Device for measuring apparent viscosity of liquefied sand and method therefor

A technology for apparent viscosity and measuring devices, applied in measuring devices, flow characteristics, instruments, etc., can solve the problems of high apparent viscosity, beyond the measurement range of conventional viscometers, and inability to effectively measure apparent viscosity, so as to improve the test efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

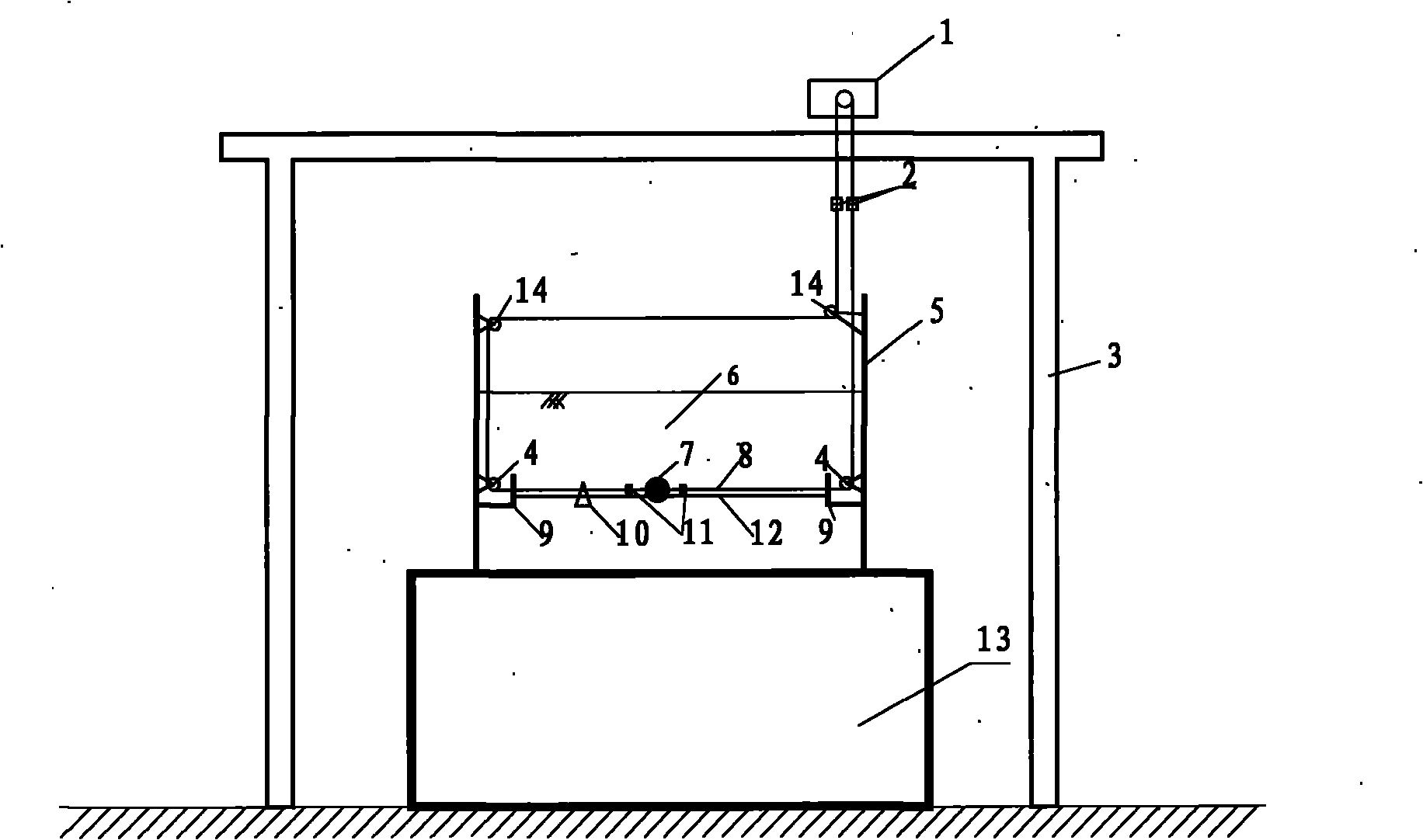

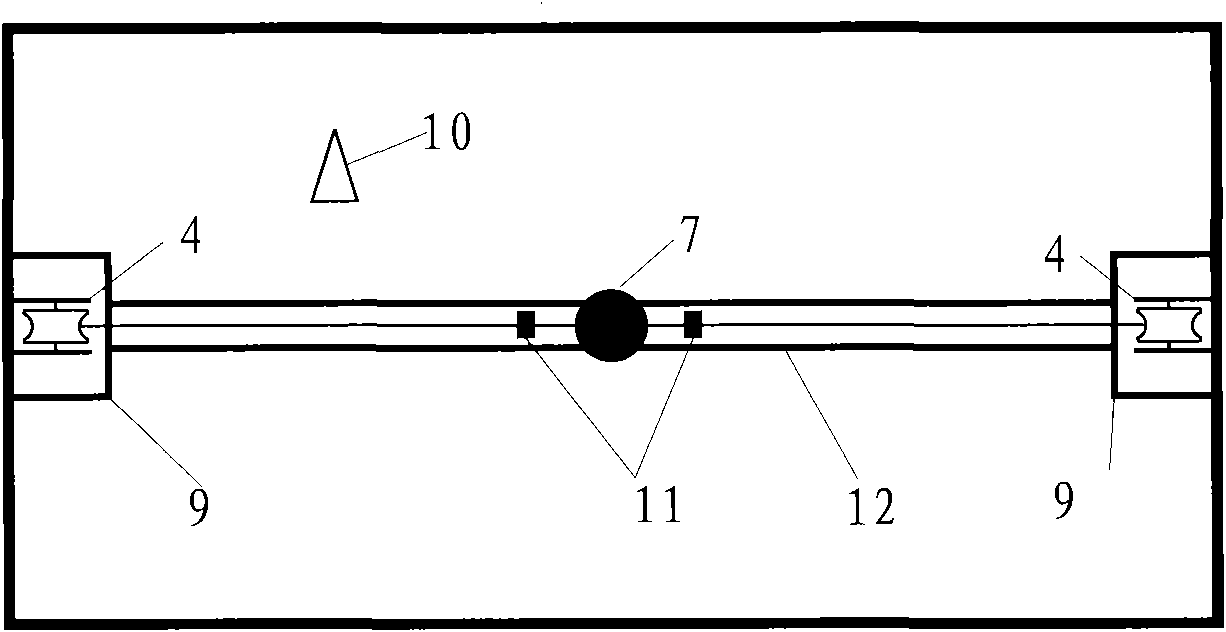

[0040] Such as figure 1 , figure 2 As shown, a device for measuring the apparent viscosity of saturated sandy soil after liquefaction includes a vibrating table 13 and a model box 5 fixed on the vibrating table 13, and also includes a low-speed adjustable motor 1, a dynamic displacement sensor 2, a fixed pulley 4, a steel Ball 7, wire rope 8, track support 9, dynamic hole pressure sensor 10, dynamic tension sensor 11, track 12 and fixed pulley 14. The excitation direction of the vibrating table 13 is perpendicular to the direction of the track 12 .

[0041] The track 12 is formed by two parallel smooth steel bars with a diameter of 5mm horizontally arranged in the model box, and can be fixed by two symmetrical track supports 9 . A kind of fixing method is to go out screw thread at both ends of the steel bar, pass through the round hole or groove in the track support 9, and fix with nuts. A group of holes with different distances can be set on the track support 9 to fix and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com