Rotary wire connector

A connector, rotary technology, applied in the direction of flexible/rotatable wire connectors, connections, contact parts, etc., can solve problems such as twisting deformation and breaking of cables or wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

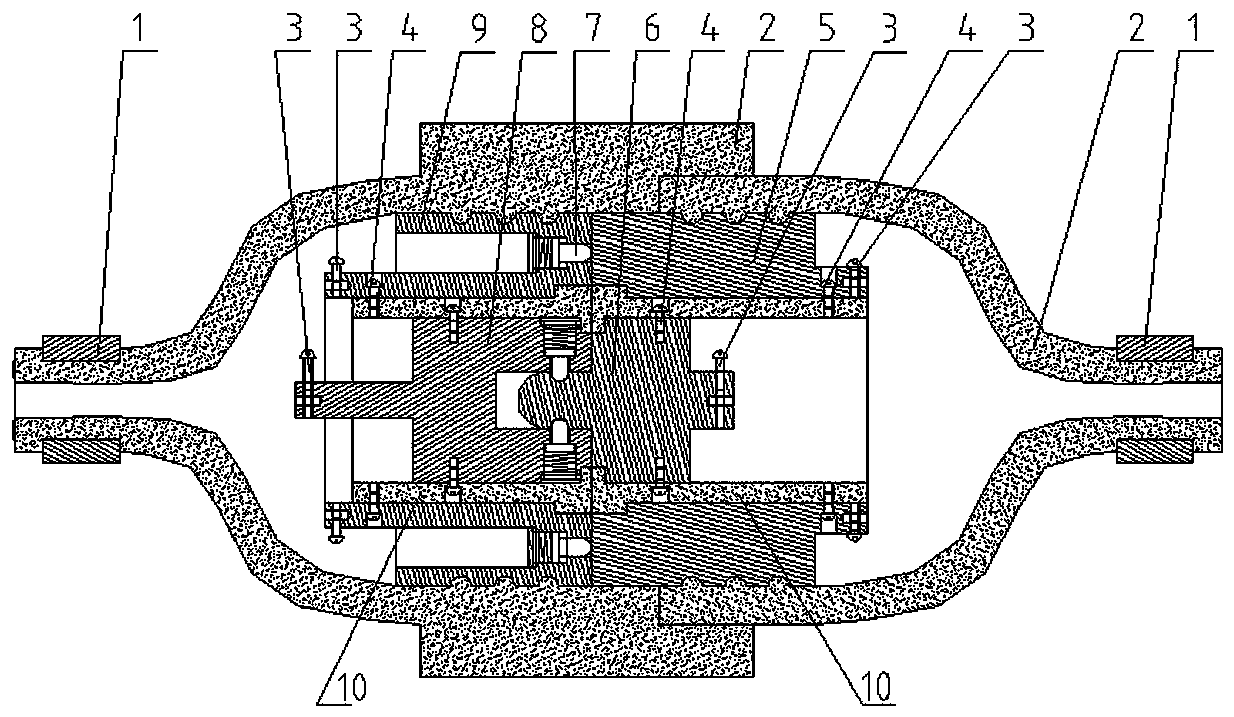

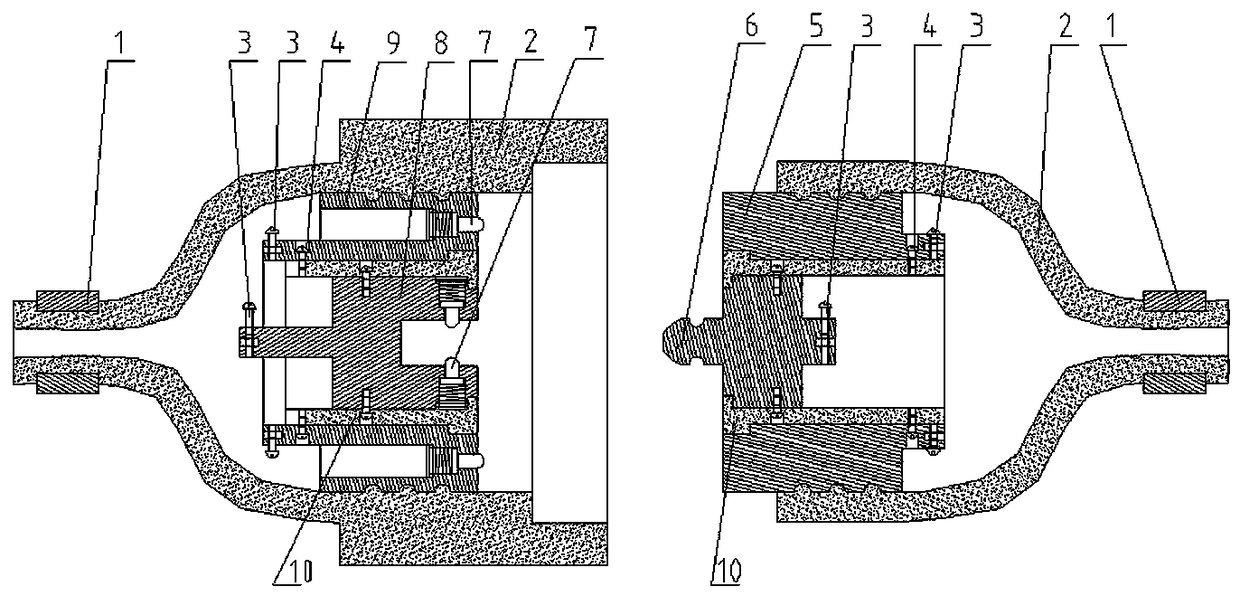

[0009] Such as figure 1 , figure 2 As shown, the rotary connector of the present invention mainly includes a sheath 2 . The two trumpet-shaped sheaths 2 that can be inserted into each other are respectively equipped with an annular plug end 5, a cylindrical plug end 6, a terminal post 3, a positioning stud 4, an annular socket end 9, a cylindrical socket end 8, a terminal post 3, Locating stud 4, spring post 7. An insulating sleeve 10 is installed between the annular plug end 5 and the cylindrical plug end 6 , the annular socket end 9 and the cylindrical socket end 8 . There is an annular groove at the corresponding contact position between the cylindrical plug end 6 and the elastic post 7 . Tightening straps 1 are installed at both ends of the sheath 2 .

[0010] Such as figure 1 , figure 2 As shown, when making and using the present invention, in order to make the sheath 2 firmly connected with the annular plug end 5 or the annular socket end 9 and not easy to diseng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com