Dynamic tension experiment fixture

A dynamic stretching and experimental technology, applied in the field of material mechanics experimental research, can solve the problems of complex and time-consuming preparation process, and achieve the effect of simple processing technology, avoiding stress concentration, and convenient clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

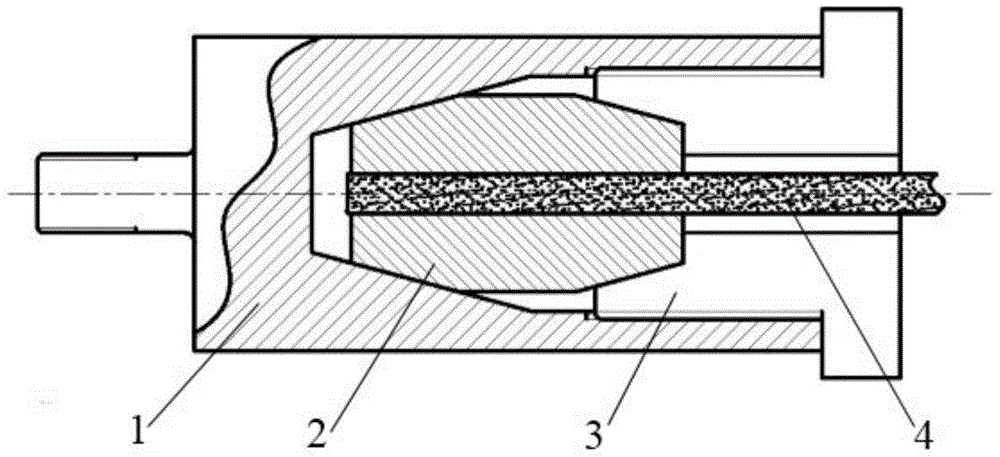

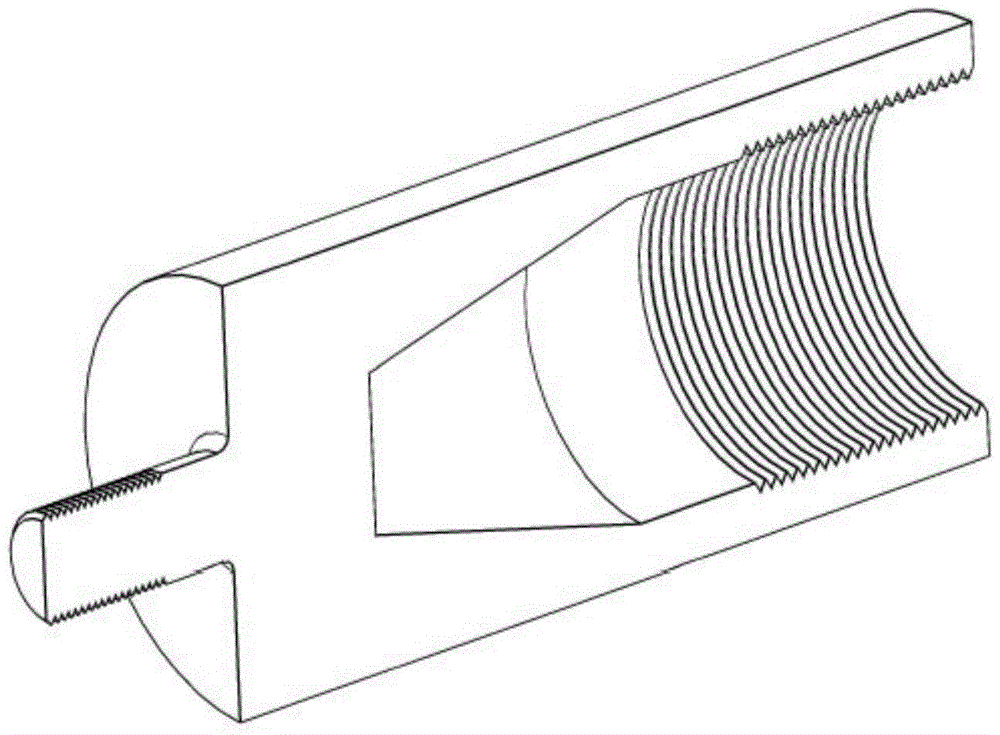

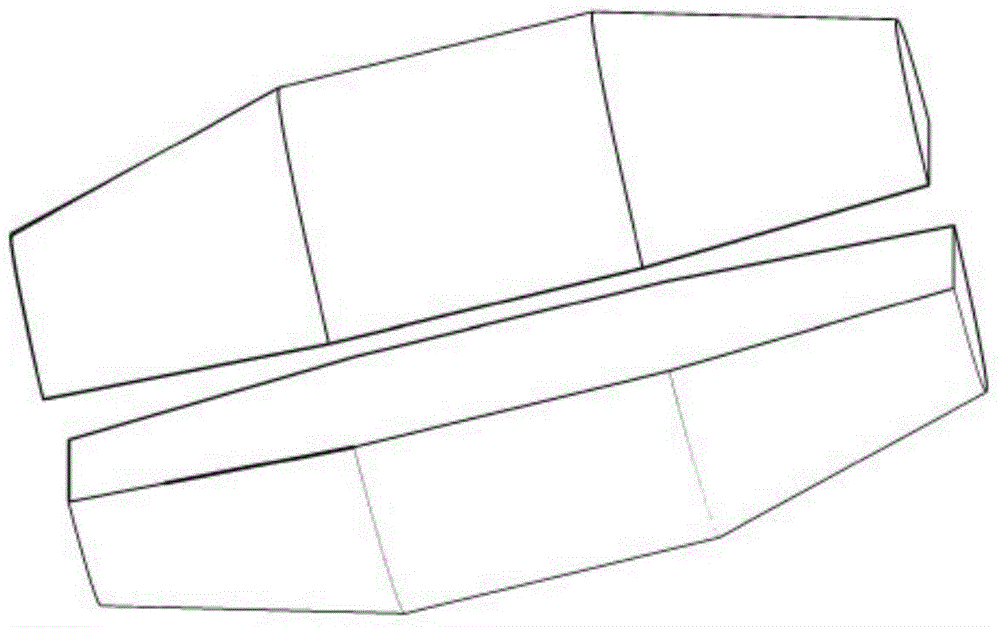

[0017] combine Figure 1 to Figure 4 :

[0018] The present invention is a kind of fixture for dynamic tension experiment, which comprises main fixture 1, clip 2 and thread fixing fixture 3, wherein, one end of main fixture 1 is provided with the external thread that is configured to be connected with the Hopkinson rod, and the other end is opened The inner wall of the hole is provided with an internal thread and an internal tapered surface sequentially from the outside to the inside, and the outer circumference of one end of the threaded fixture 3 is provided with an external thread that matches the internal thread of the main fixture 1, and the threaded fixture 3 is provided along the axis. The central hole through which the lath-shaped test piece 4 passes, and a tapered hole coaxial with the central hole and whose minimum diameter is larger than the central hole is opened at one end extending into the main fixture 1. Two symmetrical clips 2 are configured for For clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com