Dynamic tension fracture experiment method of material

A technology of dynamic stretching and experimental methods, which is applied in the direction of testing the strength of materials with one-time impact force, can solve the problems of changing the loading strain rate, impact hardening effect, difficulty, etc., and achieve the effect of convenient implementation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

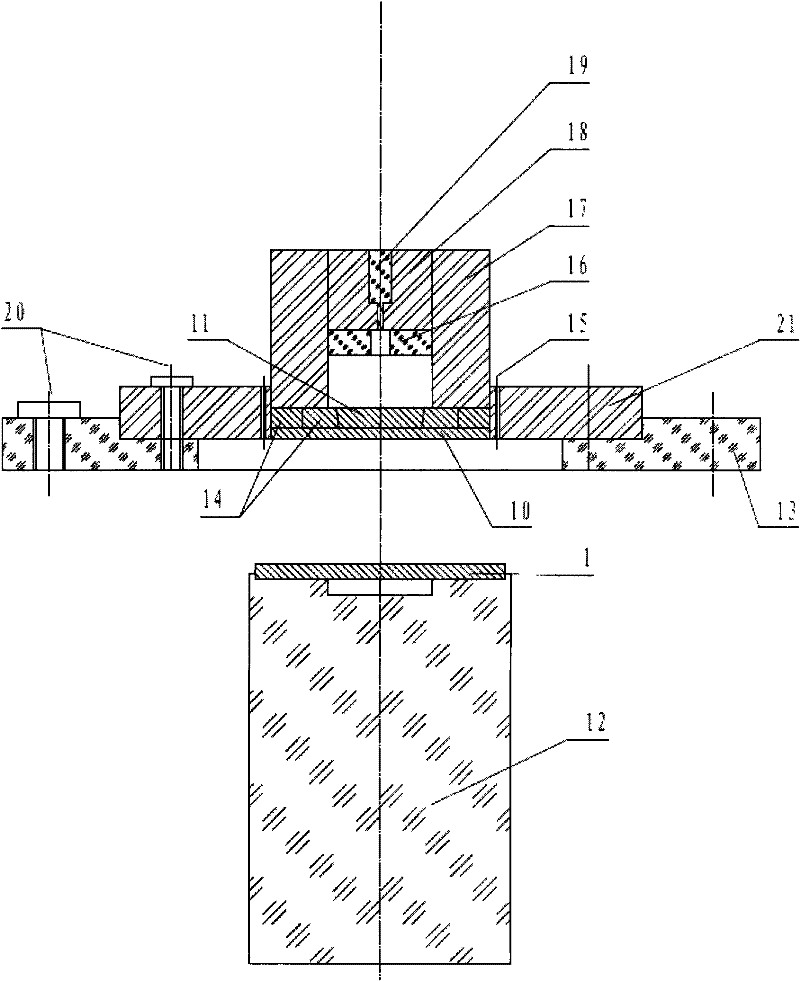

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

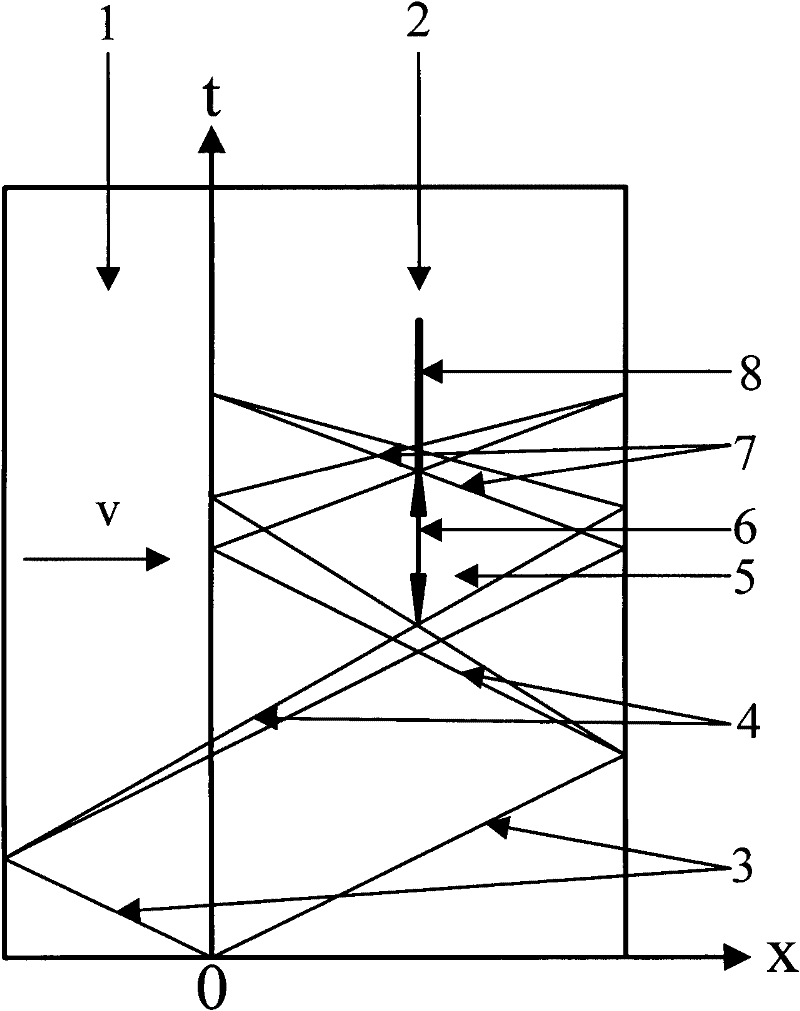

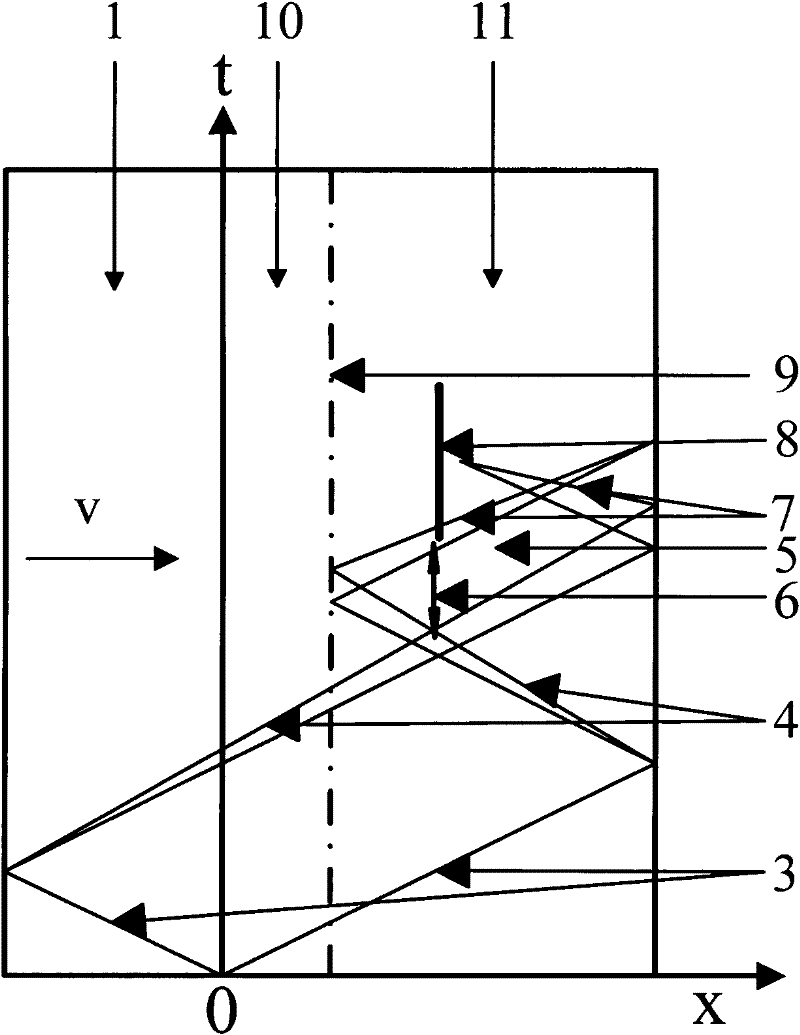

[0017] like figure 1 As shown, the spall is formed by the interaction (collision) of two sparse (expansion) waves to generate tensile stress. The basic principle of spallation is: the flyer 1 hits the target plate 2 (the thickness of the flyer is smaller than the thickness of the target plate, and the thickness ratio of the two is generally 1 / 2), and a shock wave 3 is generated in the flyer 1 and the target plate 2 respectively. , when the shock wave reaches the free surface of the flyer 1 and the free surface of the target plate 2, it will be reflected to form a sparse wave 4. Two beams of sparse waves 4 travel toward each other and meet in the target plate 2. Tensile stress is generated in this region. If the tensile stress pulse is strong enough, after a certain stretch duration 6, spallation or damage will occur, forming a Lamination surface or maximum damage s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com