Tension adjusting device for self-adaptive engine front end accessory gear train

A technology of tension adjustment device and front-end accessories, which is applied in transmission devices, machines/engines, mechanical equipment, etc., can solve the problems of time-consuming and labor-intensive, high professional requirements, and can not guarantee the tensioner, etc., and achieves flexible position layout and adjustment. The effect of wide range and reduction of research and development difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

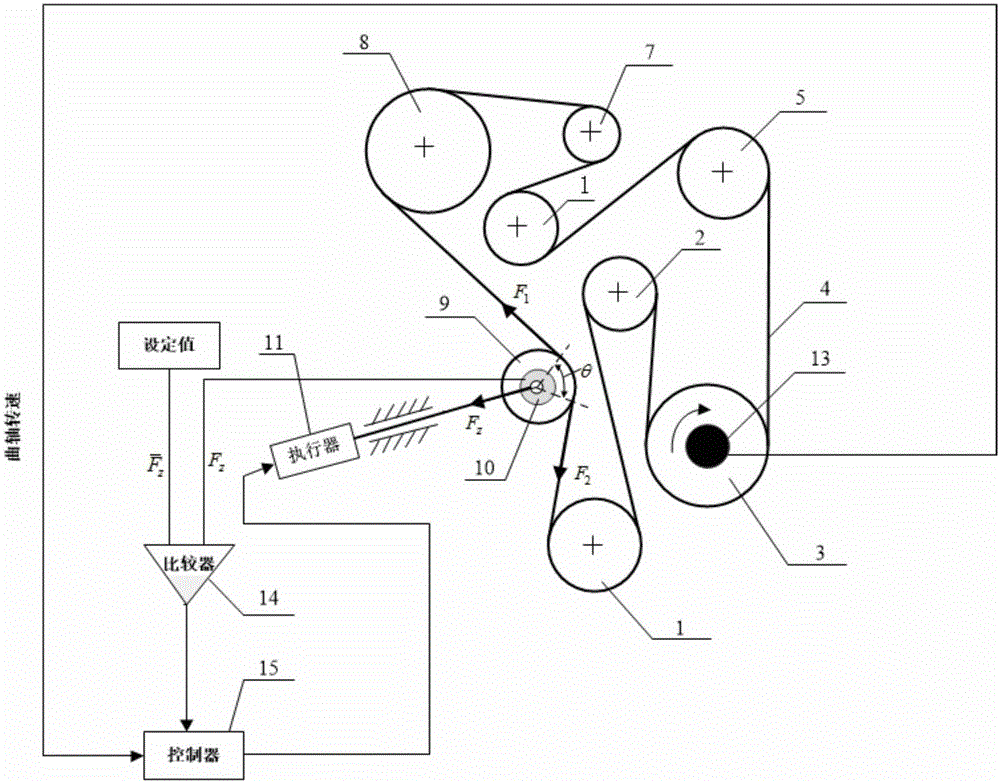

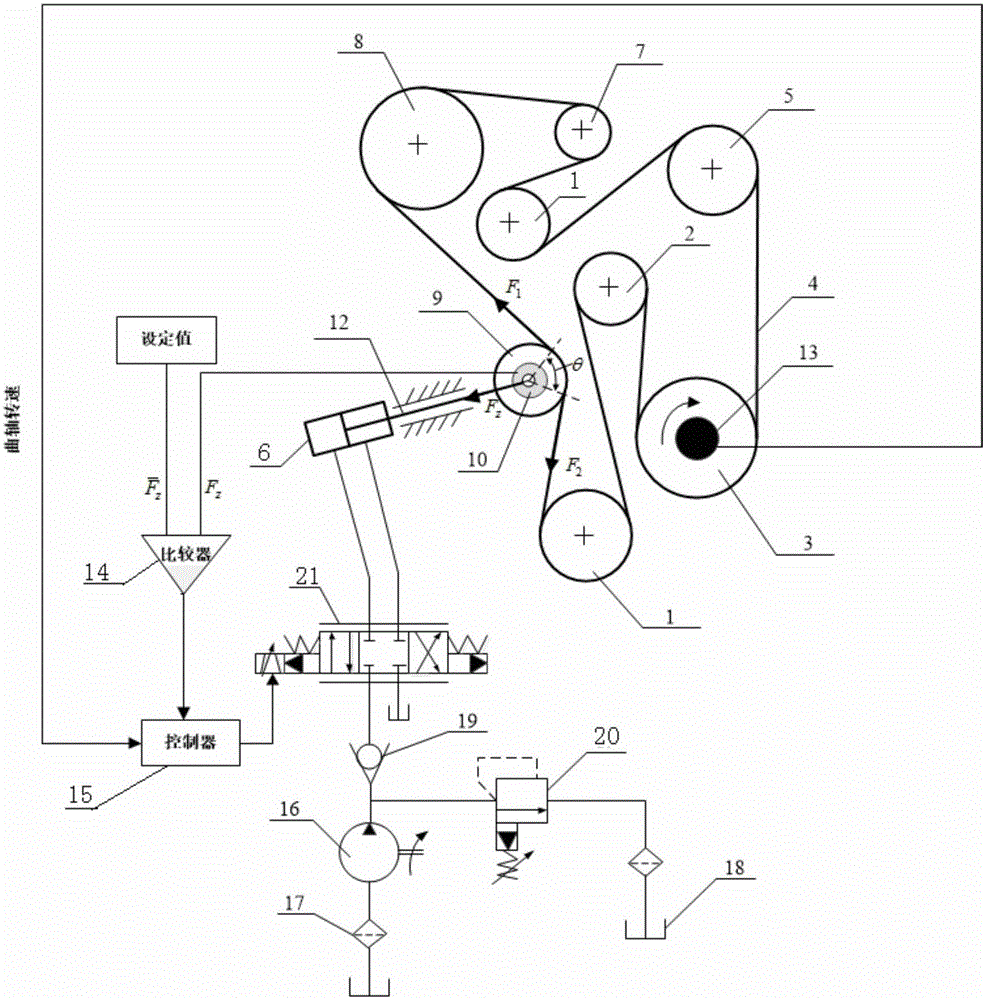

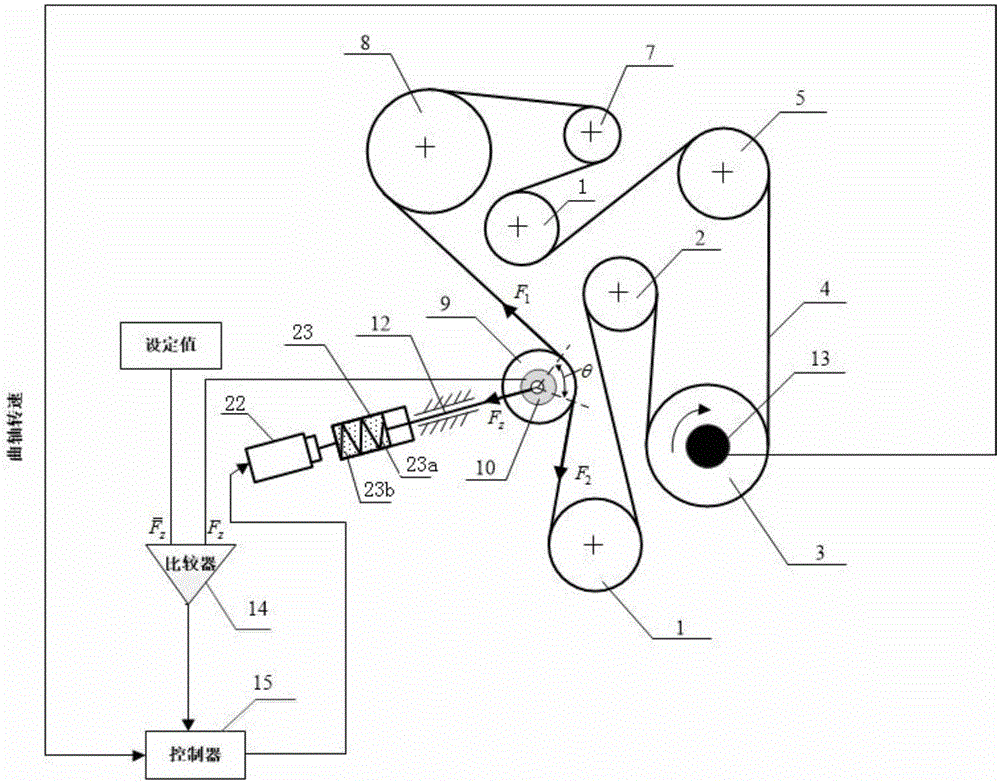

[0015] Such as figure 1 As shown in the figure, an adaptive tension adjustment device for front-end accessory gear train of the engine mainly includes two parts: the front-end accessory gear train of the engine and the belt tension control system.

[0016] The front-end accessory wheel system of the engine is mainly composed of crankshaft pulley 3, V-ribbed belt 4, water pump pulley 2, air conditioner compressor pulley 5, generator pulley 7, power steering pump pulley 8, tension pulley 9 and two idlers. Round 1 composition. The crankshaft pulley 3 drives the water pump pulley 2, the air conditioner compressor pulley 5, the generator pulley 7, and the power steering pump pulley 8 through the V-ribbed belt 4. The accessory wheel train at the front end of the engine is an integral part of the car engine, and will not be described here.

[0017] The belt t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com