An improved electric tension clamp

An improved technology for strain-resistant clamps, applied in the direction of adjusting/maintaining mechanical tension, it can solve the problems of wire dragging and loosening, wire breakage, excessive wire tension, etc., to optimize the connection effect, prevent the wire from loosening, and ensure the connection effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described below with reference to the accompanying drawings. During this process, in order to ensure the clarity and convenience of the description, we may exaggerate the width of the lines or the size of the components in the illustrations.

[0026] In addition, the following term is defined based on the function in this invention, and may differ according to a user, an operator's intention, or convention. Therefore, these terms are defined based on the entire content of this specification.

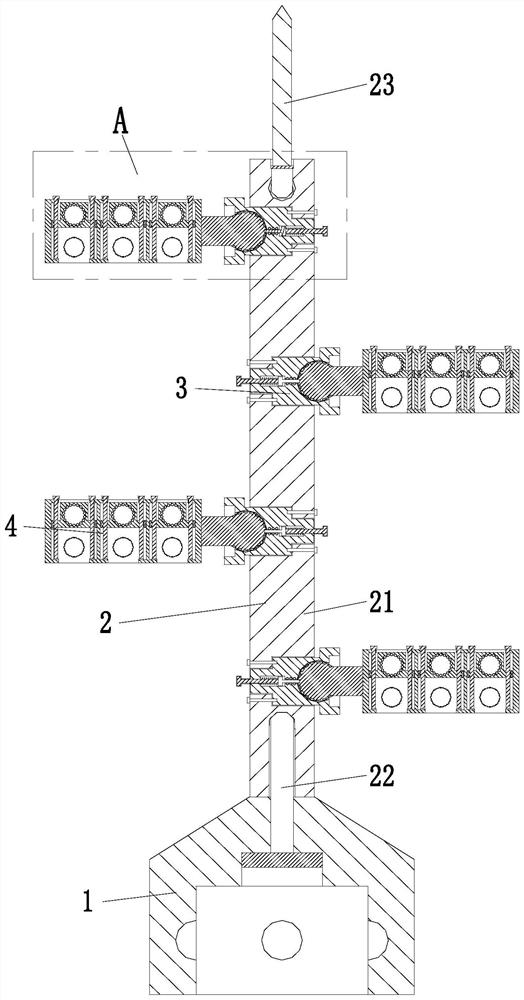

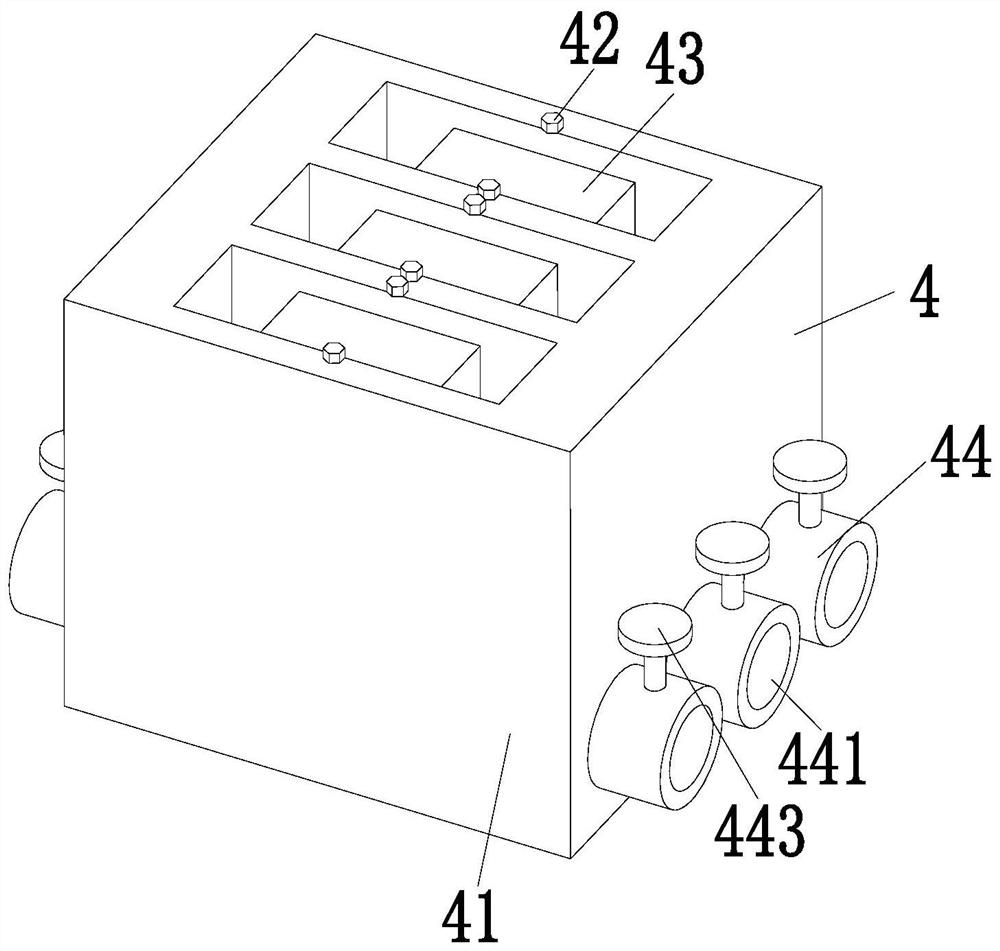

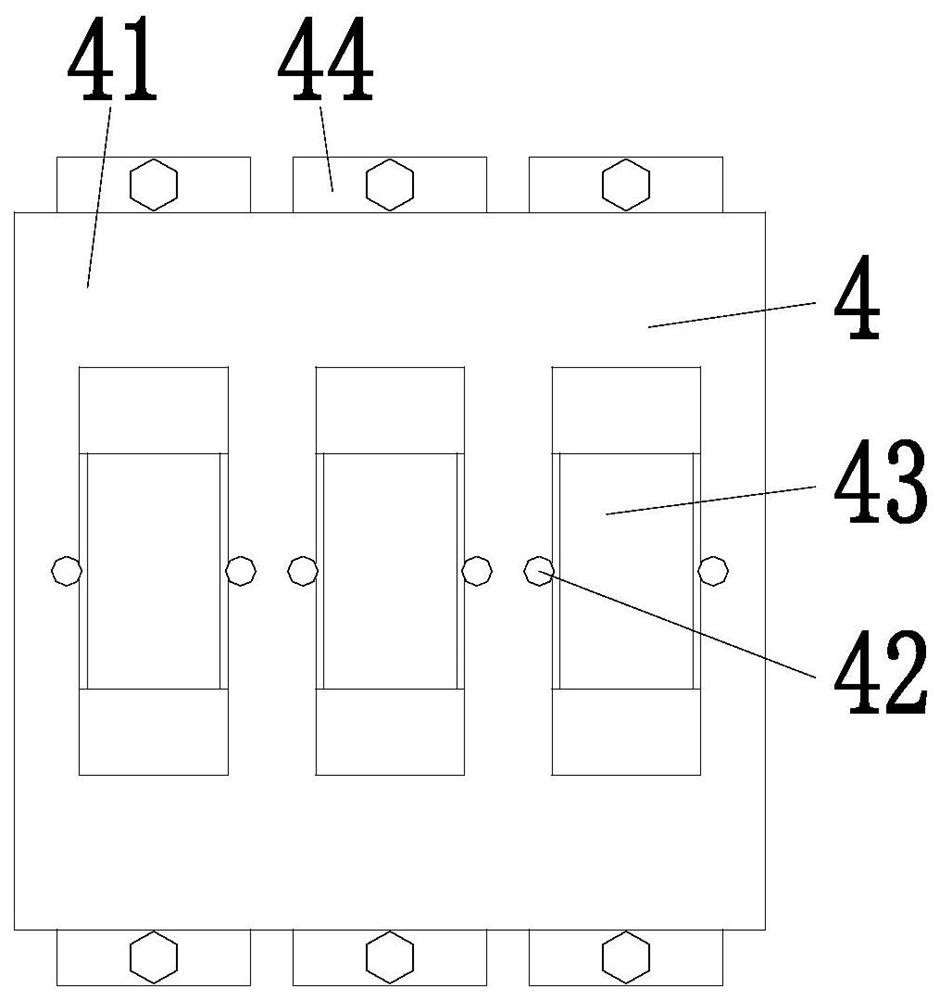

[0027] like Figure 1 to Figure 6 As shown in the figure, an improved electric tension clamp includes a fixing sleeve 1, an auxiliary unit 2, an adjusting unit 3 and a clamp unit 4; A mounting hole is provided, a metal sheet is arranged in the mounting hole of the fixing sleeve 1, and an auxiliary unit 2 is installed on the top outer wall of the fixing sleeve 1. The auxiliary unit 2 is a block-shaped structure and is located at both e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com