Patents

Literature

139results about How to "Prevent pull-off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

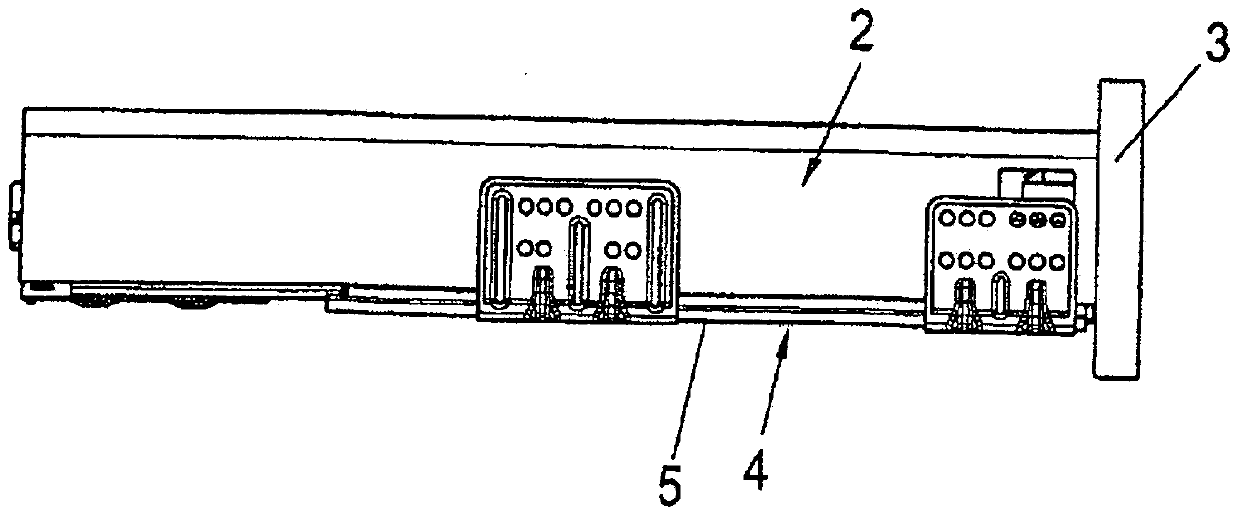

Technology for processing semi-hole of PCB board

ActiveCN101547569APrevent pull-offAvoid defectsPrinted element electric connection formationBiochemical engineeringCopper

The invention relates to a process for manufacturing a PCB board, in particular to technology for processing a PCB board provided with a semi-hole. Aiming at avoiding the phenomenon that copper on the hole wall is pulled off or damaged when the semi-hole is formed, the process that the electric milling of the semi-hole is added before etching and after film removal of a line is adopted, and the semi-hole and the external shape are not completed at the same time when the PCB board is formed. By the process that the electric milling of the semi-hole is added before etching and after film removal of the line, the electric milling is performed when the copper is fully connected with the copper on the hole wall in 360 degrees, thereby avoiding the phenomenon that the copper on the hole wall is pulled off or damaged when the semi-hole is formed, improving the yield of products and lowering cost of an enterprise.

Owner:SHENZHEN BOMIN ELECTRONICS

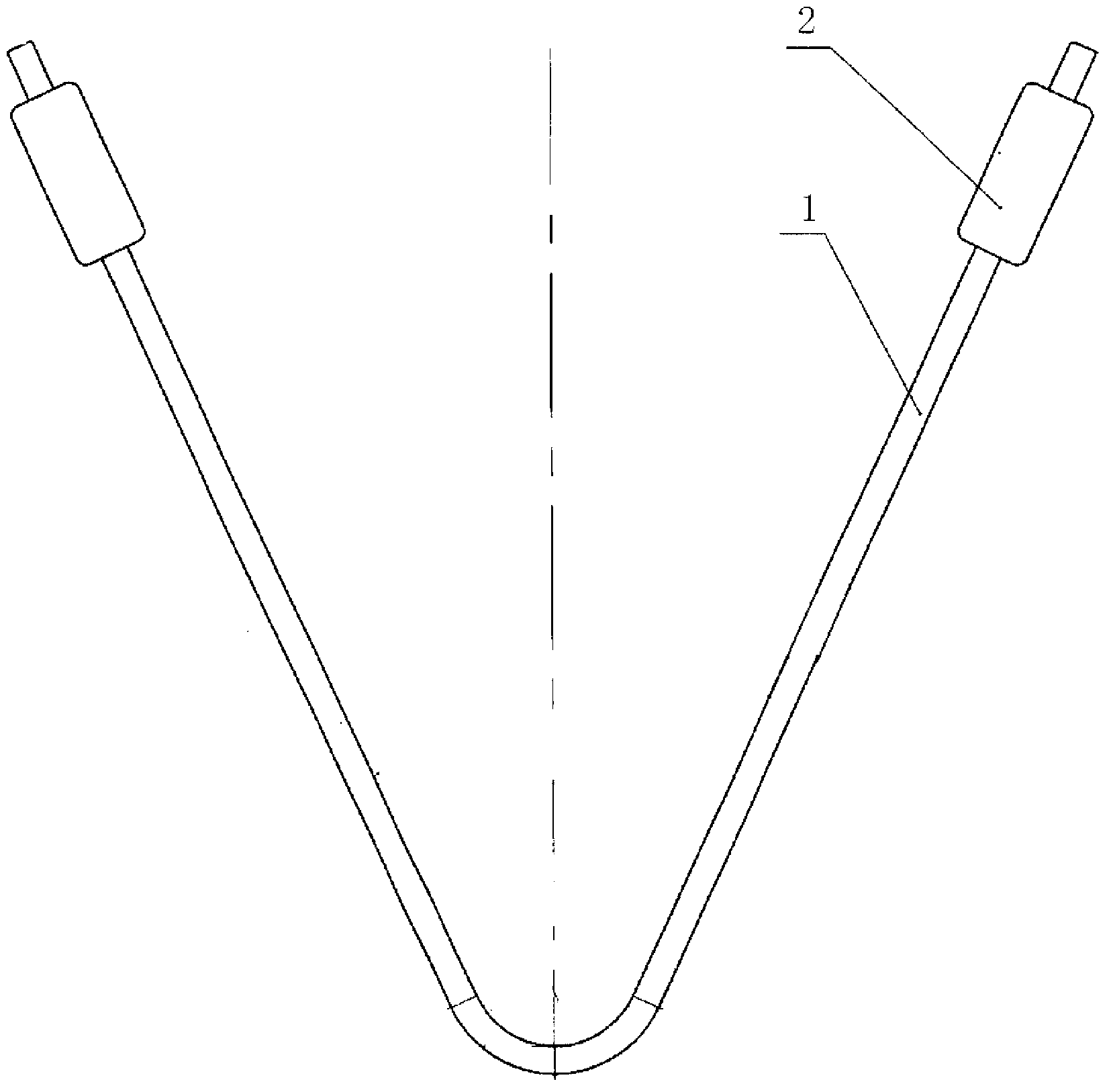

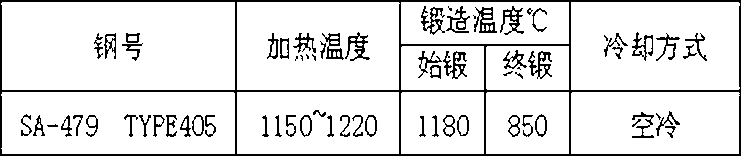

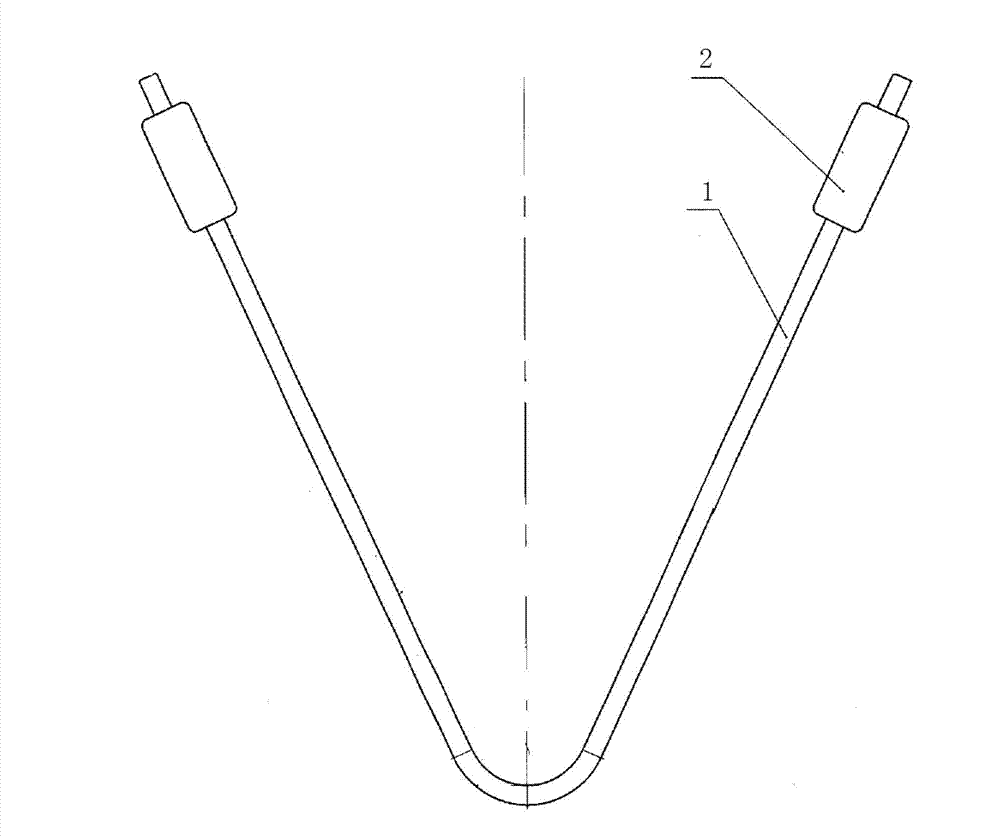

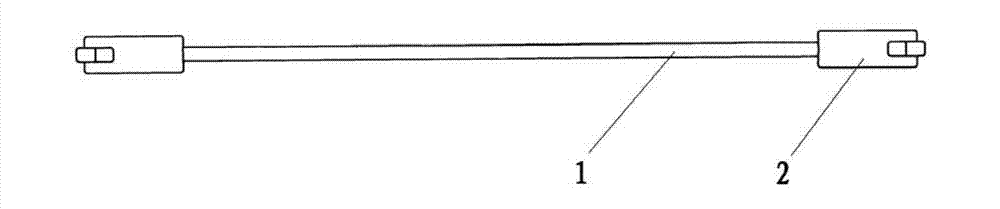

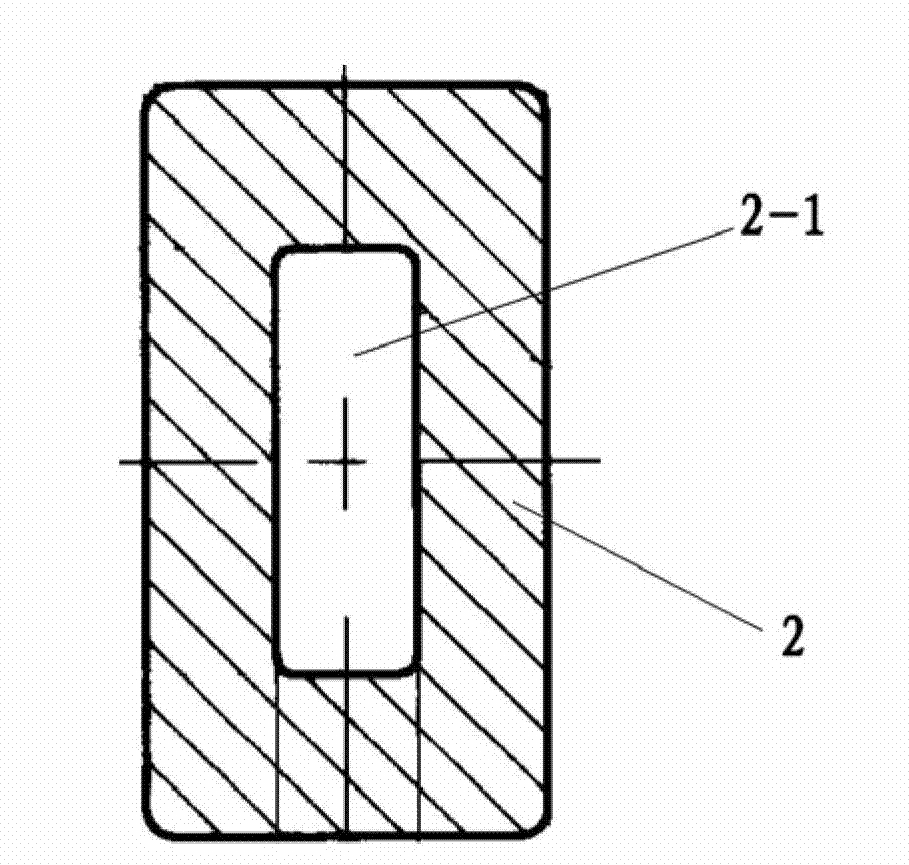

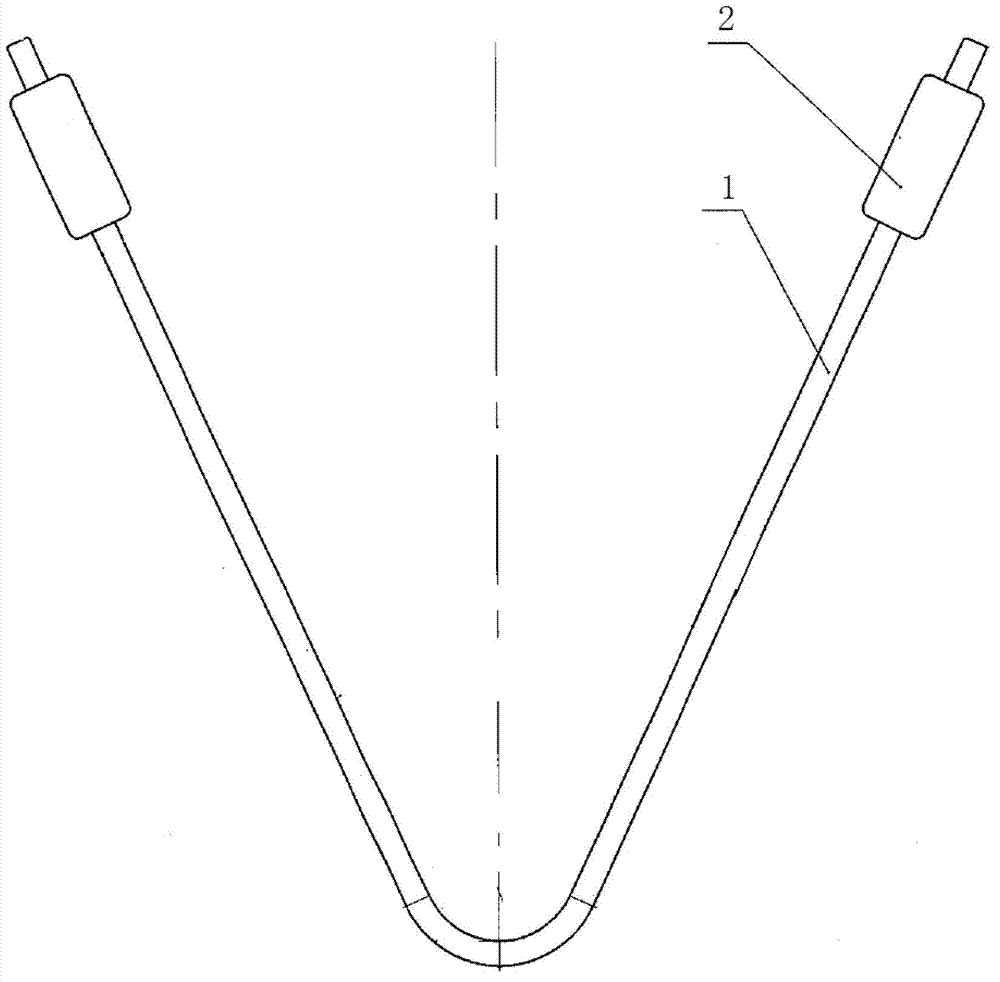

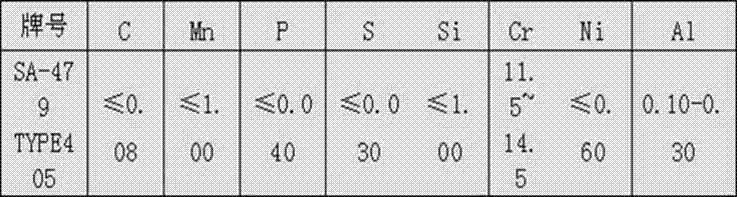

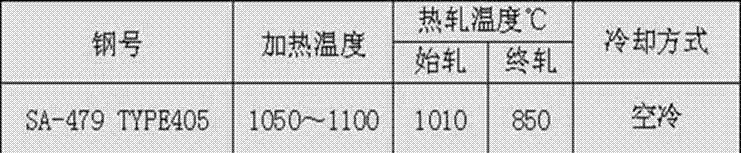

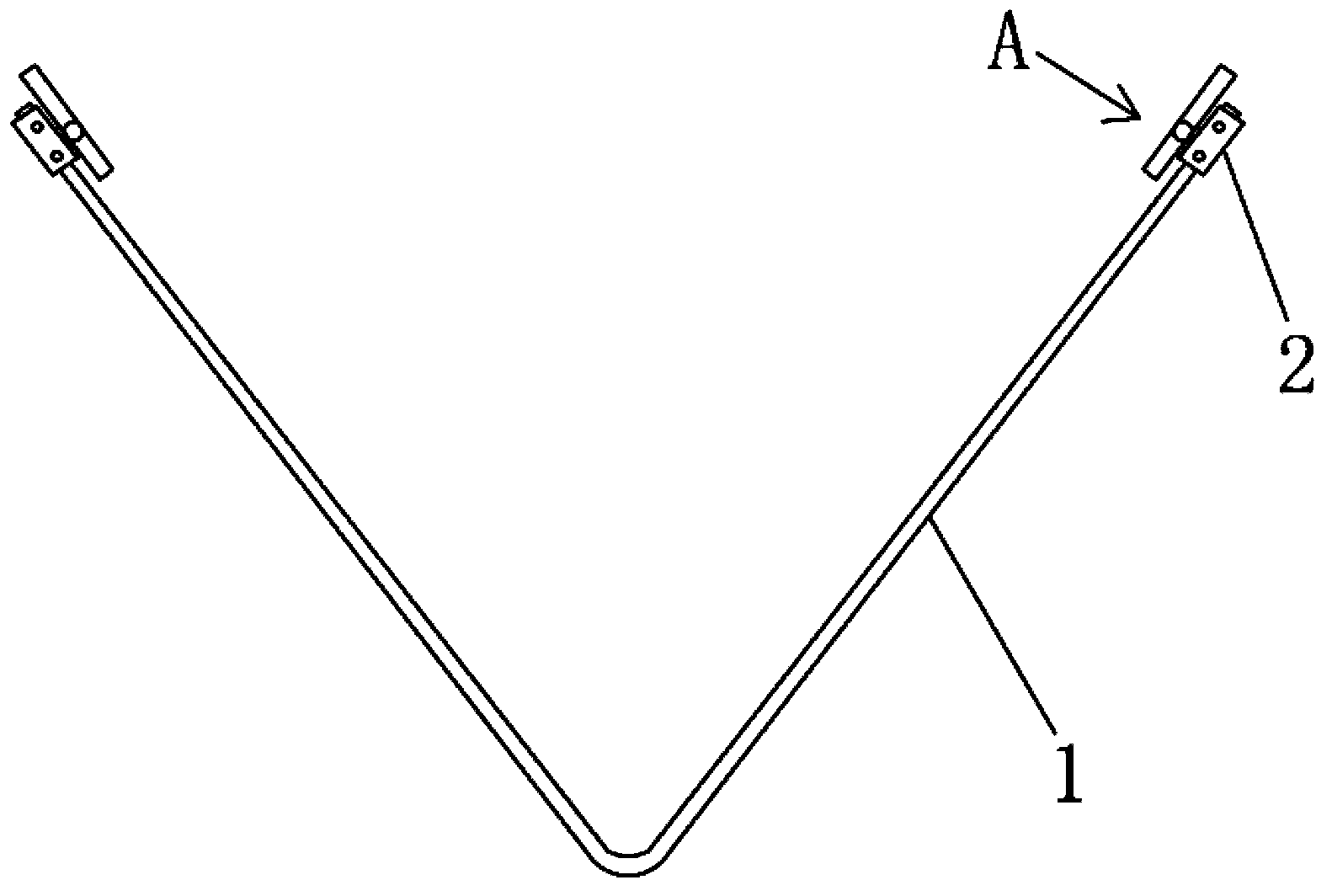

Anti-vibration strip component of steam generator of AP1000 nuclear power unit

ActiveCN102794608ASimple structureQuality assuranceNuclear energy generationNuclear power plant detailsNuclear engineeringRadiochemistry

The invention discloses an anti-vibration strip component of a steam generator of an AP1000 nuclear power unit. The anti-vibration strip component comprises a V-shaped anti-vibration strip and two end caps respectively arranged on both ends of the anti-vibration strip, wherein the anti-vibration strip is made of a 405 stainless steel material, and the end caps are made from a 609 nickel-based alloy material. A preparation method for preparing the anti-vibration strip component comprises the following steps of: preparing the anti-vibration strip, preparing the end caps, bending, assembly the end caps, heading, checking, cleaning and packaging. According to the anti-vibration strip component of the steam generator of the AP1000 nuclear power unit provided by the invention, the structure is simple, the product quality conforms to precision requirements of the steam generator in a nuclear power plant about the anti-vibration strip, and the anti-vibration strip component is safer to use. According to the preparation method of the anti-vibration strip, through strict preparation steps, the technique requirements about the anti-vibration strip component of the steam generator in the nuclear power plant are ensured, the quality is ensured, and safety is improved.

Owner:丹阳市龙鑫合金有限公司

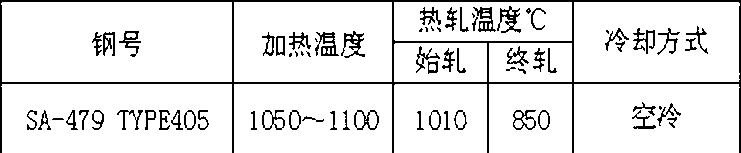

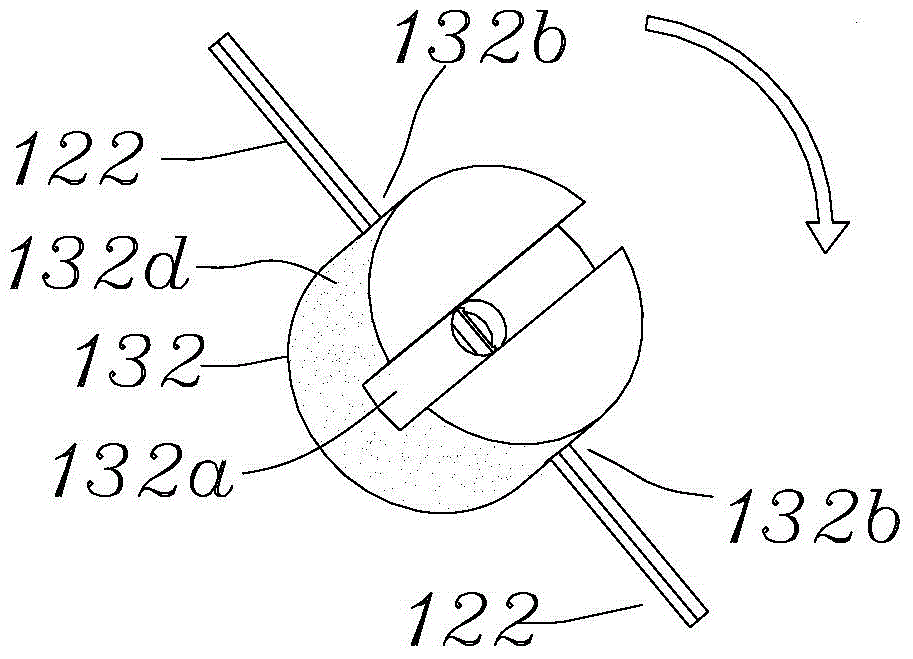

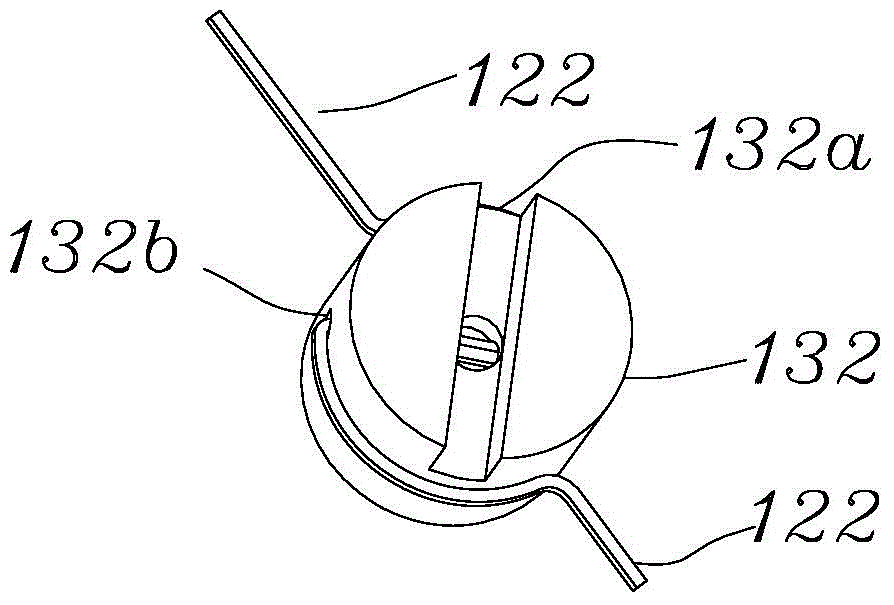

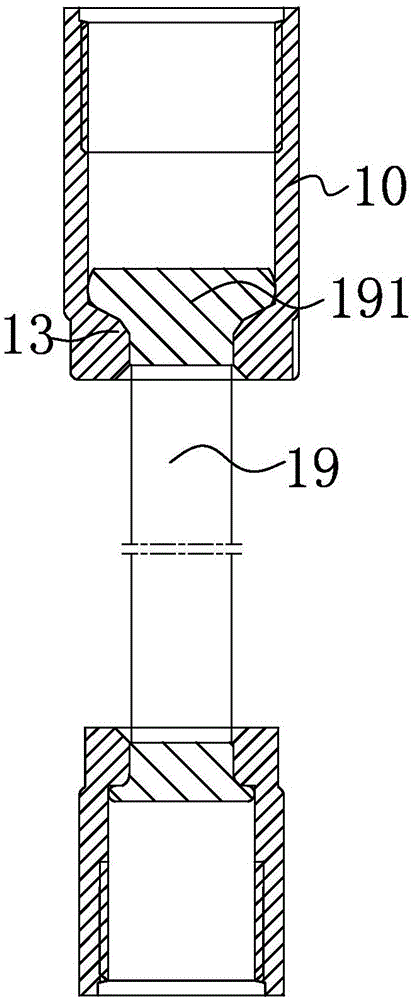

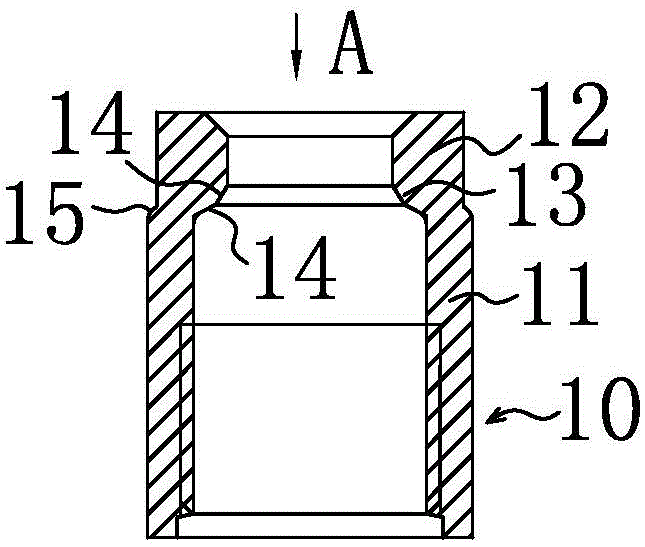

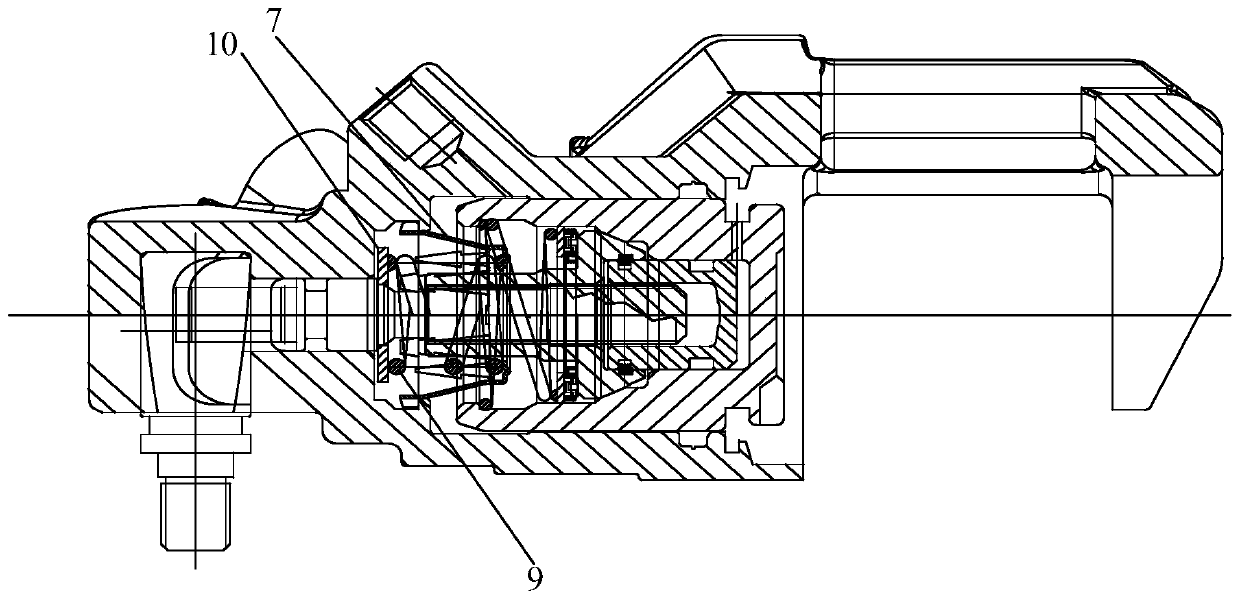

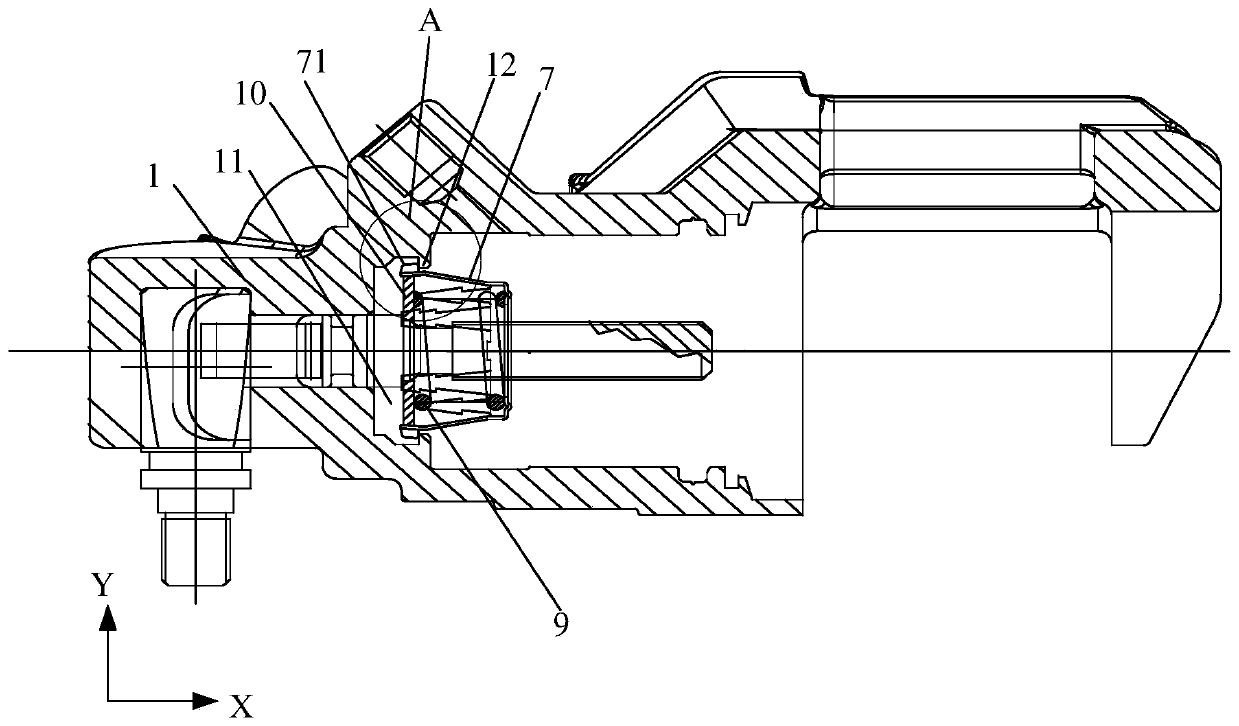

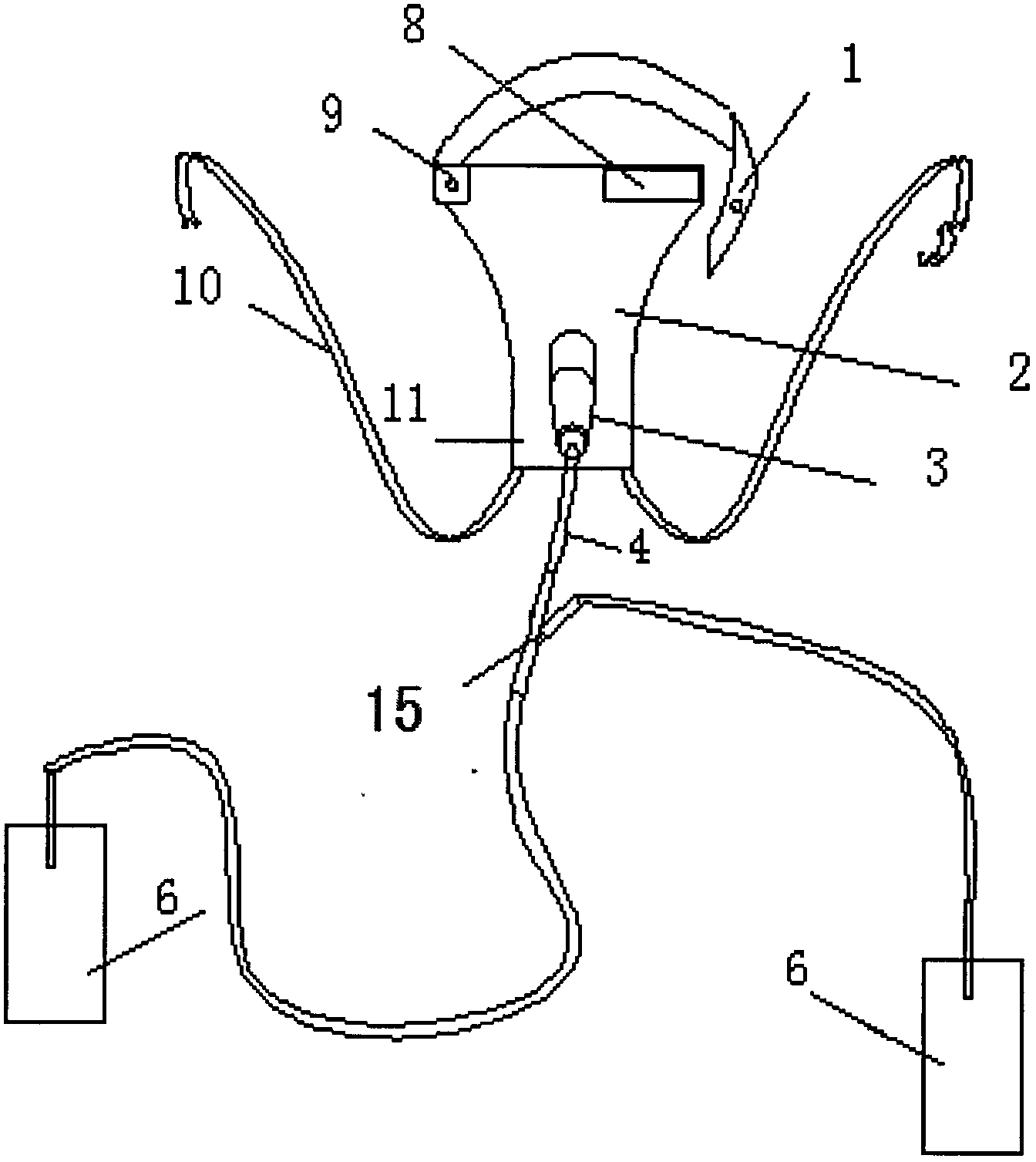

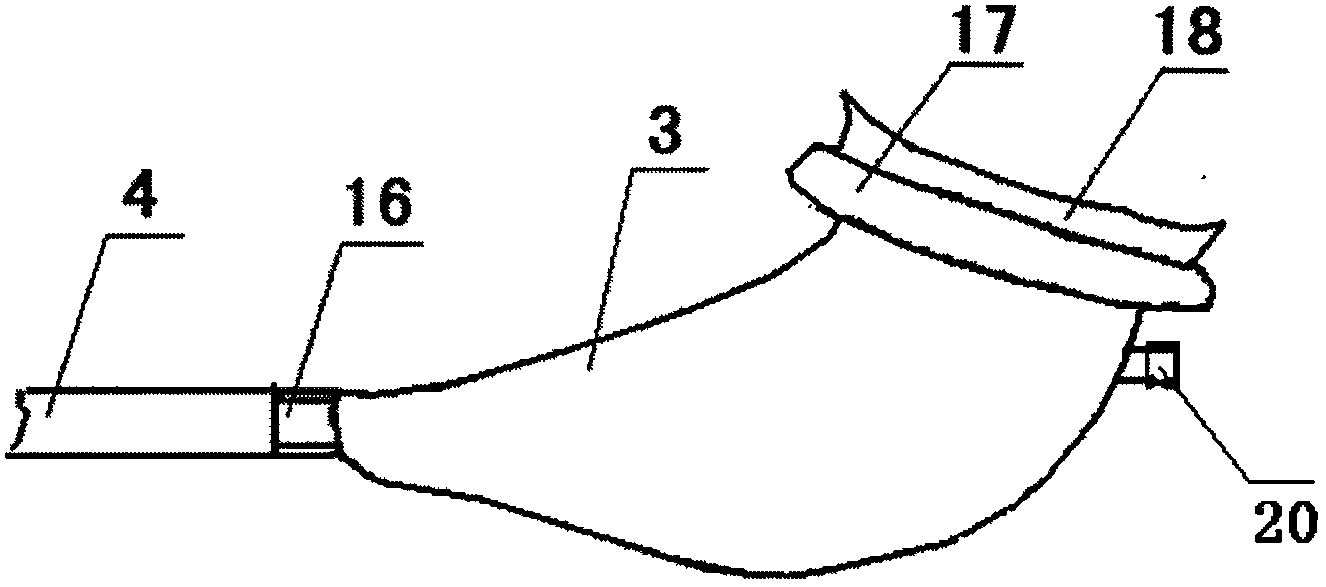

Bend-adjustable medical catheter and assembling method thereof

The invention discloses a bend-adjustable medical catheter and an assembling method thereof. The bend-adjustable medical catheter comprises a catheter, a handle and a traction wire, wherein the far end of the traction wire is connected with an elastic far end of the catheter; and the bend-adjustable medical catheter further comprises a clamping device arranged in the handle and connected with the handle, the clamping device comprises a body and a rotating part, the body is provided with an accommodating groove and guide holes penetrating through the outer wall of the body and the accommodating groove, the rotating part is accommodated in the accommodating groove, and a slot which is smaller than the diameter of the traction wire is formed between the rotating part and the inner wall of the body, and the near end of the traction wire penetrates through the guide hole and is clamped in the slot. The assembling method comprises steps as follows: the near end of the traction wire penetrates through the guide holes formed in the body of the clamping device; and the rotating part is rotated to drive the traction wire to rotate to wind around the outer wall of the rotating part until the near end of the traction wire is clamped in the slot located between the rotating part and the body. The traction wire is firmly connected, the bend-adjusting reliability and flexibility are high, and the medical catheter can be adjusted on the scene to accord with the condition of an individual; and the assembling method is simple, reliable, convenient and flexible.

Owner:LIFETECH SCI (SHENZHEN) CO LTD

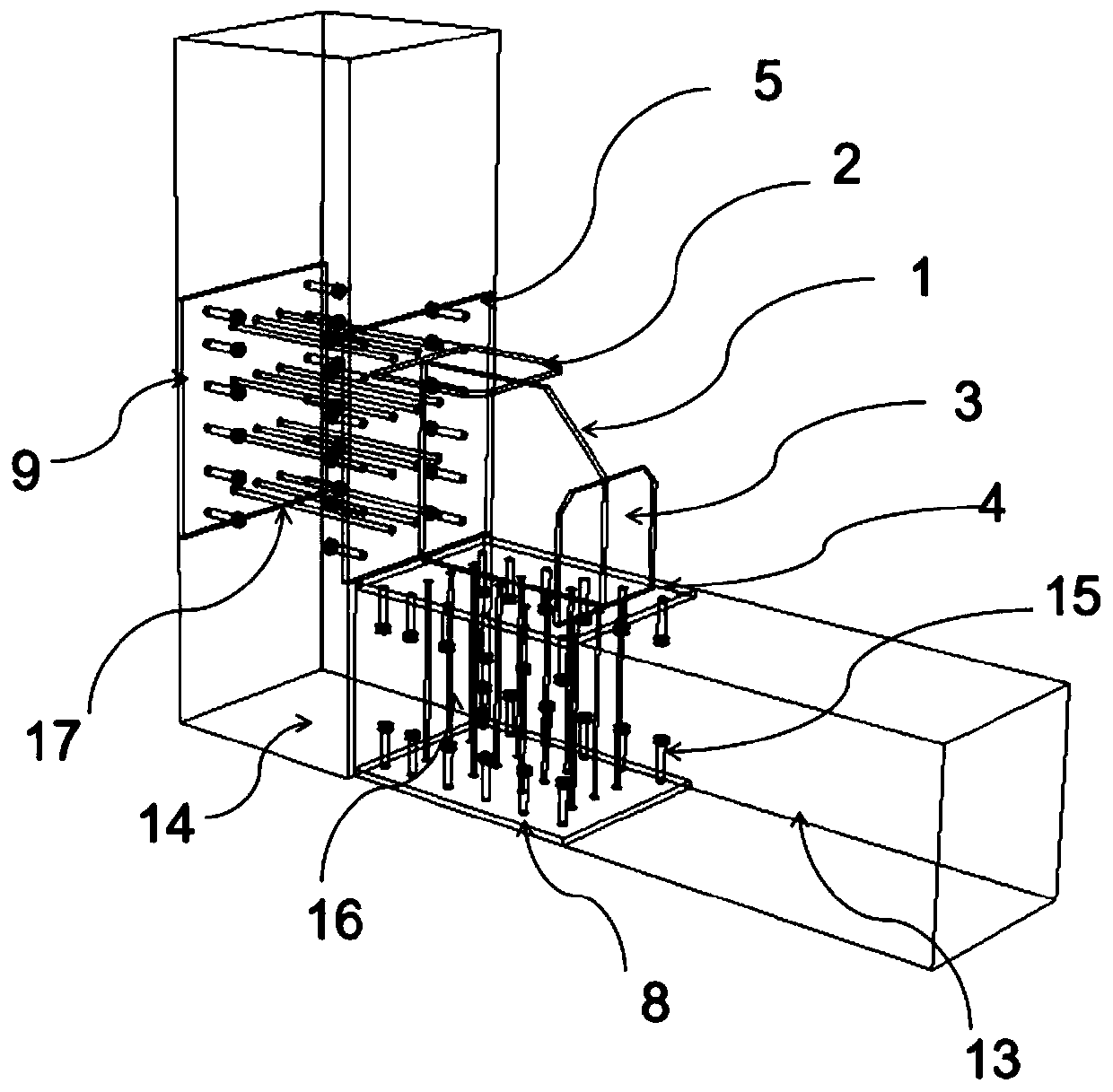

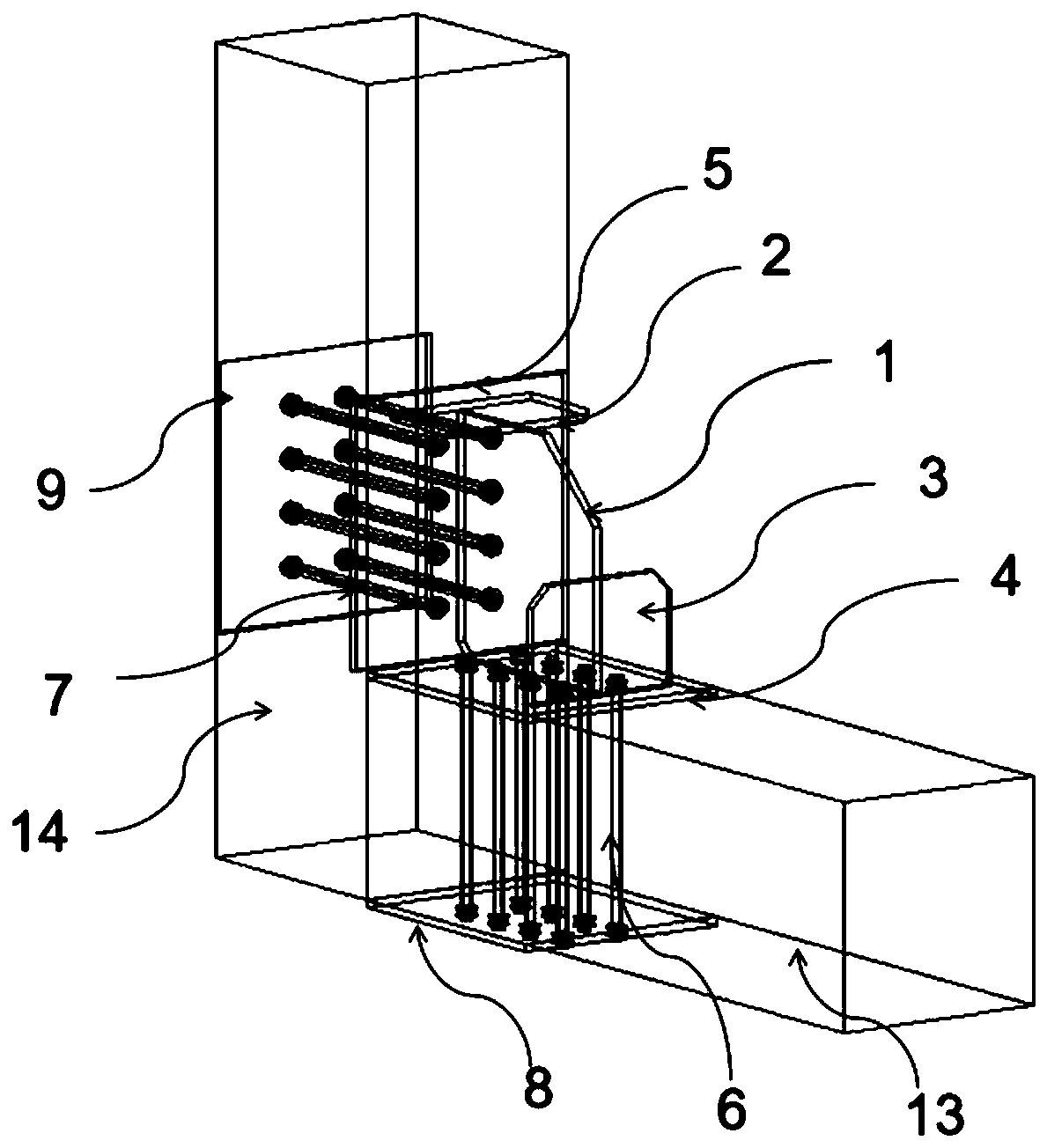

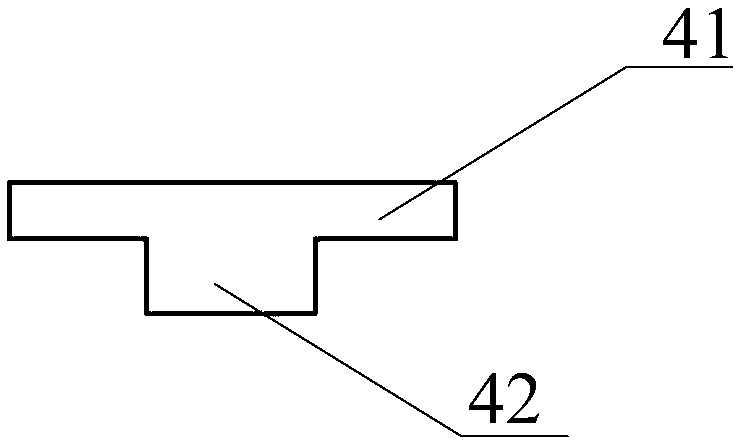

Connector used for connecting two objects and prefabricated member used for connector during connection

ActiveCN105113502AImprove tensile strengthPrevent pull-offBulkheads/pilesEngineeringMechanical engineering

The invention belongs to the technical field of building members, and relates to a connector used for connecting two objects and a prefabricated member used for the connector during connection. The invention solves the technical issues that connection is unreliable / inconvenient in the prior art. The connector comprises two connecting nuts, an inserting part is screwed into one of the connecting nut, and a middle nut is screwed in the other connecting nut, a locking stage of the connecting nut is sequentially provided with an elastic assembly and a locating clasp, the locating clasp can lock the inserting part so as to make the two connecting nuts connect with each other after the inserting part penetrates the middle nut and is inserted in the locating clasp. The connector is convenient and reliable during connection.

Owner:周兆弟

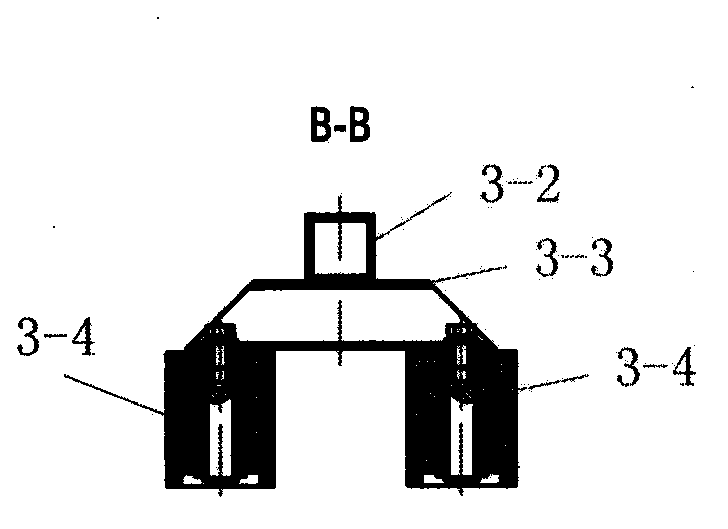

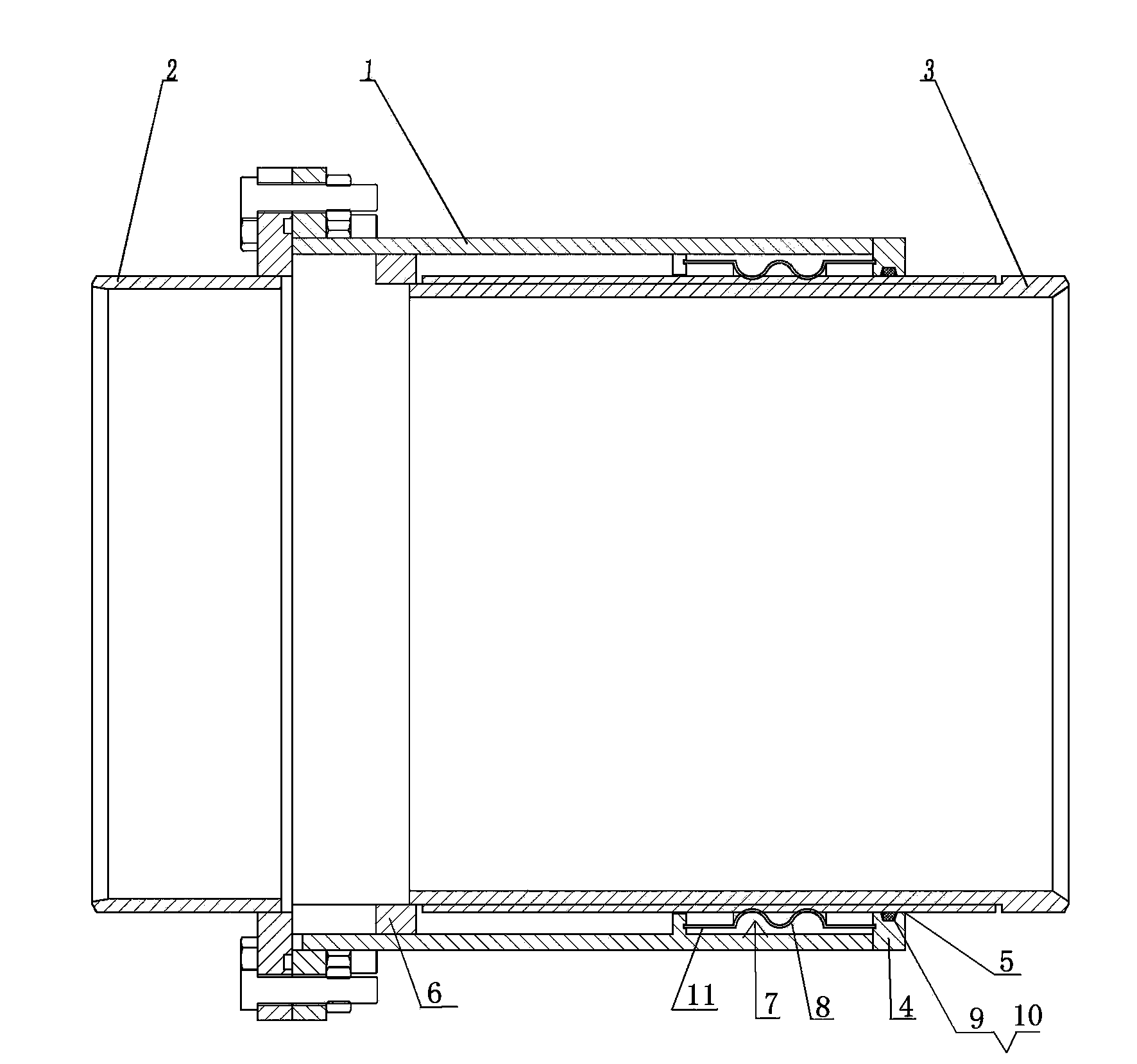

Groove type condensation solar heat collecting tube with compensation sealing structure and assembling process of groove type condensation solar heat collecting tube

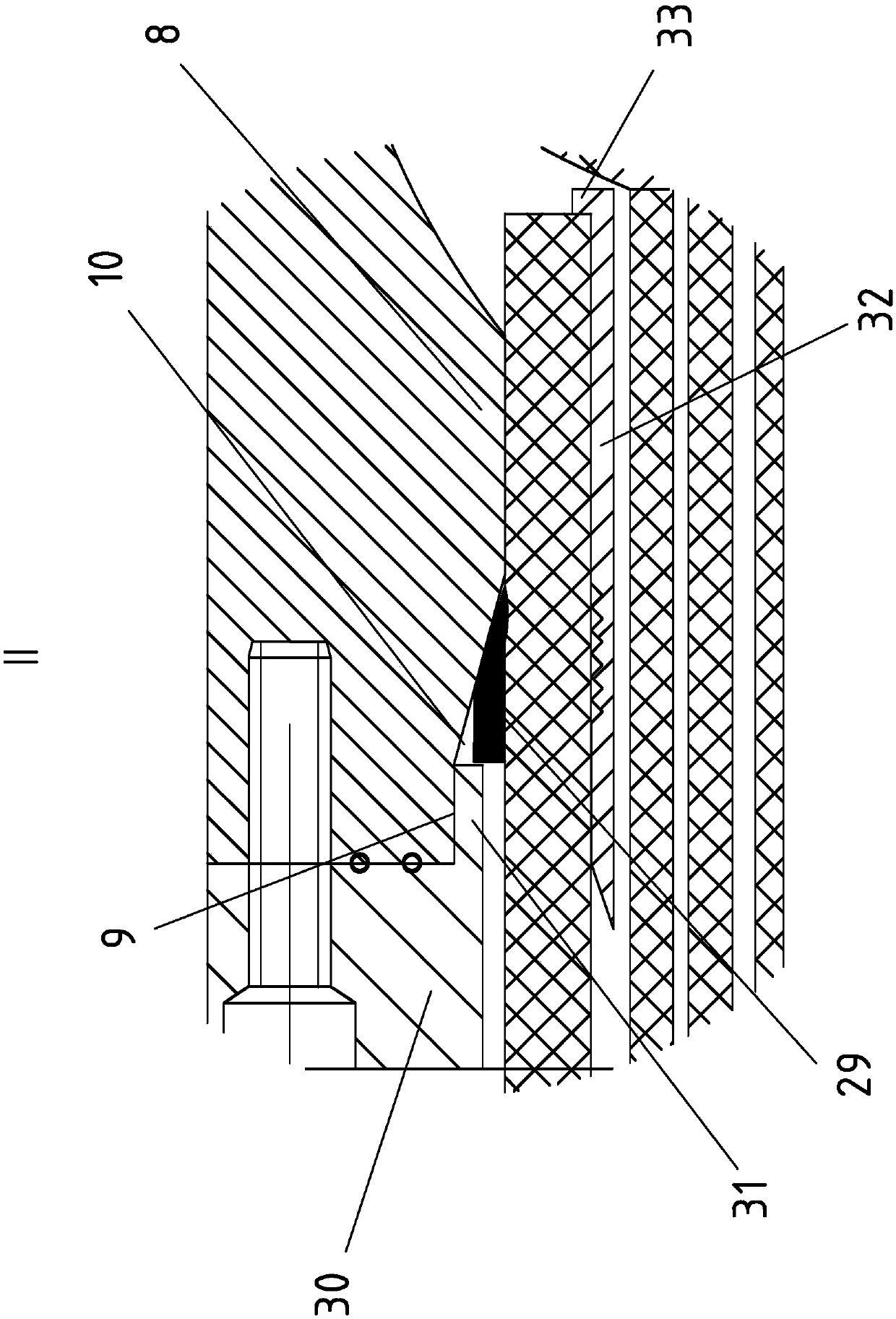

ActiveCN102563931AHas the effect of exerting stressGood deformabilitySolar heating energySolar heat devicesSilicon rubberVacuum chamber

The invention belongs to the technical field of solar thermal utilization, and particularly discloses a groove type condensation solar heat collecting tube with a compensation sealing structure. The groove type condensation solar heat collecting tube is provided with a coated stainless steel tube, a coated borosilicate glass tube is sleeved on the outside of the coated stainless steel tube, stainless steel seal heads are sleeved at both ends of the coated stainless steel tube, and the outer wall of the coated stainless steel tube is hermetically connected with the stainless steel seal heads; the coated borosilicate glass tube is slidably connected with the stainless steel seal heads; high-temperature-resistant silicon rubber compensation sleeves are sleeved on the stainless steel seal heads, and two ends of each high-temperature-resistant silicon rubber compensation sleeve are respectively hermetically connected with the coated borosilicate glass tube and the corresponding stainless steel seal head; and heat-insulation vacuum chambers are disposed among the coated stainless steel tube, the coated borosilicate glass tube and the stainless steel seal heads. The heat collecting tube is provided with the high-temperature-resistant silicon rubber compensation sleeves with cheap prices, stress destruction can be avoided, components of the heat collecting tube are welded and hermetically sealed, and accordingly the groove type condensation solar heat collecting tube is high in reliability and structural tension resistance and fine in heat-insulation performance. In addition, welding operation is seldom carried out in assembling process, yield of finished products is high, the process is simple, and labor cost is low.

Owner:溧阳常大技术转移中心有限公司

Mattress cover

InactiveUS20100088819A1Effectively and completely coveringPrevent pull-offStuffed mattressesBlanketEngineering

Disclosed is a mattress cover. The mattress cover includes a top panel and a bottom panel, and a covering member. The top panel and the bottom panel are coupled to configure an enclosure having a side opening. Further, the covering member extends from at least one of the top panel and the bottom panel. The covering member is capable of being folded inwardly to releasably close the side opening of the enclosure.

Owner:CARTER TONIA +1

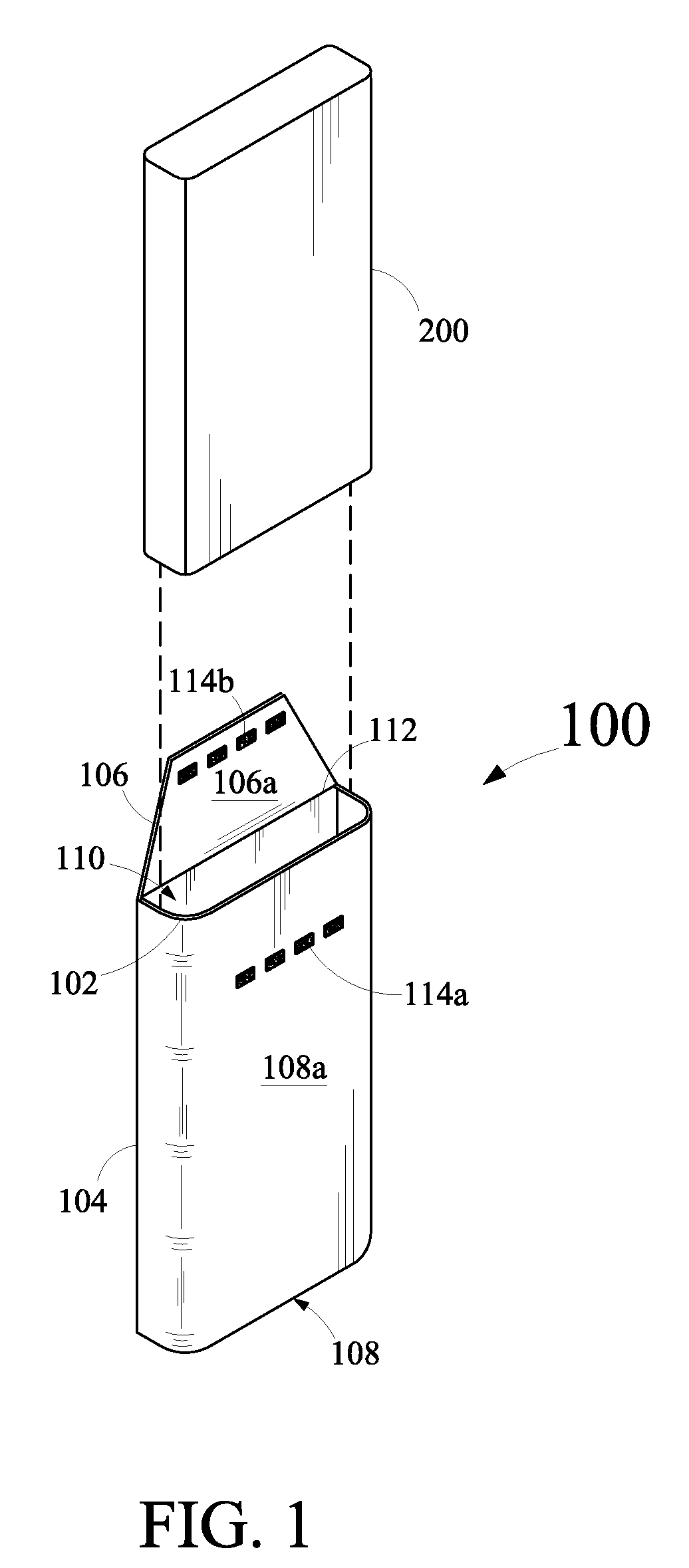

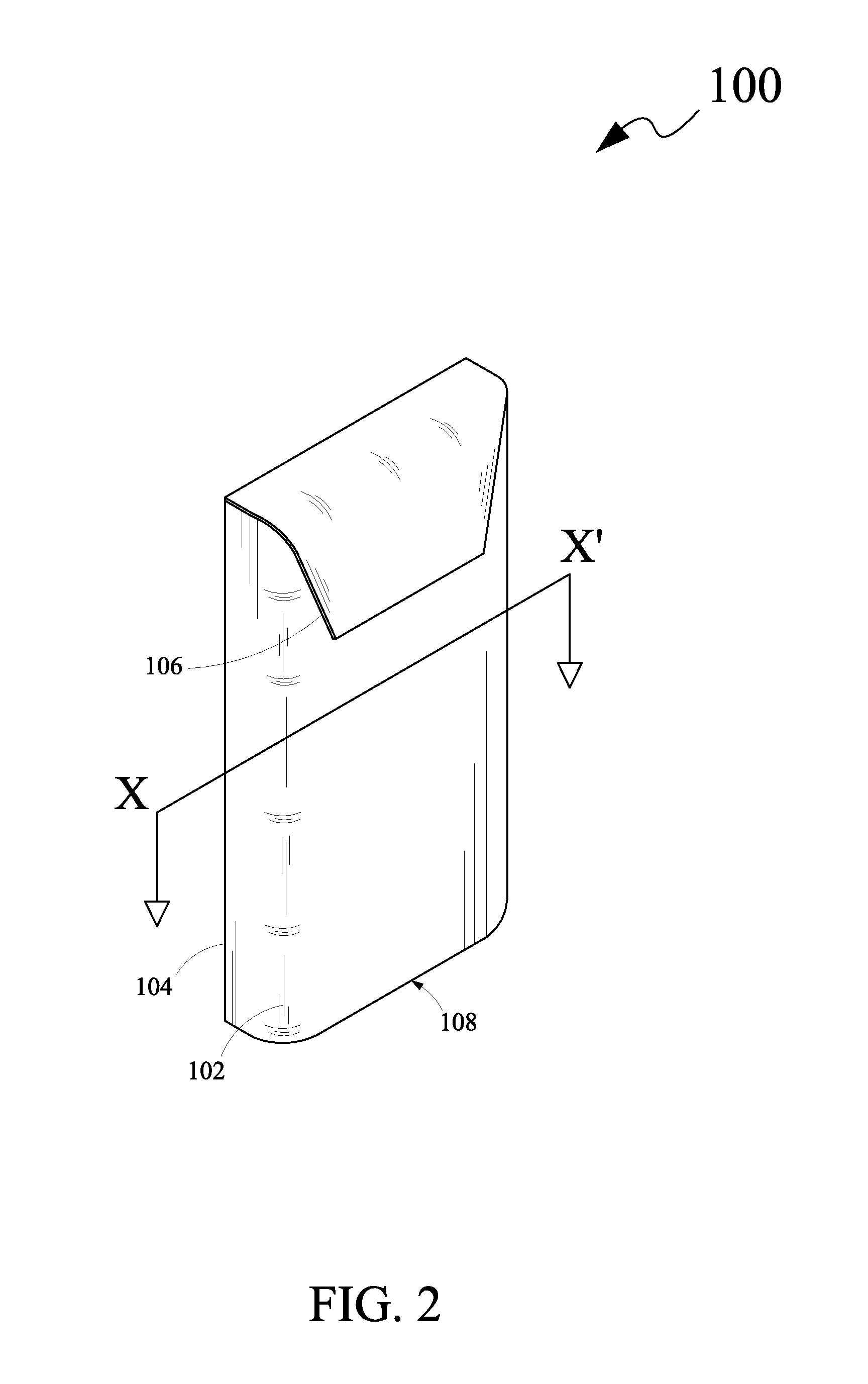

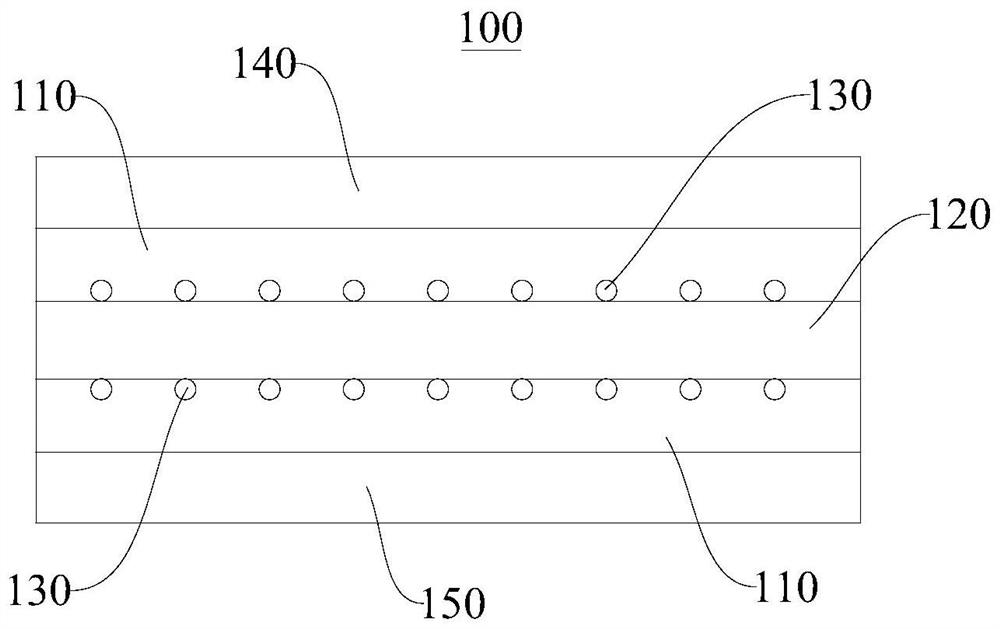

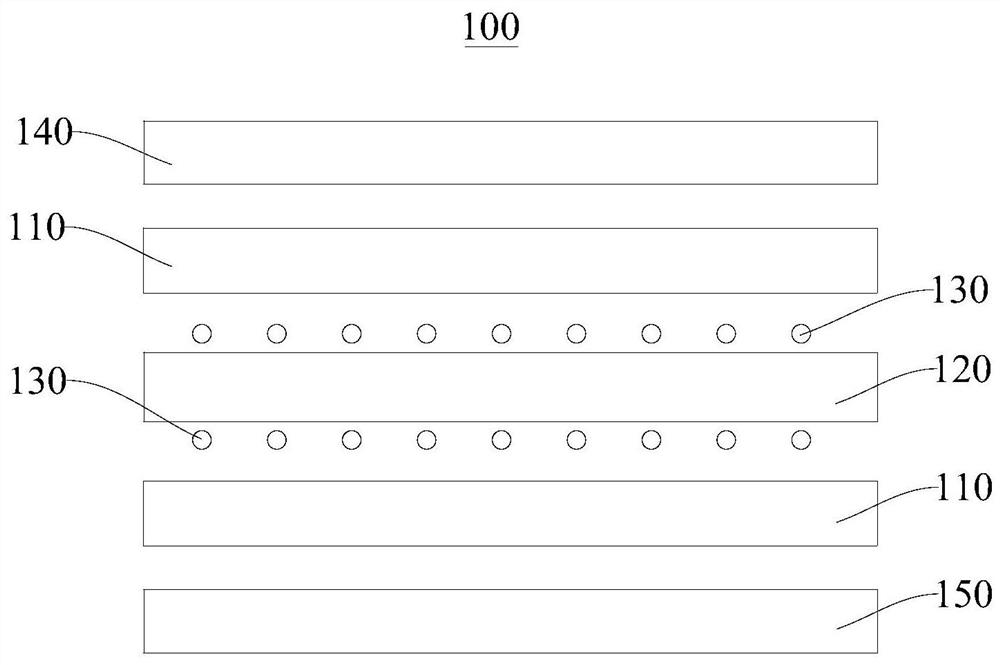

Photovoltaic packaging adhesive film, photovoltaic module and preparation method of photovoltaic module

ActiveCN112289879ASimple structureImprove adaptabilityFinal product manufacturePhotovoltaic energy generationHeterojunctionAdhesive

The embodiment of the invention provides a photovoltaic packaging adhesive film, a photovoltaic module and a preparation method of the photovoltaic module, and belongs to the technical field of photovoltaic power generation. The photovoltaic packaging adhesive film comprises an adhesive film body, the adhesive film body is provided with a first region and a plurality of second regions distributedin the first area at intervals, the crosslinking degree of the first region is not higher than 20%, and the crosslinking degree of the second regions is not lower than 50%. The photovoltaic module comprises a battery piece, a solder strip and the photovoltaic packaging adhesive film, and fine grid lines are arranged on the surface of the battery piece. One side of the solder strip abuts against the fine grid lines, and the other side of the solder strip abuts against the first region and the second region. Under the condition that the connection reliability of the welding strip and the grid lines is ensured, the Ag slurry consumption of a heterojunction cell can be reduced, and the packaging adhesive film is simple in structure and good in adaptability to existing multi-main-grid equipment.

Owner:RISEN ENERGY (CHANGZHOU) CO LTD

Continuous casting blank section casting cold material placing structure and placing method thereof

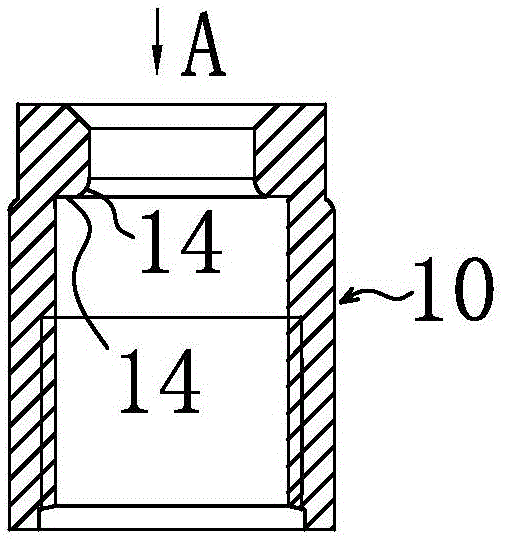

The invention discloses a continuous casting blank section casting cold material placing structure and a placing method thereof. The placing structure comprises a crystallizer, a dummy bar head arranged in the crystallizer, and the following parts arranged in sequence in the vertical direction from bottom to top: asbestos cloth, multiple steel wire shots and casting bricks; multiple asbestos ropes are filled in a gap between the crystallizer and the dummy bar head; the asbestos cloth respectively covers the upper surface of the dummy bar head and the multiple asbestos ropes; the casting bricks are coated with cold material frames; multiple reinforcements are arranged on the top surfaces of the cold material frames; and the multiple steel wire shots cover the asbestos cloth. The placing structure can reduce the economic loss in the casting process, and can prevent production accidents caused by overhigh center temperature of continuous casting blanks.

Owner:WUHU XINXING DUCTILE IRON PIPES

Rotary wire connector

InactiveCN108598754APrevent pull-offAvoid enteringRelieving strain on wire connectionCoupling contact membersEngineeringElectrical equipment

The invention discloses a rotary wire connector, which is mainly used for being connected on a cable and rotating relatively to prevent the cable from being twisted to deform and fracture. The rotarywire connector mainly comprises a ring-shaped plug end, a columnar plug end, a ring-shaped socket end, a columnar socket end and a sheath, and can relatively rotate in a good power-up state mainly bycorrespondingly inserting the ring-shaped socket end and the columnar socket end at the ring-shaped plug end of which two half body structures comprise the sheath and an insulating bush, and the columnar plug end. After using the rotary wire connector, a problem that the cable or a wire cannot rotate relatively and consequently is twisted to deform and fracture in the existing technology can be solved, and the rotary wire connector also can be used for electrical equipment which also require the cable to rotate relatively.

Owner:XINJIANG BAYI IRON & STEEL

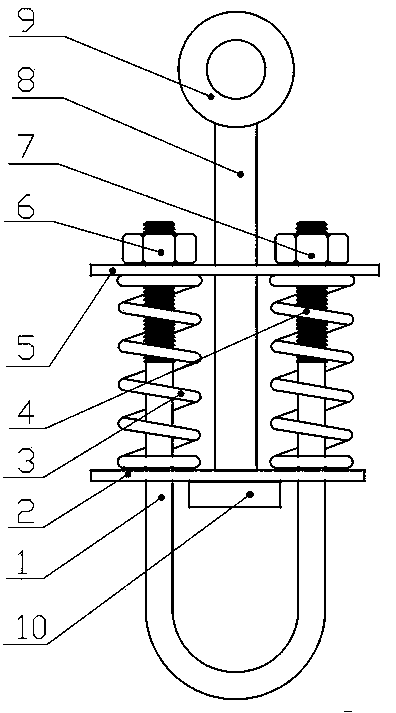

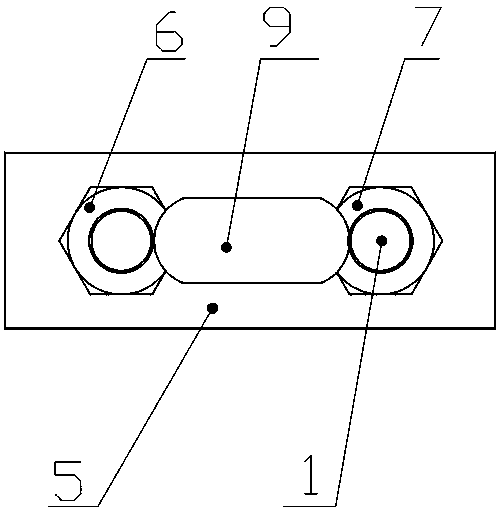

Buffer and damping wire pulling pole

The invention relates to the technical field of electric power fittings, in particular to a buffer and damping wire pulling pole. The buffer and damping wire pulling pole comprises a lower pulling pole body, a first hanging plate, a first spring, a second spring, a second hanging plate and an upper pulling pole body; the lower pulling pole body is of a U-shaped structure, and threads are arrangedat the two column ends of the lower pulling pole body; the two column ends of the lower pulling pole body are sleeved with the two ends of the first hanging plate correspondingly, the two column endsof the lower pulling pole body are sleeved with the first spring and the second spring correspondingly, and the first spring and the second spring are located above the first hanging plate; the two column ends of the lower pulling pole body are sleeved with the two ends of the second hanging plate correspondingly, and the two ends of the second hanging plate are located above the first spring andthe second spring; and the top ends of the two column ends of the lower pulling pole body are in threaded connection with a first nut and a second nut, and the lower end of the upper pulling pole bodydownwards penetrates through the second hanging plate and the first hanging plate in sequence and then is fixedly connected with a plug. According to the buffer and damping wire pulling pole, the structure is simple, the thick energy-storage springs are additionally mounted on the pulling pole bodies, tensioning of the pulling pole bodies on an electric pole can be ensured, the effects of bufferand damping are further achieved, and electric pole toppling due to the situation that fixing piles on the ground are pulled out by the pulling pole bodies under ultra-large tensile force can be prevented.

Owner:贵州航瑞电力设备制造有限公司

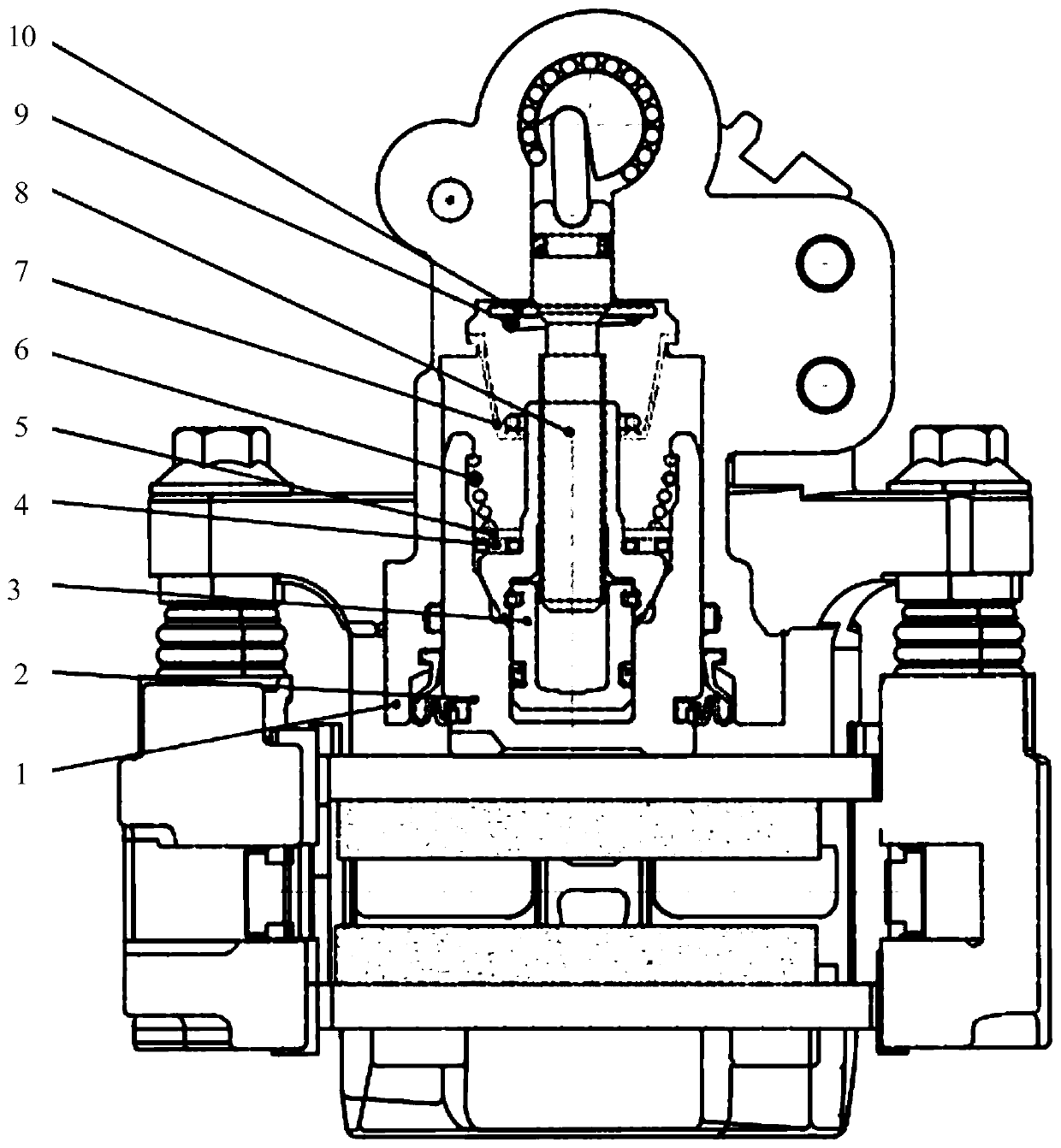

Parking brake clamp and automobile

PendingCN111120547AGuaranteed reliabilityImprove parking safetyBrake actuating mechanismsSlack adjustersPistonPush out

The invention provides a parking brake clamp and an automobile, and belongs to the technical field of motor vehicle braking. A clamp body, a piston arranged in the clamp body, a return spring base arranged in the clamp body and a screw are included, wherein one end of the screw is arranged in the piston, and the other end of the screw penetrates through the return spring base. The screw is sleevedwith a screw gasket. The screw gasket is located at the end, away from the piston, of the return spring base. When the screw drives the return spring base to move, the outer edge of the screw gasketabuts against the inner edge of the return spring base in the radial direction of the screw, so that the return spring base is clamped in the clamp body. When the piston is pushed out, the screw drives the return spring base and the screw gasket to move, the outer edge of the screw gasket abuts against the inner edge of the return spring base in the radial direction of the screw, the screw gasketis clamped at the end portion in the return spring base, pulling disengaging of the return spring base is avoided, reliability of the brake clamp during driving braking and parking braking is guaranteed, and parking safety is improved.

Owner:HUBEI HANGTE TECH CO LTD

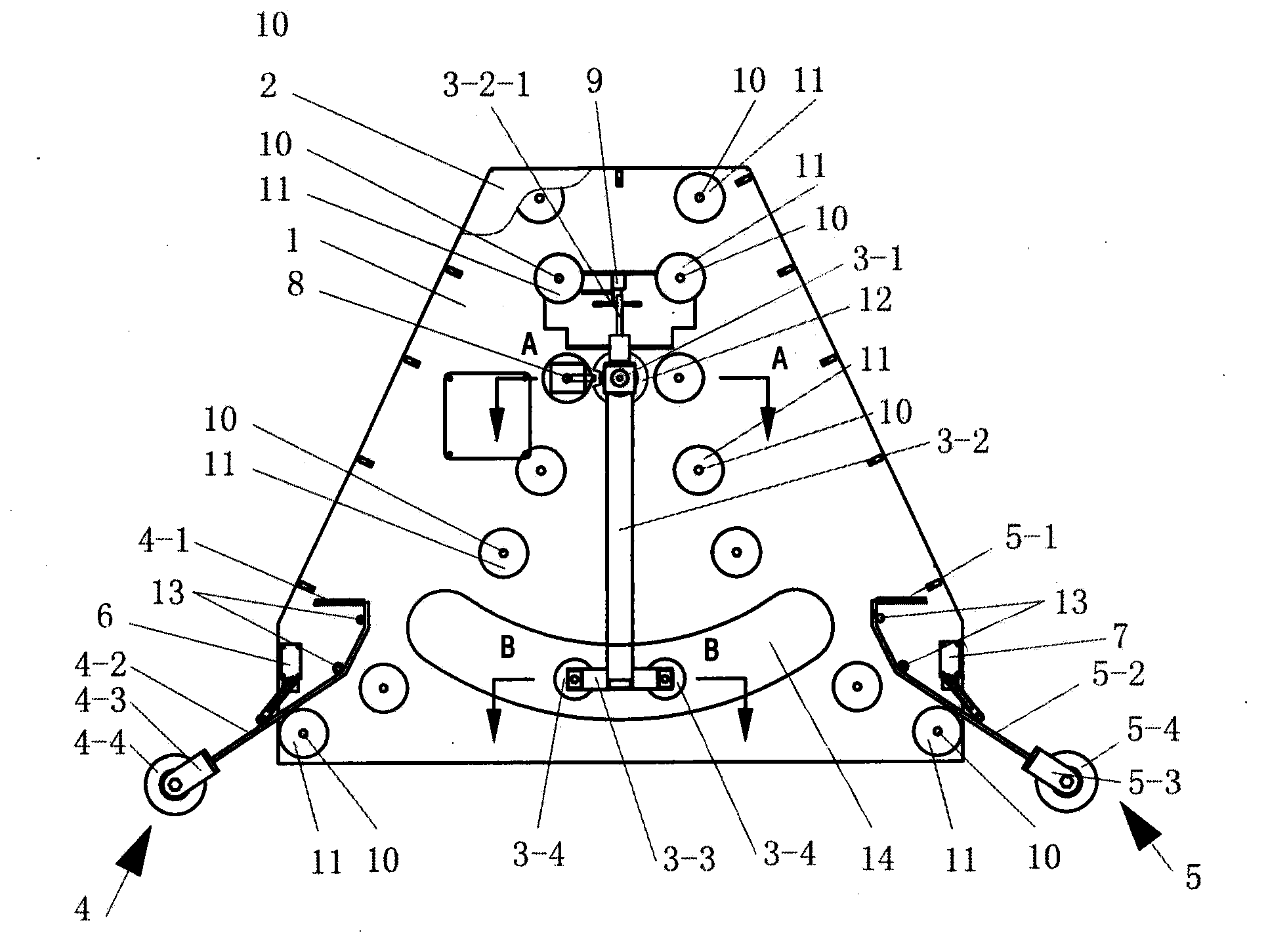

Swing cable guide

InactiveCN103896107APrevent pull offPrevent security incidentsFilament handlingContact elementLimit switch

The invention discloses a swing cable guide comprising a first clamp plate and a second clamp plate fixedly connected to each other. A swing rod device, a left tension device, a right tension device, a left limiting device, a right limiting device, a sensing proximity switch and a swing rod position limit switch are connected between the first clamp plate and the second clamp plate. The left tension device is connected between the first clamp plate and the second clamp plate on the left, and the right tension device is connected between the first clamp plate and the second clamp plate on the right. The sensing proximity switch is fixedly connected to the first clamp plate or second clamp plate. A swing rod of the swing rod device is provided with a contact element which can contact with the sensing proximity switch. The swing rod position limit switch is fixedly connected to the first clamp plate or second clamp plate. The swing rod is provided with a shift element which can contact with the swing rod position limit switch. The swing cable guide is capable of sensing a cable which is too tensioned or too loose so as to prevent safety accidents.

Owner:周敏亮

Special coating liquid for stone paper coating and preparation method thereof

The invention discloses a special coating liquid for stone paper coating and a preparation method thereof. The special coating liquid for stone paper coating is characterized by comprising the following components in parts by weight: 50-60 parts of silicone acrylic emulsion, 20-30 parts of lamellate calcium carbonate, 15-20 parts of organic silicon modified minute mineral fibers, 1-3 parts of casein, 1-1.5 parts of brightener, 0.5-1 part of disperser, 0.2-0.5 part of cross-linking agent, 50-80 parts of water and 10-20 parts of ethanol. The special coating liquid for stone paper coating of the invention is characterized by containing organic silicon modified mineral fibers which have certain wettability to stone papers. Fibers in the coating liquid can penetrate into inorganic powder in the stone paper surface by coating, so as to enhance adhesive force to solve the problem of pulling off inorganic powders in the stone paper by coating during a printing process to enhance applicability of stone paper in high-speed printing.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

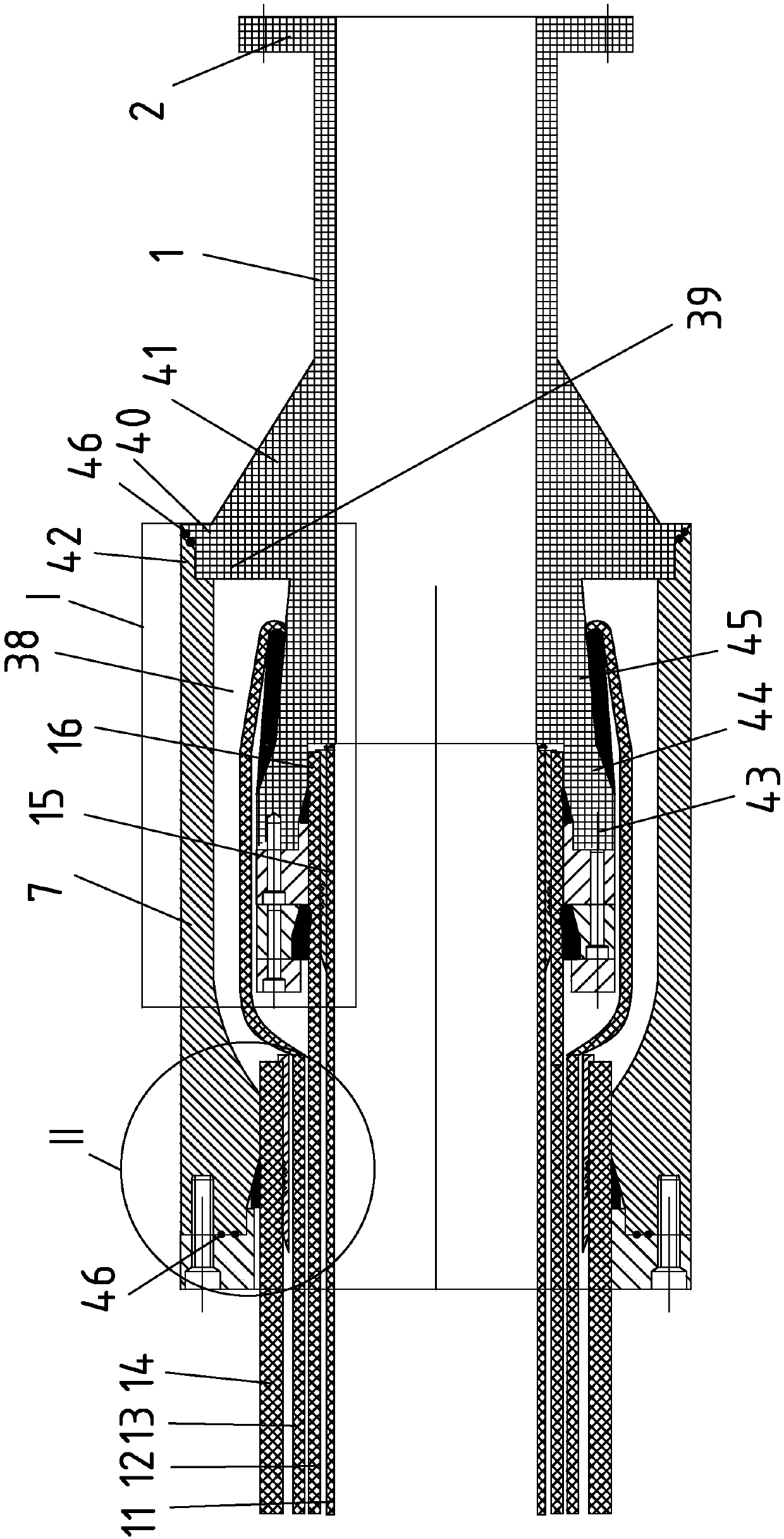

High-performance ultra-deep water non-bonded pipe joint

ActiveCN107642648AStrong stretchImprove sealingHose connectionsNon-disconnectible pipe-jointsEngineeringUltimate tensile strength

The present invention discloses a high-performance ultra-deep water non-bonded pipe joint which comprises a tubular joint body. The head end of the tubular joint body is provided with a joint body flange, the outer wall of the middle section of the tubular joint body is provided with a first annular connecting part, the outer wall of the rear section of the tubular joint body is provided with a second annular connecting part extending to the tail end of the tubular joint body, the inner cavity wall of the rear section of the tubular joint body is sequentially provided with a first cylinder ring groove, a first conical ring groove and a second cylinder ring groove along the axis of the tubular joint body, the two sides of the first cylinder ring groove are communicated with the tail end ofthe tubular joint body and the large end of the first conical ring groove respectively, the small end of the first conical ring groove is communicated with the second cylinder ring groove, the lower end of the side wall of the second cylinder ring groove close to the head end of the tubular joint body is provided with an annular connecting strip, and the annular connecting strip is provided with aCARCASS layer fixing ring. Compared with the prior art, the high-performance ultra-deep water non-bonded pipe joint is improved in connection strength, sealing property and stability, so that the high-performance ultra-deep water non-bonded pipe joint is more suitable for ultra-deep water pipes.

Owner:DALIAN UNIV OF TECH

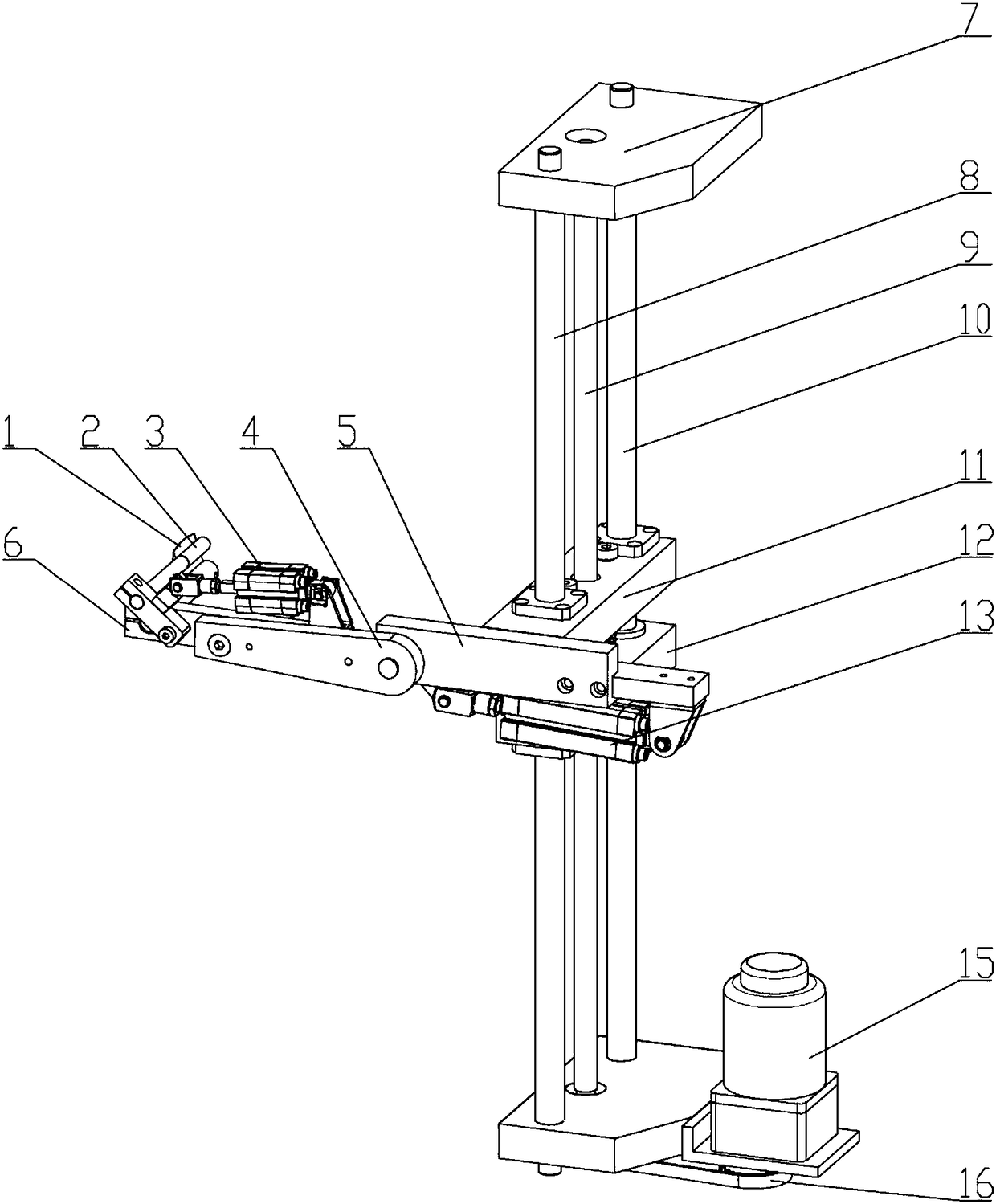

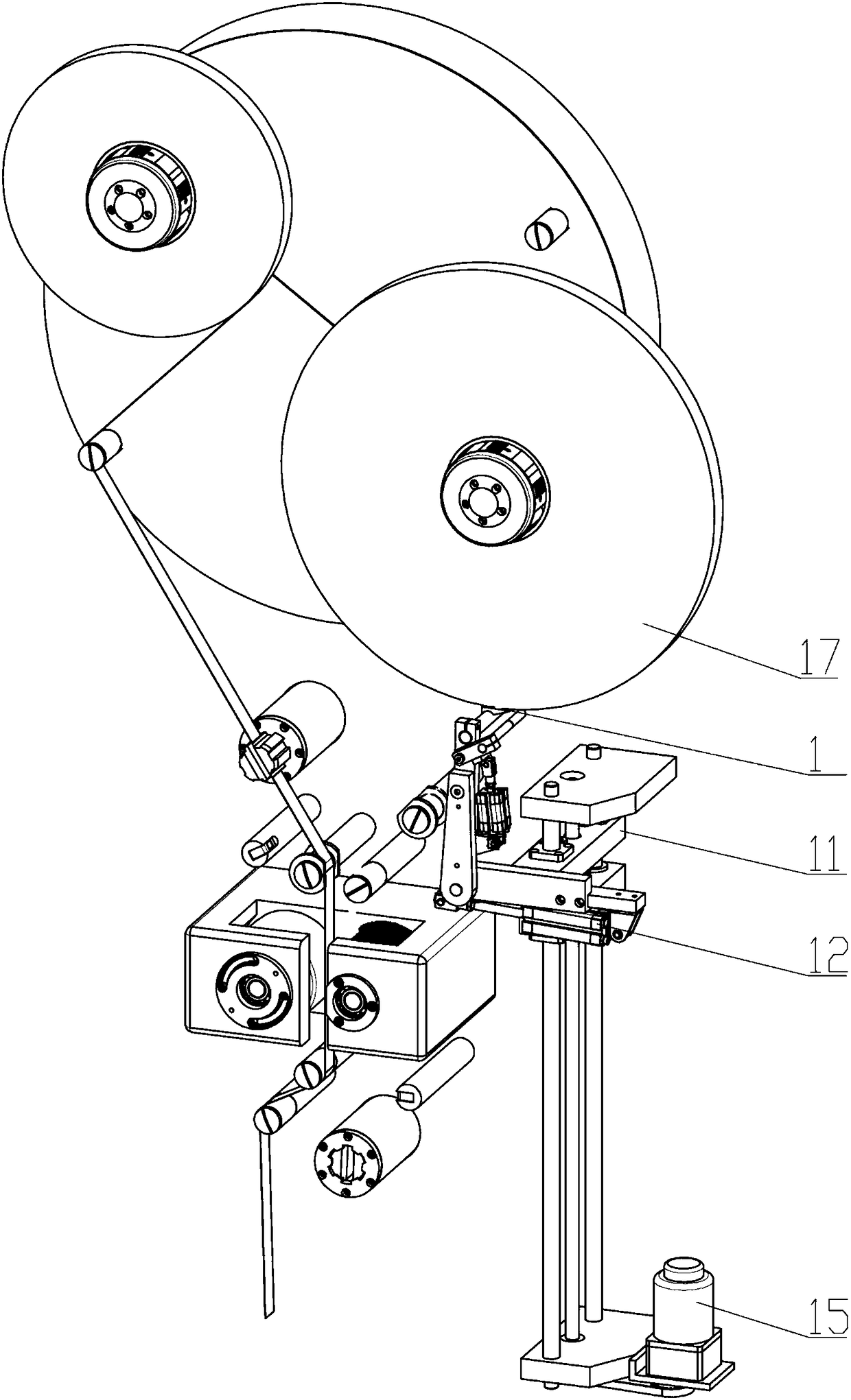

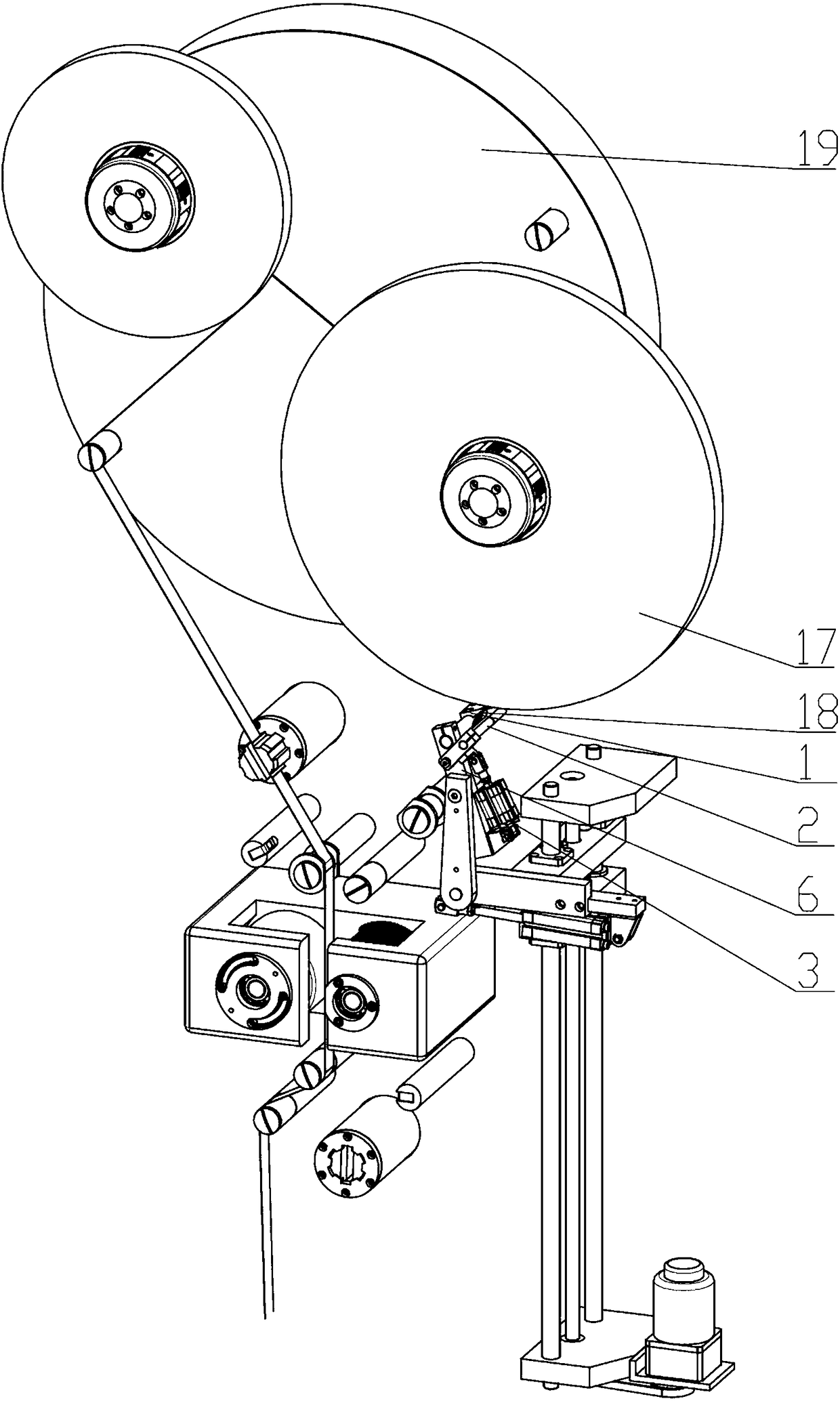

Automatic paper tape head searching and clamping mechanism for paper disc and control method

ActiveCN108217261APrevent pull-offGuaranteed reliabilityWebs handlingOptical axisPulp and paper industry

The invention discloses an automatic paper tape head searching and clamping mechanism for a paper disc and a control method. The mechanism comprises a paper peeling blade, a paper clamping rod, a first air cylinder, a connecting rod, a fixing rod, a floating connecting rod, fixing plates, a first linear main shaft, a screw rod, a second linear main shaft, a floating sliding block, a lifting sliding block, a second air cylinder, a motor and a synchronous belt, wherein the fixing plates comprise the upper fixing plate and the lower fixing plate, the first linear main shaft, the screw rod and thesecond linear main shaft are fixedly connected between the two fixing plates, the motor is connected with the screw rod through the synchronous belt, the screw rod is connected with the lifting sliding block in a matched mode, the lifting sliding block is connected with the floating sliding block through an elastic device, the floating sliding block is connected with the fixing rod, the fixing rod is hinged to the connecting rod, the tail end of the connecting rod is connected with the floating connecting rod, and the paper peeling blade and the paper clamping rod are arranged on the floatingconnecting rod. The automatic paper tape head searching and clamping mechanism has a flexible attaching mechanism, the blade can be attached to the paper disc and can not be attached to the paper disc too tightly, and therefore the problem that paper tape is damaged or can not be normally peeled off due to rigid attaching can be solved.

Owner:苏州茂泰精密机械有限公司

Continuous casting start casting operation method for square billets

The invention discloses a continuous casting start casting operation method for square billets, and belongs to the technical field of continuous casting operation methods. The continuous casting start casting operation method for the square billets aims at solving the problem that when start casting is performed, the billet drawing resistance is large due to the fact that initial billet shells and the crystallizer wall are prone to being bonded, so that the length of the billet shells in a crystallizer is too large and the strength of the billet shells in the crystallizer is too high. The method comprises the steps that 1, a dummy bar head is inserted into the crystallizer, and tundish start casting is performed; 2, a vibrating table is started; 3, a withdrawal and straightening machine is started and runs at the starting withdrawal speed; 4, the withdrawal speed of the withdrawal and straightening machine is steadily increased to the normal withdrawal speed. According to the continuous casting start casting operation method for the square billets, accidents such as withdrawal disengagement, withdrawal breakage and steel leakage are prevented from occurring, the effects are significant, the start casting production accidents are significantly reduced, and the method is suitable for being used for continuous casting start casting of the square billets, especially small square billets.

Owner:内蒙古包钢稀土钢板材有限责任公司

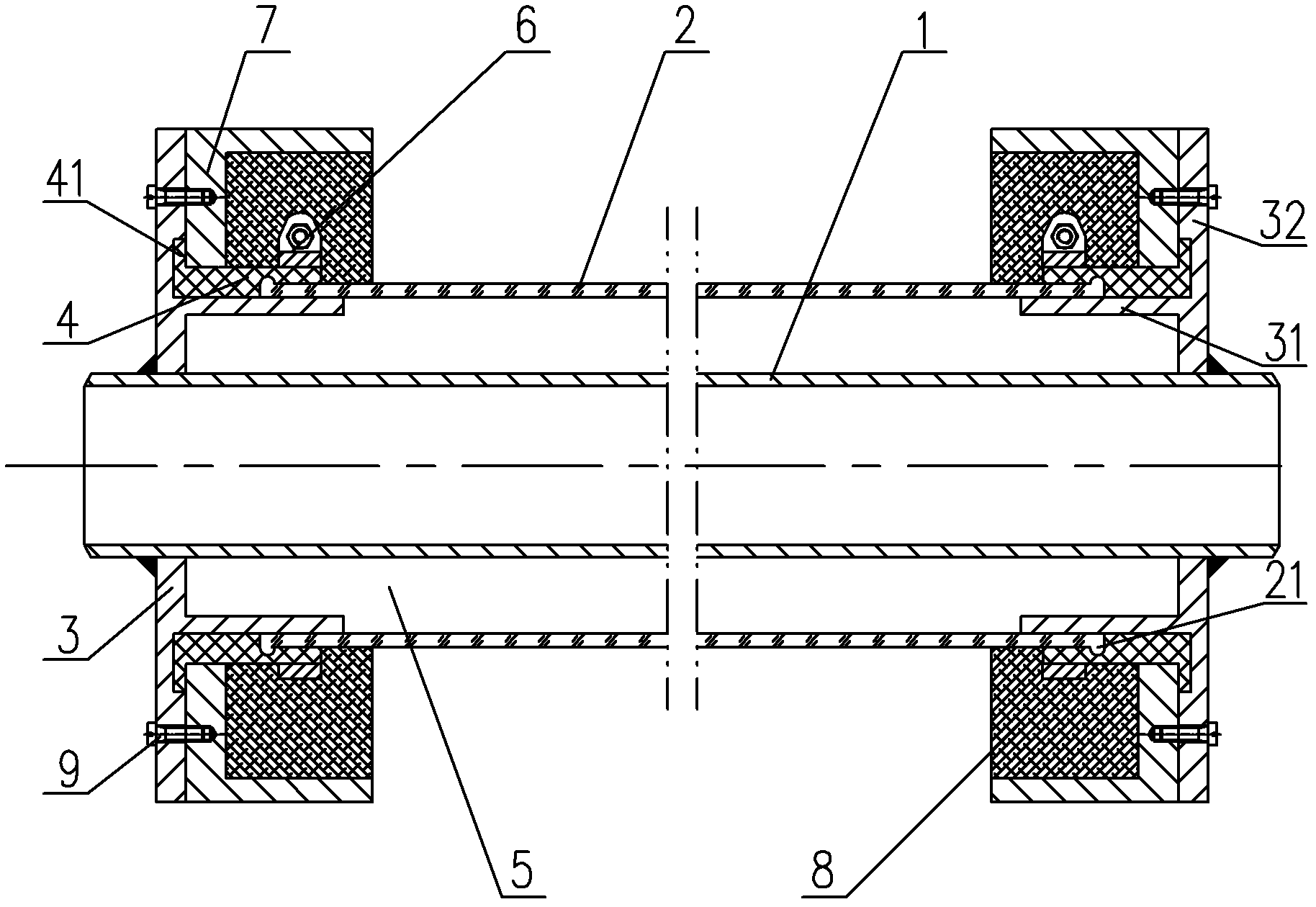

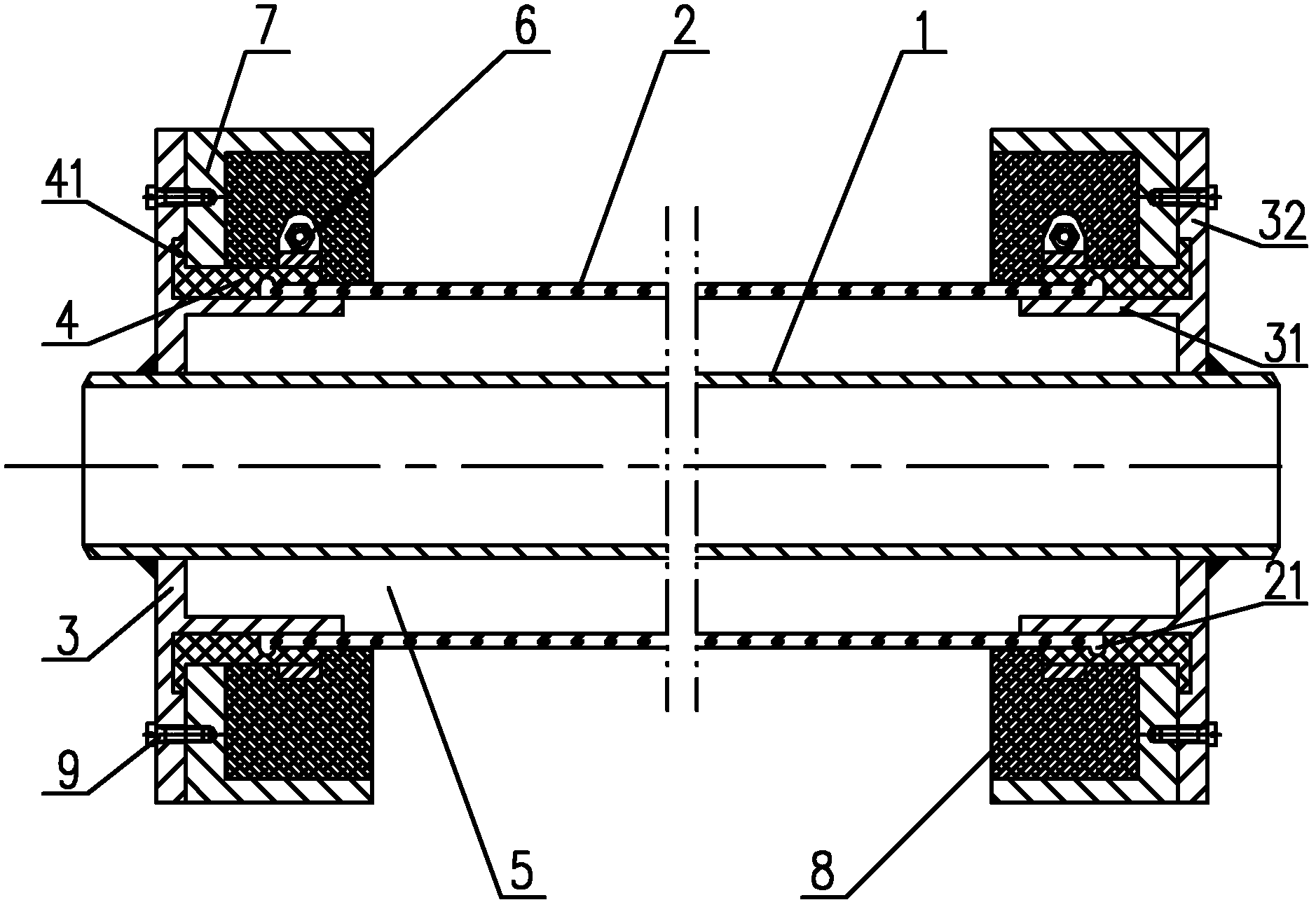

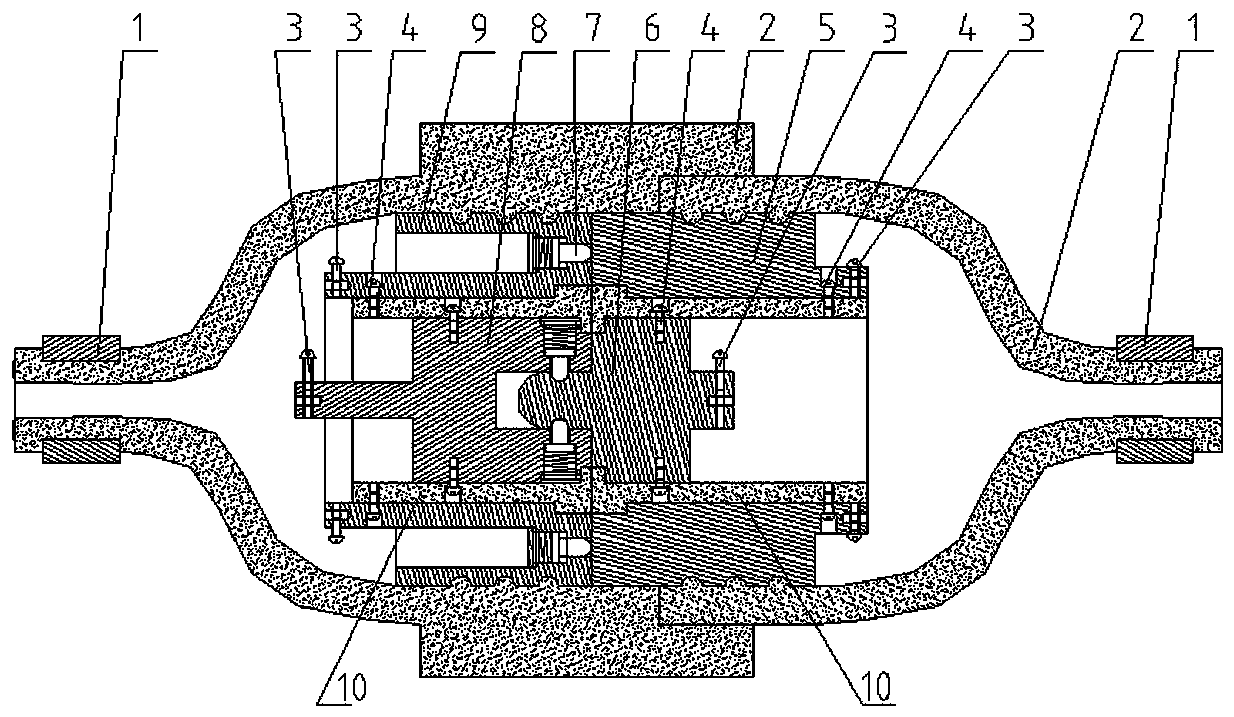

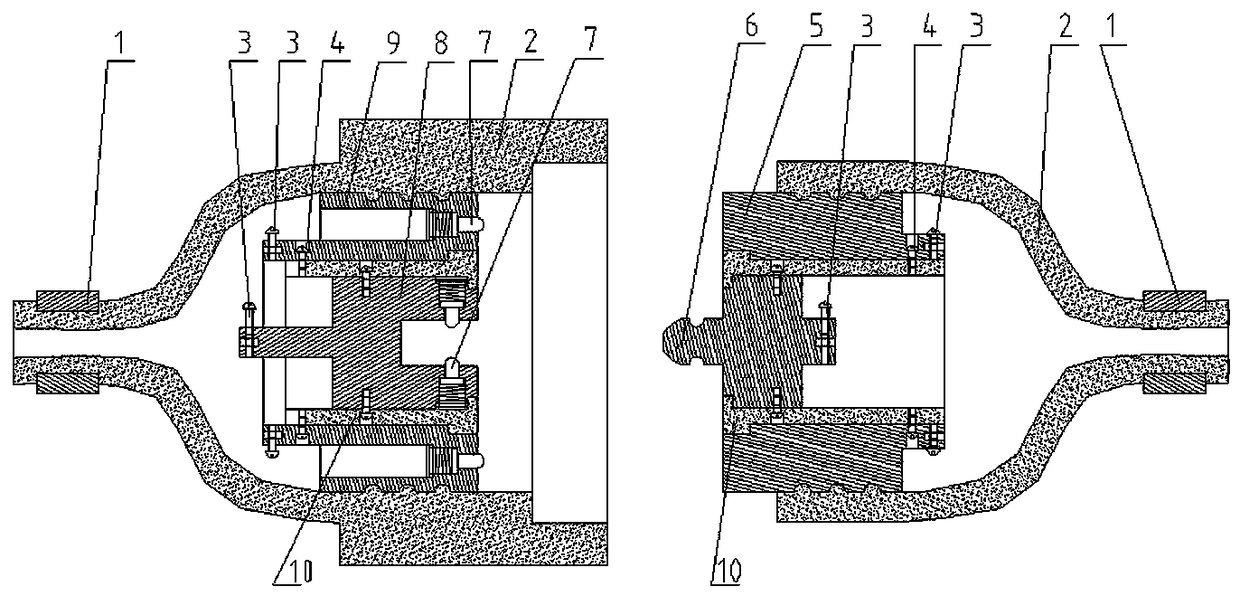

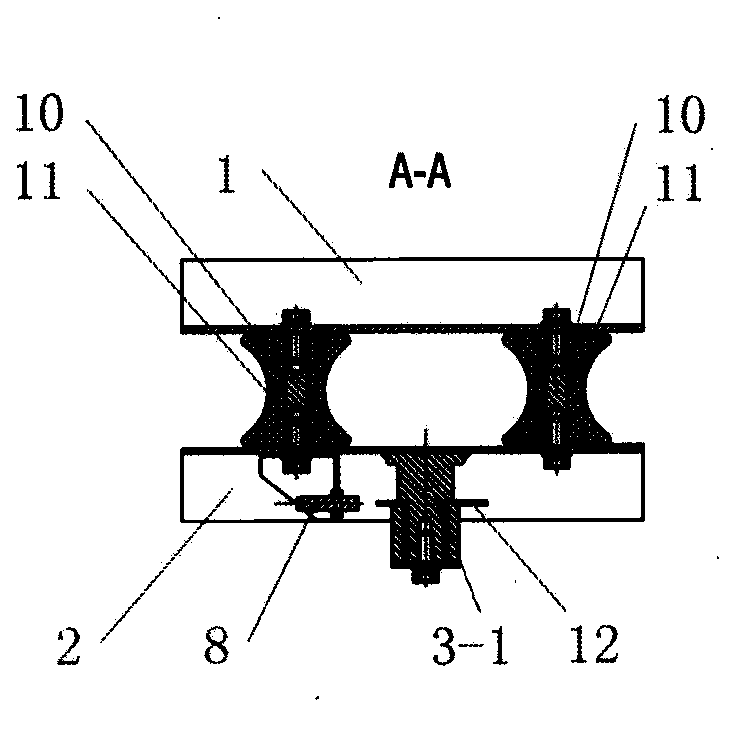

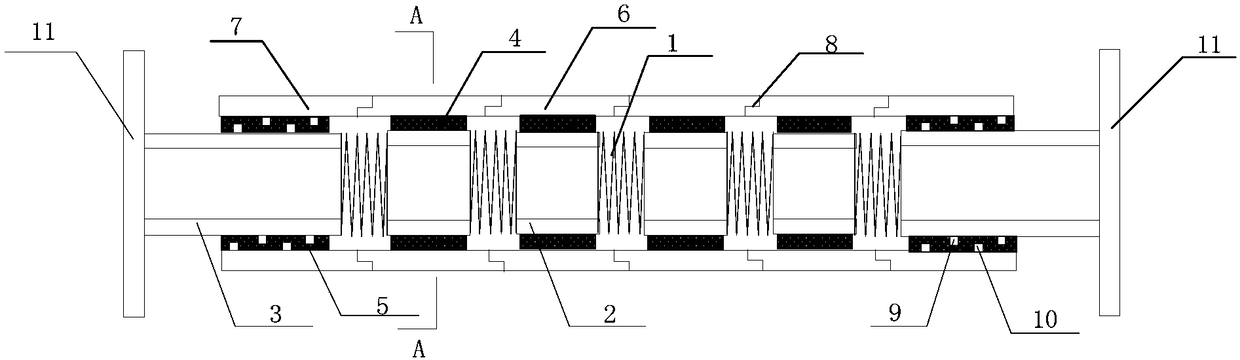

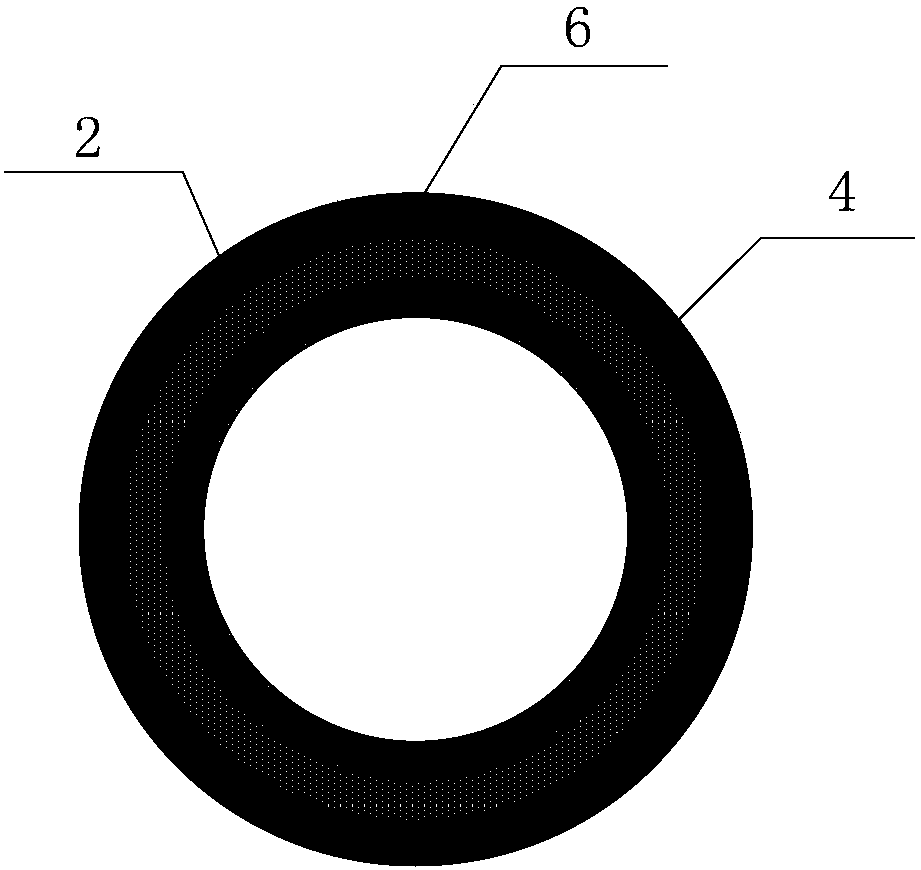

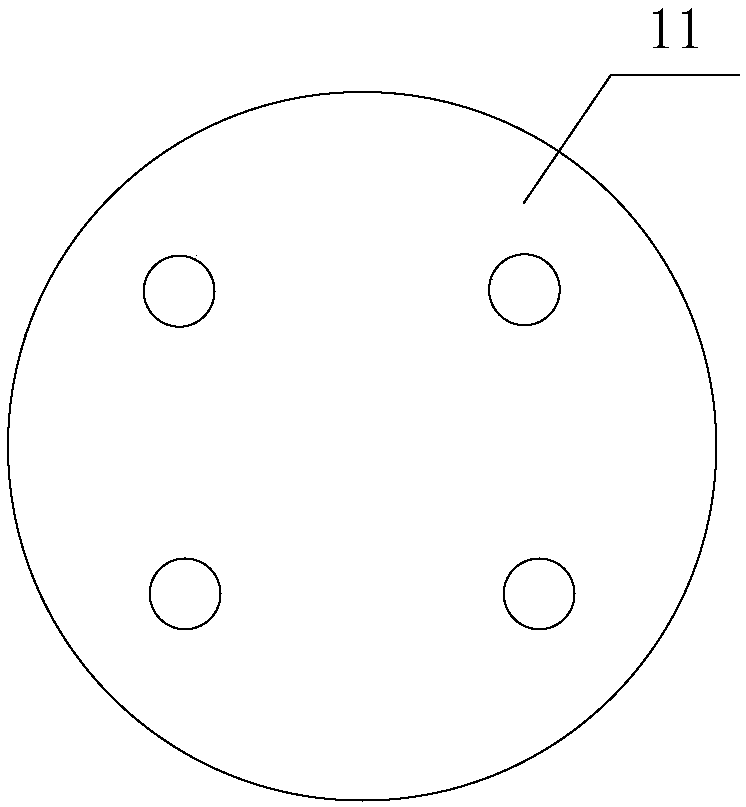

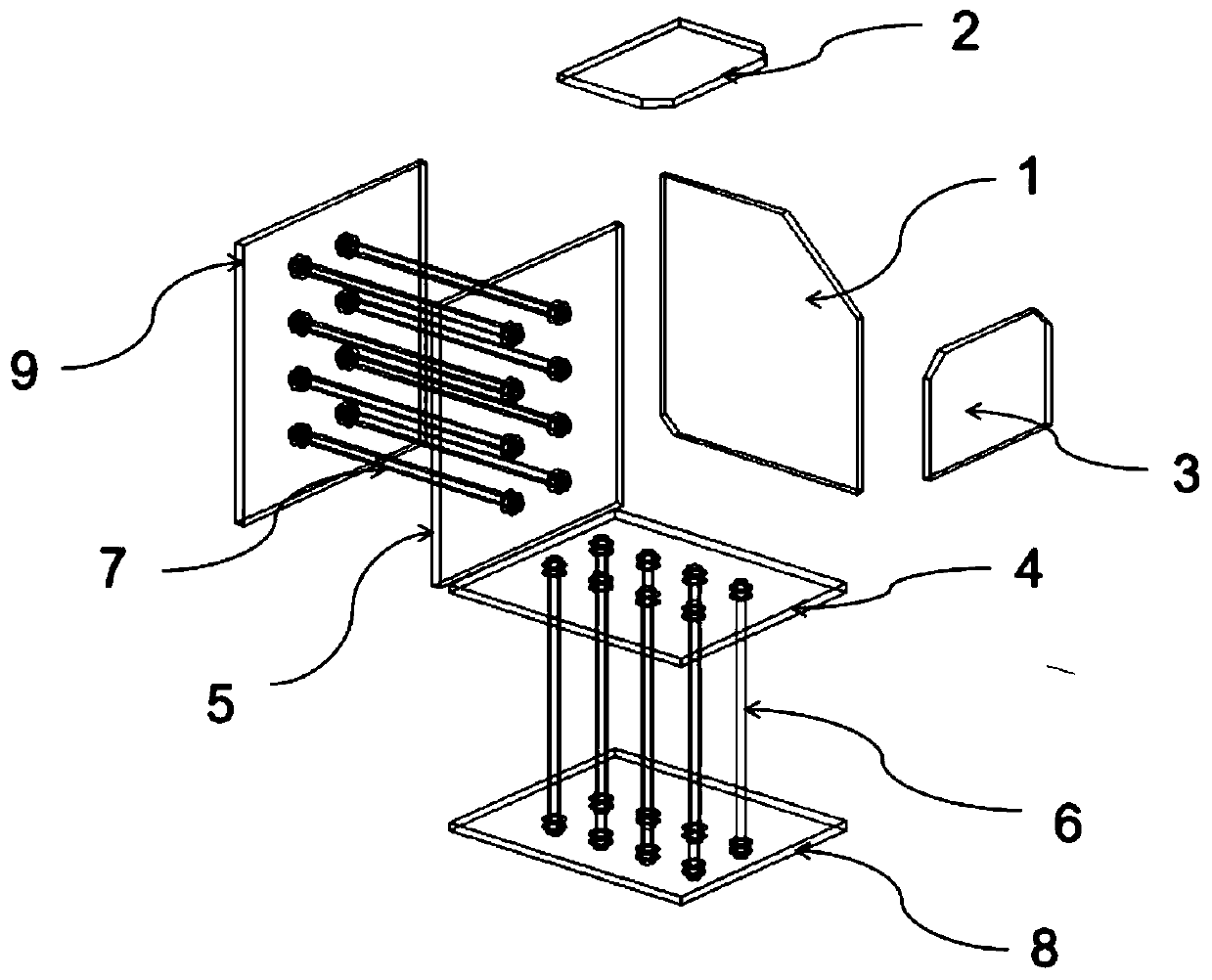

Assembly-type variable-damping variable-stiffness viscoelastic damper and anti-seismic method thereof

PendingCN108412067AGood shock absorptionHigh reuse rateProtective buildings/sheltersShock proofingType variableVariable stiffness

The invention discloses an assembly-type variable-damping variable-stiffness viscoelastic damper and an anti-seismic method thereof. The damper comprises two end viscoelastic damper bodies, the two end viscoelastic damper bodies are arranged coaxially, and a plurality of viscoelastic damper units are connected in series between the two end viscoelastic damper bodies in the axial direction of the two end viscoelastic damper bodies. Each end viscoelastic damper body comprises an end outer barrel and an end inner barrel. A viscoelastic material layer is arranged between the inner wall of each endouter barrel and the outer wall of the corresponding end inner barrel. Each viscoelastic damper unit comprises a unit outer barrel and a unit inner barrel. A viscoelastic material layer is arranged between the inner wall of each unit outer barrel and the outer wall of the corresponding unit inner barrel. Each end outer barrel and the corresponding unit outer barrel as well as the every two unit outer barrels are detachably connected to form a rigid outer barrel of the assembly-type variable-damping variable-stiffness viscoelastic damper. Each end inner barrel and the corresponding unit innerbarrel as well as the every two unit inner barrels are elastically connected through elastic connecting pieces.

Owner:SOUTHEAST UNIV

Shockproof strip assembly for steam generator of nuclear power unit

ActiveCN102927552AFine surfaceImprove inner qualitySteam boilersSteam boilers componentsNuclear engineeringNuclear power

The invention relates to a shockproof strip assembly for a steam generator of a CAP1400 unit. The shockproof strip assembly comprises a shockproof strip of a V-shaped structure and two end caps which are respectively arranged at the two ends of the shockproof strip, wherein the shockproof strip is made from 405 stainless steel material, and the end caps are made from 690 nickel-based alloy material. A method for preparing the shockproof strip assembly comprising the processes of preparation of the shockproof strip, preparation of the end caps, bending and moulding, assembling the end caps, upsetting, inspection, cleaning and packaging. The shockproof strip assembly for the steam generator of the CAP1400 unit provided by the invention is simple in structure, quality of the shockproof strip assembly meets precision requirement of the steam generator in a power nuclear unit on the shockproof strip, and the shockproof strip assembly is safe when being used. The preparation method of the shockproof strip provided by the invention is strict in processes, technological requirements on the shockproof strip assembly for the steam generator in the power nuclear unit are guaranteed, quality is guaranteed, and safety is improved.

Owner:丹阳市龙鑫合金有限公司

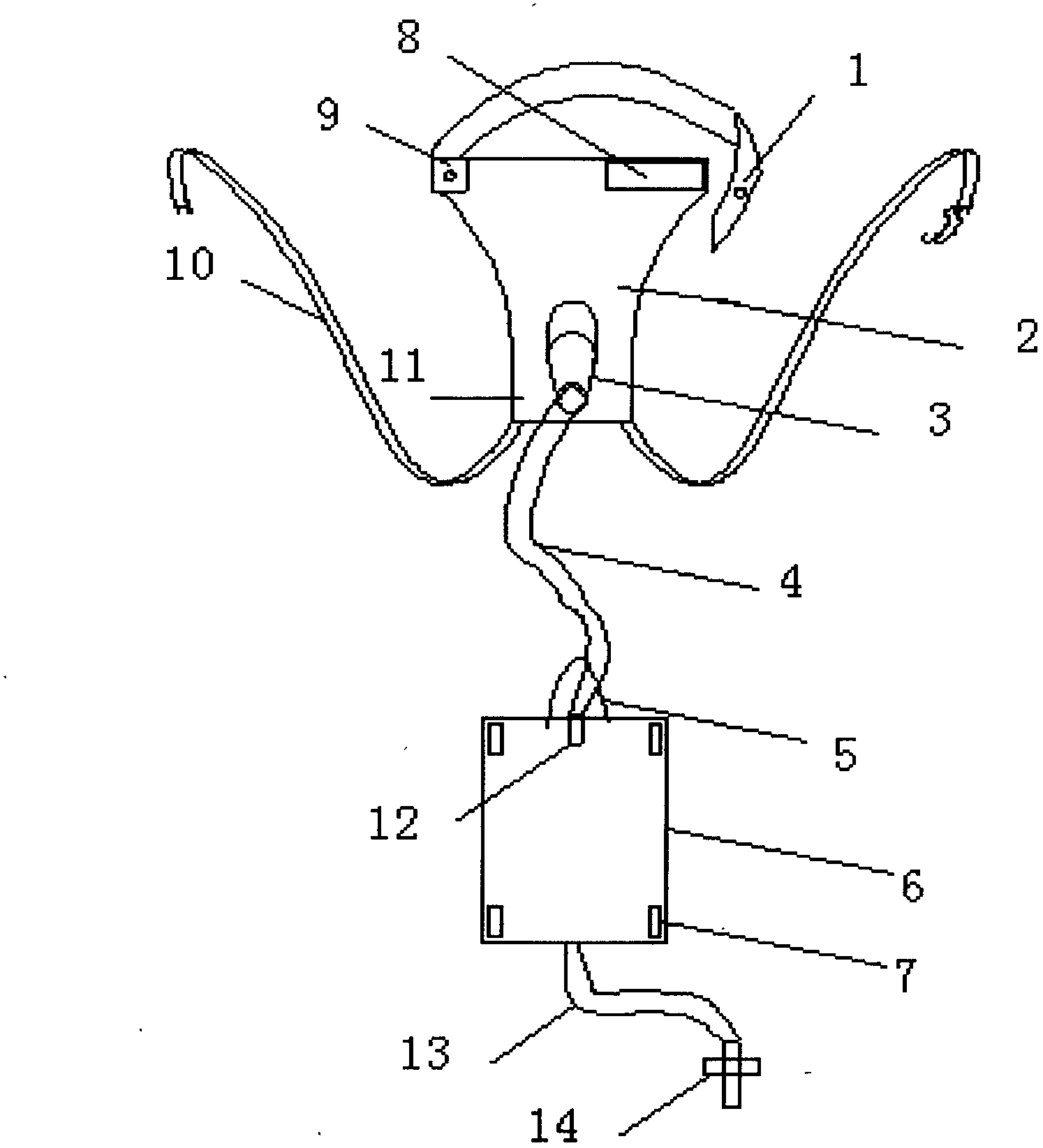

Safe urine collector

The invention relates to a urine collector for the disabled, comprising a urine collecting cover, a urine transporting pipe, a urine bag and a urine bag outlet pipe, wherein the urine collector is characterized in that the urine collecting cover is covered at the crotch of short pants, the genitals is covered into the urine collecting cover from the short pants, the front end of the urine collecting cover is connected with the urine transporting pipe and the urine bag by a horn-shaped joint, the urine transporting pipe can be used as the sitting posture, the standing posture and the sleeping posture, the urine transporting pipe for the sitting posture and the standing posture is a single-pipe urine transporting pipe to be connected with the urine bag, the urine bag is provided with a bandage to be banded on the leg, the lower end of the urine transporting pipe extends into the urine bag, a side hole is arranged on the urine transporting pipe, so that the urine can overflow into the urine bag from places, an outlet of the urine bag is further provided with a urine bag outlet pipe to be connected with a urine bag switch, and the urine bag is provided with an urine bag box, so that the urine bag can not be flatly pressed by trouser legs; and the urine transporting pipe for the sleeping posture is bifurcated pipes, to be respectively connected with the urine bag. The urine collector is simple in structure, thereby being applicable to the crowds who unconsciously urinate, can not control the urination and the like caused by various reasons.

Owner:韦阳

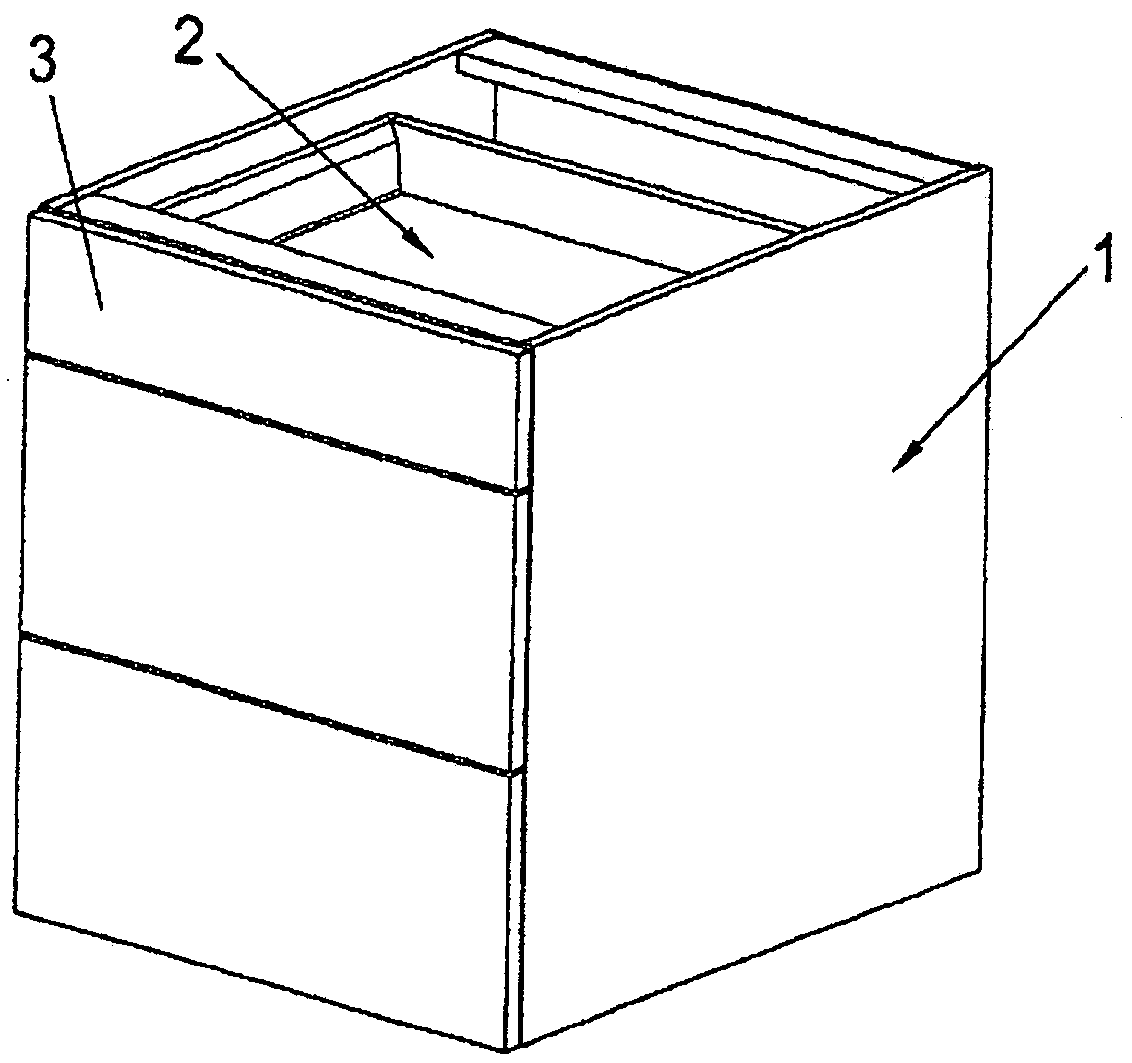

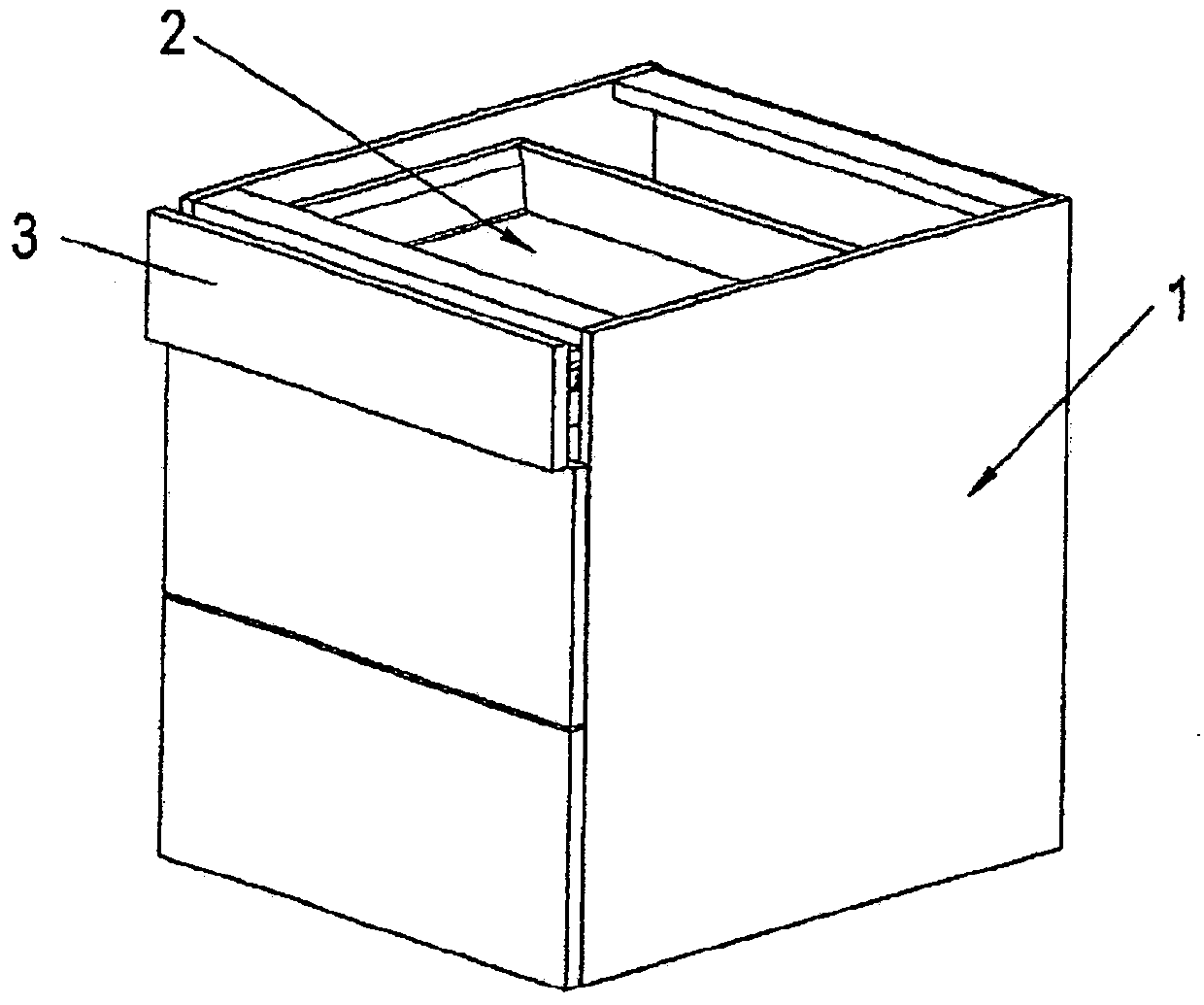

Pull-out guide for a drawer

The invention concerns a pull-out guide (4) for a drawer (2), with a runner (6) that can be coupled to a drawer (2), and with a front and a rear coupling device which can be used to secure the drawer (2) on the runner (6), a further coupling device, which secures the drawer (2) at least against being pulled down off the runner (6), being in engagement with the drawer before at least one of the two other coupling devices.

Owner:PAUL HETTICH

Method for producing vibration-resistant bar assembly of AP1000 nuclear power generating set steam generator

ActiveCN102764966AMeet the precision requirementsGuaranteed process requirementsNuclear engineeringNuclear power

Disclosed is a method for producing a vibration-resistant bar assembly of an AP1000 nuclear power generating set steam generator. The method comprises processes of production of vibration-resistant bars, production of end caps, bending molding, assembly of end caps, heading, detection, cleaning and packaging. The vibration-resistant bar assembly of the AP1000 nuclear power generating set steam generator has a simple structure, the quality of the vibration-resistant bar assembly meets accurate requirements of steam generators in a nuclear power plant for vibration-resistant bars and the vibration-resistant bar assembly is safe during usage. According to the method for producing the vibration-resistant bars, the production processes are strict, the technical requirements for the vibration-resistant bar assembly of the steam generator in the nuclear power plant are guaranteed, the quality is guaranteed and the safety is improved.

Owner:丹阳市龙鑫合金有限公司

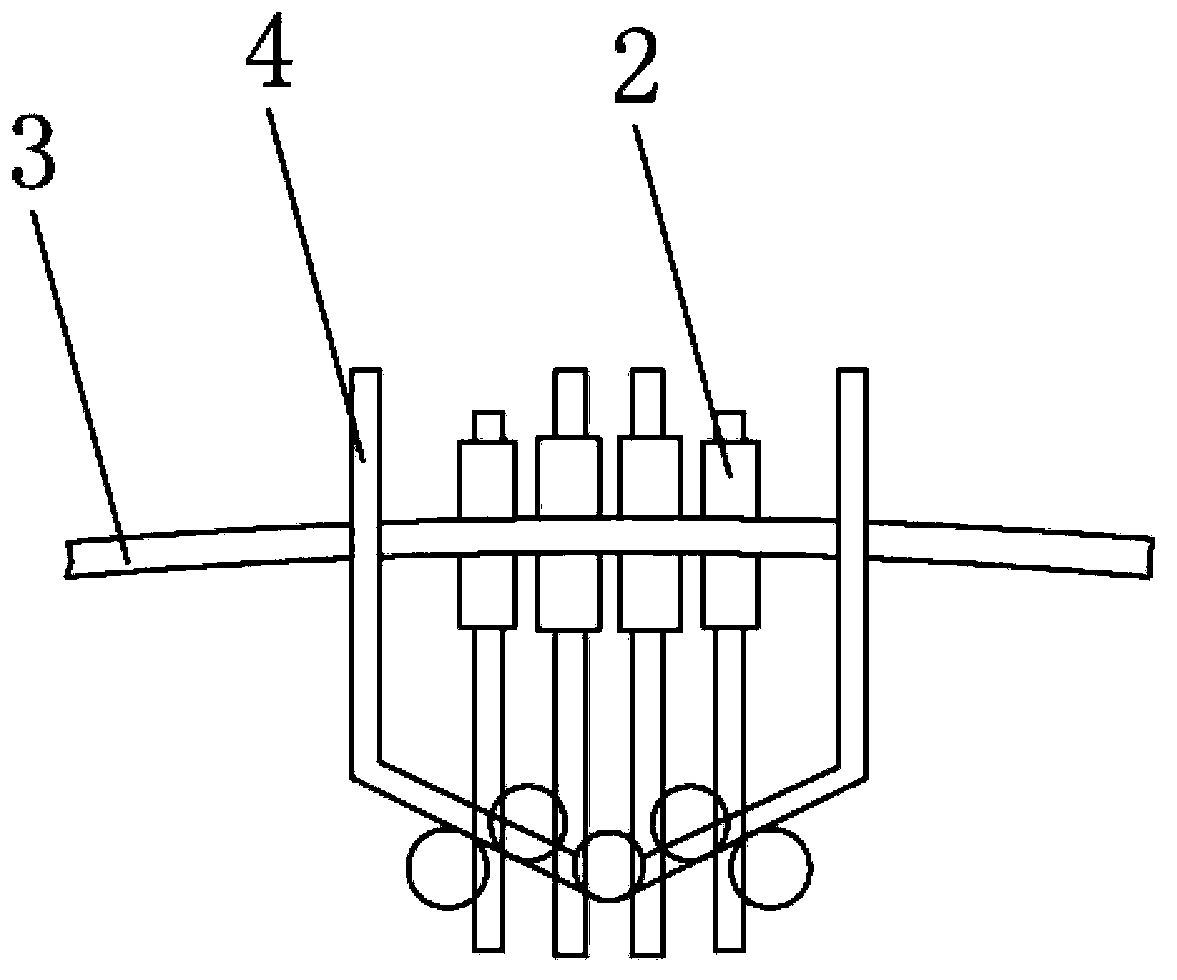

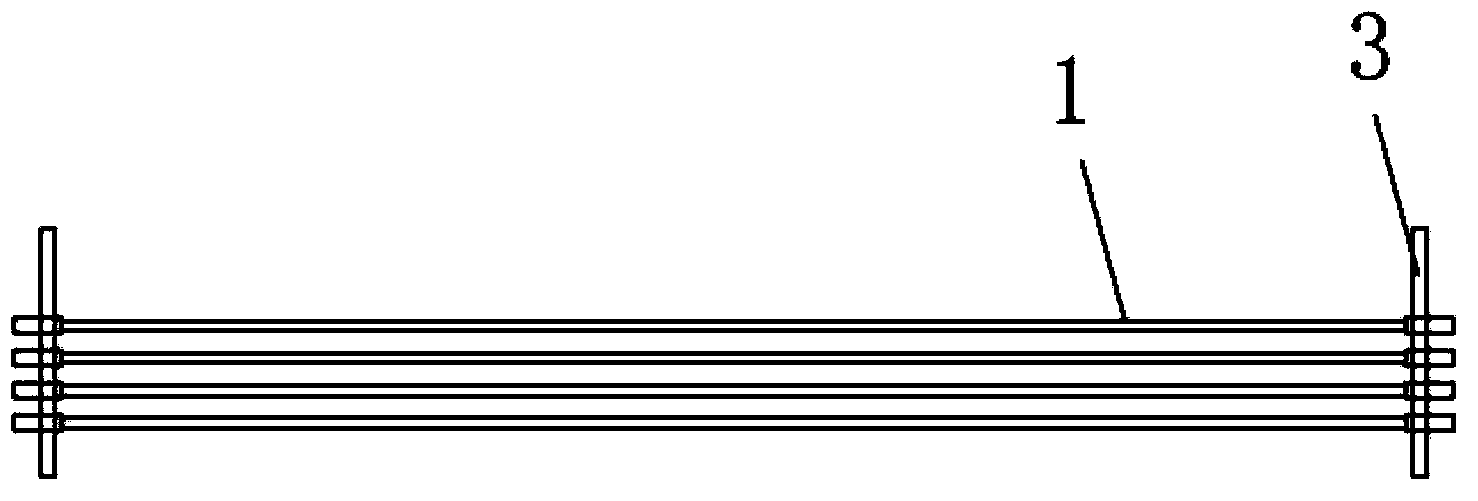

Preparation method for anti-vibration bar assembly of steam generator of CAP1000 nuclear power unit

InactiveCN103801903AMeet the precision requirementsGuaranteed process requirementsNuclear energy generationSteam generator primary sideNuclear powerProcess engineering

The invention relates to an anti-vibration bar assembly of a steam generator of a CAP1000 nuclear power unit. The anti-vibration bar assembly of the steam generator of the CAP1000 nuclear power unit comprises V-shaped anti-vibration bars and end caps which are respectively arranged at the two ends of the anti-vibration bars, pin holes are formed in the end parts and the end caps of the anti-vibration bars, the anti-vibration bars and the end caps are assembled through pins and the pins and the end caps are fixed through electric welding. The anti-vibration bar assembly comprises four anti-vibration bars which are aligned and arranged in parallel, the end caps on the same side are fixedly connected with a retaining ring, and the parts of the anti-vibration bars adjacent to the corresponding end caps are fixedly connected with the retaining ring by the retaining bar. The invention additionally relates to a preparation method for the anti-vibration bar assembly. The preparation method comprises the steps of anti-vibration bar preparation, end cap preparation, bending, end cap assembling, assembly assembling, check, cleaning and packaging. The anti-vibration bar assembly of the steam generator of the CAP1000 nuclear power unit provided by the invention has the advantages that the structure is simple, the product quality meets the requirement on the precision of the anti-vibration bar of the steam generator in a nuclear power station and the anti-vibration bar is safer to use. The preparation method for the anti-vibration bar has strict preparation steps.

Owner:丹阳市龙鑫合金有限公司

High-temperature metal seal sleeve compensator

InactiveCN103672277AAct as a pressure regulatorImprove sealingPipeline expansion-compensationAdjustable jointsPetrifactionWork performance

A high-temperature metal seal sleeve compensator comprises an outer sleeve, an inner sleeve and a pulling-out preventing flange, wherein a flange of the outer sleeve is connected with the pulling-out preventing flange through a bolt, the inner sleeve is inserted into the outer sleeve through an outer sleeve inserting hole in a front end cover of the outer sleeve, the outer wall of the inner sleeve is tightly matched with the outer sleeve inserting hole, the rear end of the inner sleeve is fixedly connected with a supporting ring, and the outer annular surface of the supporting ring is in sliding fit with the inner wall of the outer sleeve. The high-temperature metal seal sleeve compensator is reasonable in design and safe and reliable in work performance, service life is more than 20 years, and therefore a maintaining well which is specially arranged can be omitted, construction cost can be greatly lowered, and the high-temperature metal seal sleeve compensator can be used for conveying pipelines of city and town heating, metallurgy, electric generation, petrifaction, construction and other industries more conveniently.

Owner:李建军

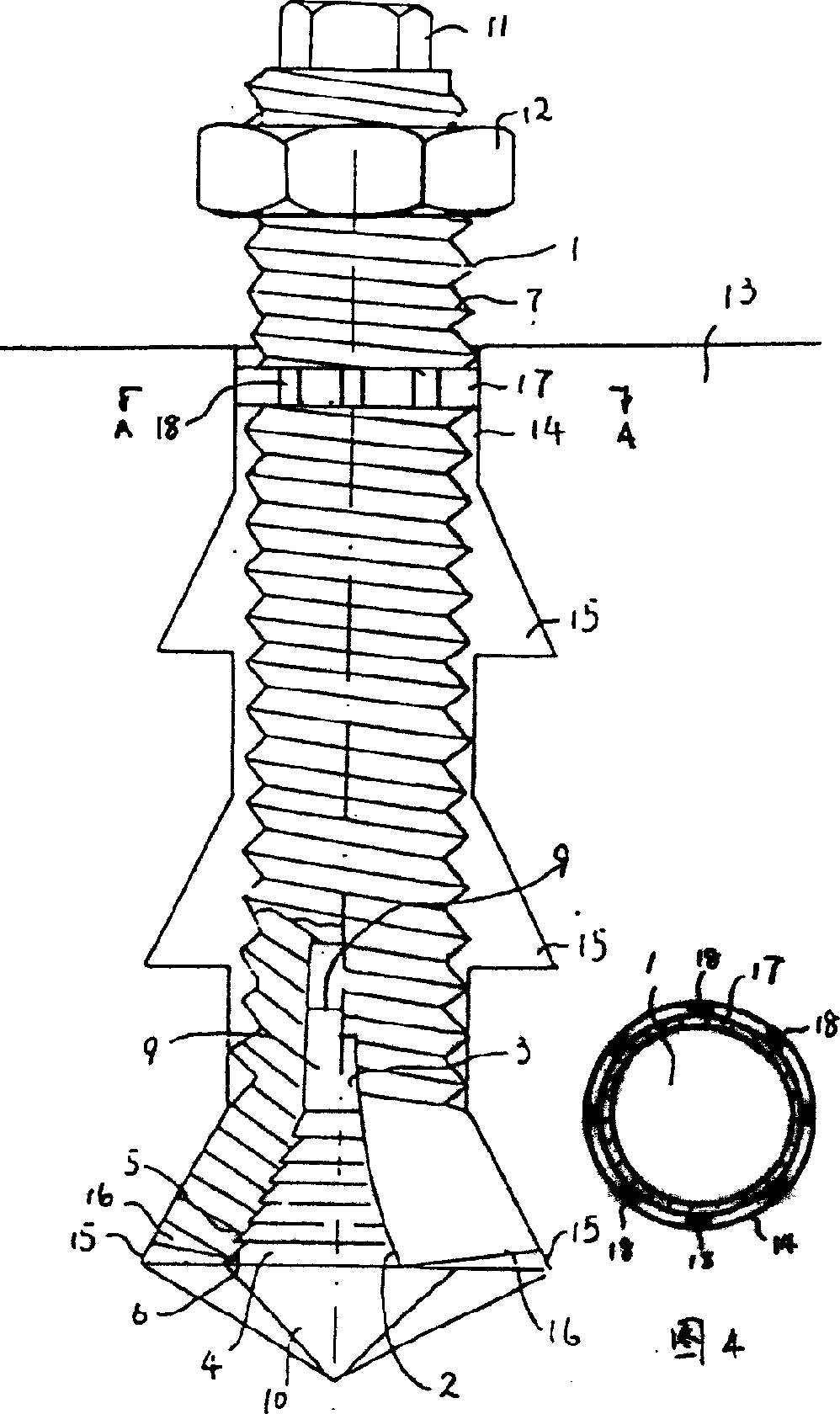

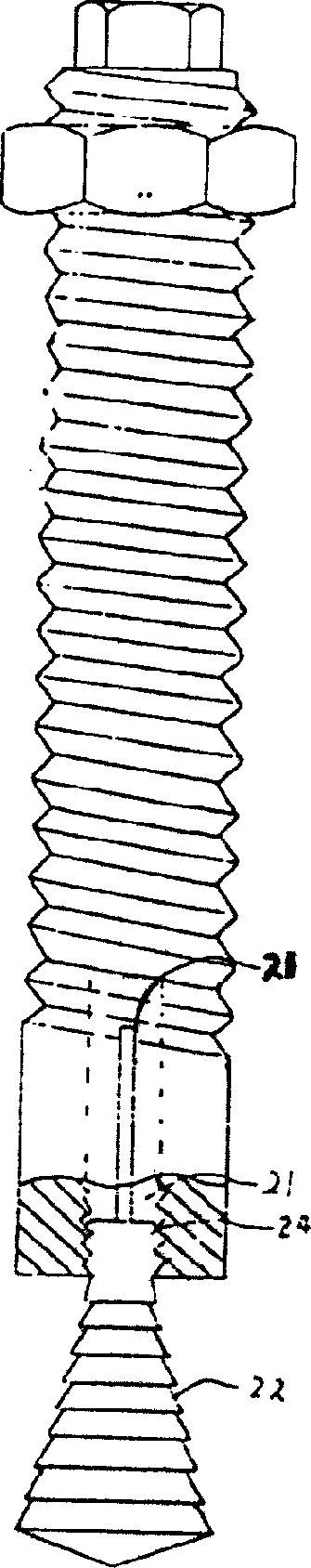

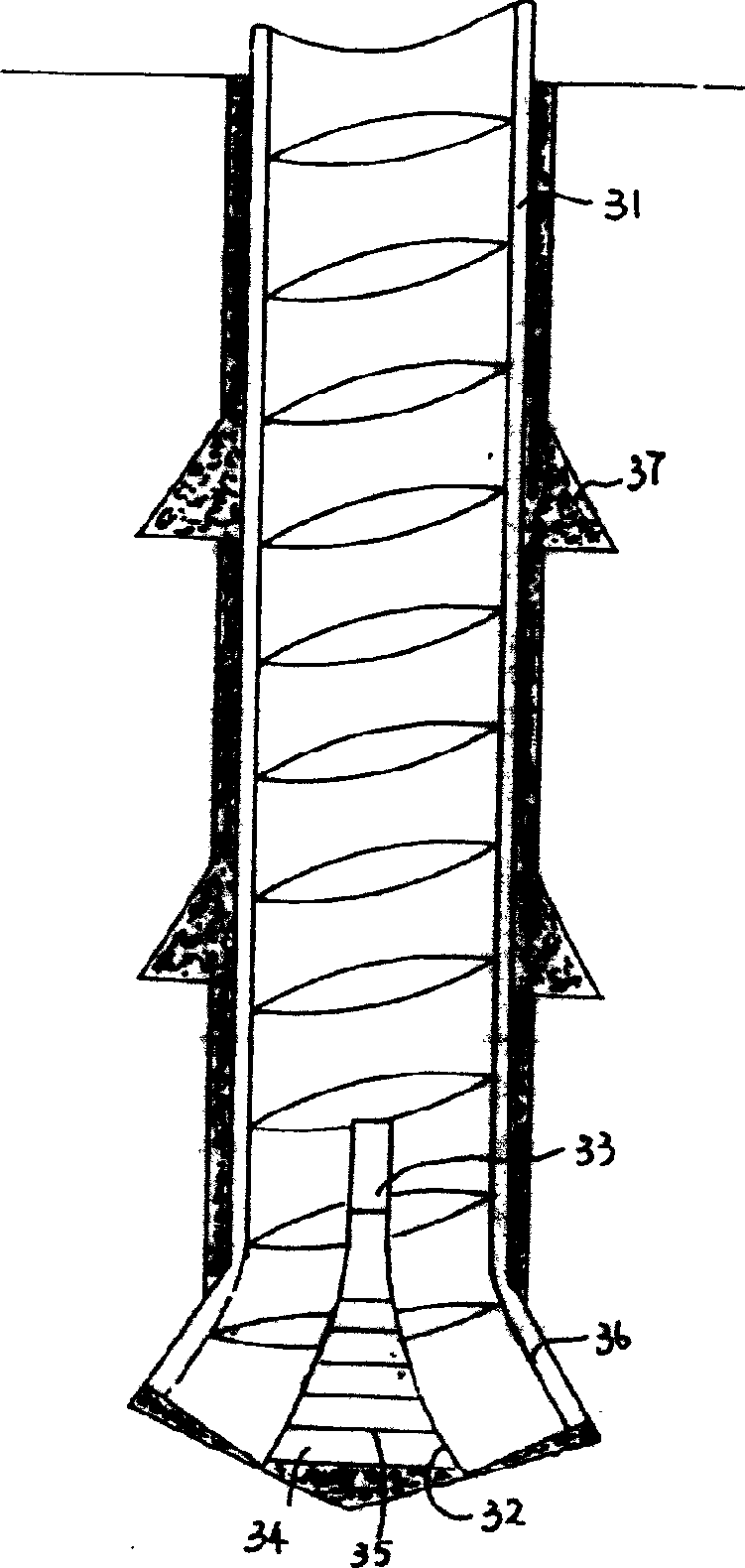

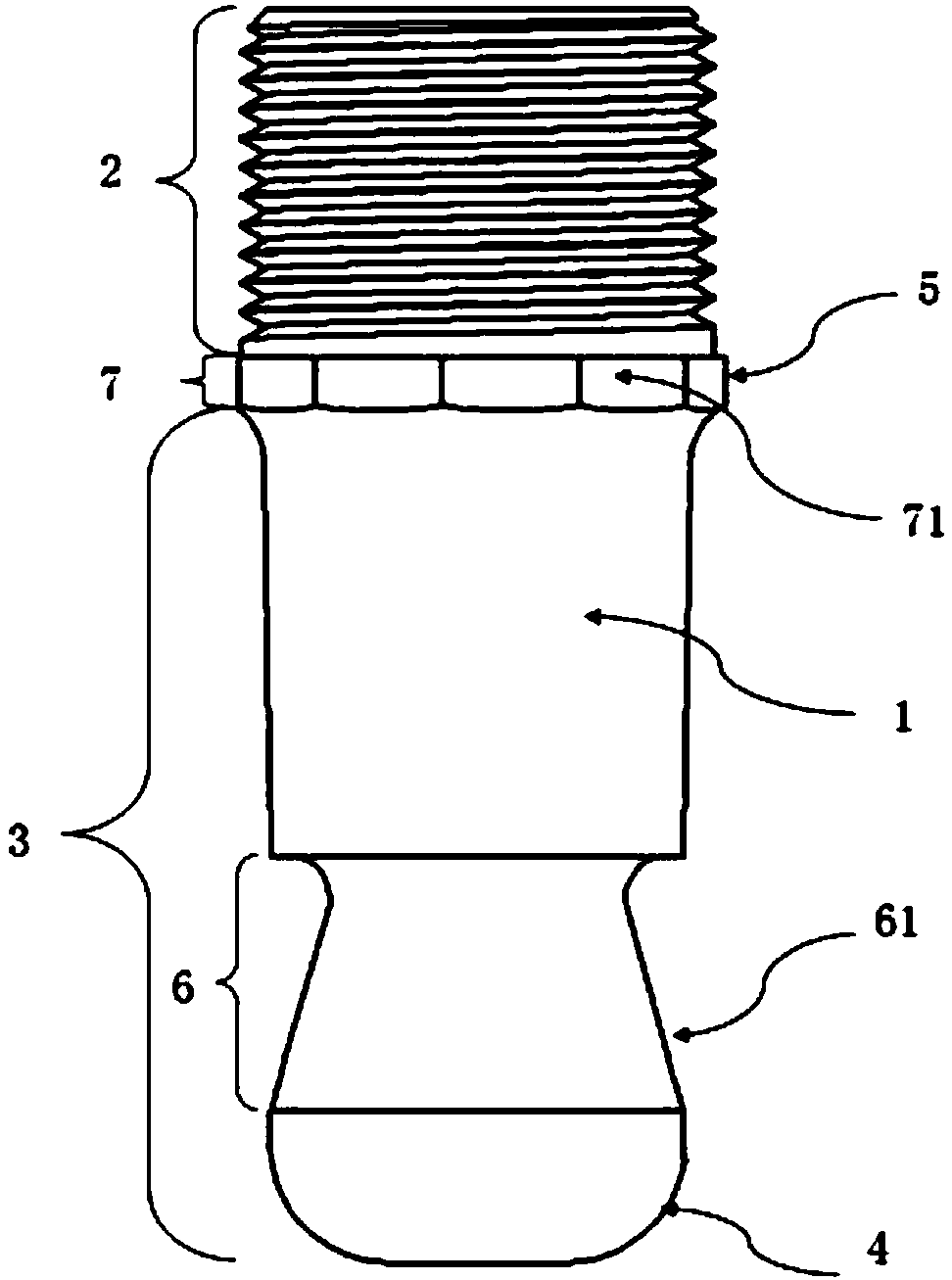

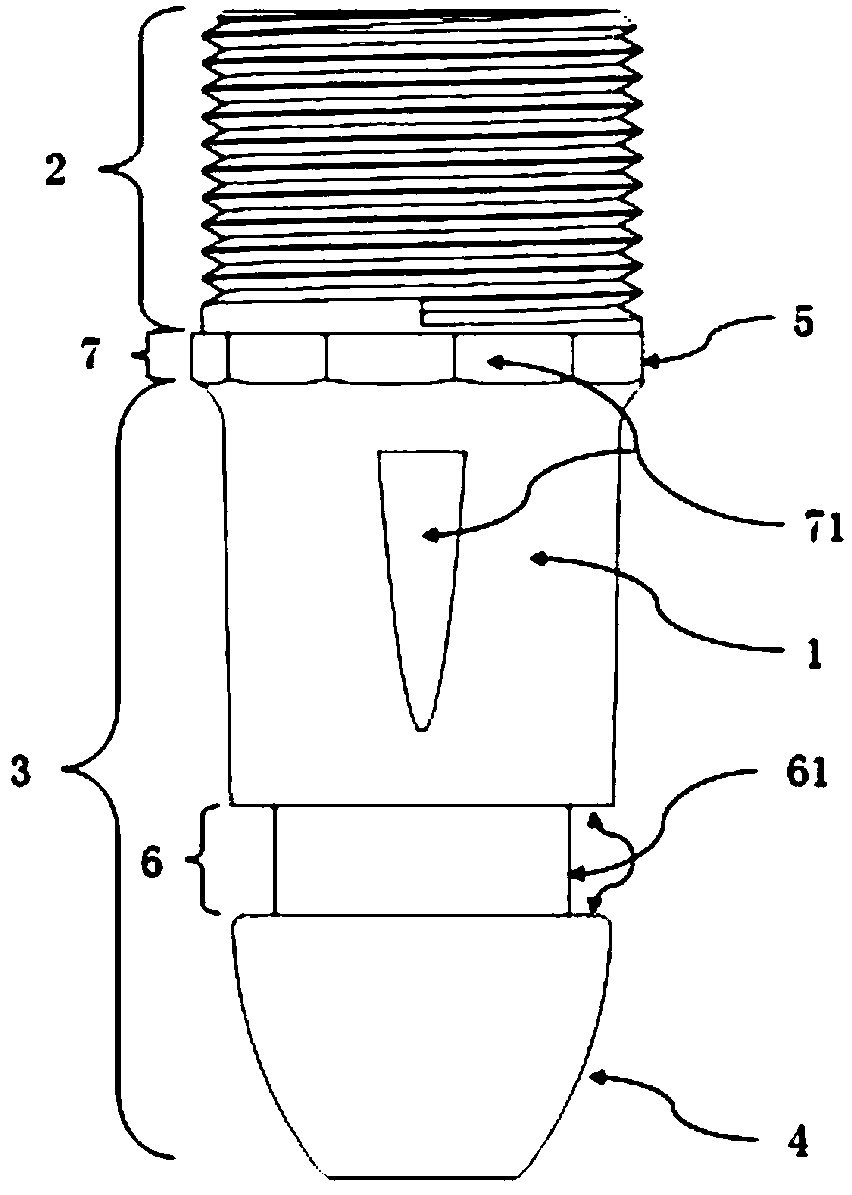

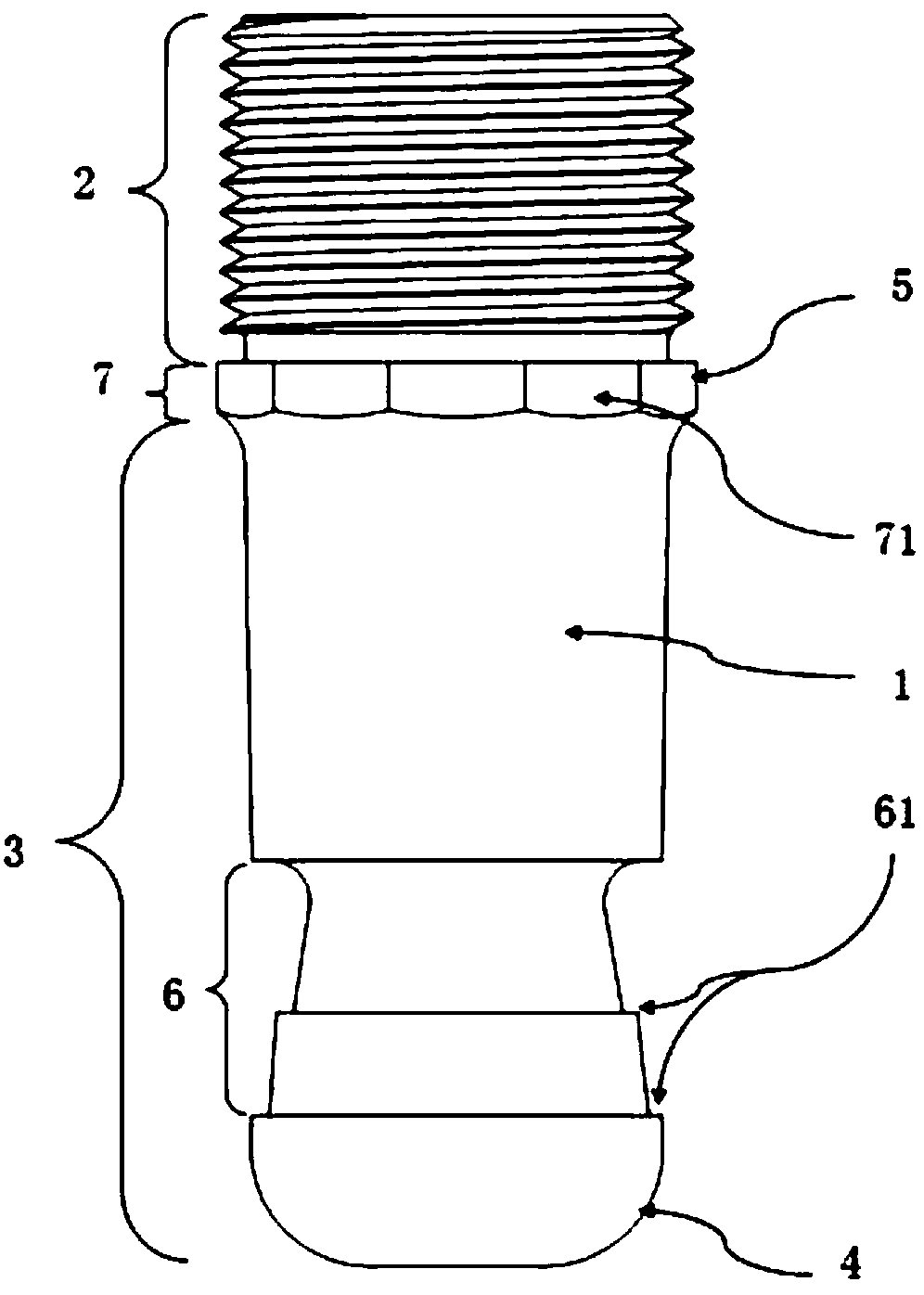

After-planting expansion piece

InactiveCN1587578AThe main structure is firm and strongHigh strengthBuilding reinforcementsEngineeringExpansion joint

The post-mounted expansion unit includes an expansion rod, and an expansion mechanism in the lower part of the expansion rod, and the expansion mechanism includes the expansion hole in the lower part of the expansion rod, expansion slot and conic push head with guide section and matching the expansion hole. The said technological scheme has strong and firm expansion rod, and expansion mechanism with obviously raised connection strength between the post-mounted part and the deep hole. In addition, the expansion hole wall and the conic push head have anti-skid thread to further raise the connected strength.

Owner:徐洁媛

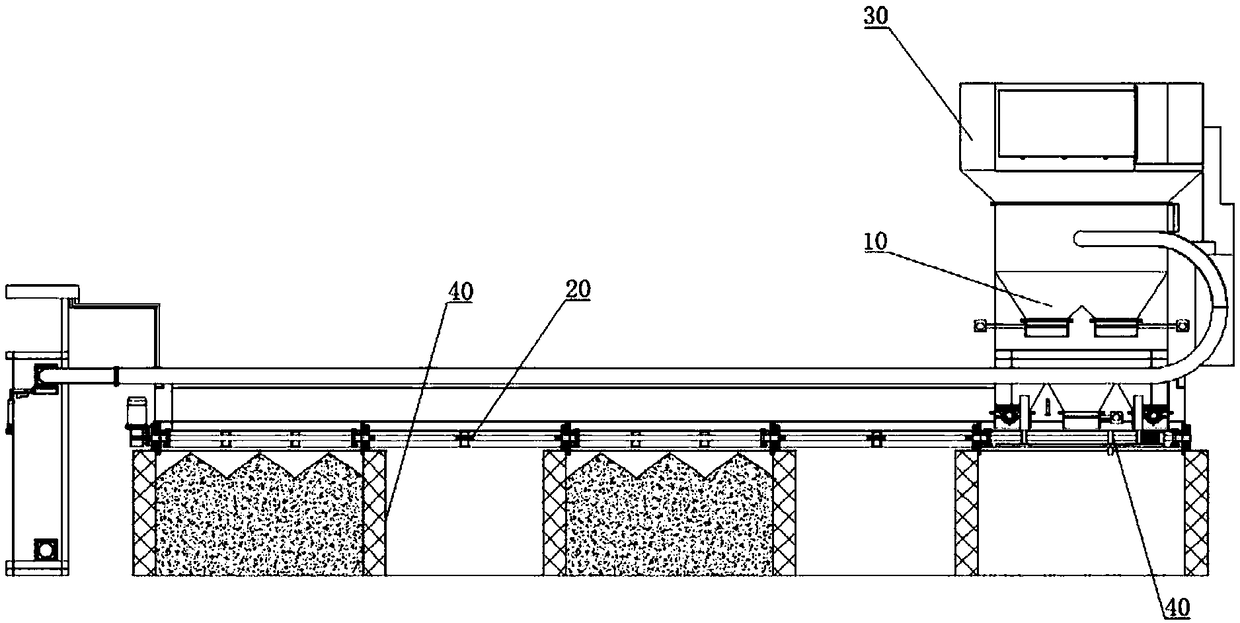

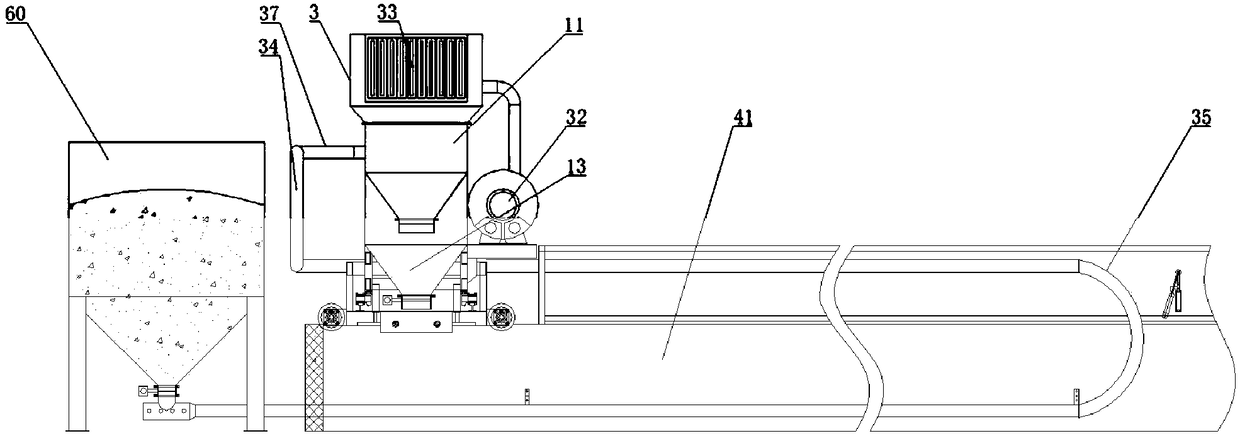

Intelligent transverse and longitudinal cloth machine

ActiveCN108220116AIncrease the feeding speedIncrease productivityVinegar preparationEngineeringBrewing

The invention discloses an intelligent transverse and longitudinal cloth machine, belongs to the field of automatic vinegar brewing equipment and aims to solve the problems of slow feeding speeds andlow production efficiency in the prior art. The machine comprises a double-chamber feeding machine, wherein the double-chamber feeding machine comprises a sucking chamber I; a feeding hole is formed in the sucking chamber I; a sucking chamber II is formed below the sucking chamber I; the sucking chamber I and the sucking chamber II are communicated through discharge holes; outlet holes are formedin the sucking chamber II; discharge devices are arranged in both the outlet holes and the discharge holes. By adopting the machine, material cloth for brewing vinegar can be put into a fermentation tank.

Owner:LUZHOU JIANGXU MACHINERY MFG

High-strength screw sliding embedded part connecting joint used for supporting concrete frame

PendingCN111441471AImprove axial stiffnessReduce adhesionProtective buildings/sheltersShock proofingSteel platesStructural engineering

The invention provides a high-strength screw sliding embedded part connecting joint used for supporting a concrete frame. The connecting joint comprises a beam joint unit, a column joint unit above the beam joint unit, rubber layers, bonding-free layers, and a joint plate unit, the joint plate unit is connected with the beam joint unit and the column joint unit, the beam joint unit comprises a first horizontal embedded steel plate, a second horizontal embedded steel plate and a first vertical screw, the outer wall of the first vertical screw is provided with the rubber layer, the column jointunit comprises a first vertical embedded steel plate, a second vertical embedded steel plate and a second horizontal screw, the rubber layer is mounted on the outer wall of the second horizontal screw, and the bonding-free layers are mounted on surfaces where the first horizontal embedded steel plate, the second horizontal embedded steel plate, the first vertical embedded steel plate and the second vertical embedded steel plate make contact with concrete. The problems of joint breakage and beam and column shear damage caused by a concrete frame supporting joint opening and closing effect can be effectively solved through the connecting joint, and the axial rigidity of an embedded part under the supporting tension effect can be improved.

Owner:SOUTH CHINA UNIV OF TECH +1

Connecting inserting rod, connecting joint device and pre-stressed prefabricated part

InactiveCN109869386AAvoid the problem of loose and unstable connectionsGuaranteed to be plugged in placeRod connectionsBulkheads/pilesPre stressPre stressing

The invention provides a connecting inserting rod, a connecting joint device and a pre-stressed prefabricated part applying the connecting joint. The connecting inserting rod is simple in structure, firm in connection and convenient to install. The connecting inserting rod comprises a rod body, wherein the rod body comprises a connecting part and an inserting part, the end of the inserting part isprovided with a clamping joint which is matched with an outer buckling barrel in a limiting mode, a guide surface is arranged at one end of the clamping joint, at least part of the guide surface is an arc surface, at least two clamping tables are arranged at one end of the buckling barrel and are inserted into the buckling barrel and are in clamping connection with each other, and a plurality ofconnecting joint devices are uniformly and correspondingly arranged between an upper pre-stress prefabricated part and a lower pre-stress prefabricated part. The guide part of the connecting insertingrod is an arc surface, the contact surface of the guide part and the buckling barrel clamping tables is a circular surface, and the contact surfaces in the guide process are free of dead corners andcannot be clamped, so that the insertion of bolts in place is guaranteed, and the connection reliability of a pile body is improved.

Owner:周兆弟

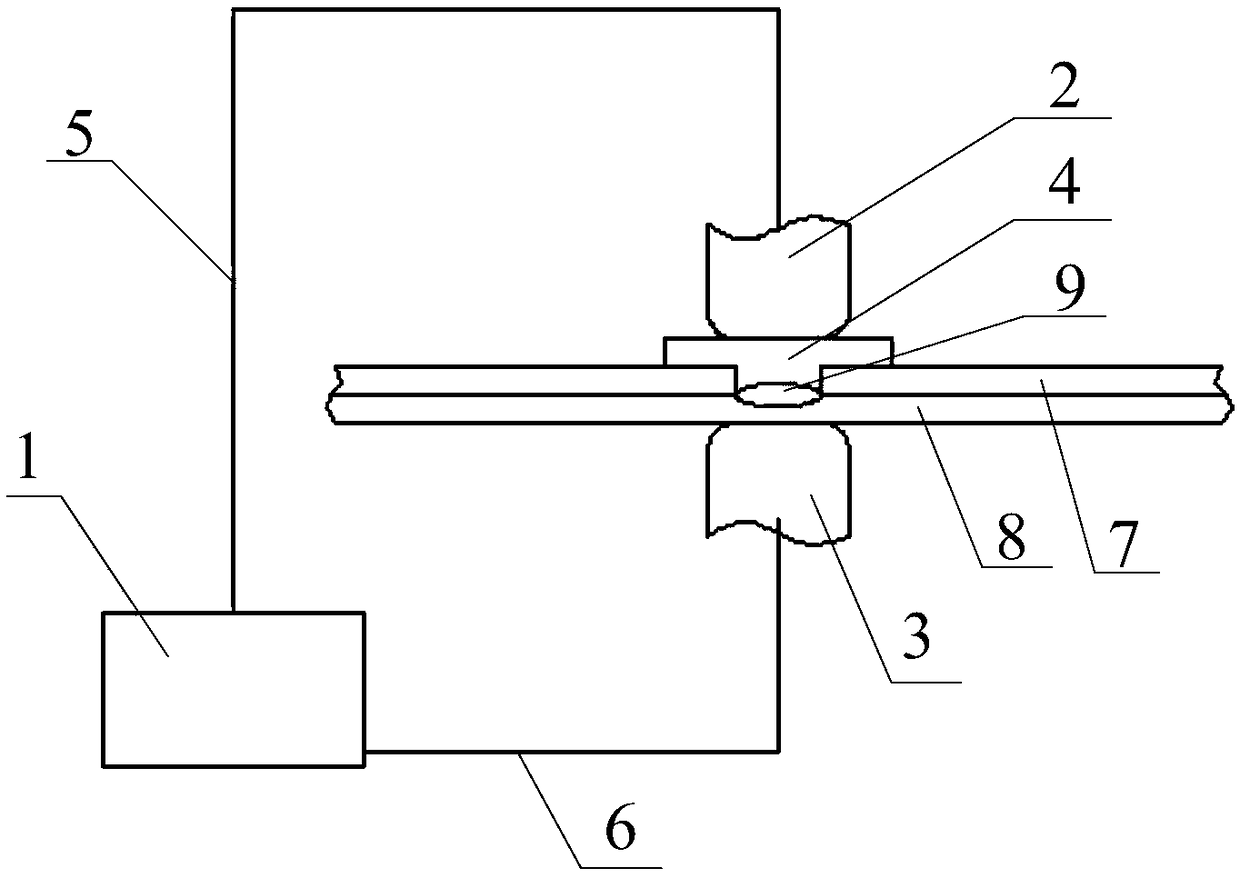

Dissimilar material connecting device and connecting method

InactiveCN109396627AEnables resistance spot welding connectionsSolve the lack of connection strengthResistance welding apparatusEngineeringWeld strength

The invention discloses a dissimilar material connecting device and a connecting method. The connecting device comprises a power supply, an upper electrode, a lower electrode and a conductive auxiliary part, wherein the upper electrode is connected with a first output end of the power supply, and the lower electrode is connected with a second output end of the power supply; the conductive auxiliary part comprises a first column body and a second column body, one bottom surface of the first column body is connected with one bottom surface of the second column body, and the horizontal projectionof the second column body falls into the horizontal projection of the first column body; and the melting point of the second column body is higher than the melting point of a first sample, the melting point of the first sample is lower than the melting point of a second sample, the welding strength of the second column and the second sample is higher than the welding strength of the first sampleand the second sample, the height of the second column body is larger than the height of the first sample. According to the dissimilar material connecting device and the connecting method, the problemthat the connecting strength between different materials is insufficient is solved.

Owner:SHOUGANG CORPORATION

Technology for processing semi-hole of PCB board

ActiveCN101547569BPrevent pull-offLow costPrinted element electric connection formationBiochemical engineeringCopper

The invention relates to a process for manufacturing a PCB board, in particular to technology for processing a PCB board provided with a semi-hole. Aiming at avoiding the phenomenon that copper on the hole wall is pulled off or damaged when the semi-hole is formed, the process that the electric milling of the semi-hole is added before etching and after film removal of a line is adopted, and the semi-hole and the external shape are not completed at the same time when the PCB board is formed. By the process that the electric milling of the semi-hole is added before etching and after film removal of the line, the electric milling is performed when the copper is fully connected with the copper on the hole wall in 360 degrees, thereby avoiding the phenomenon that the copper on the hole wall ispulled off or damaged when the semi-hole is formed, improving the yield of products and lowering cost of an enterprise.

Owner:SHENZHEN BOMIN ELECTRONICS

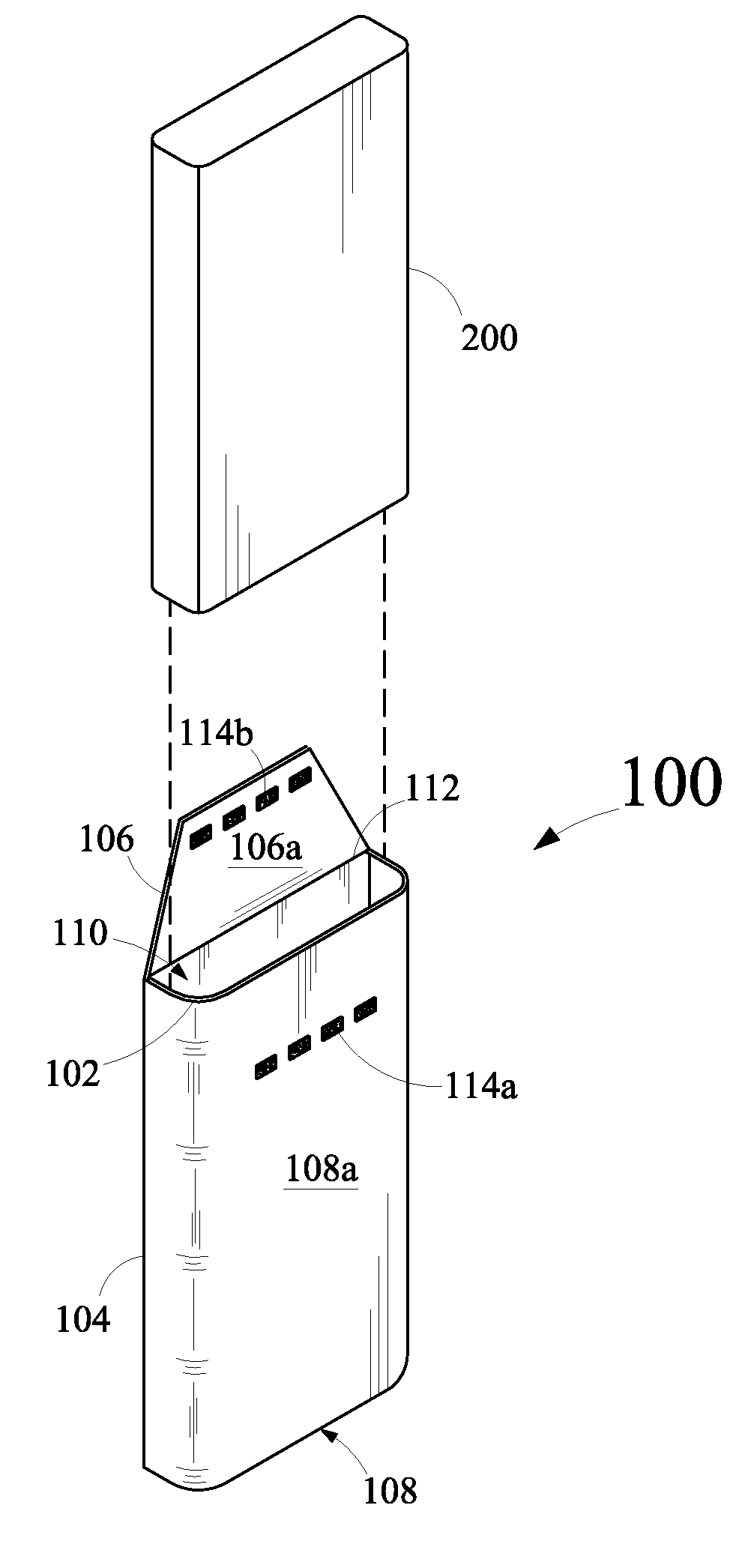

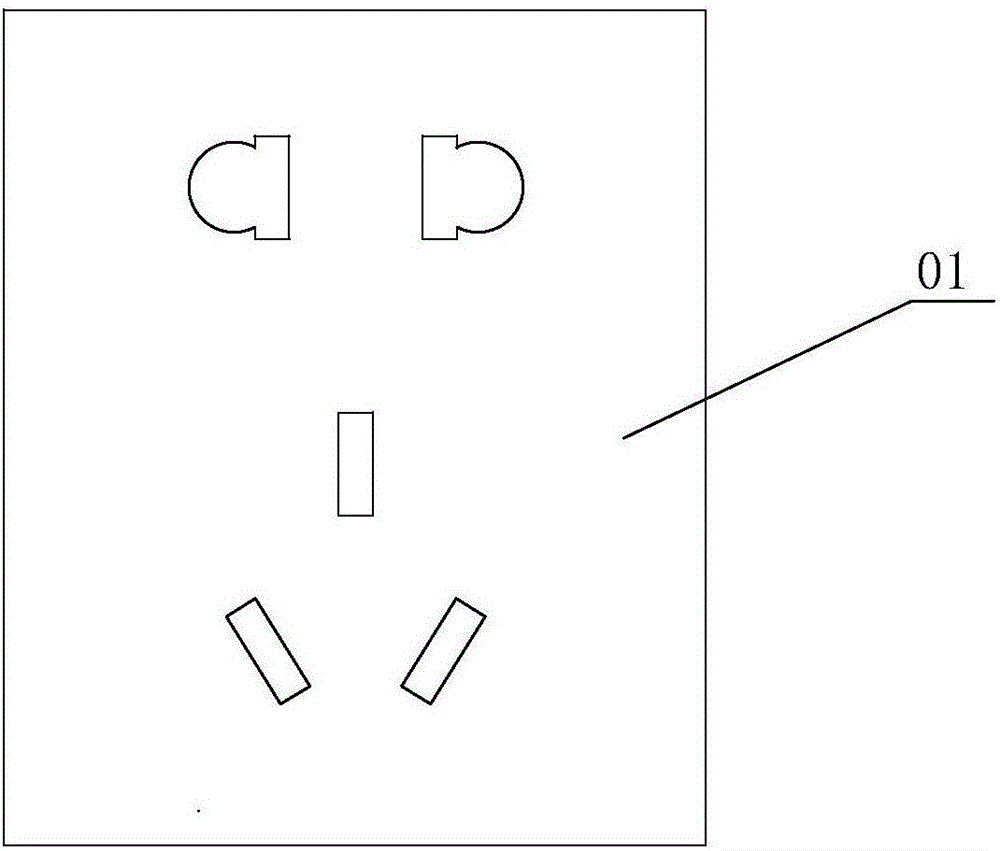

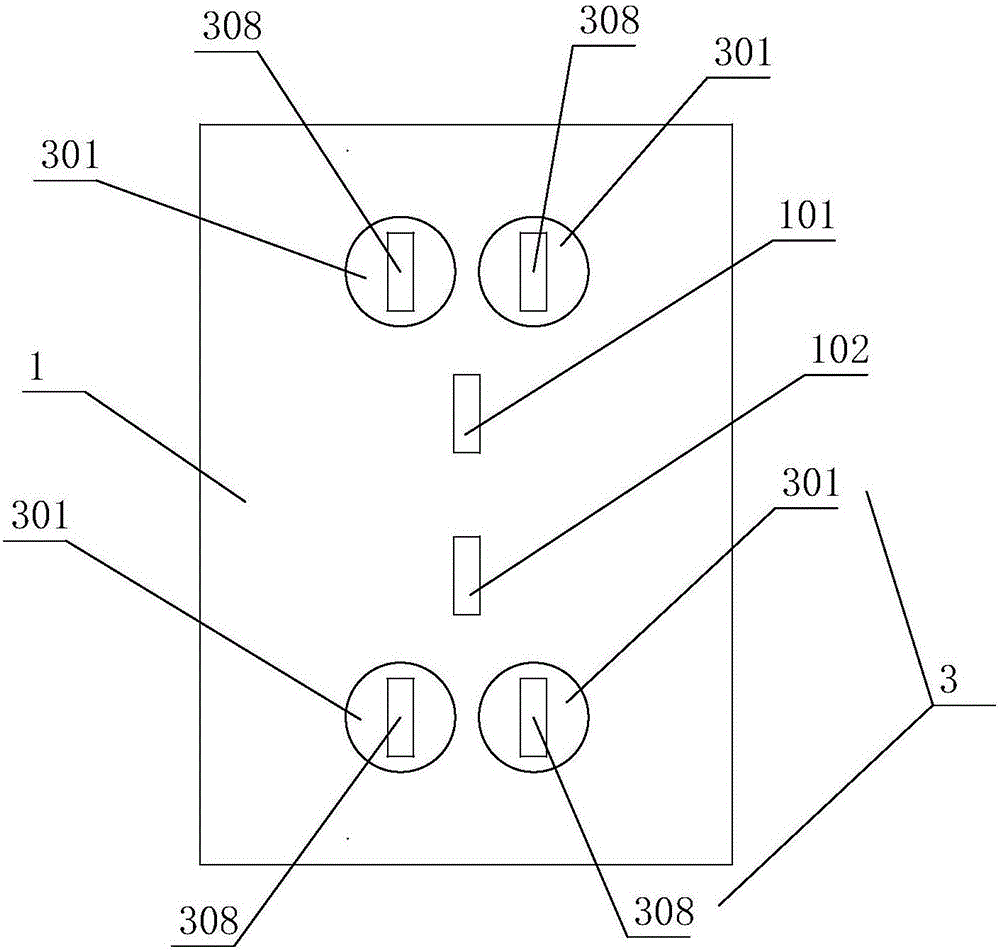

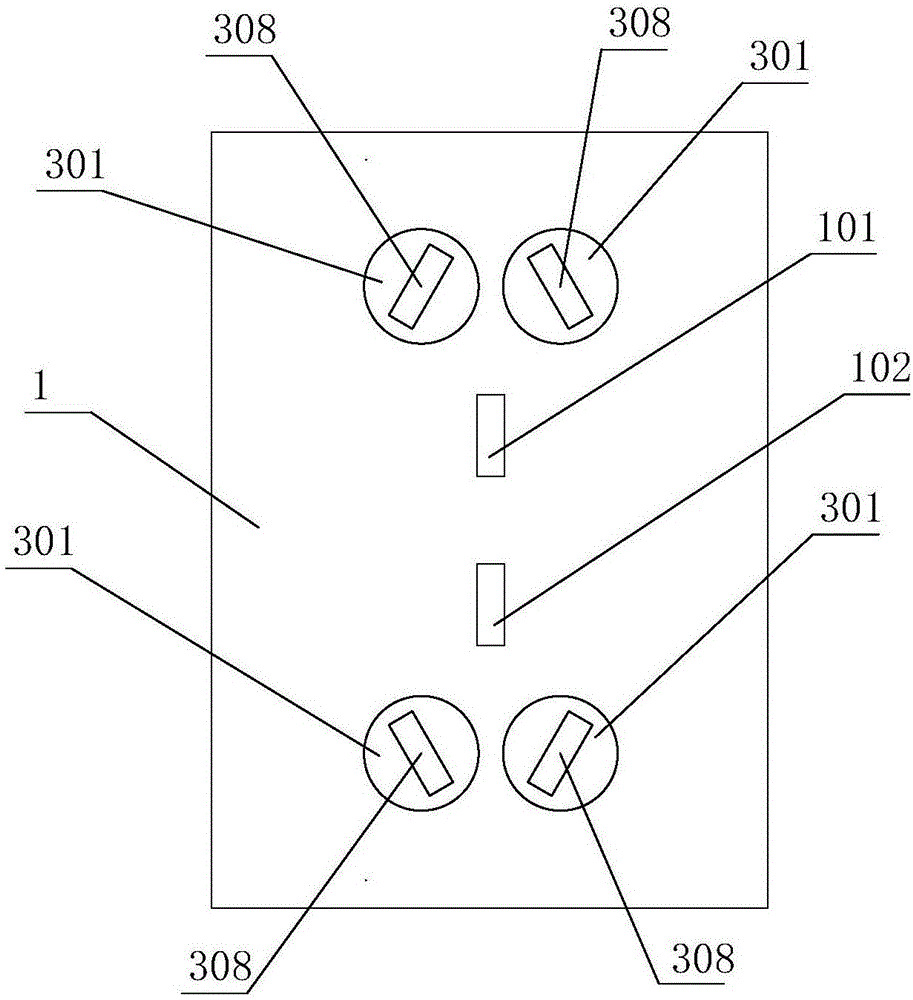

Intelligent tripping-preventive power supply device

InactiveCN106058542AImprove ease of useImprove the safety of useCoupling contact membersDiagonalEngineering

The invention discloses an intelligent tripping-preventive power supply device. The power supply device comprises an upper casing, a pedestal, four jack assemblies into which flat insertion pieces of a plug are inserted, an unlocking ring and an unlocking rod; and each jack assembly comprises a sub-casing, a self-locking piece, a self-locking rod, a sleeve into which the flat insertion piece is inserted, a copper bearing, a conductive connecting piece and a conductive rod. Thus, two jacks, except a jack connected to a ground wire, among three jacks of each group can rotate in the surface of the upper casing around an intersection point of two diagonals of a rectangular opening of the jack, so that both three-pole and two-pole flat plugs can be inserted into the three-pole jack, two three-pole flat plugs or two two-pole flat plugs or one three-pole flat plug and one two-pole flat plug can be inserted into the power supply device at the same time, and the using convenience of the power supply device is improved.

Owner:SHANGHE COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com