Photovoltaic packaging adhesive film, photovoltaic module and preparation method of photovoltaic module

A technology for encapsulating adhesive film and photovoltaics, which is applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of complex structure and inability to adapt the compound wire film, and achieve the effect of simple structure and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] As an example, the method for preparing the photovoltaic encapsulation adhesive film 110 provided in the embodiment of the present application includes: relatively moving the adhesive film body relative to the electron cathode ray gun emitting electron beams along a preset path, so that the electron beams penetrate The body on the path is set so that the area where the film body is in contact with the electron beam is cross-linked to form a target pre-cross-linked area.

[0054] It can be understood that, in the embodiment of the present application, the distribution form of the first area 111 and the second area 112 is not limited, as long as the photovoltaic encapsulation adhesive film 110 is applied to the photovoltaic module 100, the welding ribbon 130 can be connected with the second area respectively. The abutment between the first area 111 and the second area 112 enables the area of the soldering ribbon 130 corresponding to the first area 111 to be better packag...

Embodiment 1

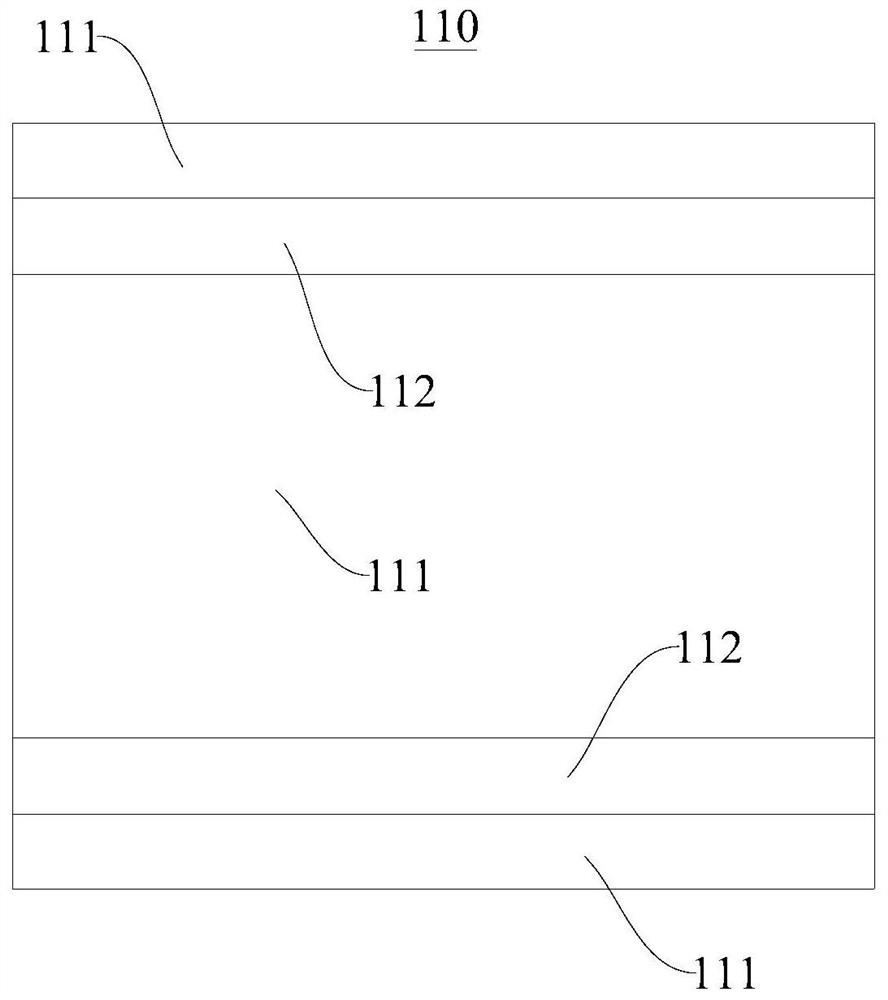

[0066] A photovoltaic encapsulation adhesive film 110, such as image 3 As shown, the photovoltaic encapsulation adhesive film 110 is composed of an adhesive film body. Wherein, the adhesive film body is composed of three first regions 111 and two second regions 112 .

[0067] Wherein, the extension directions of the opposite two sets of edges of the adhesive film body are respectively a first preset direction and a second preset direction, and the first preset direction and the second preset direction are perpendicular to each other. Each first area 111 and each second area 112 extend along the first predetermined direction from one side edge of the adhesive film body to the other side edge, and the distance between two adjacent second areas 112 is A , the width of the second region 112 is B, and B / A is 1 / 9. A plurality of first regions 111 and a plurality of second regions 112 are alternately arranged in a second predetermined direction, and the edge of the adhesive film b...

Embodiment 2

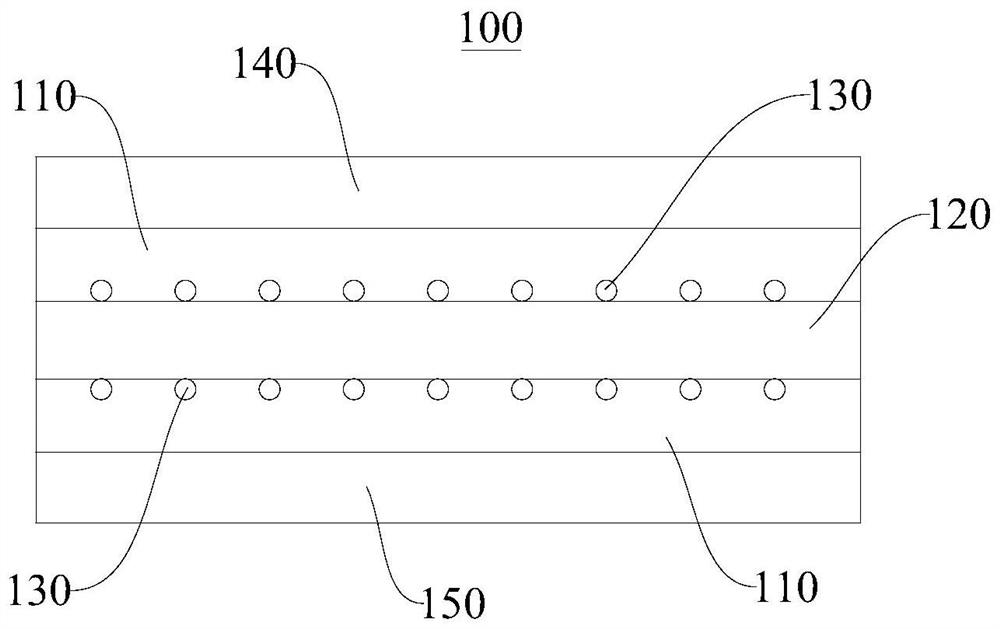

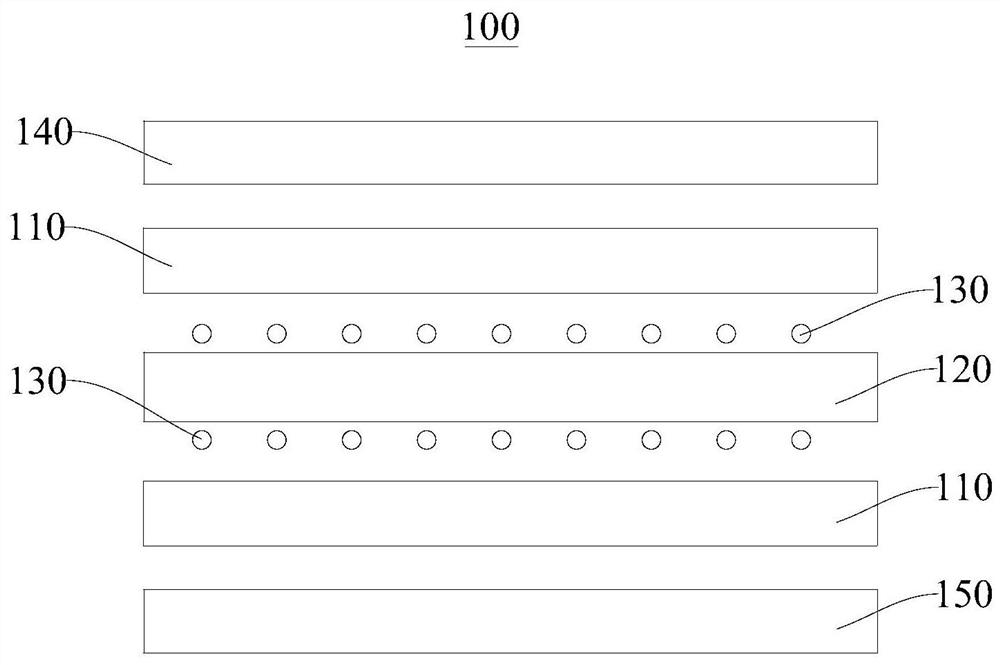

[0069] A photovoltaic module 100 includes a surface glass, a first encapsulation film, a plurality of first soldering strips 130 , a battery sheet 120 , a plurality of second soldering strips 130 , a second encapsulation film and a back plate 150 arranged in sequence.

[0070]Wherein, both the first encapsulating adhesive film and the second encapsulating adhesive film are the photovoltaic encapsulating adhesive film 110 provided in the first embodiment. A plurality of fine grid lines 121 are provided on the upper surface of the battery sheet 120 close to the first encapsulant film and the back surface close to the second encapsulant film. On each surface of the battery sheet 120 , each thin grid line 121 extends along a first preset direction, and a plurality of thin grid lines 121 are distributed at intervals along a second preset direction. The plurality of first welding strips 130 are distributed alternately along the first predetermined direction, and the plurality of sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com