Coal mine thread jamming machine and using method thereof

A technology of wire clamps and coal mines, applied in the field of wire clamps, can solve the problems of wasting anchor ropes and slings, long operation time, and low construction efficiency, and achieve high construction efficiency, good safety performance, and convenient installation and removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described below in conjunction with the drawings:

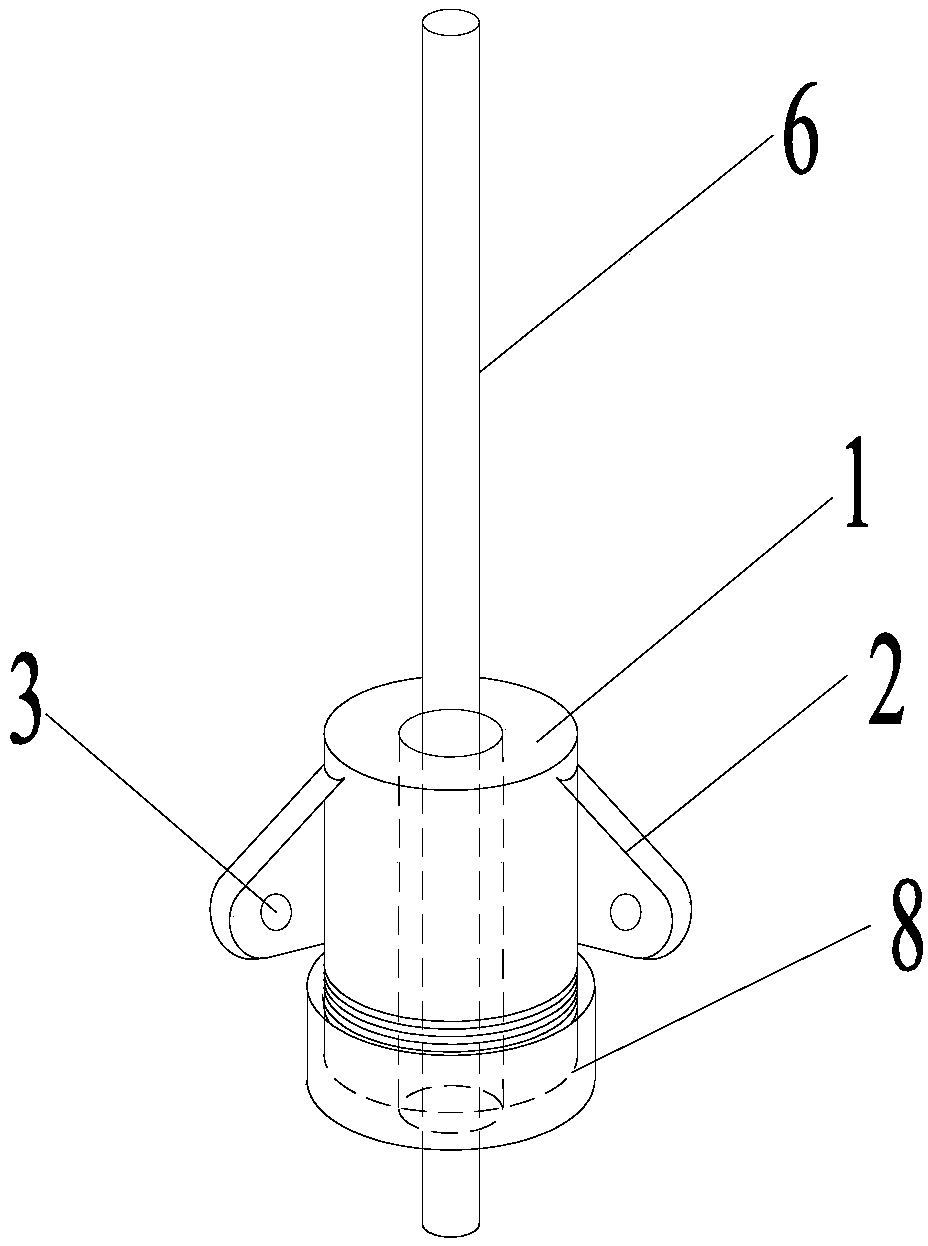

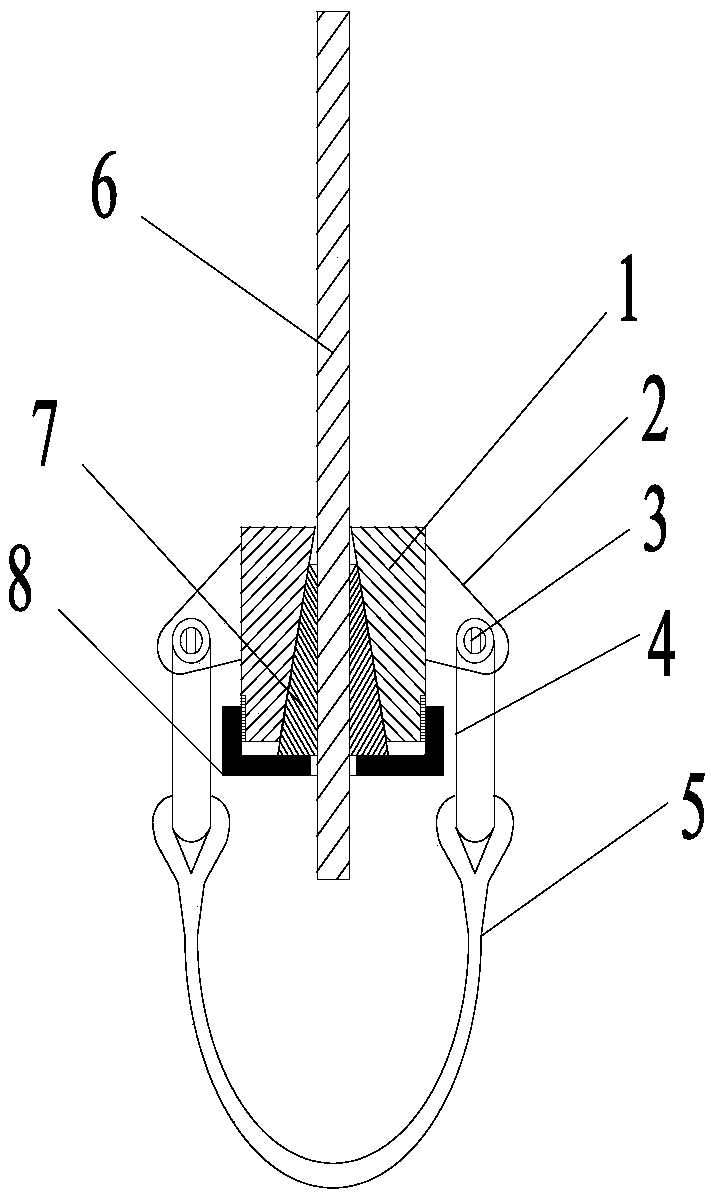

[0018] Such as figure 1 with figure 2 As shown, the special wire clamp for coal mines of the present invention includes a tapered sleeve 1. The tapered sleeve 1 is a columnar structure. The tapered sleeve 1 is provided with a tapered hole through which the anchor cable 6 passes. There are two ear-shaped structures 2 on both sides of the sleeve 1. The ear-shaped structures 2 are symmetrically arranged on both sides of the tapered sleeve 1. The tapered sleeve 1 and the ear-shaped structure 2 are cast in one piece, which is the cone shape of the sleeve 1. Open the hole, the upper hole is 3-10mm larger than the anchor cable 10, the lower hole is matched with the clip 7, the ear-shaped structure 2 is provided with a connecting hole 3, and the two ear-shaped structures 2 are respectively provided with a shackle 4 through a threaded nut The two shackles 4 are eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com