Synchronizing system of multi-transmission rubber belt conveyor

A technology of synchronous system and belt conveyor, which is applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., and can solve problems such as the tail motor not following the solution well, shortening the service life of the conveyor, and poor synchronization control , to achieve the effect of increasing safety and reliability, reducing impact and suppressing hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

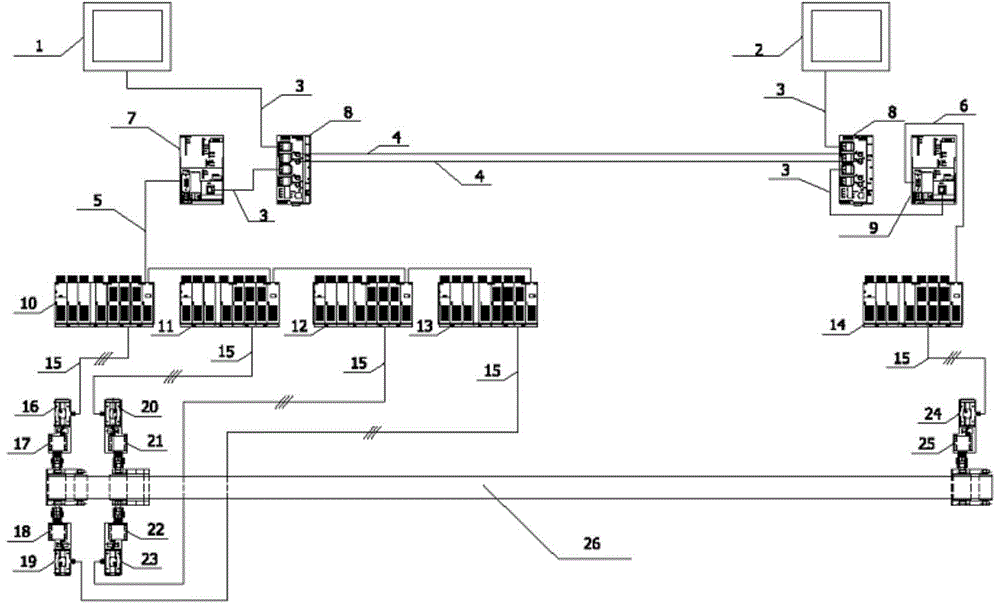

[0020] Such as figure 1 As shown, the multi-drive belt conveyor synchronization system provided by the present invention includes five motors, belt conveyors, 2 sets of control devices (programmable logic controllers), 5 sets of high-voltage frequency converters and related networks.

[0021] In the present invention, two sets of control devices are used to carry out synchronous real-time calculations, and the operating speed and current of five motors are monitored in real time. The control program of the control devices is divided into 2 parts:

[0022] Among the four motors at the head, the first motor 16 and the second motor 18 are rigidly connected, the third motor 20 and the fourth motor 22 are rigidly connected,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com