Process for manufacturing continuous non-woven cloth and cross cloth with more than two layers

A production process, non-weft cloth technology, applied in the direction of lamination, lamination device, layered products, etc., can solve the problems of bulletproof, decreased protection performance, low efficiency of the non-weft cloth process, and the quality cannot meet the requirements, etc. Fully expanded fiber, high bulletproof and protective performance, and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

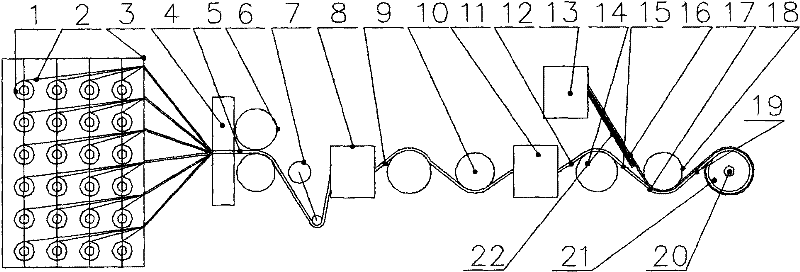

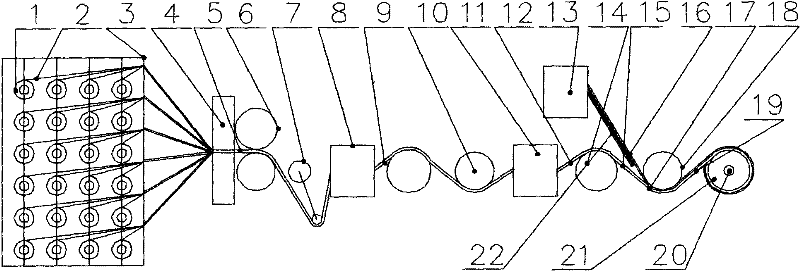

[0036] refer to Figure 1-Figure 2 , a continuous non-weft fabric manufacturing process, according to the following steps:

[0037] (1) A certain number of fiber bobbins (1) are installed on the tension-adjustable creel (3) of single yarn and sheet yarn single yarn and sheet yarn tension;

[0038] (2) The fiber bundle (2) on the fiber bobbin (1) passes through the single yarn and sheet yarn tension-adjustable creel (3), so that the dynamic tension of the fiber bundle (2) is consistent;

[0039] (3) The fiber bundles (2) pass through the fiber bundle positioning mechanism (4) in parallel to form precisely positioned fibers (5) arranged in parallel at equal intervals;

[0040] (4) The precisely positioned fiber (5) is drawn into the main machine by the first traction mechanism (6);

[0041] (5) The precisely positioned fiber (5) entering the main machine enters the first spreading mechanism (8) through the tension uniform mechanism (7), and the fiber is pulled as a whole, and ...

Embodiment 2

[0048] For the production process of cross cloth with more than two layers, follow the steps below:

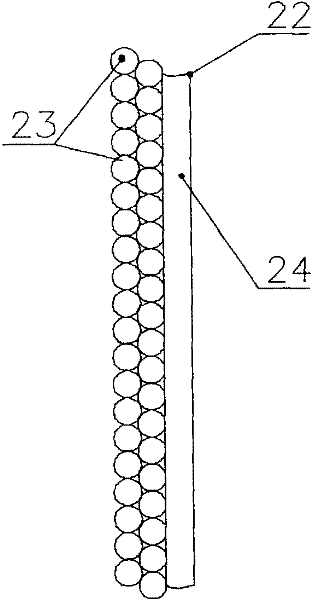

[0049] (1) automatically or manually cut the finished non-weft cloth or orthogonal cloth (19) into 1600 mm long non-weft cloth pieces (22);

[0050] (2) The length and width of the non-weft cloth block (22) are all 1600 mm, and they are automatically or manually rotated at an angle of 90 degrees, with the film surface facing the smooth and wrinkle-free film (16) or guide belt, and are automatically or manually deposited on a flat and non-wrinkled surface. On the thin film (16) of wrinkle, then form continuous horizontal non-weft cloth as being deposited on the conduction belt continuously and seamlessly;

[0051] (3) meet with the fibrous sheet (15) of the uniform coating adhesive that is advancing along with film (16) or guide belt from the film unfolding mechanism (13);

[0052] (4) No weft cloth piece (22) is combined with the fiber sheet (15) of uniform coating adhesive o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com