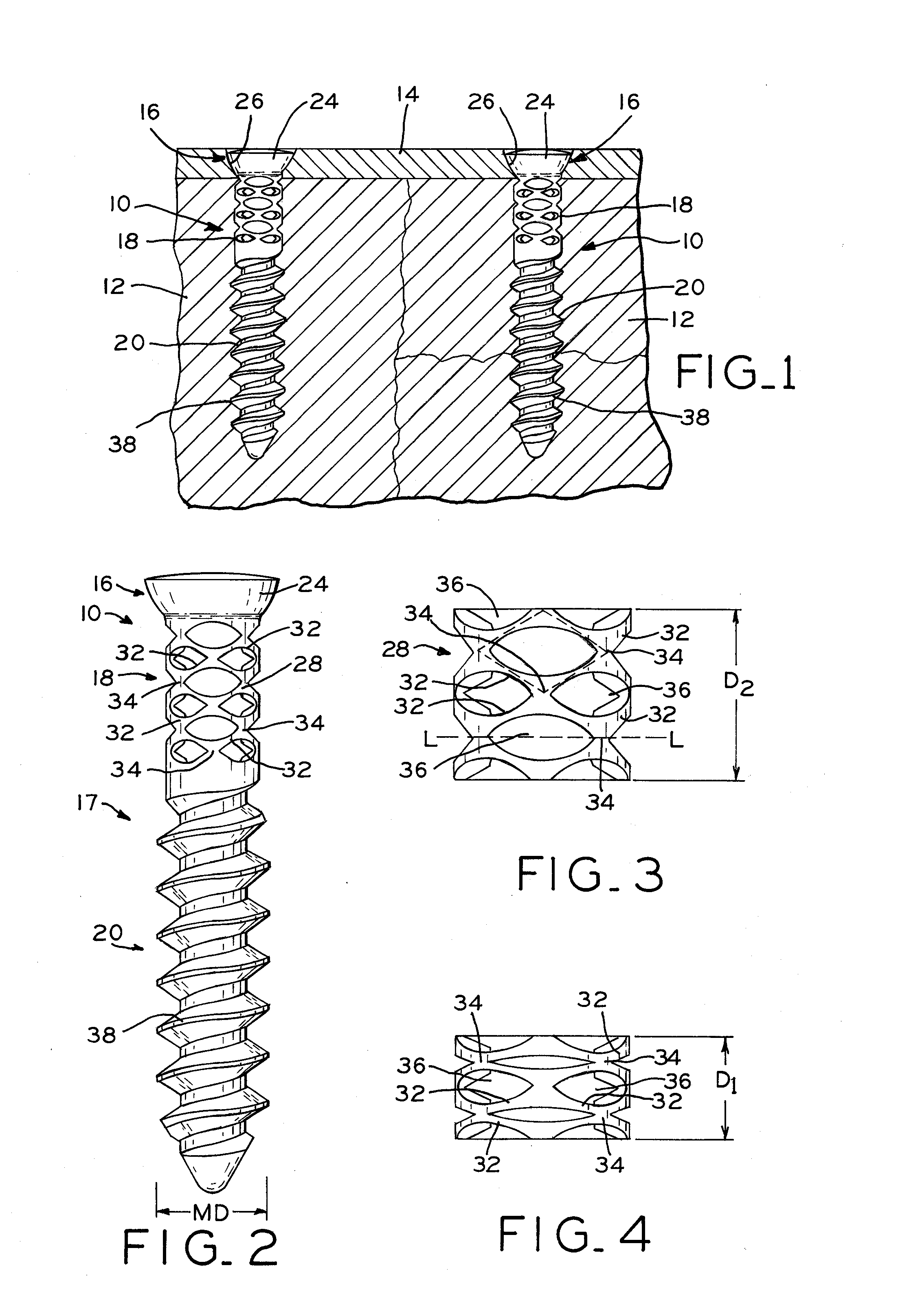

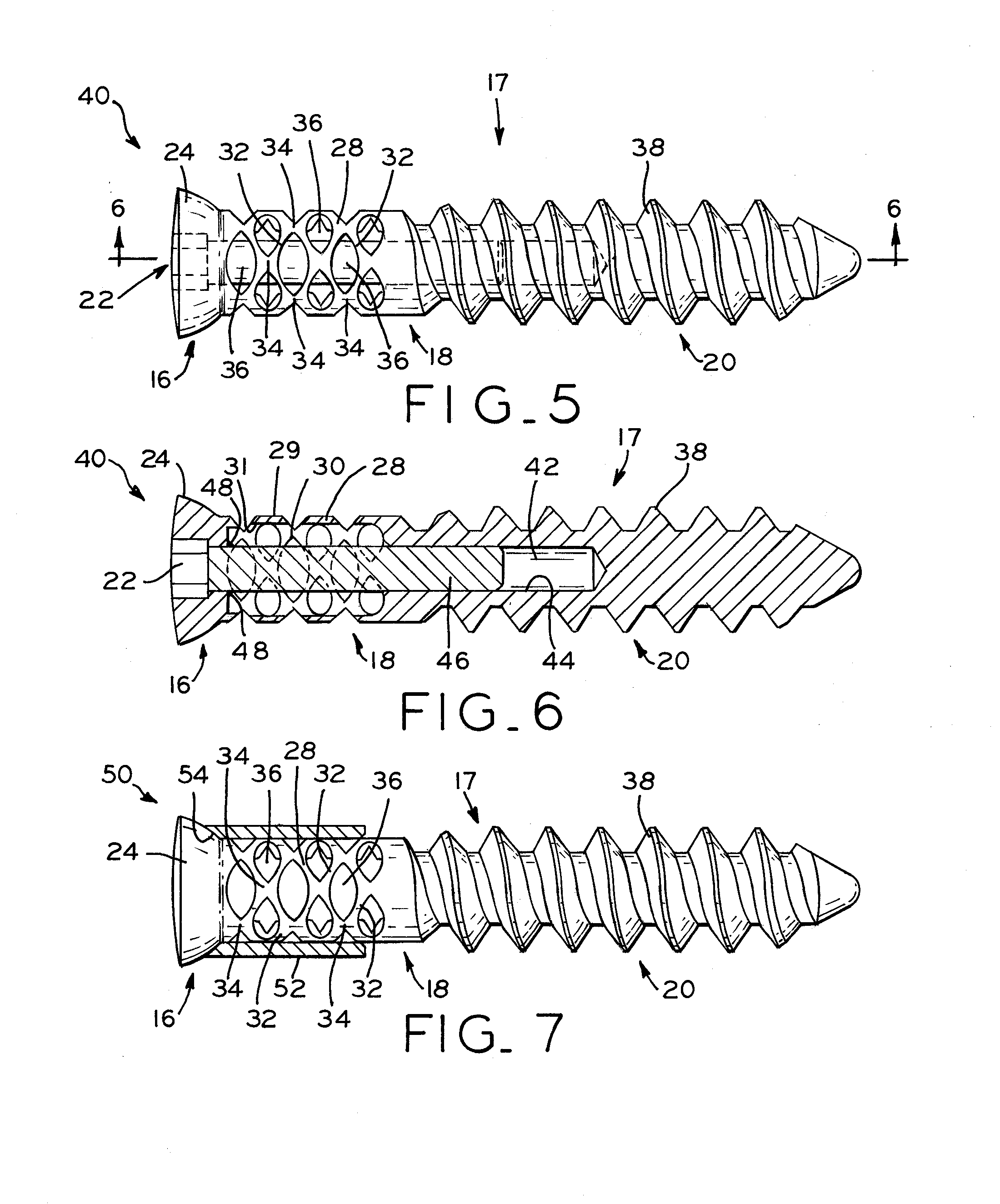

[0024]Referring to FIG. 1, bone screws 10 are shown secured within opposing portions of fractured bone 12. In this position, bone screws 10 function to retain bone plate 14 substantially adjacent bone 12, as described in detail below, and also function to retain opposing portions of fractured bone 12 adjacent one another. Referring to FIG. 2, bone screws 10 include head portion 16 and shaft 17, which includes intermediate portion 18 and threaded portion 20. Head portion 16 of bone screw 10 interacts with the surface of bone plate 14 to retain bone plate 14 against bone 12. In one exemplary embodiment, bone screw 10 is cannulated. In order to provide dynamic tension, intermediate portion 18 may be expanded during implantation of bone screws 10. Intermediate portion 18 is shown in an expanded state in FIG. 3, for example. Then, as bone 12 begins to undergo stress relaxation, the tension on bone screws 10 decreases. Specifically, bone, such as bone 12, is a viscoelastic material and, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com