Continuous casting start casting operation method for square billets

An operation method, the technology of billet continuous casting, applied in the field of continuous casting operation, can solve the problems of excessive billet shell length, large billet drawing resistance, etc., and achieve the effects of reducing billet drawing resistance, preventing bonding, and shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

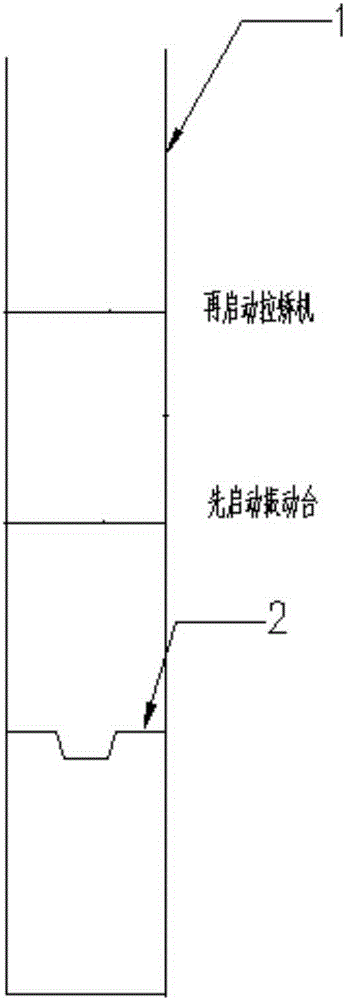

[0015] Such as figure 1 As shown, in this specific embodiment, the billet section is 150×150, and the mold length is 900mm. A method for continuous casting and pouring of billet, the method includes the following steps:

[0016] Step 1: Insert the dummy head 2 into the crystallizer 1 at a position of 250mm, and start pouring the tundish.

[0017] Step 2: When the tundish is poured, open the stopper rod for 15 seconds and then start the vibrating table. At this time, the molten steel in the mold 1 rises to about 450mm in the mold 1, such as figure 1 In the position shown in , the primary shell in the crystallizer 1 is forced to demould.

[0018] Step 3: Start the tension leveler 5 seconds after the vibrating table starts, and set the starting speed to 0.2m / min. At this time, the molten steel in mold 1 rises to about 600mm in mold 1, such as figure 1 In the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com