Buffer and damping wire pulling pole

A pull rod and pull rod technology, applied in the field of electric power fittings, can solve the problems of large distance difference, uneven force on the middle pole, and loose fixed pile, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

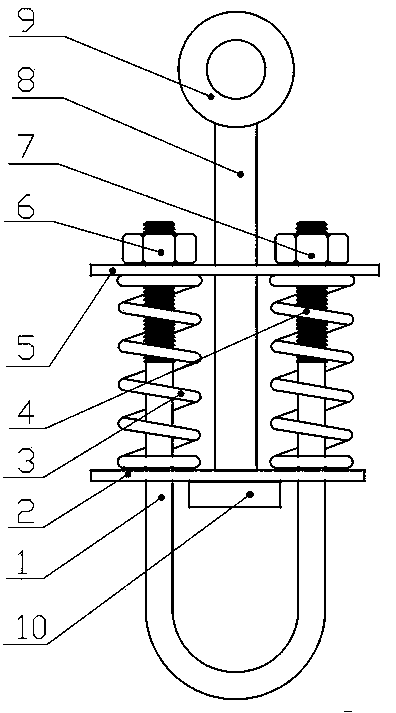

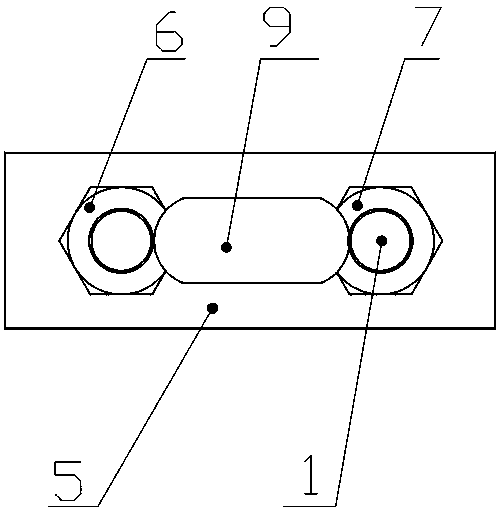

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] A kind of cushioning shock-absorbing stay wire rod, comprises pull-down rod 1, hanging board one 2, spring one 3, spring two 4, hanging board two 5, upper pull rod 8; The stigma is provided with threads; the two ends of the hanging plate 1 are respectively sleeved on the two stigmas of the pull-down rod 1 and can move up and down; the spring 1 3 and spring 2 4 are respectively set on the two stigmas of the pull-down rod and are located above the plate one 2; the two ends of the hanging plate two 5 are respectively sleeved on the two stigmas of the pull-down rod 1 and are located above the spring one 3 and the spring two 4; , nut two 7, the nut one 6 and the nut two 7 are located above the hanging plate two 5; the upper tie rod 8 is located between the two stigmas of the lower rod 1, and the lower end of the upper tie rod 8 penetrates the hanging plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com