Bending fatigue damage monitoring system for steel wire under action of corrosion-alternating load coupling

A bending fatigue and damage monitoring technology, which is applied in the direction of testing material strength by applying stable bending force, weather resistance/light resistance/corrosion resistance, and testing material strength by applying repetitive force/pulsation force, which can solve the problem that the enclosing angle cannot be adjusted , unable to quantitatively monitor the steel wire rope, unable to simulate the bending fatigue behavior of the steel wire rope, etc., to achieve the effect of wide practicability, complete functions and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

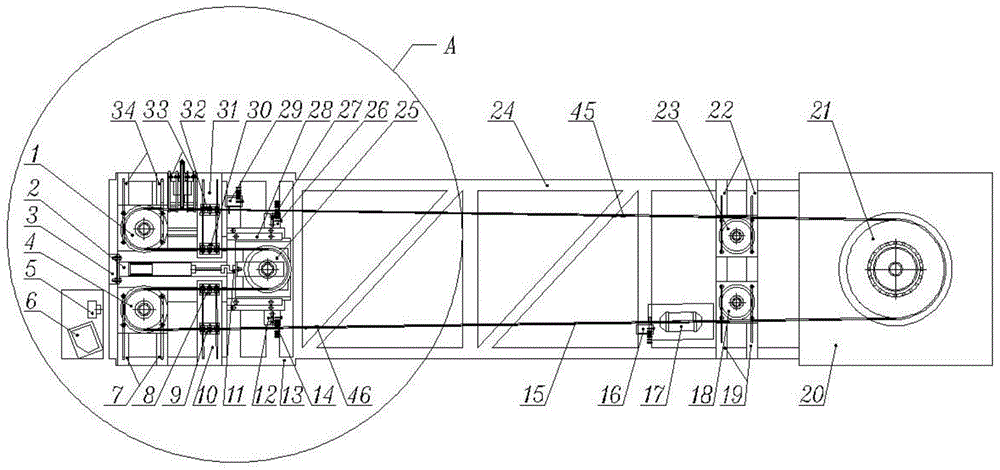

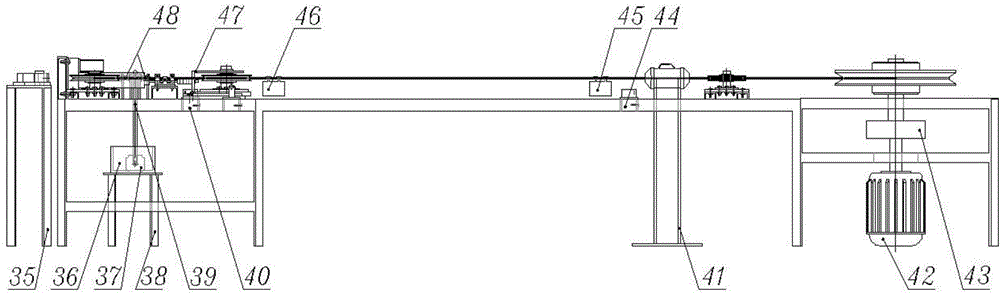

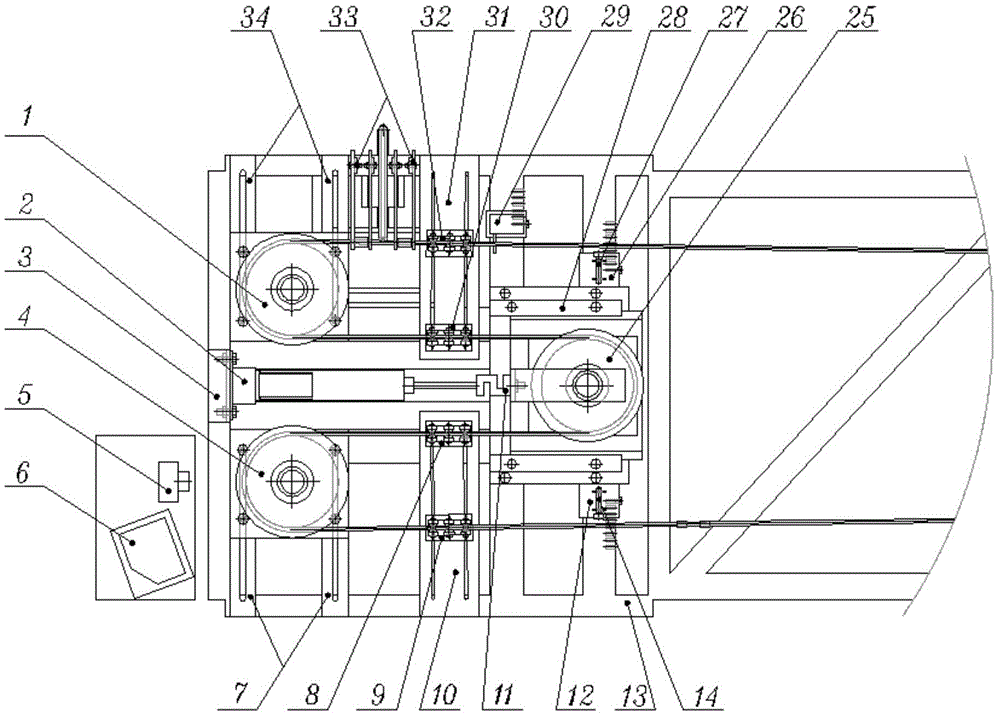

[0040] The test method of the steel wire rope bending fatigue damage monitoring system under the coupling action of corrosion and alternating load includes the following steps:

[0041] (1) Turn the wire rope around the driving wheel 21, the A adjustment wheel 23, the A experiment wheel 1, the loading wheel 25, the B experiment wheel 4, and the B adjustment wheel 18 in turn, and adjust their positions in turn so that the axis of each wheel is on the same horizontal plane; Start the servo electric cylinder 2 and push the loading wheel 25 to make the wire rope 15 tighten, the wire rope tension value reaches the initial minimum value, and the servo electric cylinder 2 is stopped;

[0042] (2) Adjust the positions of the driving wheel 21, the loading wheel 25, the A test wheel 1, the B test wheel 4, the A adjustment wheel 23 and the B adjustment wheel 18 to obtain the wire rope 15 required for the experiment in the A test wheel 1, the B test wheel 4 and the wrap angle on the loading wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com