Synthetical fatigue testing system and method for extensional vibration and torsion of composite insulator

A composite insulator, tensile vibration technology, applied in the field of comprehensive fatigue test system, can solve the problems of unadjustable vibration frequency, long time, and small change of insulator axial tension, so as to reduce the test time and meet the effect of diversity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

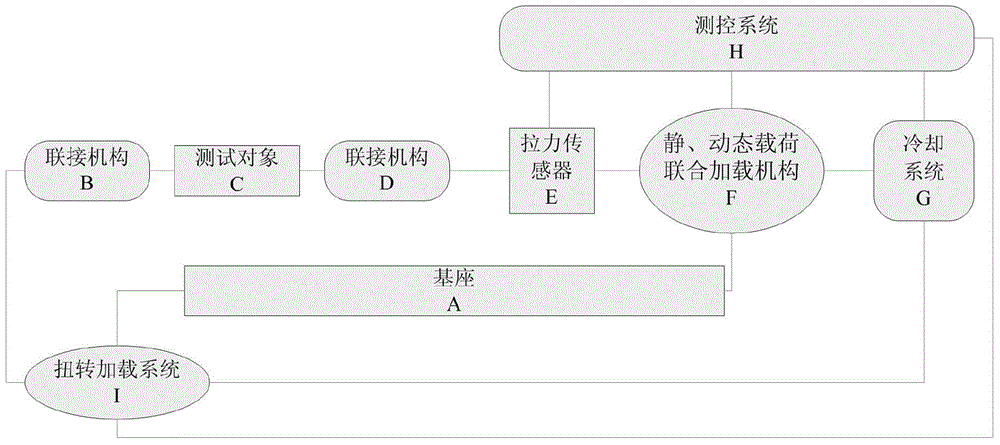

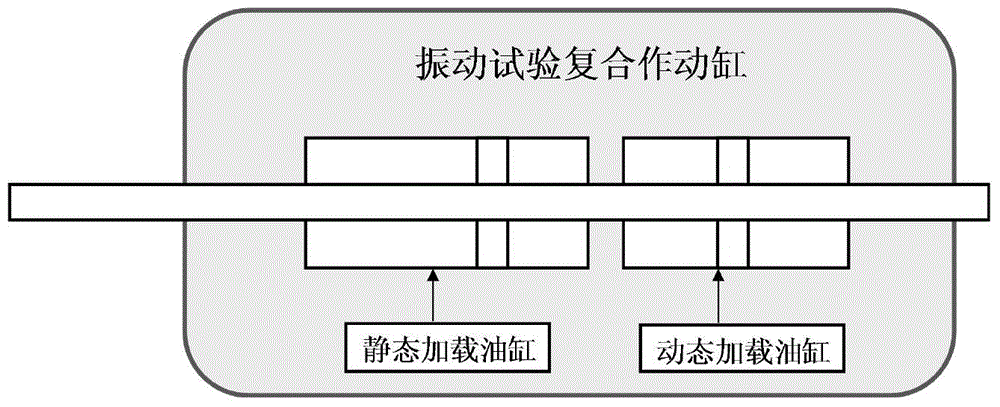

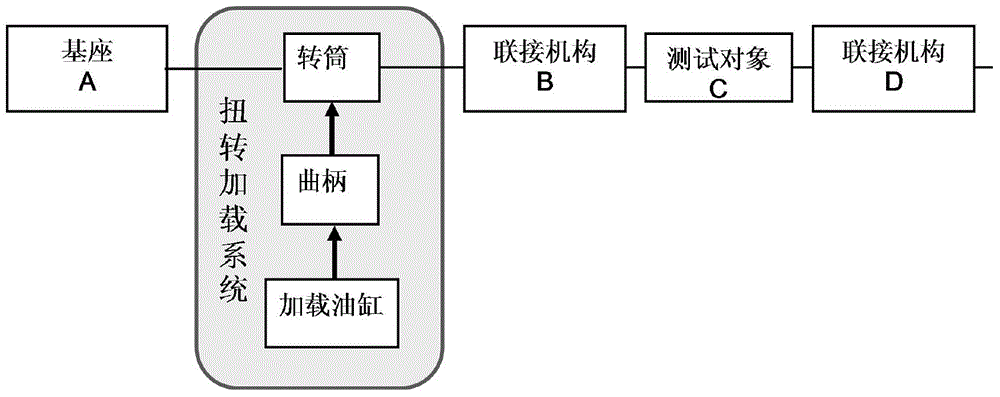

[0028] Such as Figure 1-5 As shown, the test system of the invention of this example includes a coupling mechanism 1, a test object, a coupling mechanism 2, a tension sensor, a combined static and dynamic load loading mechanism, a cooling system, and a torsion loading mechanism that are connected end to end in sequence; the tension sensor, static and dynamic loading The load combined loading mechanism, the cooling system and the torsion loading mechanism are respectively connected with the measurement and control system; the static and dynamic load combined loading mechanism and the torsion loading mechanism are respectively connected with the base. In the present invention, the base provides a carrier for installing the coupling mechanism, the test object, the tension sensor, and the static and dynamic load combined loading mechanism, and can provide a single-channel or multiple-channel test circuit. When a multi-channel structure is used, parallel tests of multiple test prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com