High-temperature metal seal sleeve compensator

A technology of sleeve compensator and metal seal, which is applied in expansion compensation devices for pipelines, pipes/pipe joints/fittings, adjustable connections, etc. It can solve the problems of increasing maintenance costs, aggravating corrosion, and increasing project cost. Achieve safe and reliable working performance, wide applicable temperature range, and reduce project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

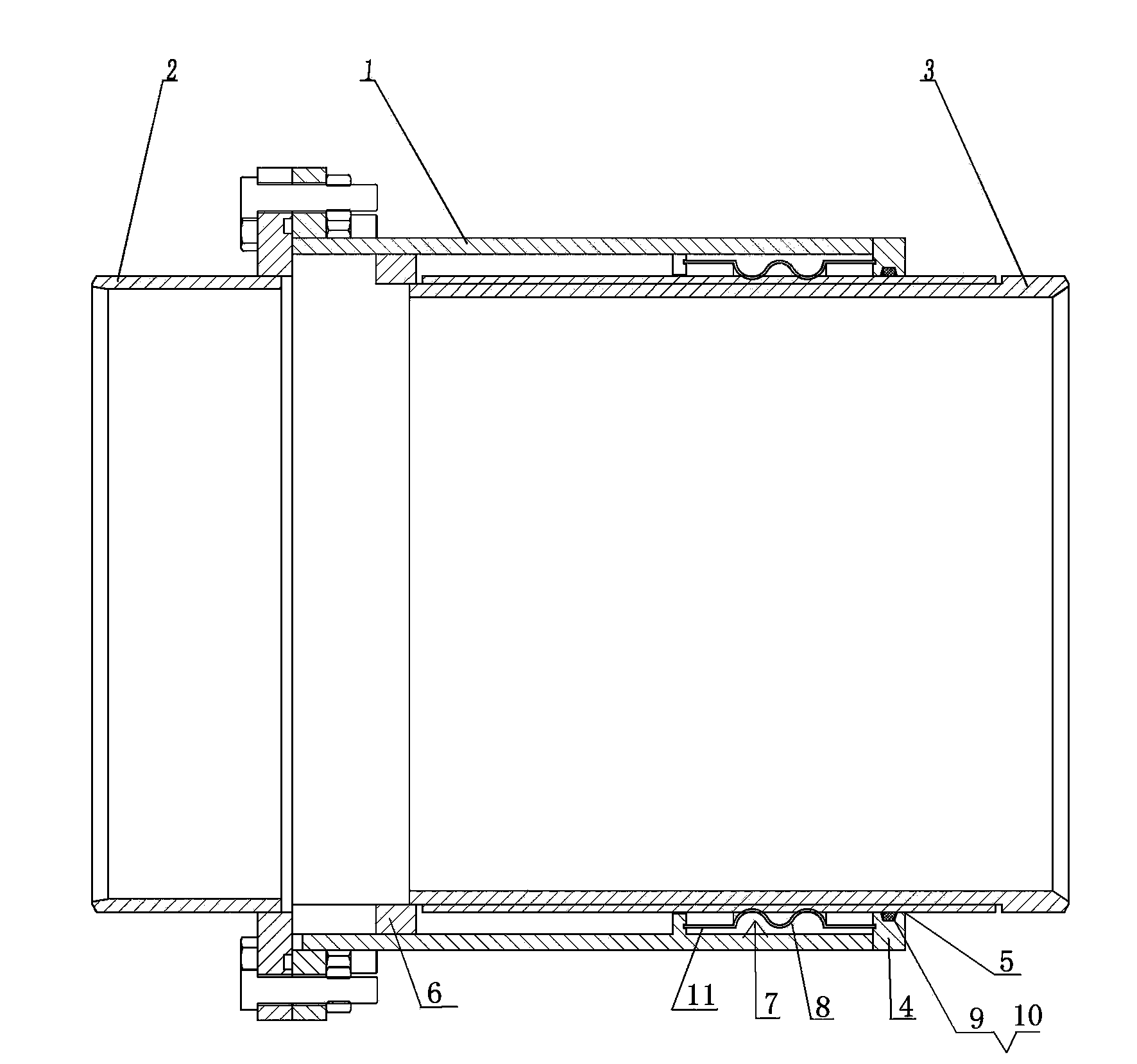

[0017] A high-temperature metal-sealed sleeve compensator, comprising an outer sleeve 1, an inner sleeve 3 and an anti-breakage flange 2, characterized in that:

[0018] The flange of the outer sleeve 1 is connected with the anti-break flange 2 by bolts, and the inner sleeve 3 is inserted into the outer sleeve 1 from the outer sleeve socket 5 on the front end cover 4 of the outer sleeve 1, and the inner sleeve 3 The outer wall of the outer sleeve is closely matched with the outer sleeve jack 5, and the rear end of the inner sleeve 3 is fixedly connected with a support ring 6, and the outer ring surface of the support ring 6 is slidably matched with the inner wall of the outer sleeve 1.

[0019] A stainless steel metal sealing ring 7 is installed on the front inner wall of the outer sleeve 1. The middle part of the stainless steel metal sealing ring 7 is a corrugated section 8, and the two ends of the stainless steel metal sealing ring 7 are straight sections. The corrugated sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com