Patents

Literature

30results about How to "Guaranteed taut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

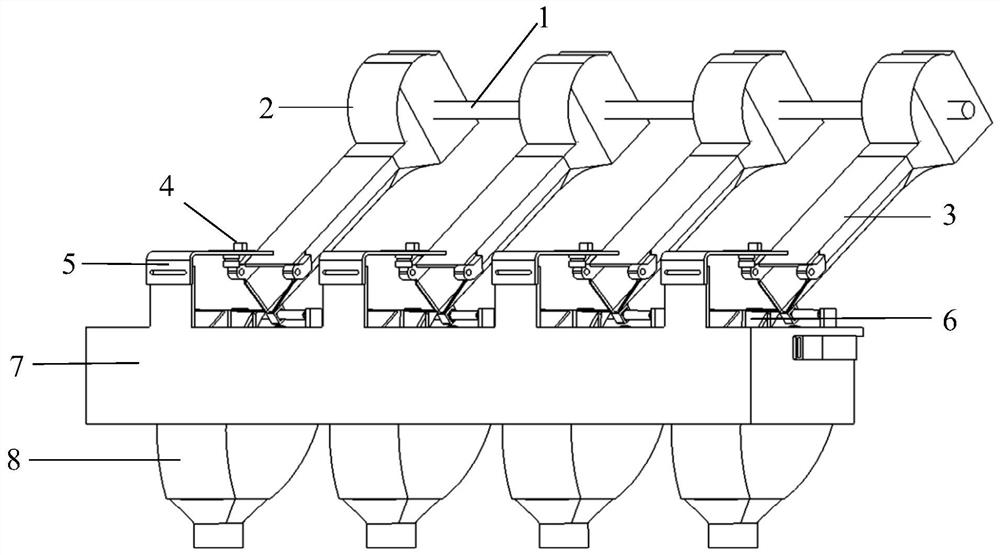

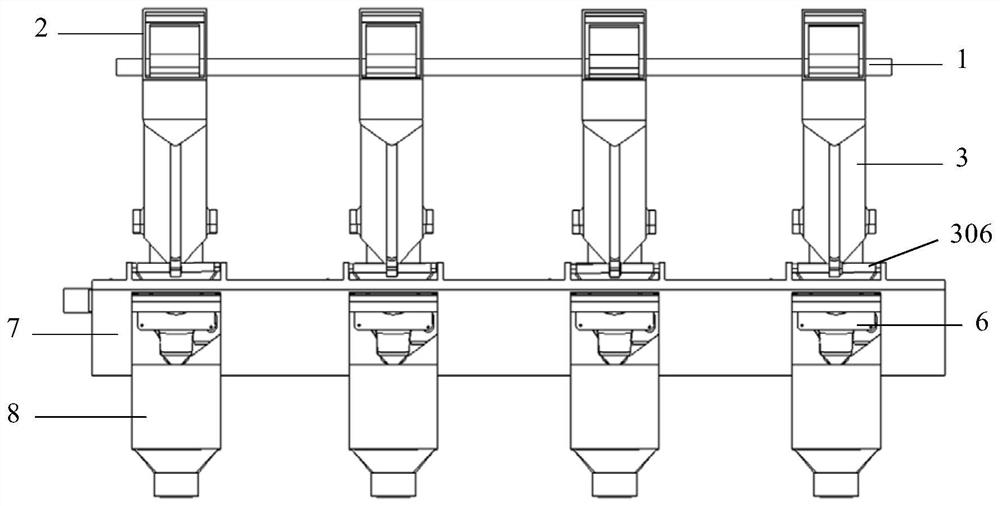

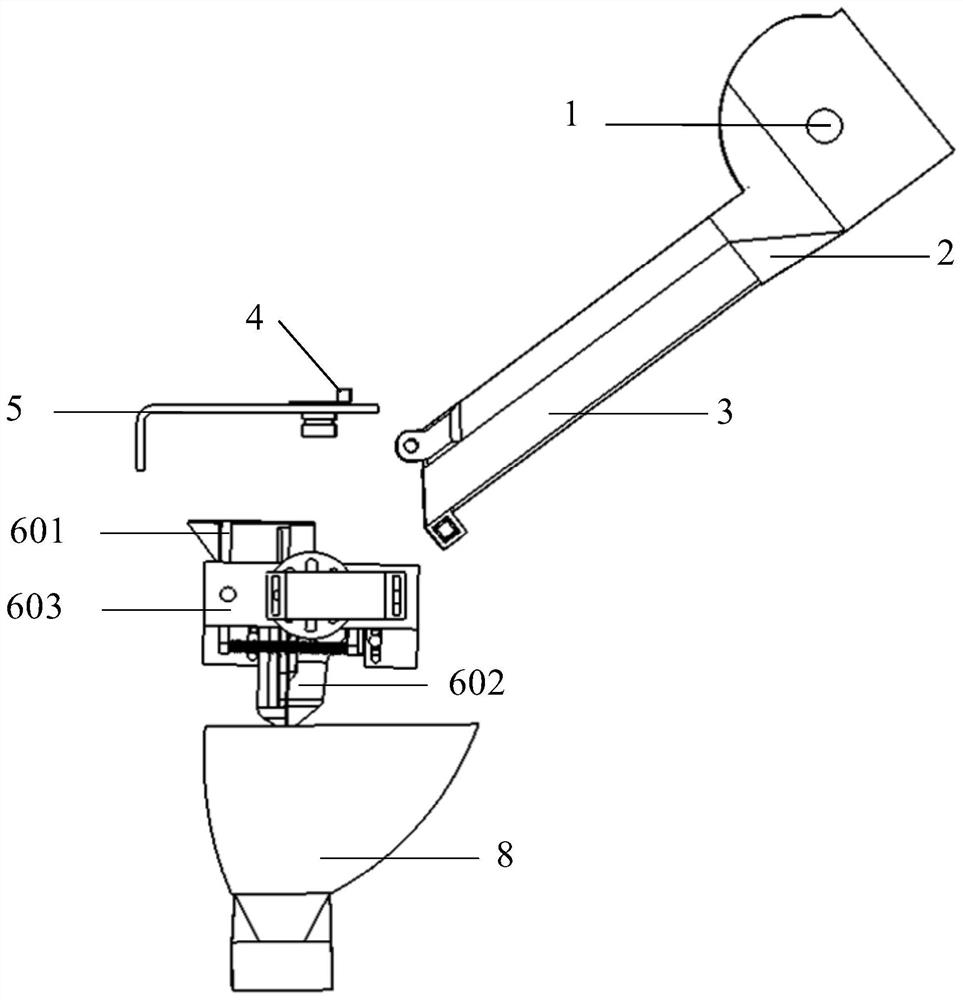

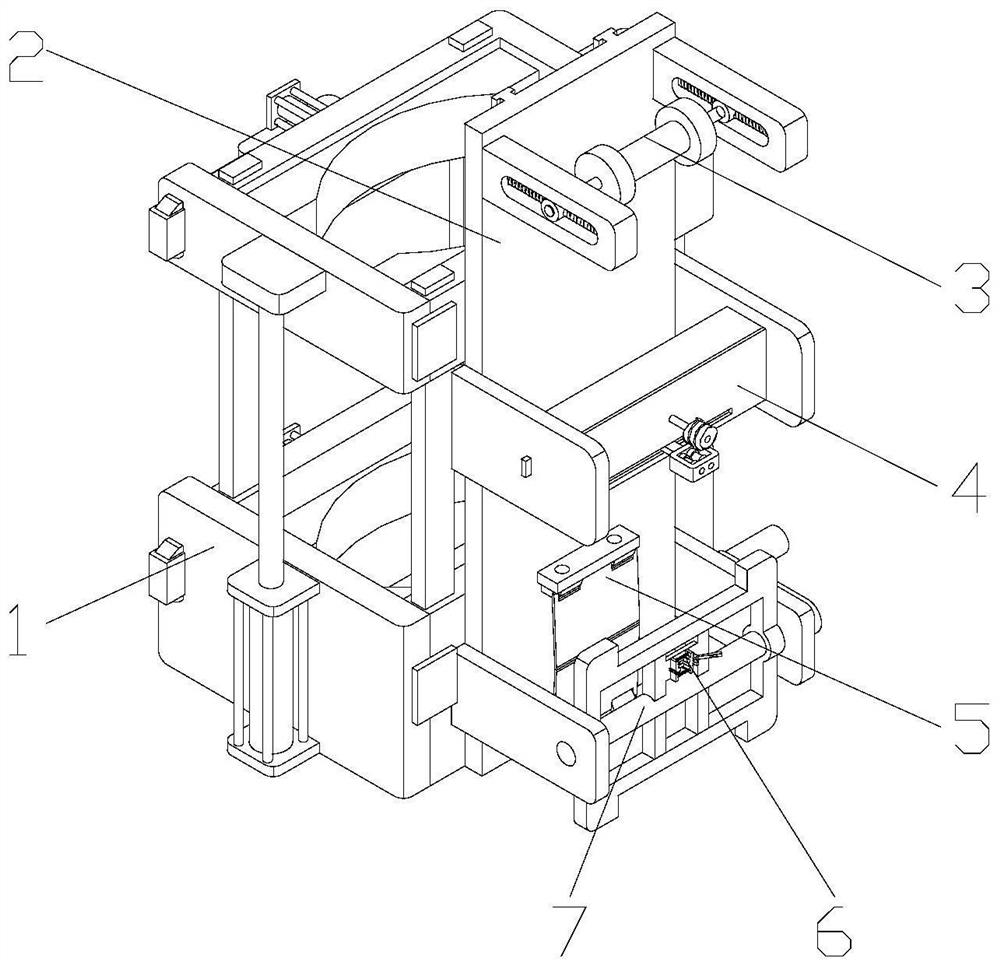

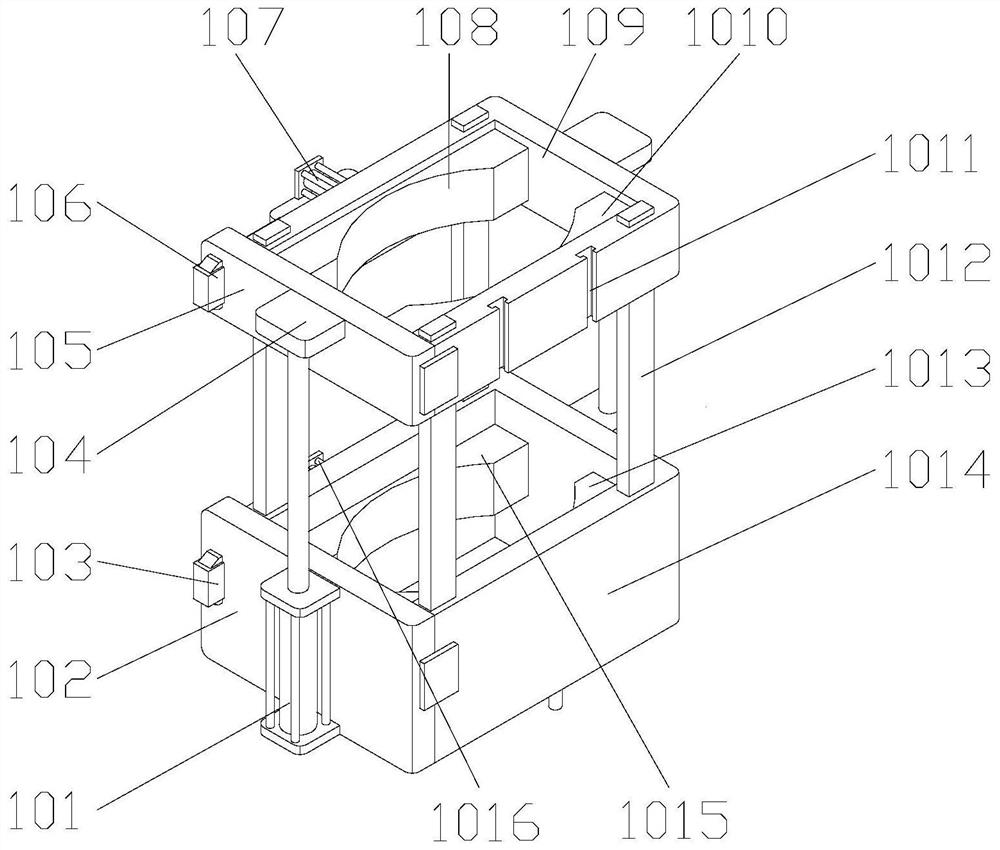

Garlic directional sowing device and method based on machine vision

ActiveCN112913399AAchieve structural stabilityEnsure structural stabilityPotato plantersNeural architecturesMachine visionAllium sativum

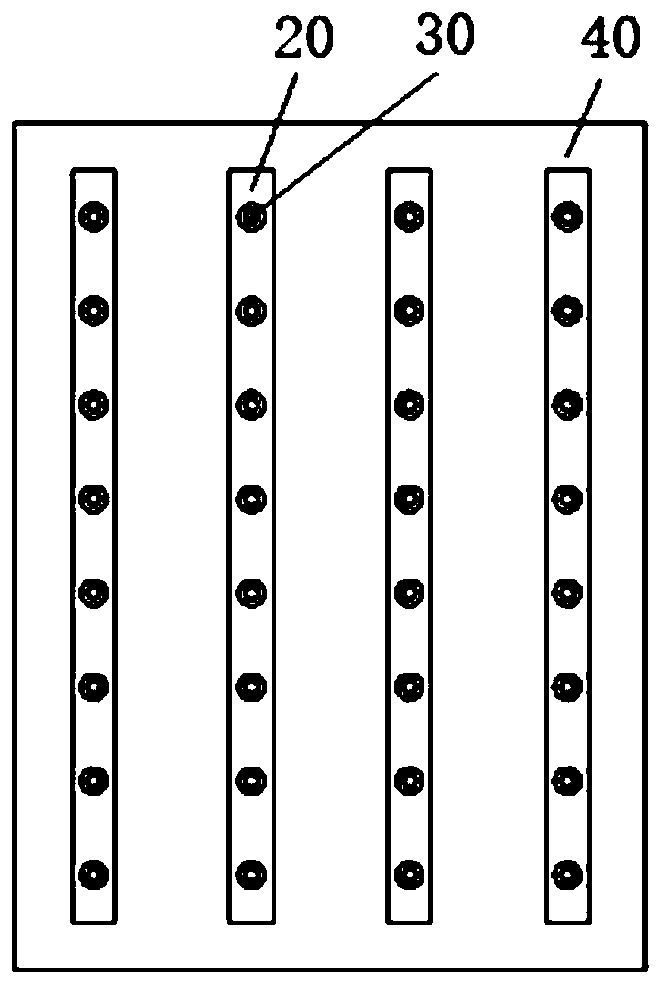

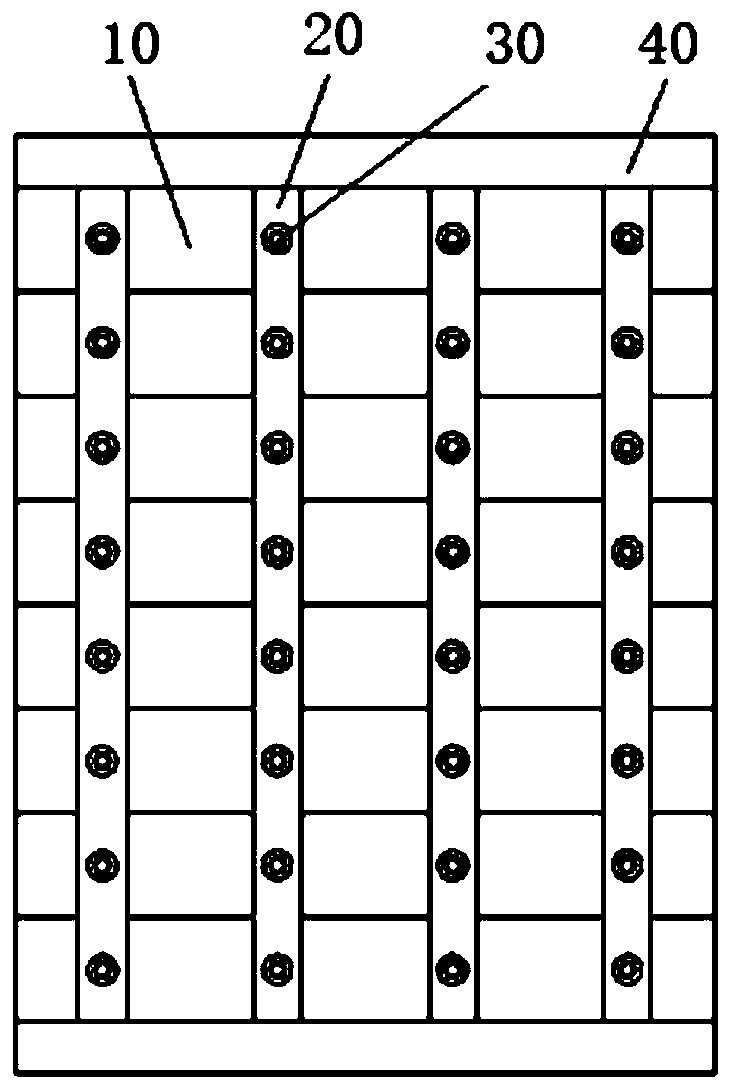

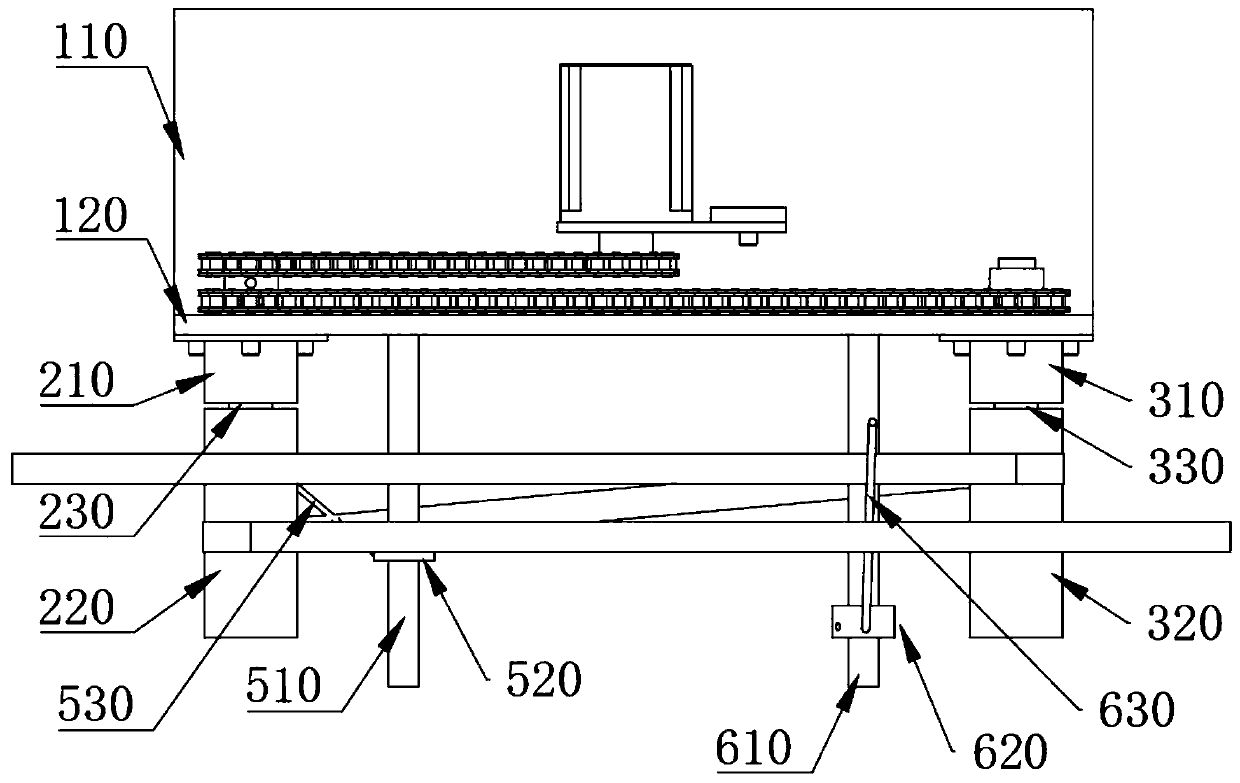

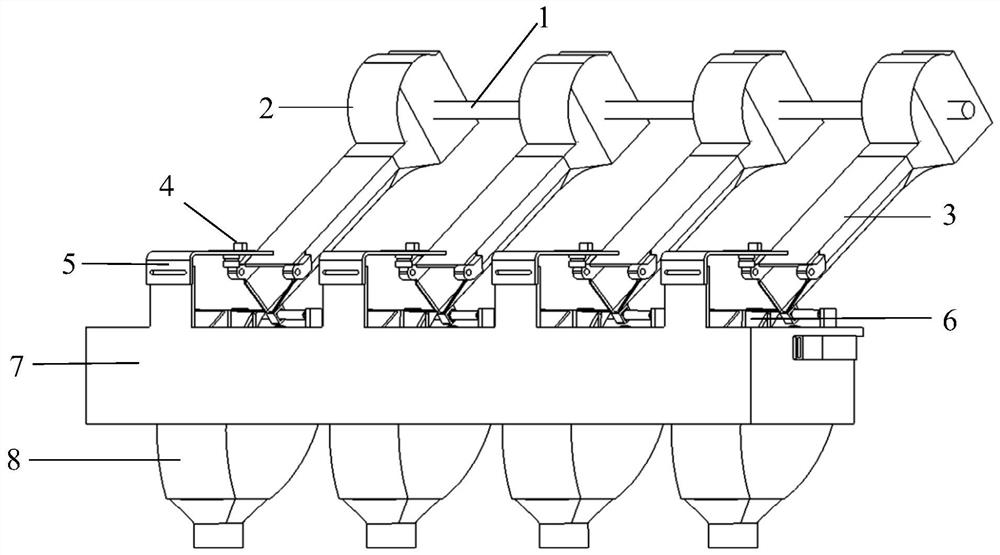

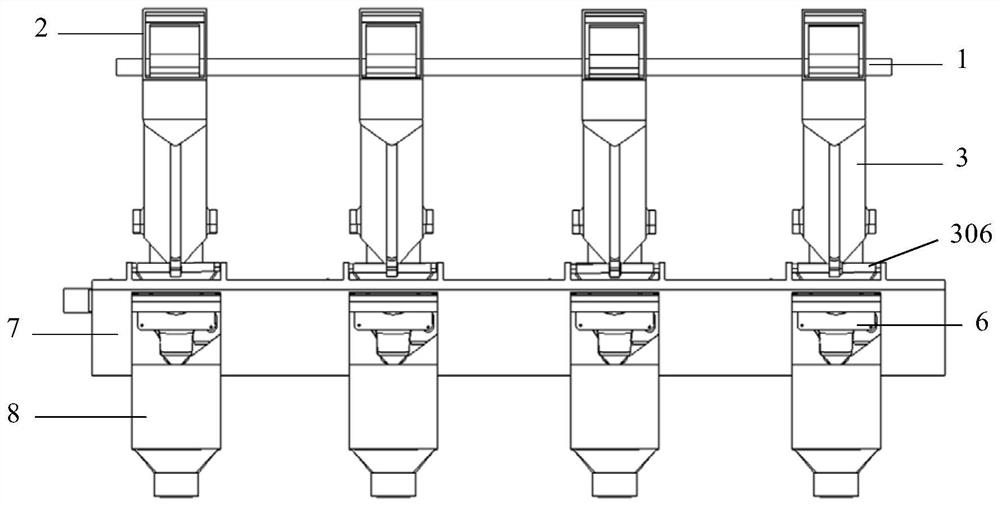

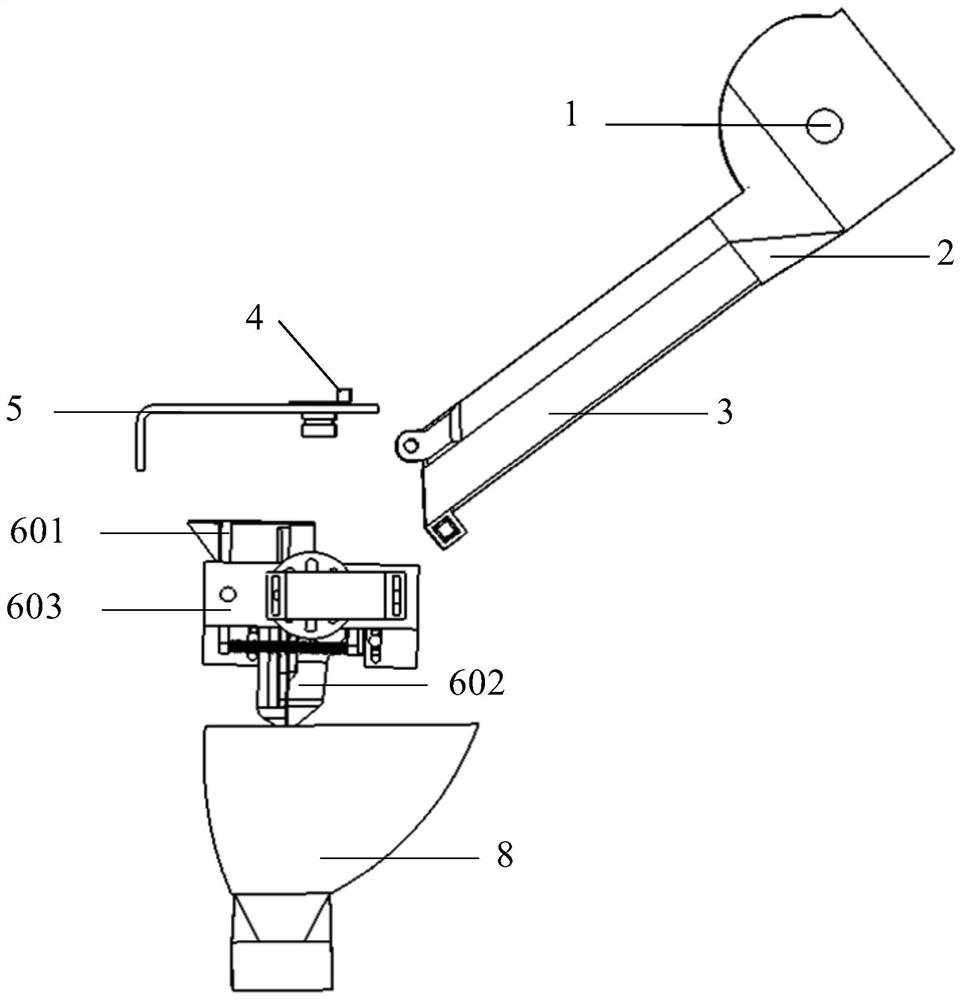

The invention discloses a garlic directional sowing device and method based on machine vision. The device comprises seed shifting and discharging devices, wherein a garlic seed outlet of each seed shifting and discharging device is connected with a first end of a corresponding garlic seed transmission channel, and a second end of each garlic seed transmission channel is arranged at a garlic seed inlet of a corresponding garlic seed feature recognition and directional sowing mechanism; an image collector is correspondingly arranged right above each garlic seed feature recognition and directional sowing mechanism, and an image collection end of each image collector faces the interior of the corresponding garlic seed feature recognition and directional sowing mechanism and is used for collecting posture information photos of garlic seeds; and the garlic seed feature recognition and directional sowing mechanisms recognize and adjust the posture of the garlic seeds according to the posture information picture. According to the garlic directional sowing device and method, secondary seed shifting and discharging of garlic, directional and ordered transmission of garlic seeds, image recognition and directional sowing can be completed at a time, the planting agronomic requirement that bulbil of the garlic seeds faces upwards is met, space and size occupied by the garlic directional sowing device are greatly reduced due to the intensive design, the integrality is high, and mechanical and intelligent sowing of the garlic is met.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Cable tensioning device for high-altitude power construction

ActiveCN112909830AReduce labor intensityPrevent rotationApparatus for overhead lines/cablesControl theoryElectric cables

Owner:国网山东省电力公司曹县供电公司

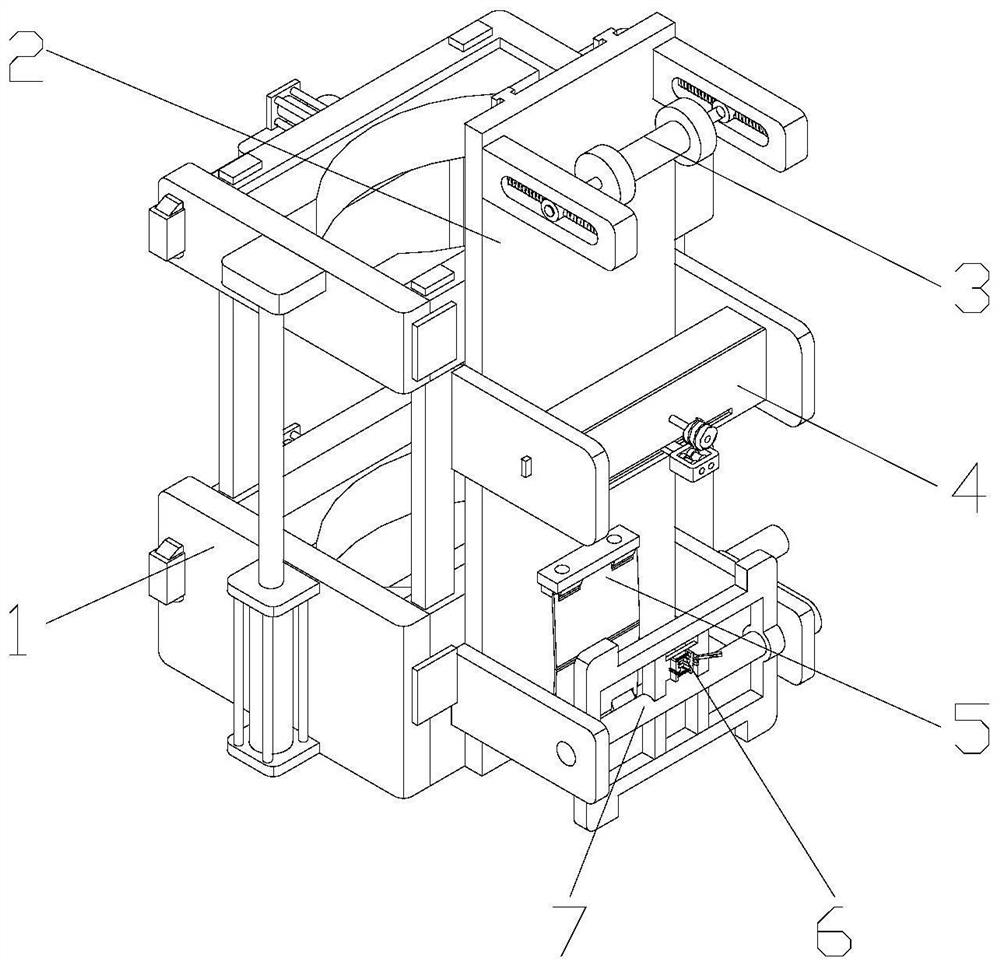

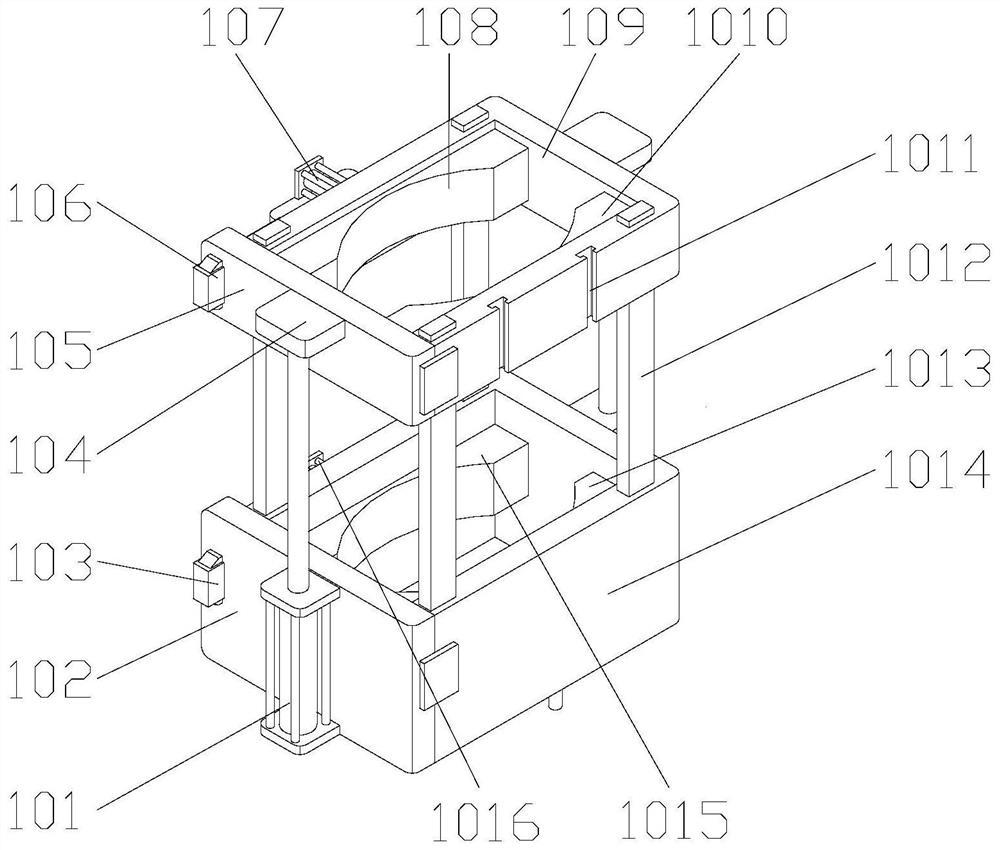

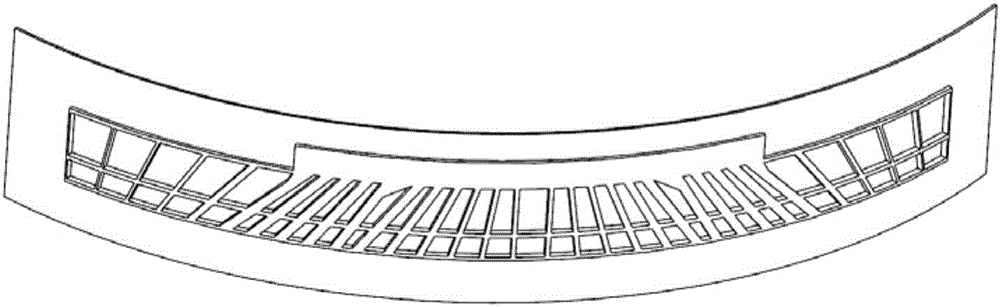

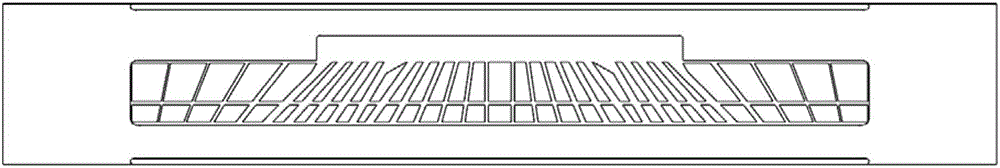

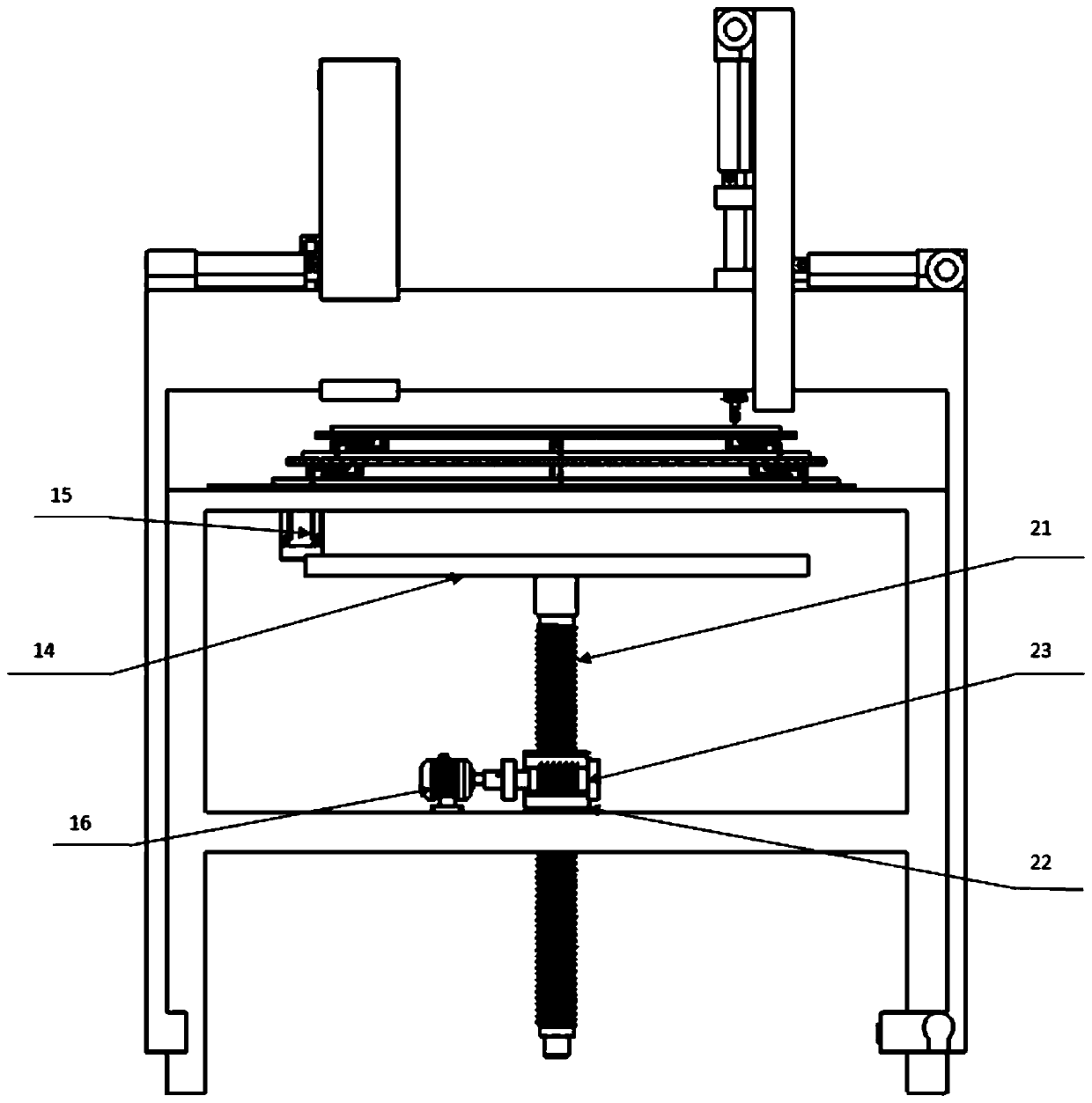

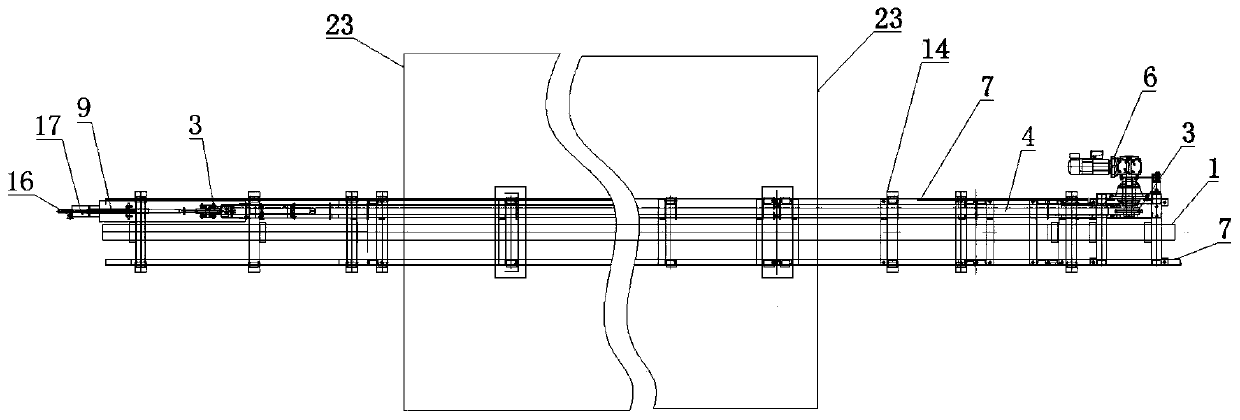

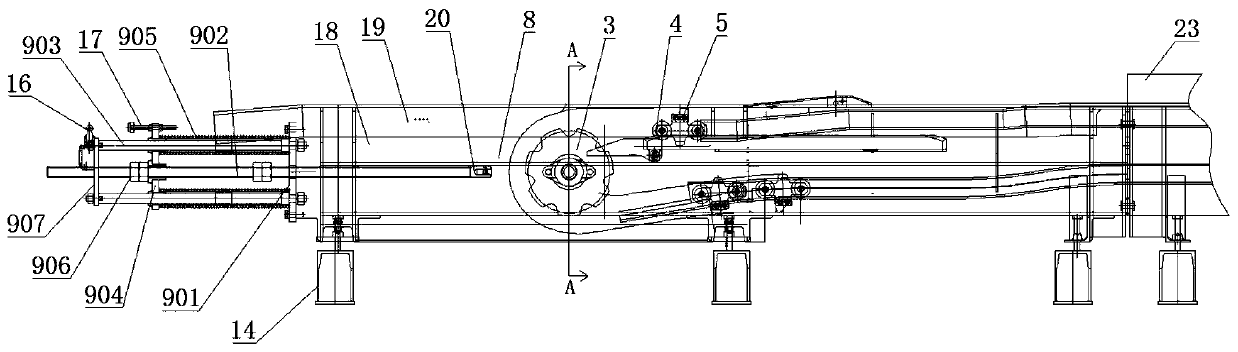

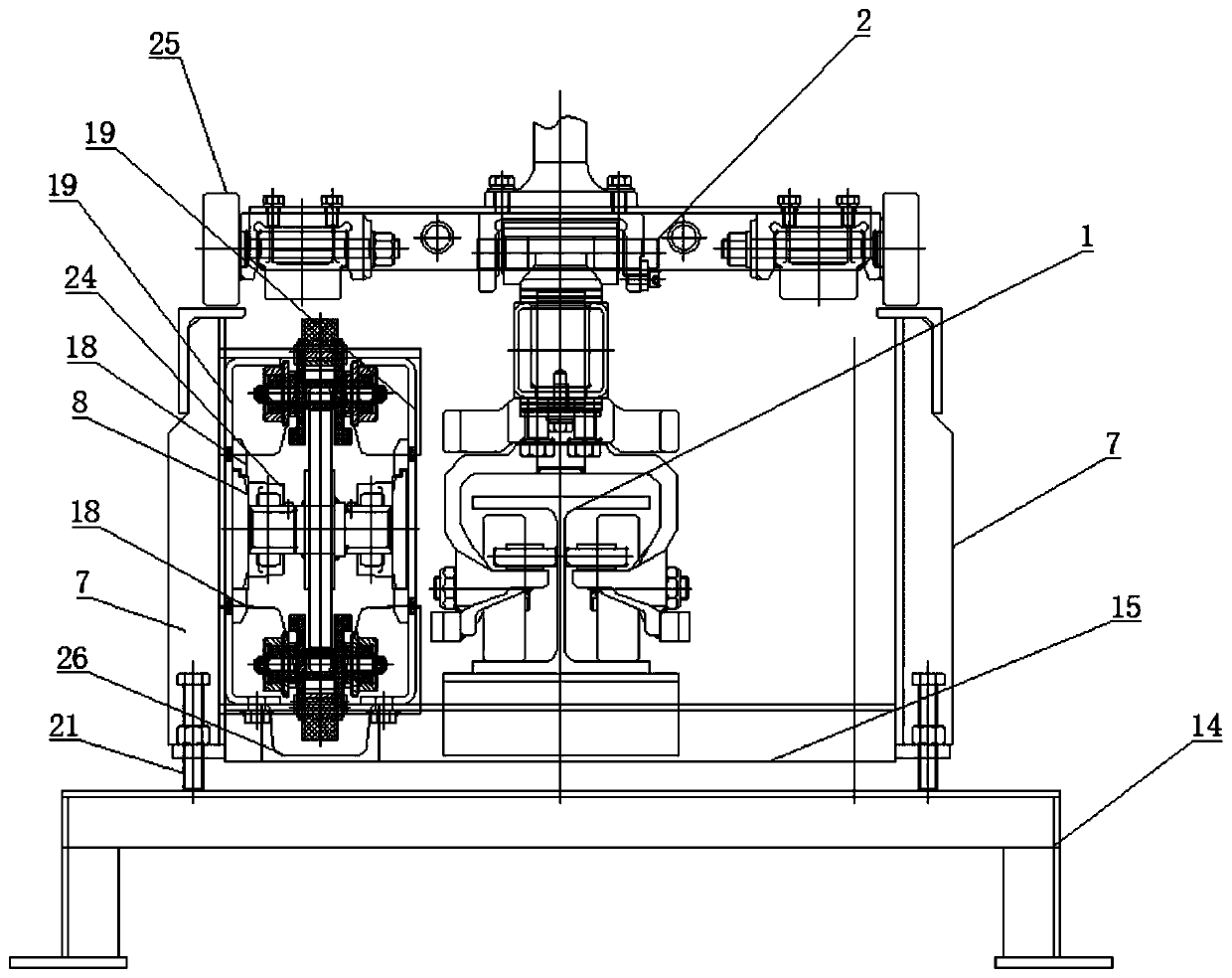

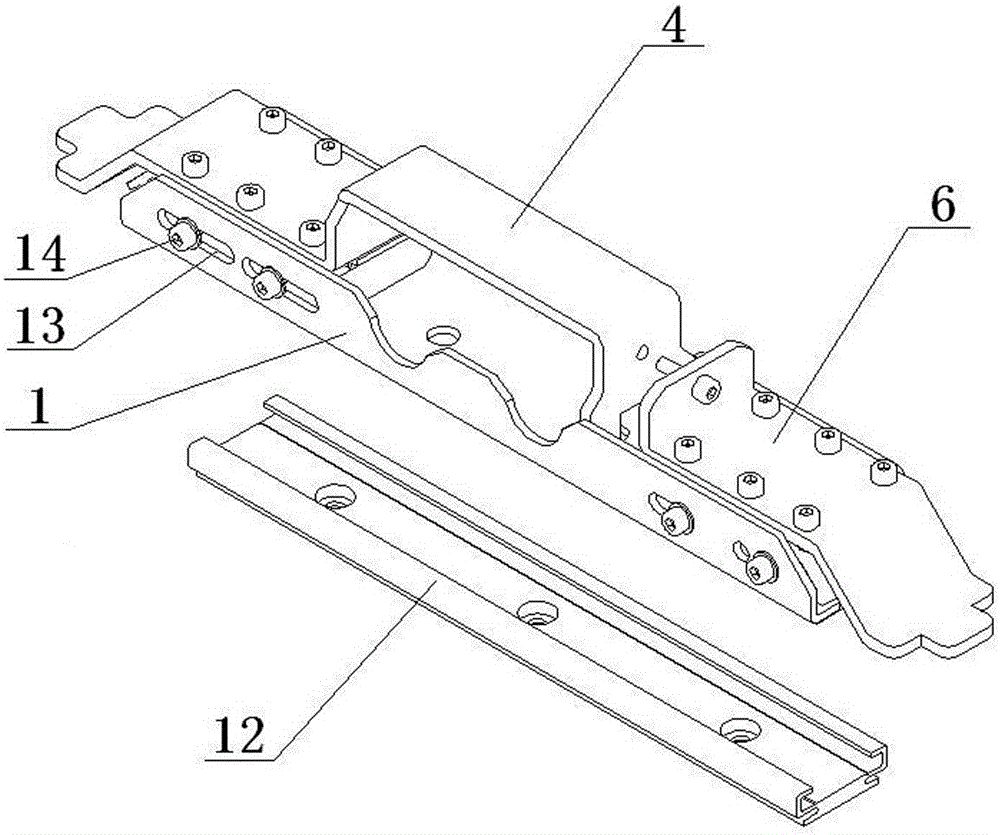

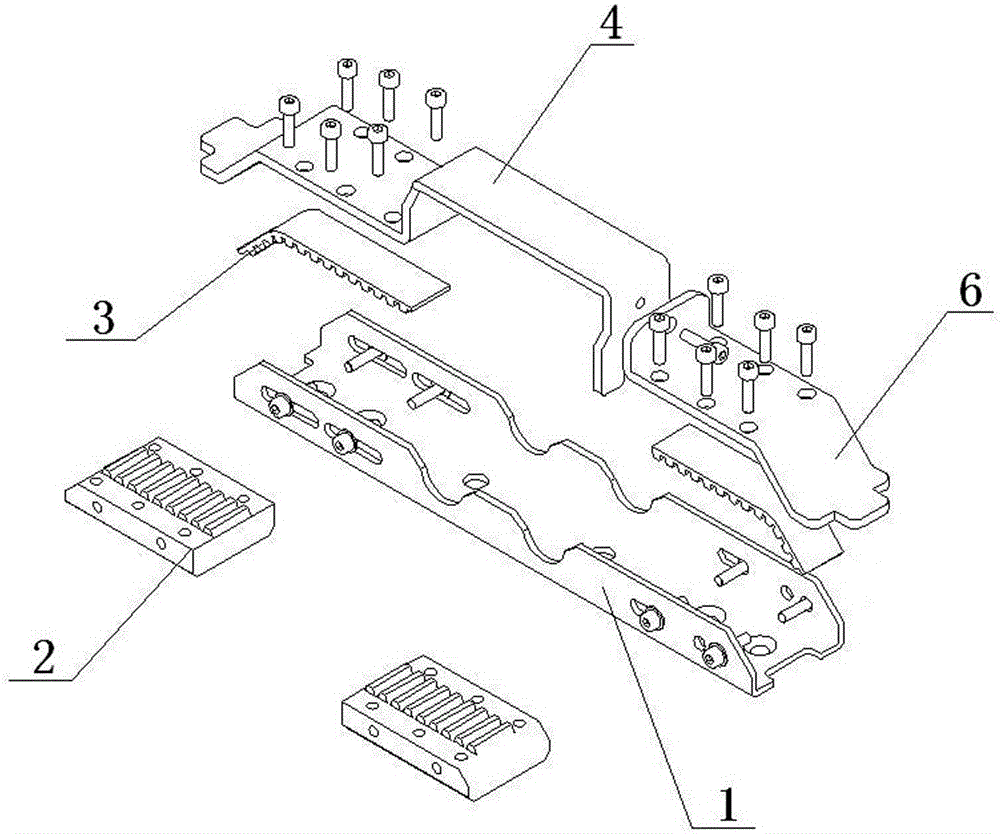

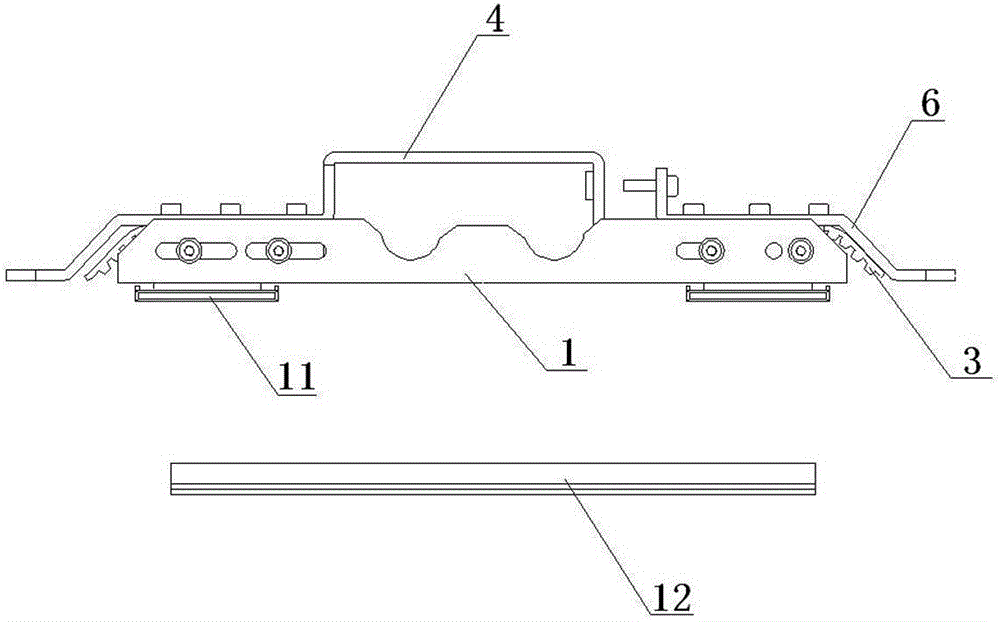

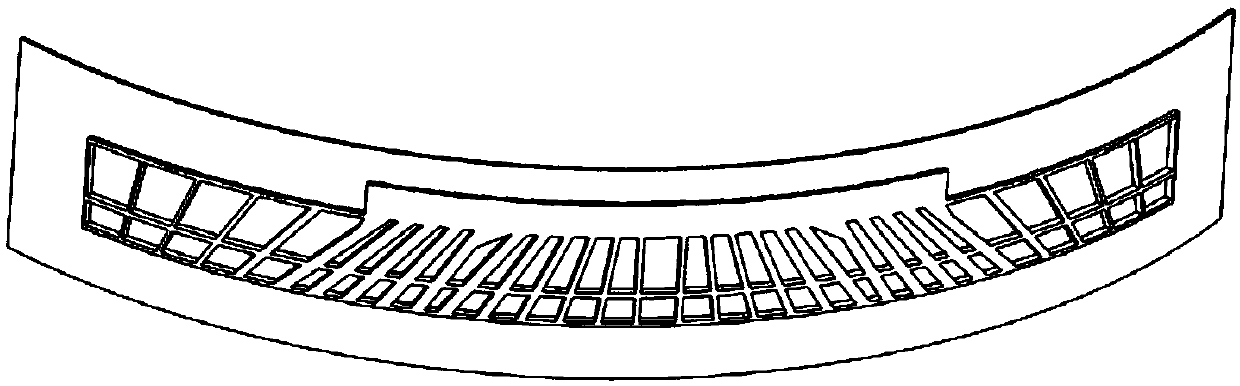

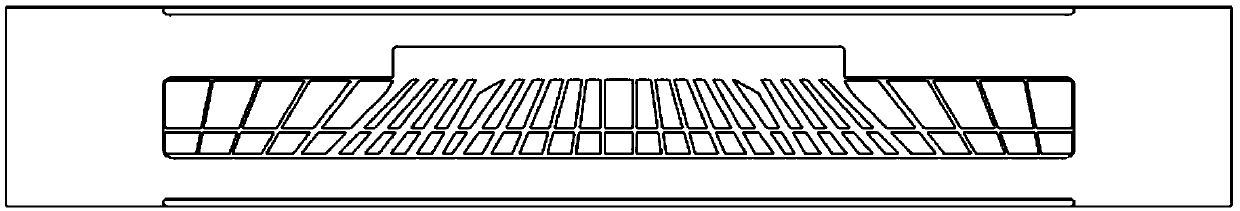

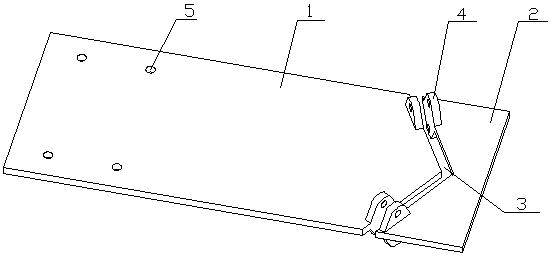

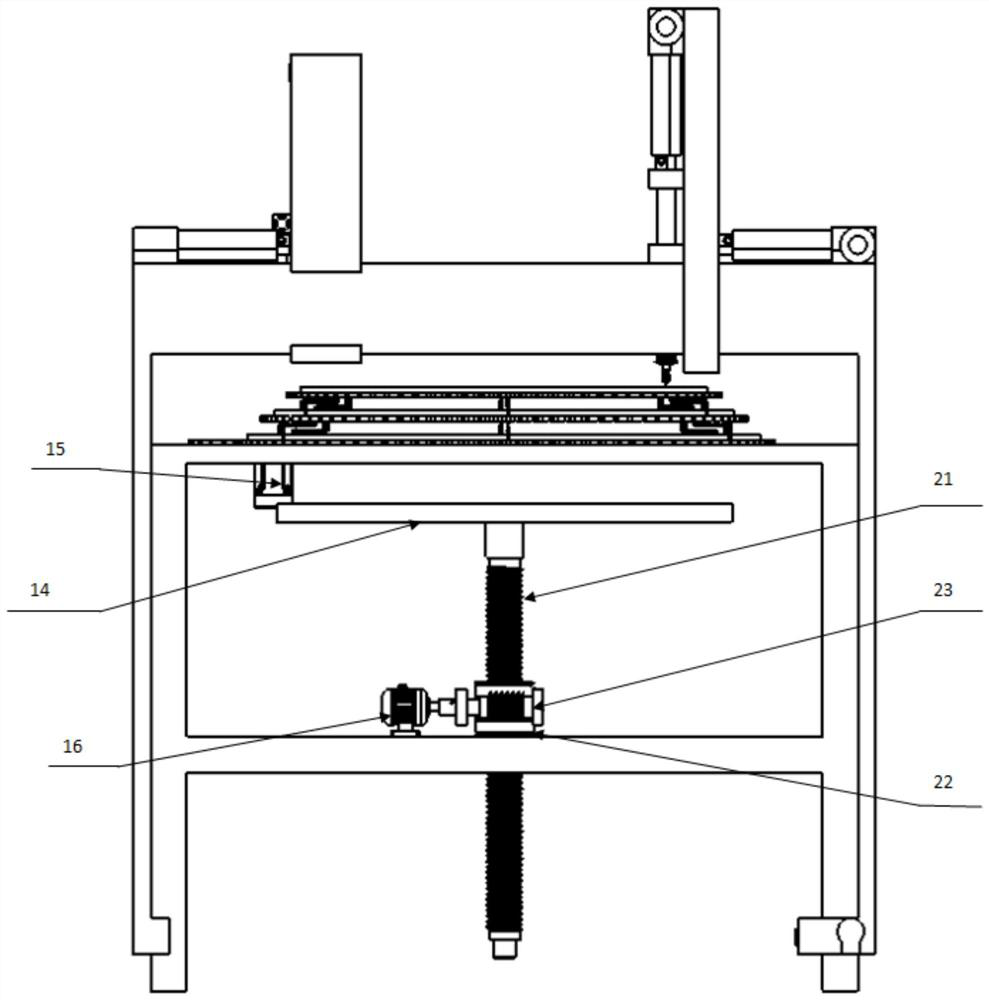

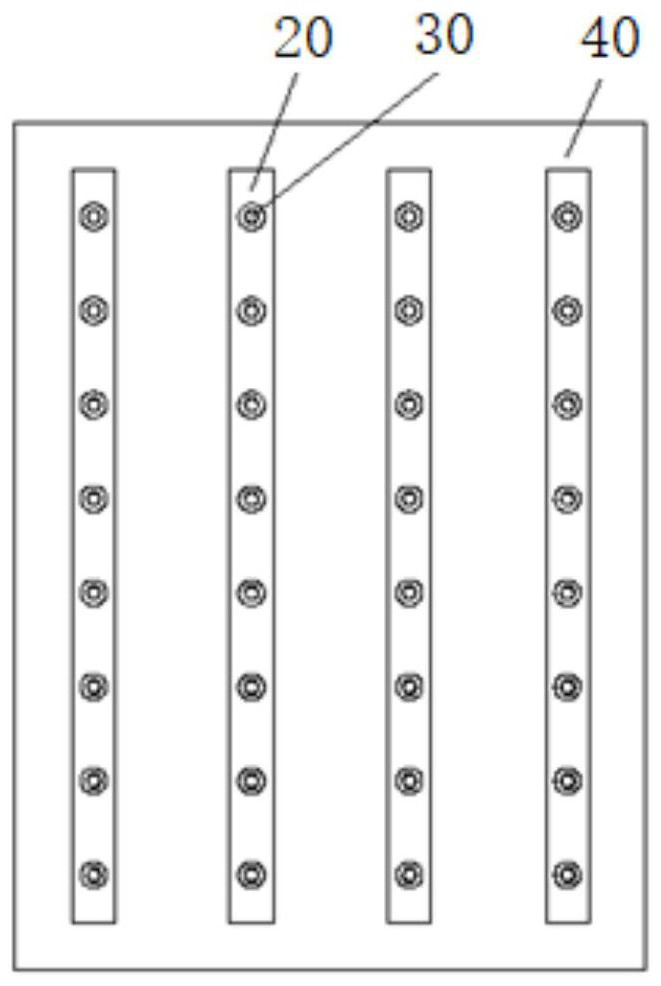

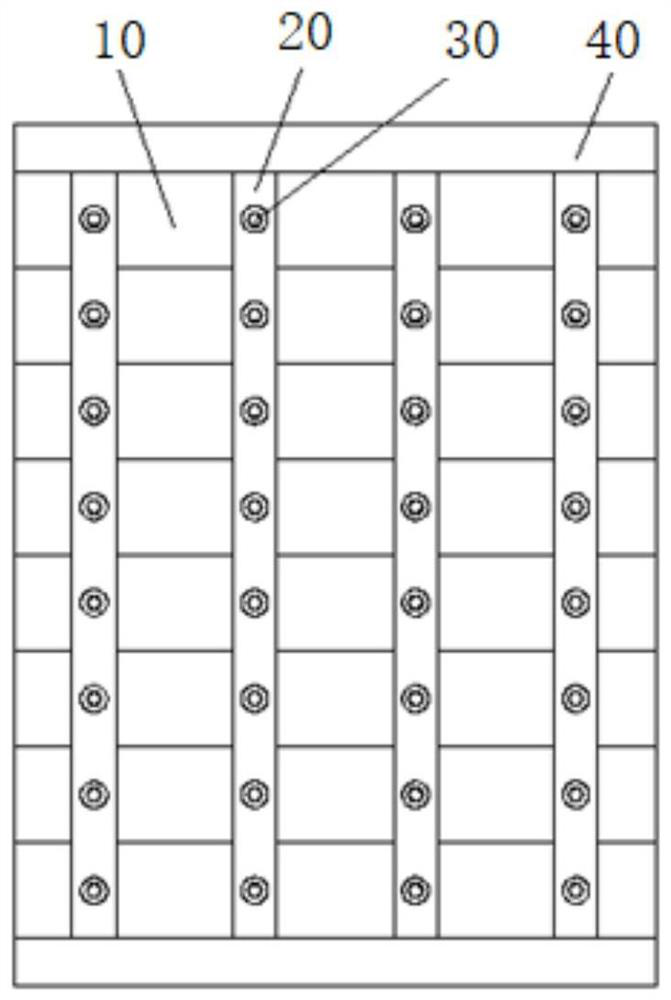

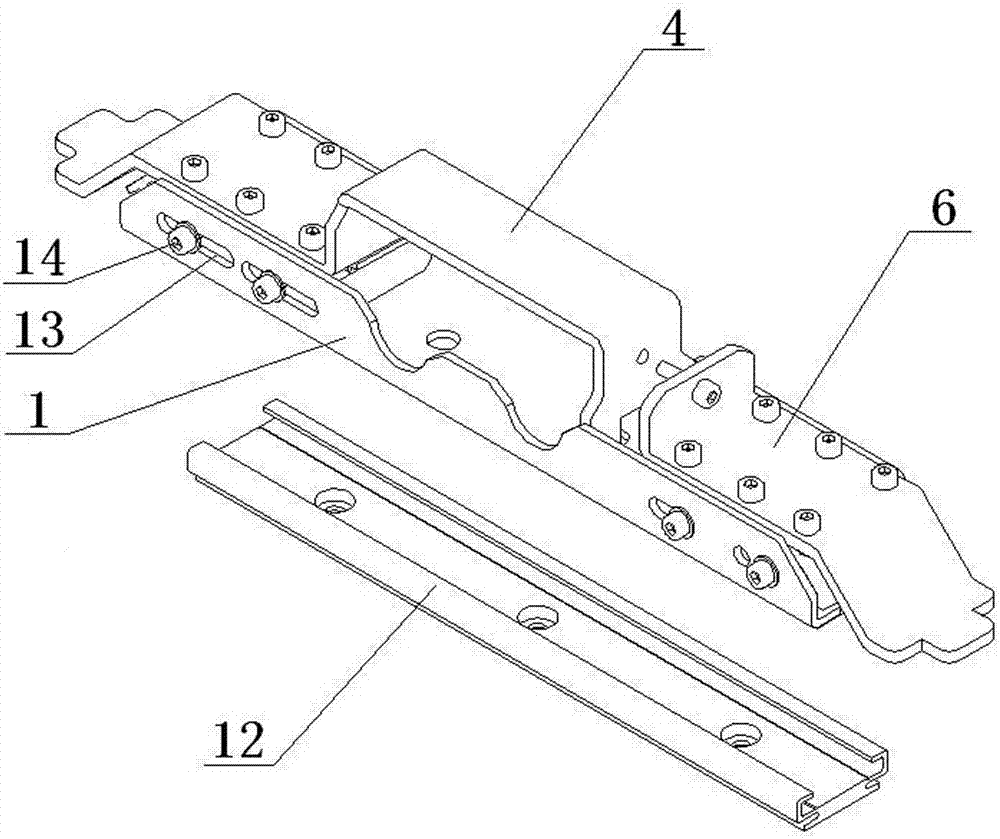

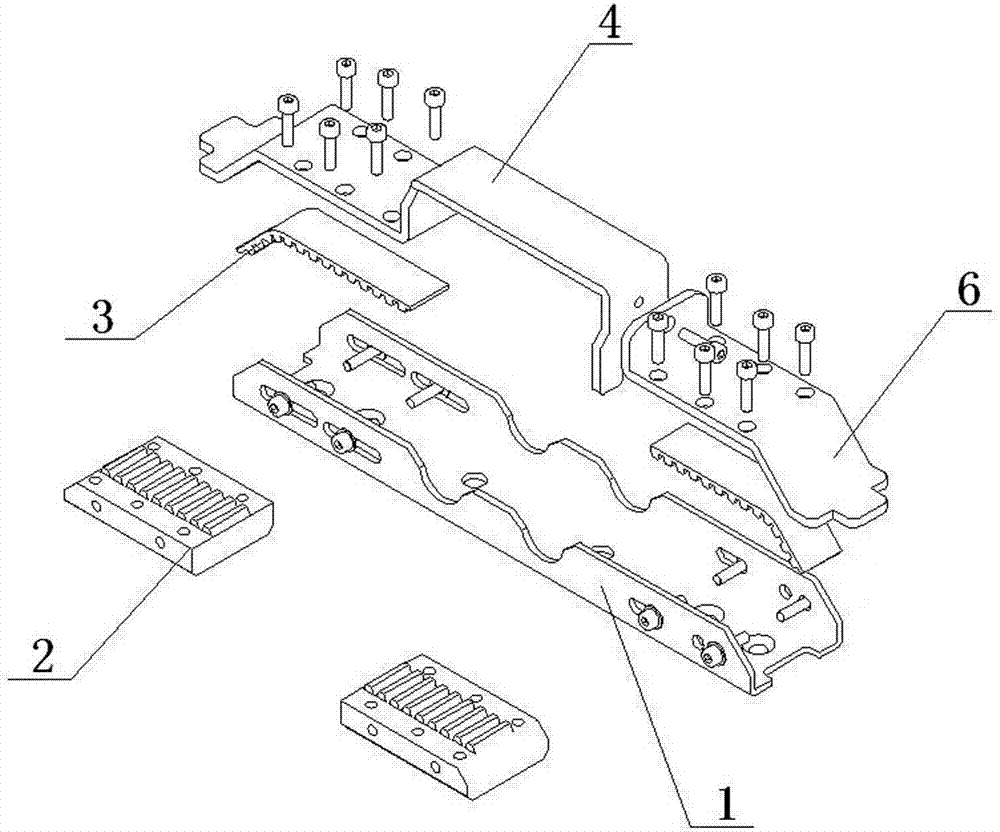

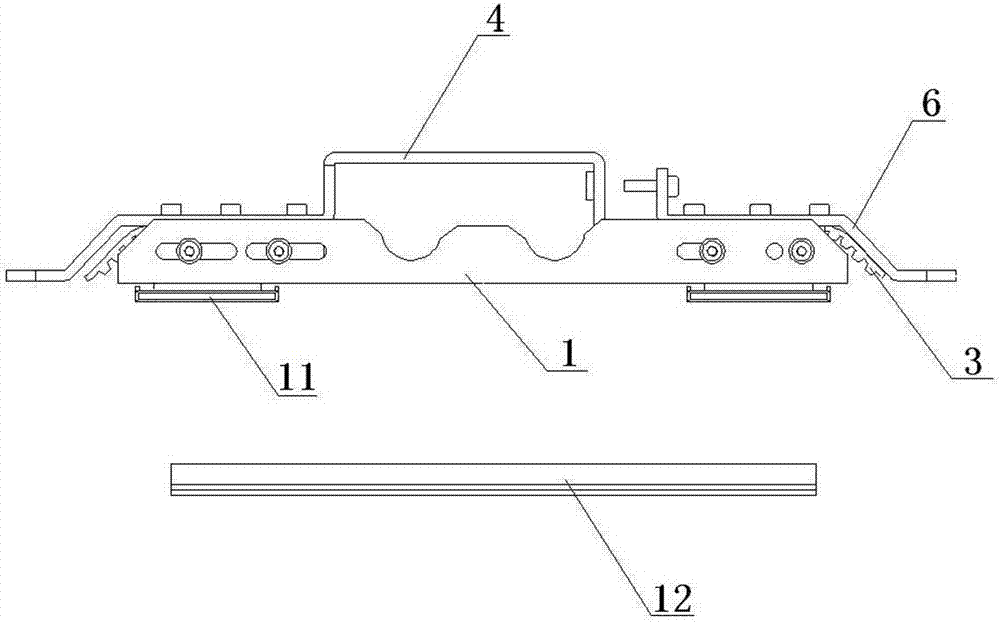

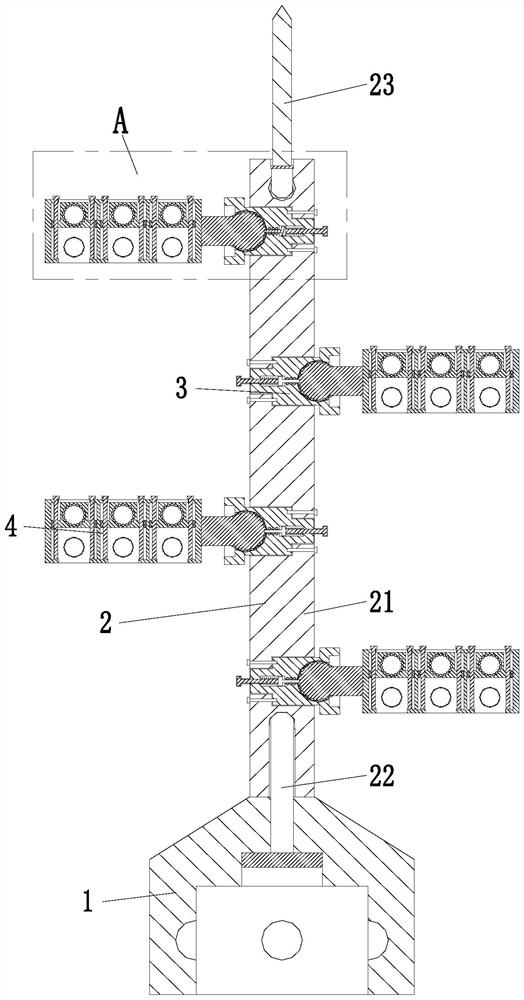

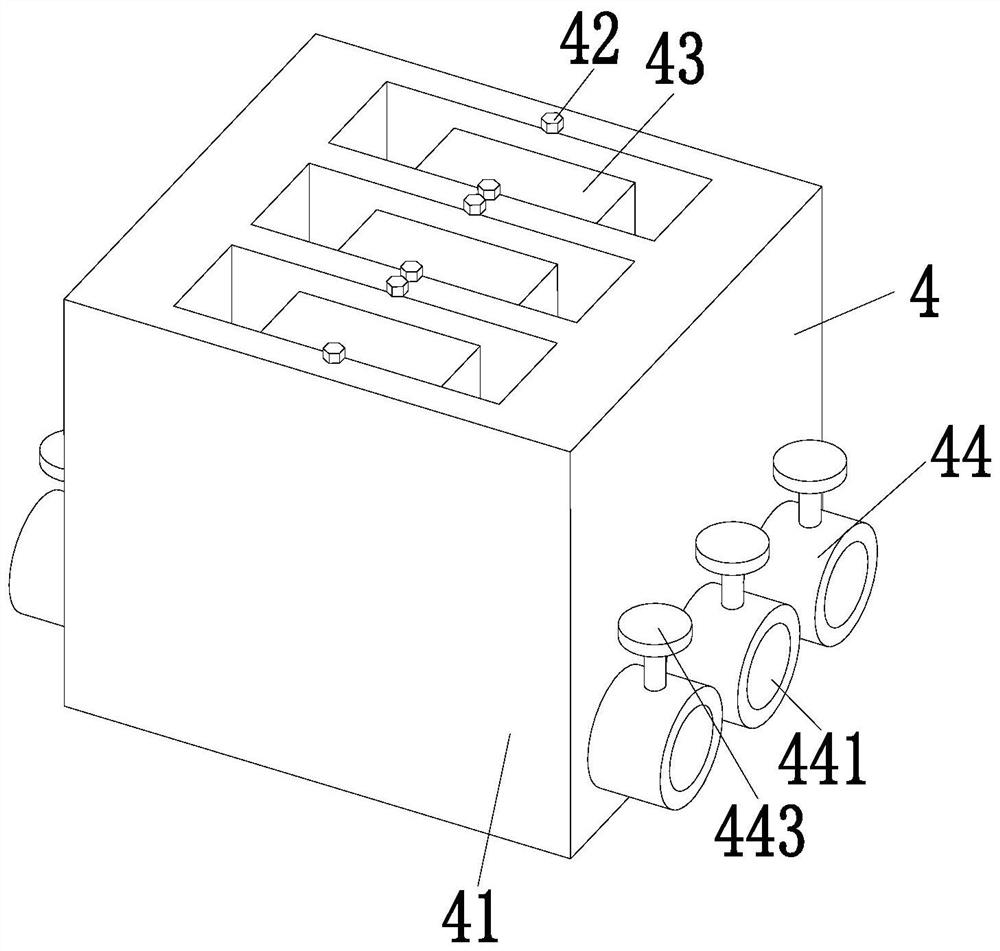

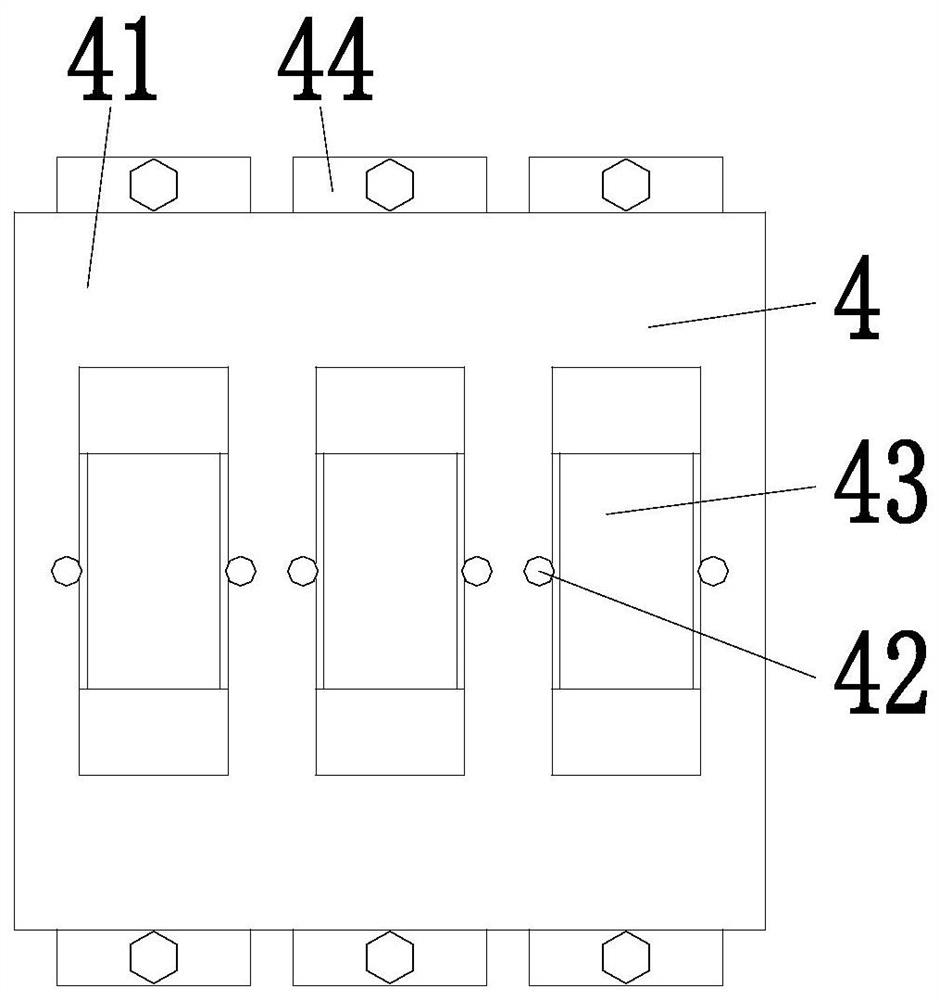

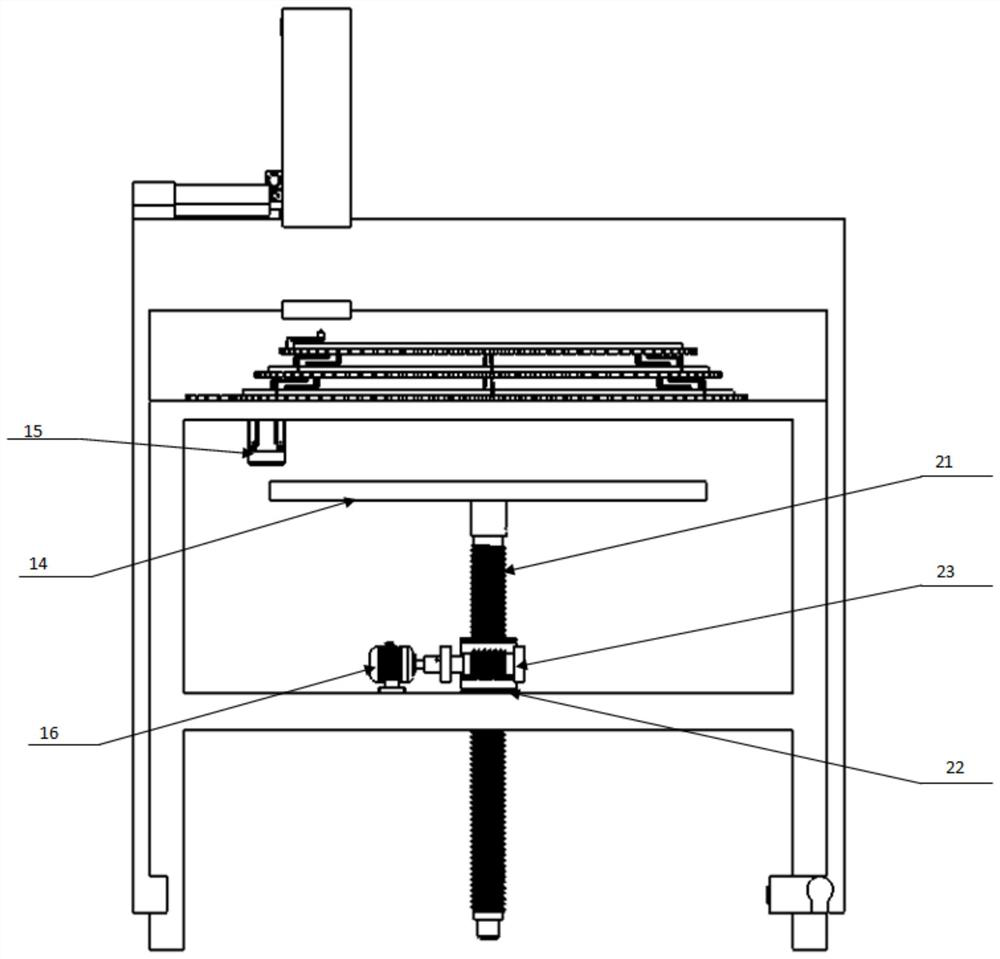

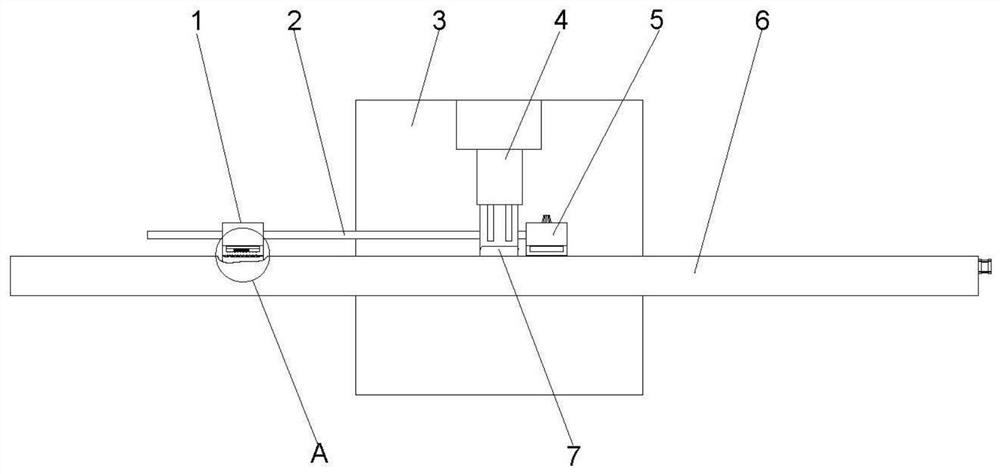

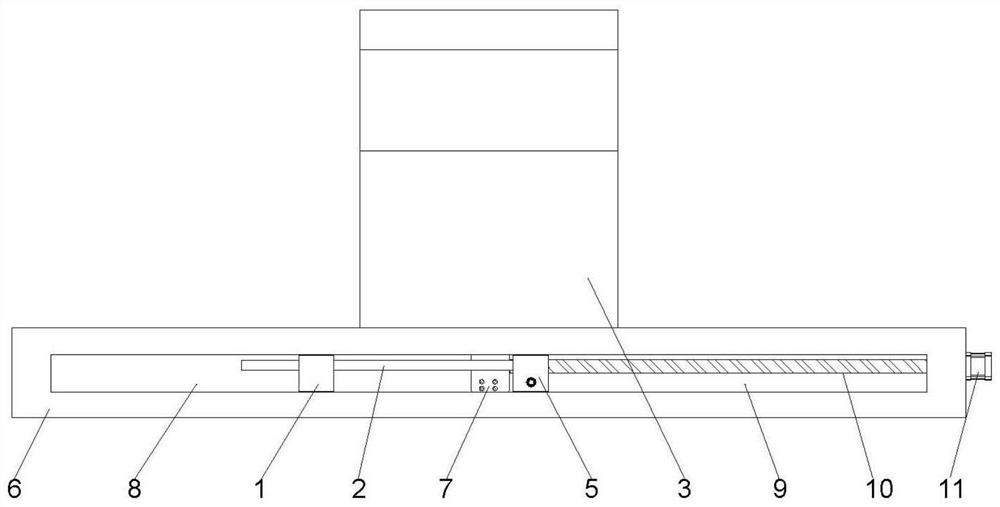

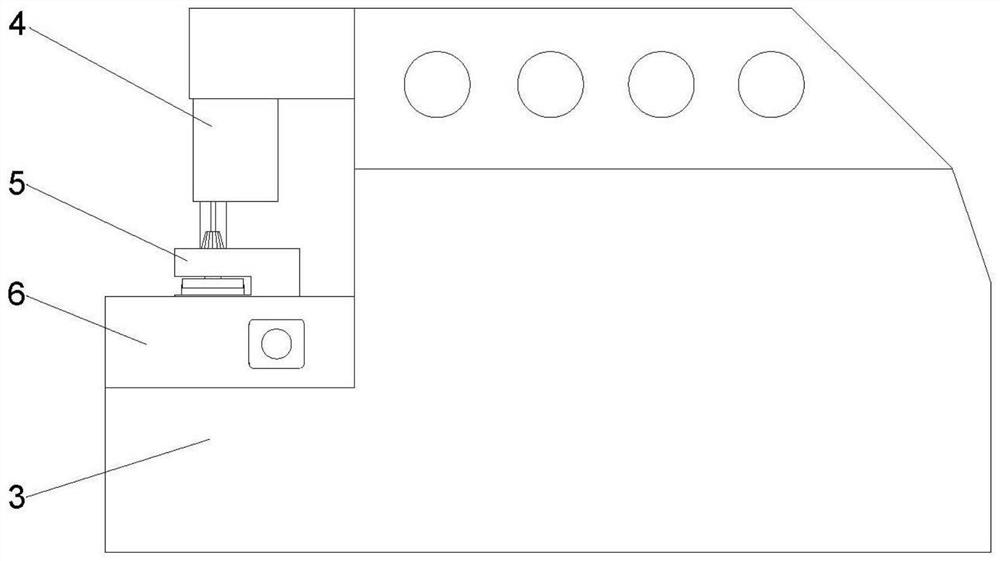

Numerical control machining technological equipment for outer-grid wall plates

ActiveCN106425493AImprove fitImprove pass rateOther manufacturing equipments/toolsPositioning apparatusNumerical controlEngineering

The invention discloses numerical control machining technological equipment for outer-grid wall plates. The equipment comprises pressing plates (3), tension devices (2), tightly-pressing devices (5) and an arc blank (4) with a vacuum sucking disc. The arc blank (4) with the vacuum sucking disc is matched with a shell wall plate in radian. After being bent according to the radian of the shell wall plate, a to-be-machined flat plate is placed on the arc blank (4). The two ends, in the direction of the generatrix of the arc blank (4), of the bent to-be-machined flat plate are tightly pressed through the pressing plates (3), and the other two ends are tensioned in the tangential direction of the outer end of the bent to-be-machined flat plate through the tension devices (2); and after out-grid milling is completed, allowances, in the arc direction, of the two ends of the bent flat plate are cut off, and instead, the two ends of the bent flat plate are subjected to normal pressing through the tightly-pressing devices (5).

Owner:CAPITAL AEROSPACE MACHINERY +1

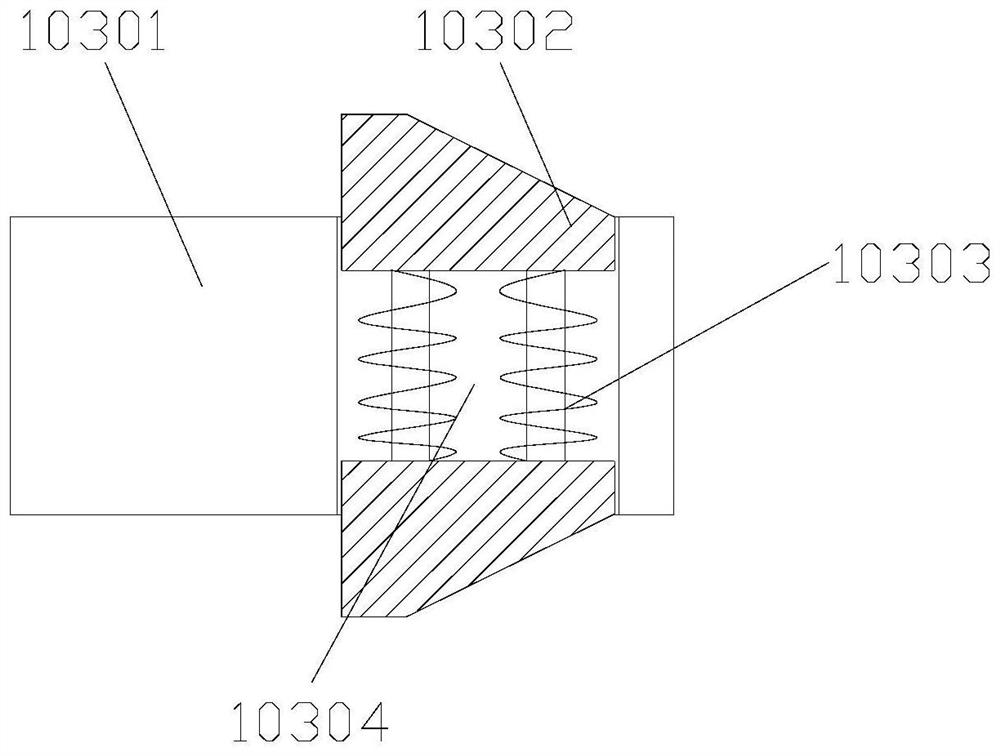

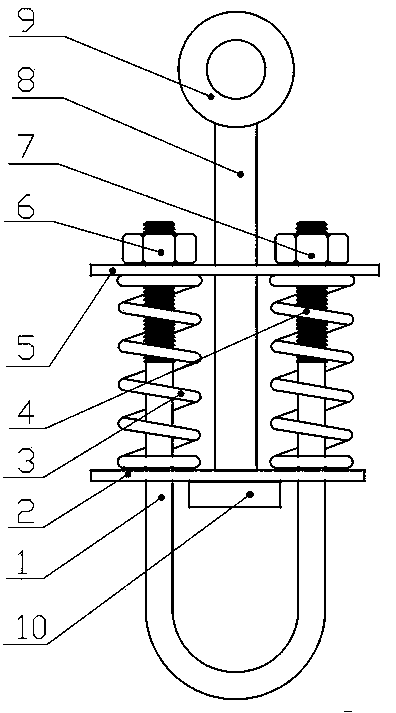

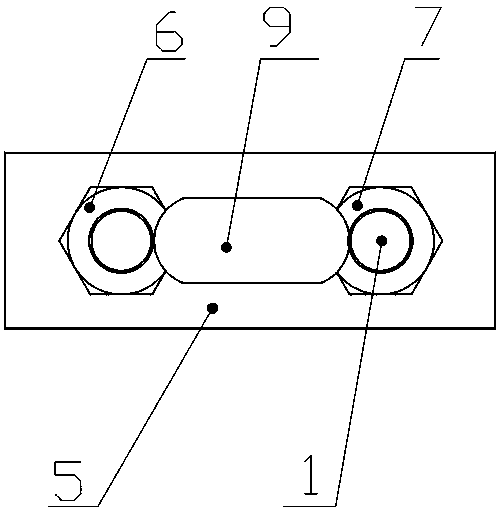

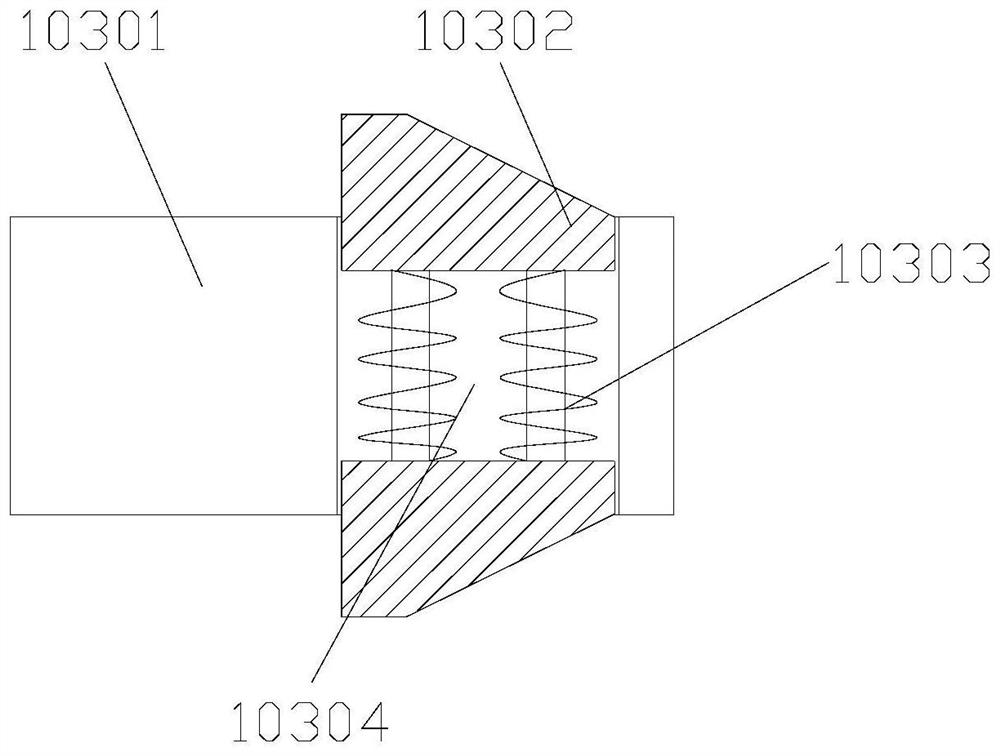

Buffer and damping wire pulling pole

The invention relates to the technical field of electric power fittings, in particular to a buffer and damping wire pulling pole. The buffer and damping wire pulling pole comprises a lower pulling pole body, a first hanging plate, a first spring, a second spring, a second hanging plate and an upper pulling pole body; the lower pulling pole body is of a U-shaped structure, and threads are arrangedat the two column ends of the lower pulling pole body; the two column ends of the lower pulling pole body are sleeved with the two ends of the first hanging plate correspondingly, the two column endsof the lower pulling pole body are sleeved with the first spring and the second spring correspondingly, and the first spring and the second spring are located above the first hanging plate; the two column ends of the lower pulling pole body are sleeved with the two ends of the second hanging plate correspondingly, and the two ends of the second hanging plate are located above the first spring andthe second spring; and the top ends of the two column ends of the lower pulling pole body are in threaded connection with a first nut and a second nut, and the lower end of the upper pulling pole bodydownwards penetrates through the second hanging plate and the first hanging plate in sequence and then is fixedly connected with a plug. According to the buffer and damping wire pulling pole, the structure is simple, the thick energy-storage springs are additionally mounted on the pulling pole bodies, tensioning of the pulling pole bodies on an electric pole can be ensured, the effects of bufferand damping are further achieved, and electric pole toppling due to the situation that fixing piles on the ground are pulled out by the pulling pole bodies under ultra-large tensile force can be prevented.

Owner:贵州航瑞电力设备制造有限公司

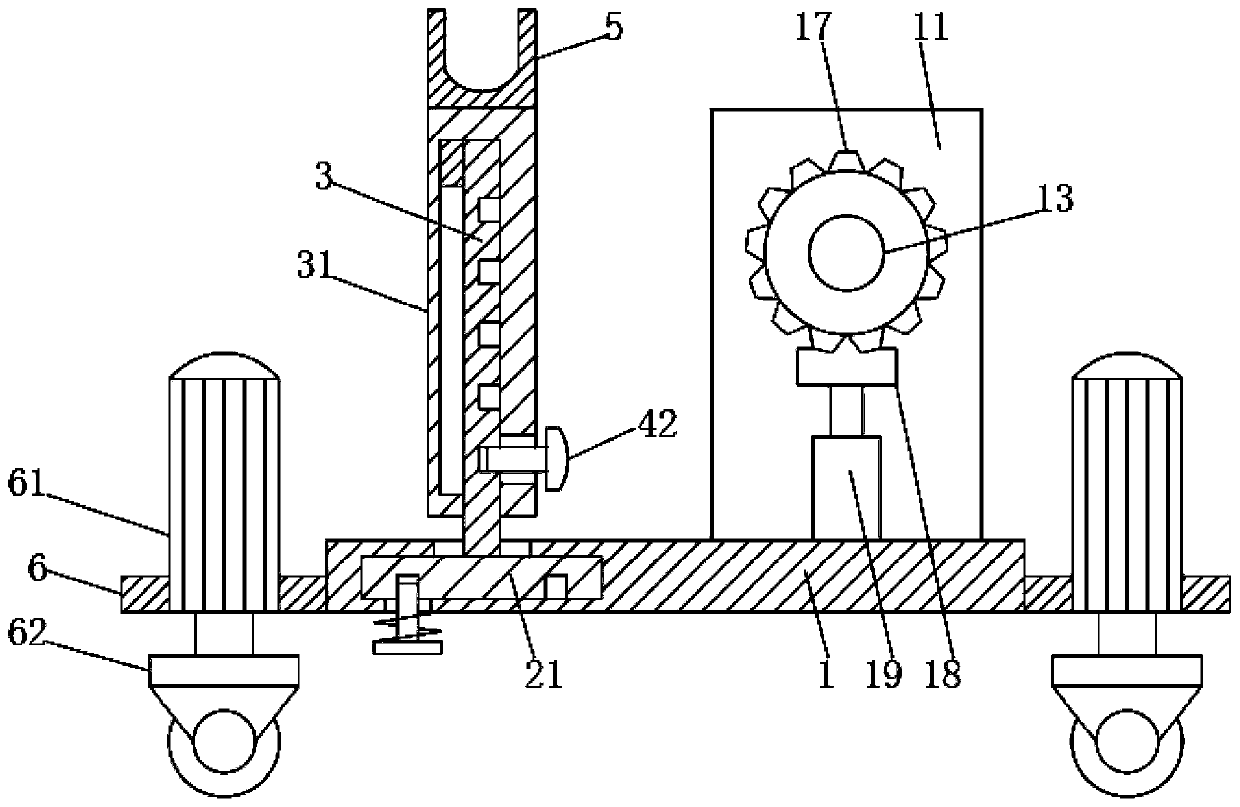

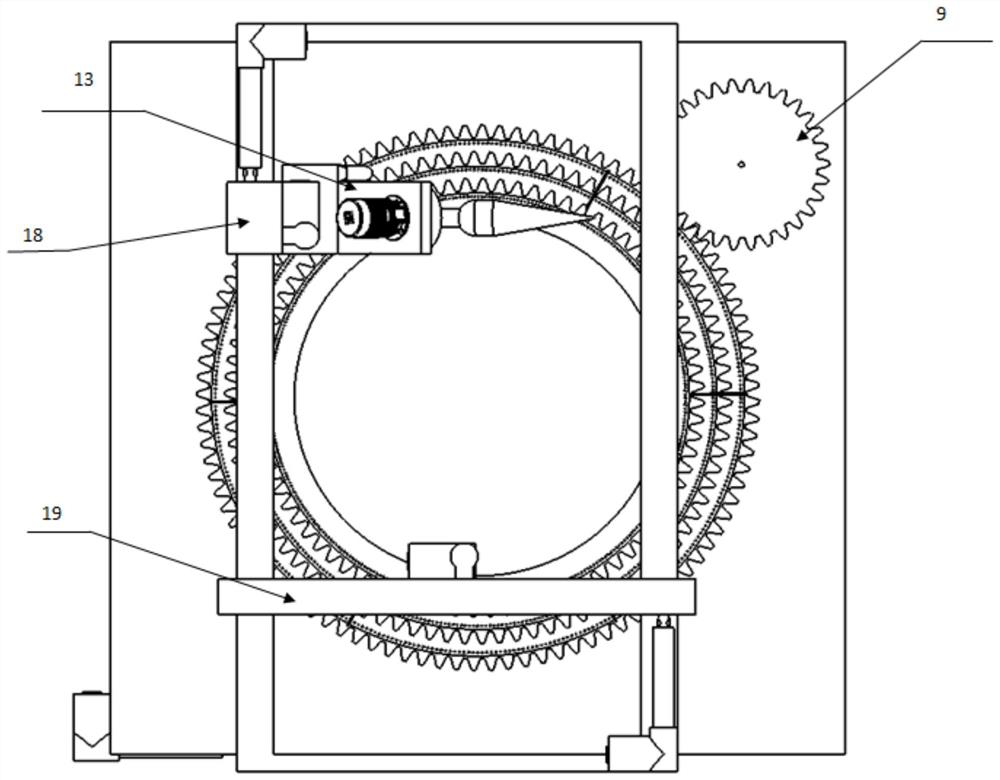

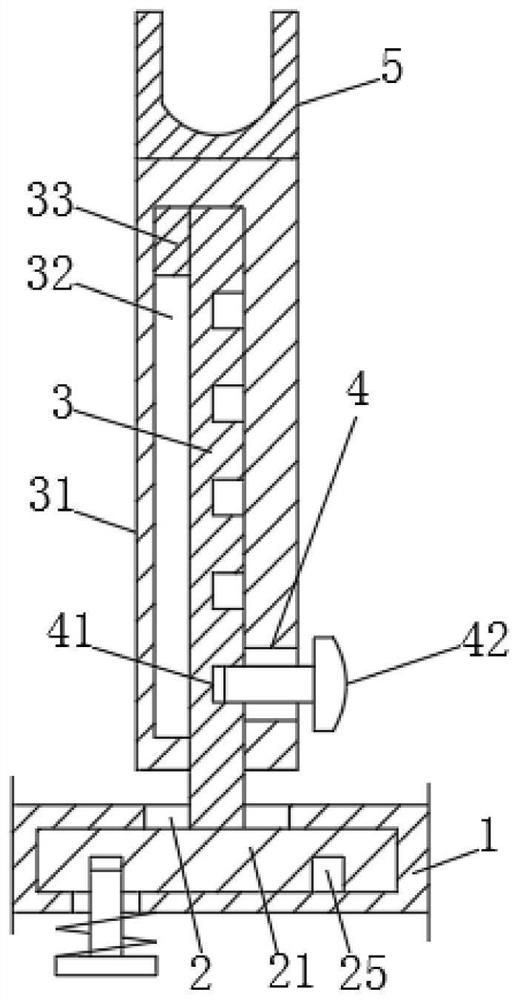

Wire-tightening device for electric power installation

ActiveCN110867774AGuaranteed tautStuck stableApparatus for overhead lines/cablesInterference fitGear wheel

The invention discloses a wire-tightening device for electric power installation. The device comprises a base. Two side plates are fixedly installed on the base. A bearing is fixedly embedded in the side plates. A driving shaft is interference-fit in the bearing. A motor is fixedly installed on each side plate. The rotating shaft of the motor and the driving shaft are fixedly installed through a coupler. A winding drum is fixedly installed on the driving shaft, cables are wound on the winding drum, a gear is fixedly installed on the driving shaft, a first cylinder is fixedly installed on the base, and clamping teeth are fixedly installed on the piston rod of the first cylinder and the clamping teeth are meshed and connected with the gear. The cables can be released or tightened through thewinding drum. After the driving shaft is rotated and positioned, the clamping teeth can be matched with the gear to mesh so as to realize the clamping stability of the driving shaft, ensure that thecables can be tightened during construction and lift the cables from the bracket through the wire base, thus preventing workers from climbing in the bracket and reducing the occurrence of safety accidents.

Owner:中国南方电网有限责任公司超高压输电公司百色局

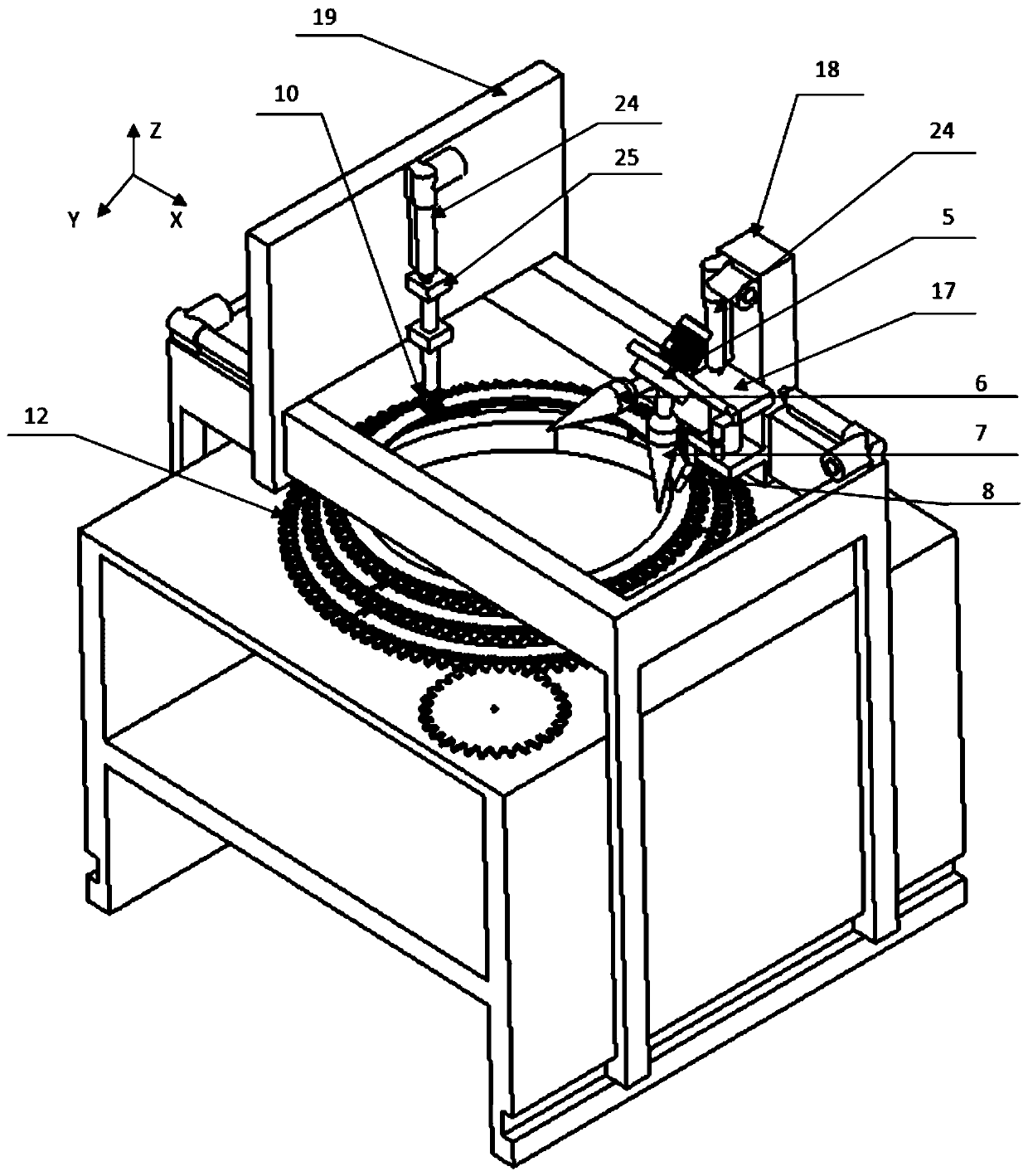

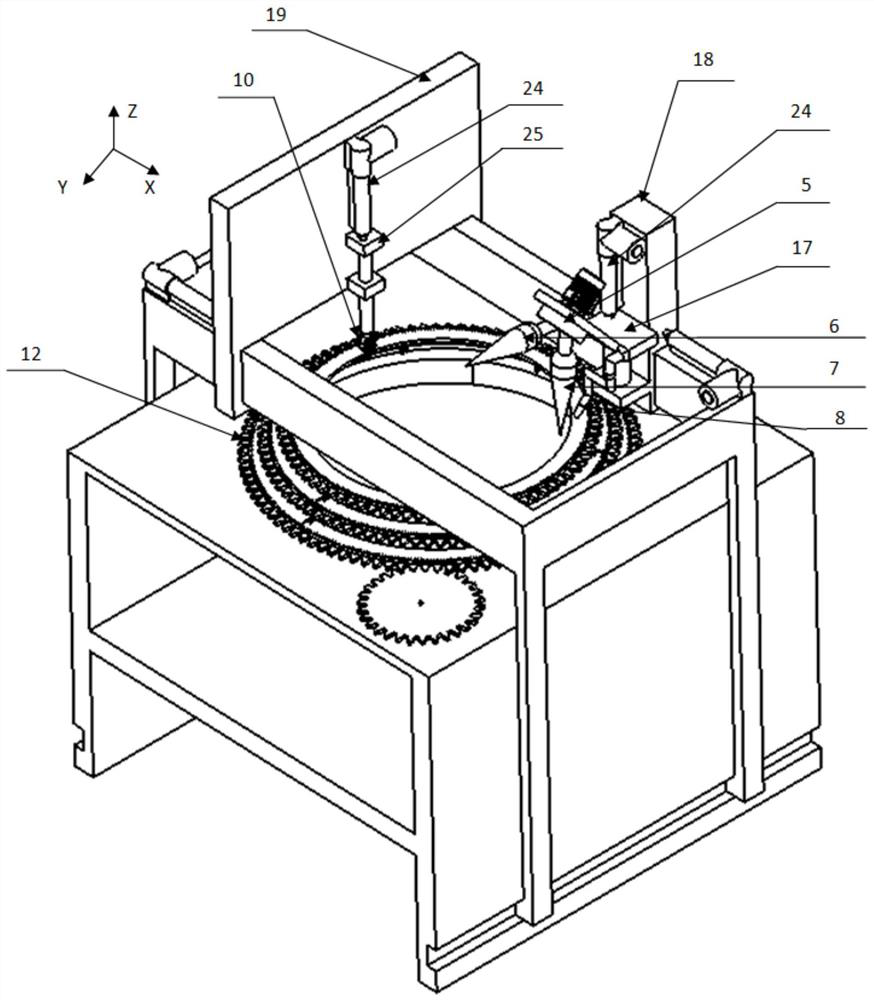

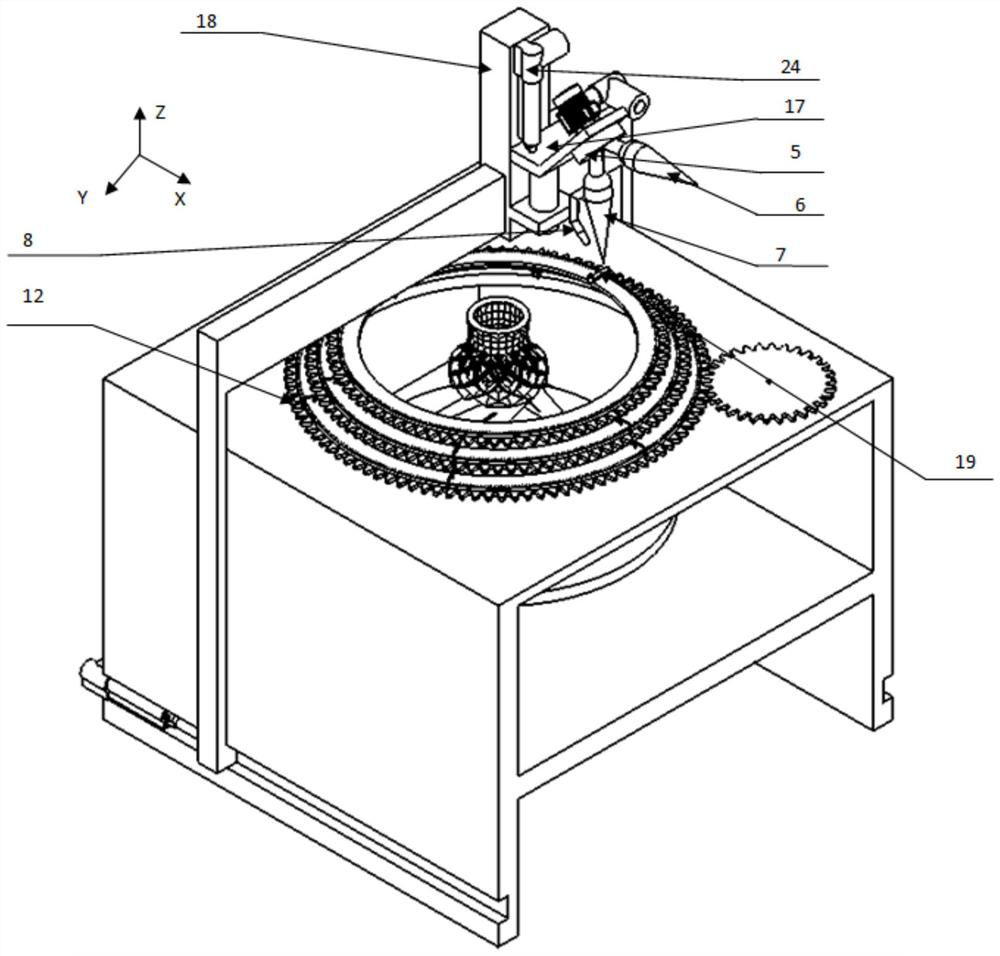

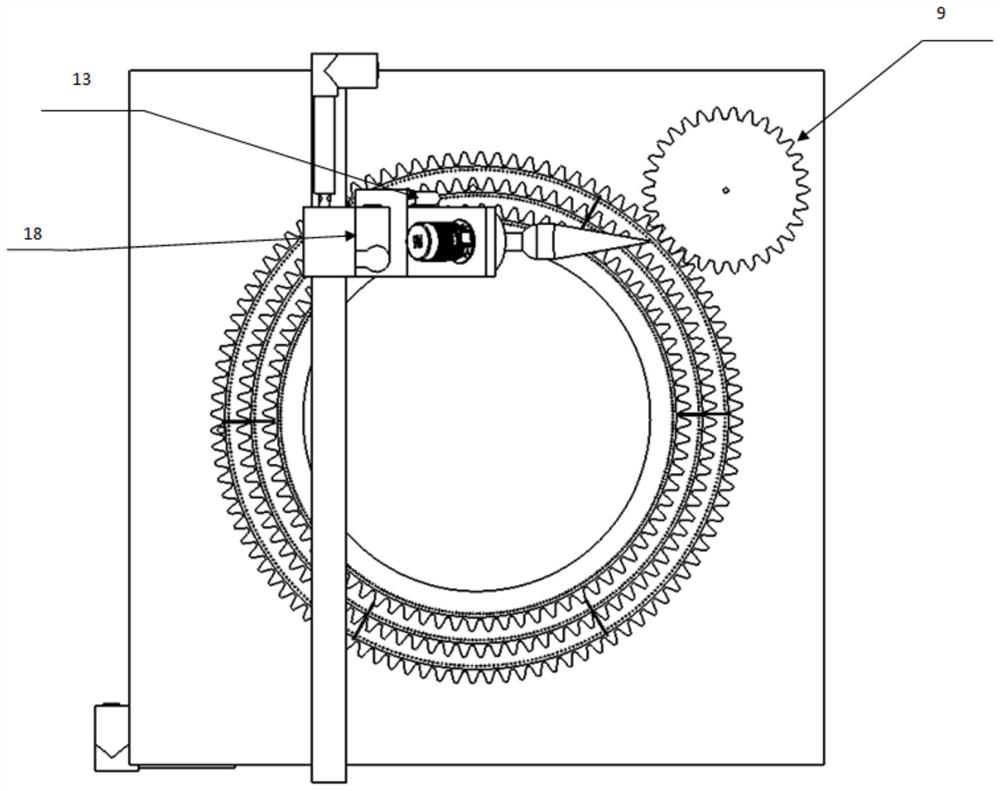

3D printing modification machine capable of laying carbon fiber/ resin composite material product at angle and method

ActiveCN111037923AWell laidGuaranteed tautAdditive manufacturing apparatusAdditive mnaufacturing with solid and fluidFiberConverters

The invention discloses a 3D printing modification machine capable of laying a carbon fiber / resin composite material product at an angle. The 3D printing modification machine comprises a machining platform, a fiber penetrating plate structure, a fiber resin multifunctional spray head and a modification cutter, the diameter of a single-layer fiber penetrating plate can be independently selected according to the size of a workpiece during printing, the number of layers of the fiber penetrating plate structure can be determined by the size of the machined workpiece, carbon fibers can be effectively saved by selecting the proper number of layers of the fiber penetrating plate structure, and meanwhile the fiber penetrating efficiency is improved; the fiber resin multifunctional spray head comprises a fiber laying spray head, a thermoplastic material spray head, a spray head converter and a heating spray head, and can achieve the functions of fiber laying, resin spraying, solidification accelerating and intelligent adjusting; the modification cutter is used for cutting off the carbon fibers connected between the workpiece and the fiber penetrating plate and removing burrs on the surfaceof the workpiece when machining is finished at each layer, and meanwhile, the surface of the workpiece can be accurately modified like a cutter of a machine tool spindle after machining is finished; and a lifting platform of the machining platform moves up and down, so that each layer of material is conveniently and quickly laid.

Owner:NORTHEASTERN UNIV LIAONING

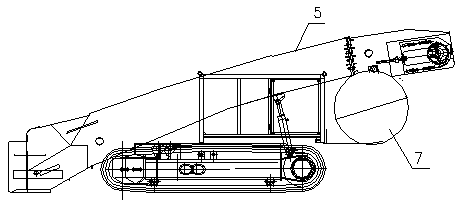

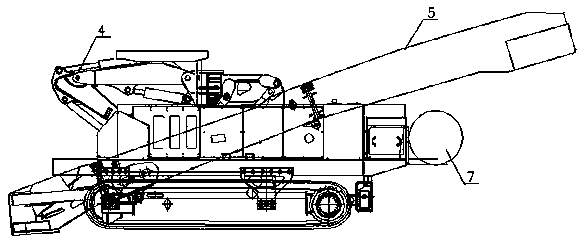

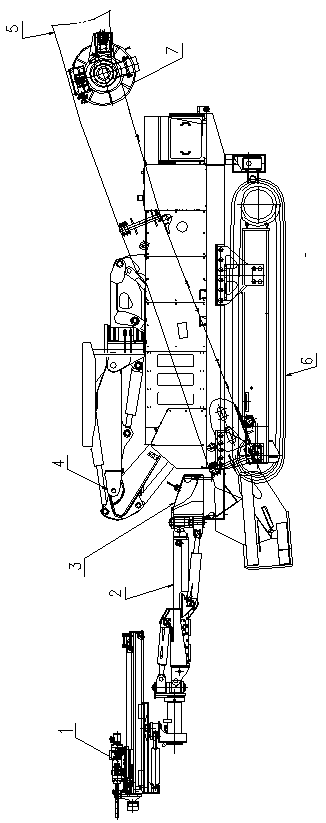

Drilling and assembling unit with transport tank body being provided with cable reel

The invention discloses a drilling and assembling unit with a transport tank body being provided with a cable reel. The unit comprises a drilling machine, an excavating working arm, the transport tankbody and a traveling mechanism; the drilling machine is connected to a mobile trolley through a drill arm; the cable reel is arranged on the rear portion of the transport tank body; the cable reel comprises a flange base fixedly connected to the rear portion of the transport tank body; the flange base is provided with a bearing seat and a guide frame; the bearing seat is provided with a sprocketshaft; one end of the sprocket shaft is provided with an electric brush and a rotating body; one end of the rotating body is provided with a cable inlet; a cable outlet is formed in the guide frame; alarge sprocket is connected with a small sprocket through a chain; and the small sprocket is driven by a hydraulic motor. The cable can be blown and radiated, the situation that insulation layers areaged early and are short in service life due to the fact that cables emit heat for a long time and radiating is more difficult especially in high temperature gas mines is avoided, and major safety accidents such as cable burning and even gas explosion are effectively prevented.

Owner:JIANGXI LANXIANG HEAVY IND

Vertical chain conveying system of coating production line

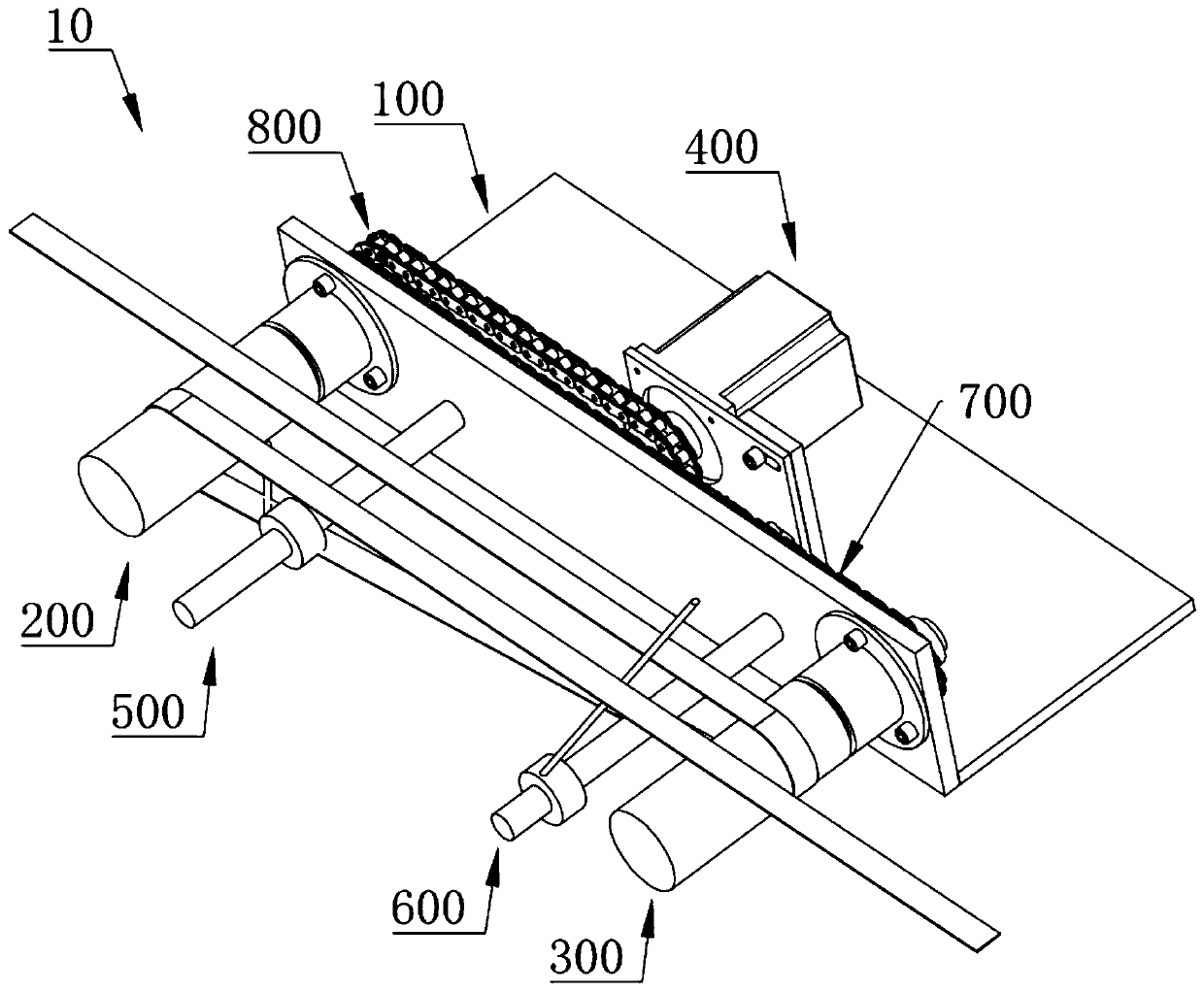

PendingCN110124907AReasonable structural designSmooth taxiingLiquid surface applicatorsSpraying apparatusProduction lineClamp connection

The invention discloses a vertical chain conveying system of a coating production line. The vertical chain conveying system of the coating production line comprises a conveying sliding rail and a transportation trolley which slides on the conveying sliding rail; a chain transmission mechanism is arranged on one side of the outer part of the conveying sliding rail; the chain transmission mechanismcomprises a supporting base; two chain wheels arranged vertically are arranged at the two ends of the supporting base; annular chains are arranged on the two chain wheels; a chain push head capable ofbeing in clamping connection with the transportation trolley is arranged on the annular chain; a motor driving mechanism connected with one of the chain wheels is arranged on the outer side of one end of the supporting base; a frame capable of sliding and a tensioning mechanism connected with the frame are arranged at the other end of the supporting base; and the other one of the chain wheels isarranged on the frame. The vertical chain conveying system of the coating production line provided by the invention belongs to the technical field of automobile body coating production; the transportation trolley is dragged to move through the chain transmission mechanism arranged vertically; and the trolley slides stably, can adapt to different rails and has high adaptability.

Owner:深圳市中星永盛技术有限公司

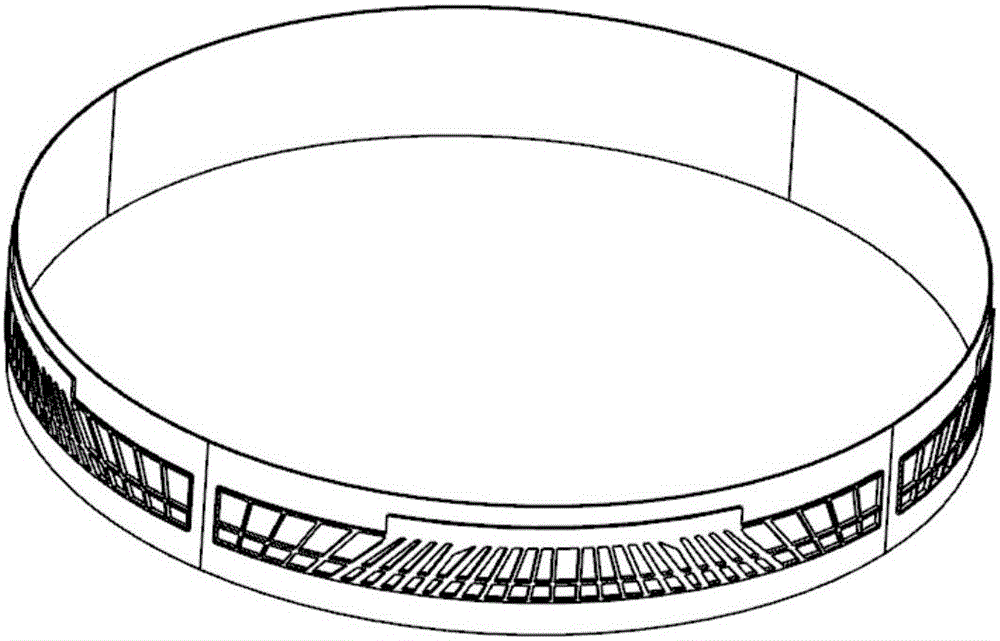

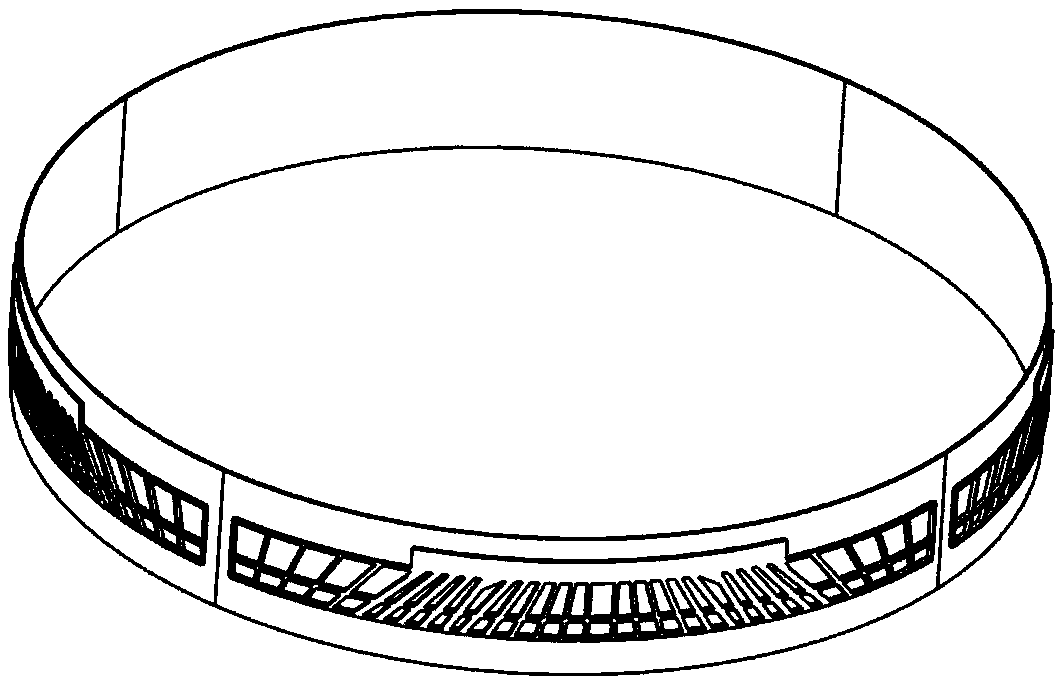

Magnetic pole protection structure, rotor, motor and rotor installation method

ActiveCN111342581AReduce temperature riseImprove efficiencyMagnetic circuit rotating partsManufacturing stator/rotor bodiesRotor magnetsMagnetic poles

The invention discloses a magnetic pole protection structure, a rotor, a motor and a rotor installation method. The magnetic pole protection structure is applied to multiple columns of magnetic poles,the magnetic poles are arranged in the circumferential direction of a rotor magnet yoke at intervals, and an unshielded axial channel is formed between every two adjacent columns of magnetic poles. The magnetic pole protection structure comprises a plurality of magnetic pole protection belts arranged in the circumferential direction of the rotor magnet yoke at intervals; each magnetic pole protection belt is buckled on a column of magnetic poles, and two ends of each magnetic pole protection belt are respectively fixed on the rotor magnet yoke by adopting fixing pieces, so each magnetic poleprotection belt is abutted against the magnetic poles. The purposes of enlarging the gaps of the magnetic poles in the circumferential direction of the rotor, increasing the ventilation quantity of anaxial air path of the rotor, reducing the temperature rise of the motor, improving the efficiency and generating capacity of the motor, further reducing the effective material consumption of the motor and bringing the benefits of cost reduction and benefit increase to the motor are achieved.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

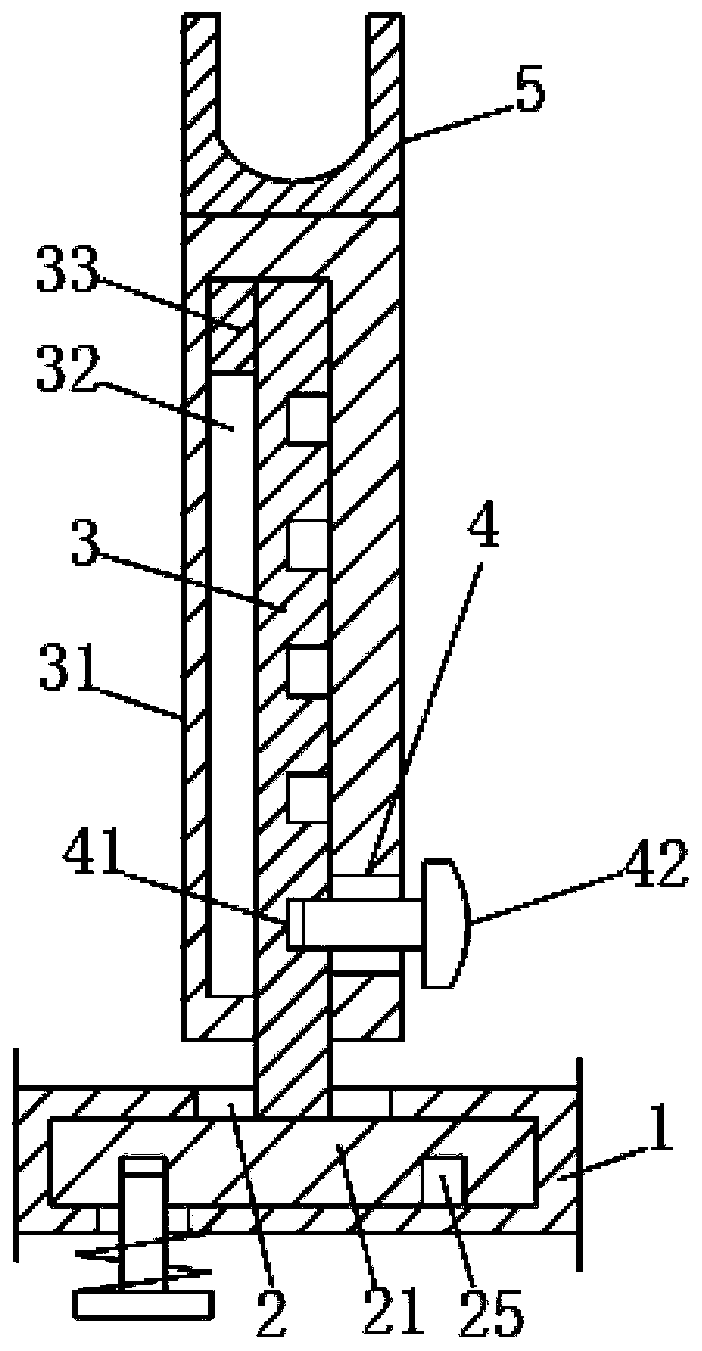

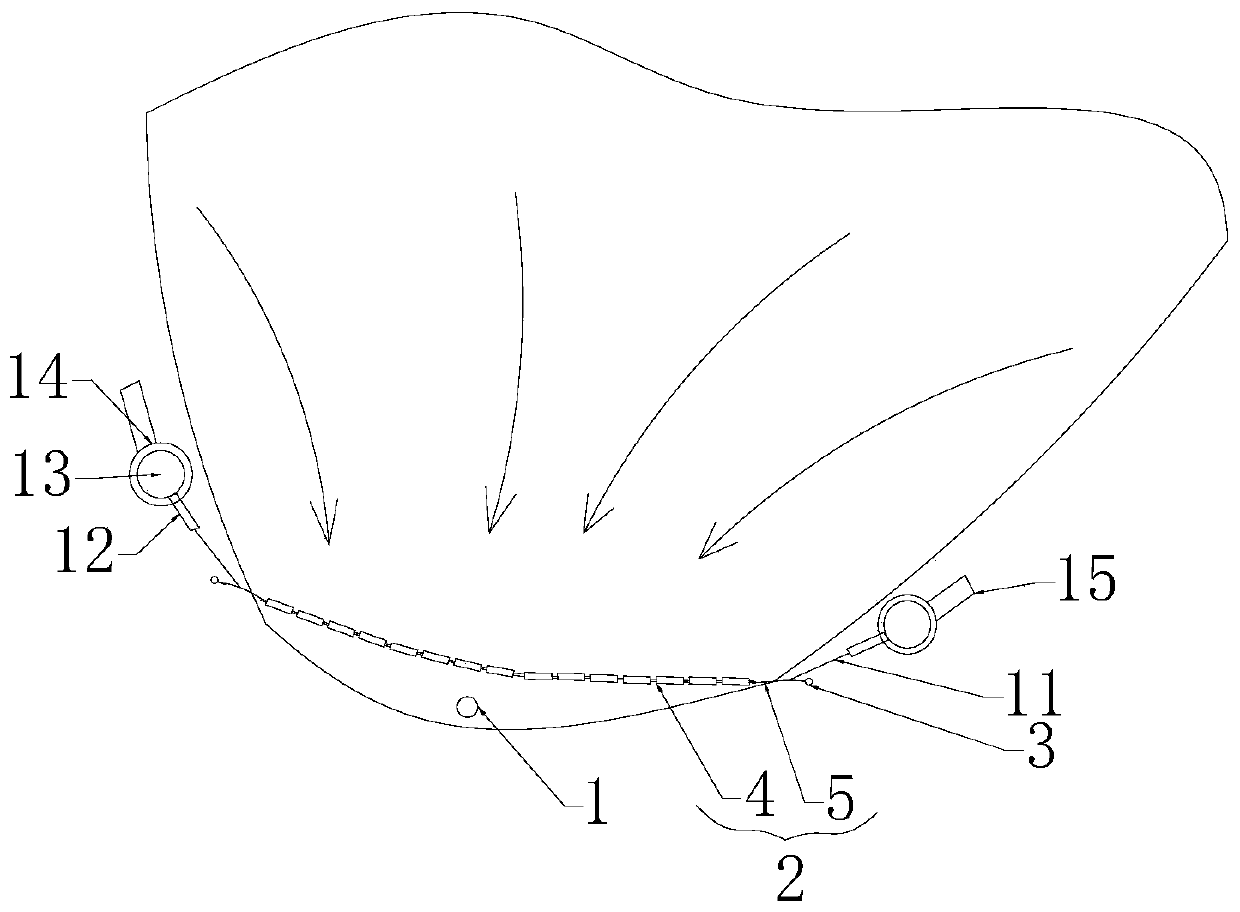

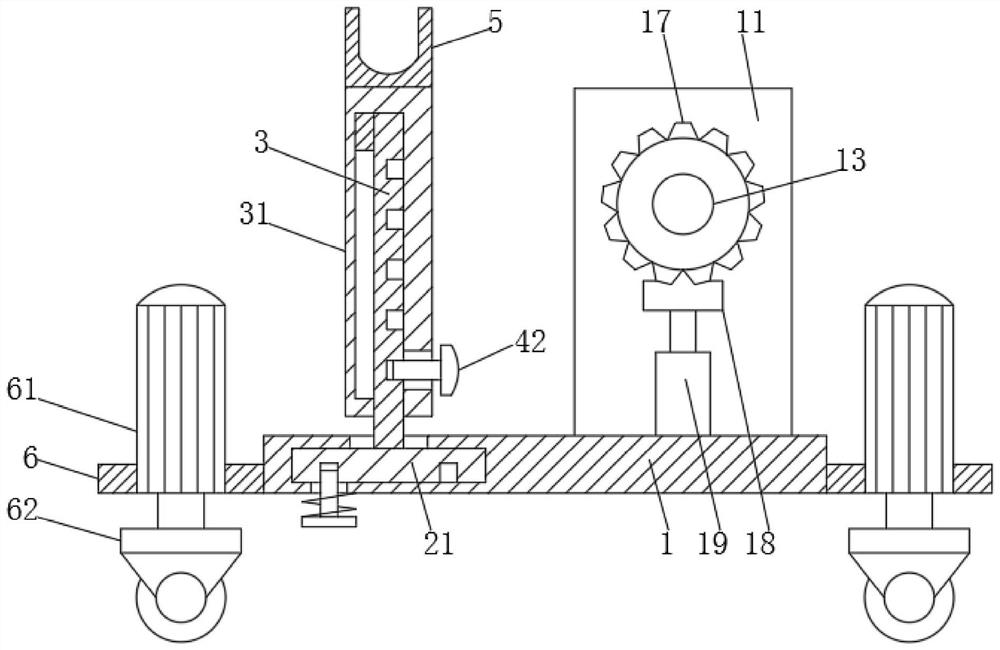

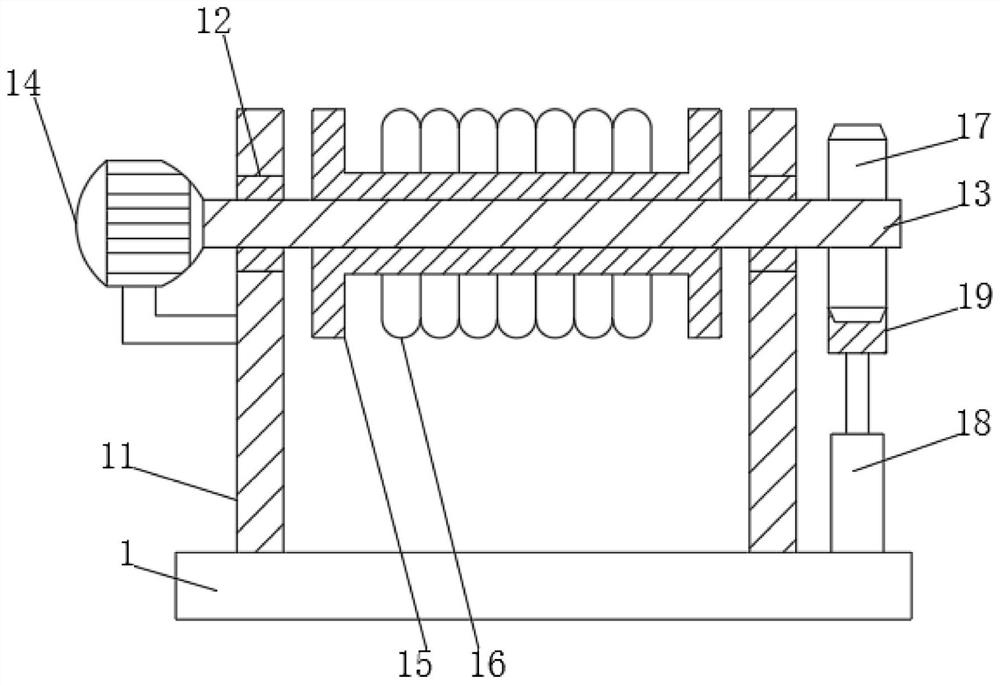

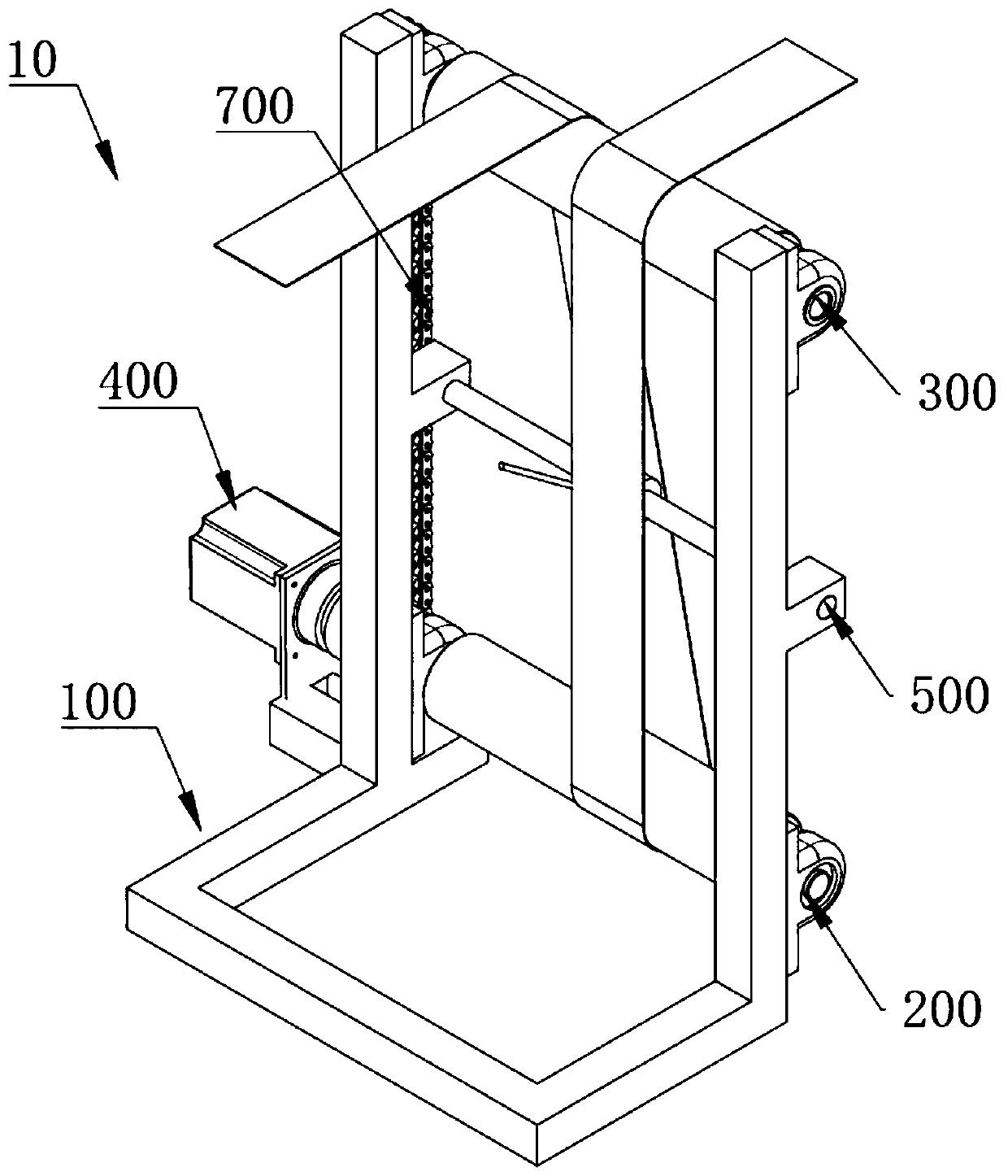

Automatic take-up and pay-off mechanism for mooring rotor wing and using method thereof

ActiveCN112340547AGuaranteed tautRealize the effect of automatic windingElectric machineRotor (electric)

The invention discloses an automatic take-up and pay-off mechanism for a mooring rotor wing and a using method thereof. The automatic take-up and pay-off mechanism comprises a base, wherein universalwheels are arranged at four corners of the bottom of the base; one side of the top of the base is fixedly connected with a mounting frame; a roller shaft is rotatably connected on the mounting frame;a winding roller is fixedly arranged on the roller shaft in a sleeving mode; the top of the base is fixedly connected with a motor; one side of the roller shaft extends to the outer side of the mounting frame, and is in transmission connection with the same belt with an output shaft of the motor; and a cable is wound on the winding roller. According to the automatic take-up and pay-off mechanism disclosed by the invention, a cable inlet guide wheel, a cable passing guide wheel and a cable outlet guide wheel are matched, so that the cable is conveniently taken up and paid off; meanwhile, a balancing weight is matched with the cable outlet guide wheel, so that a convex plate can be driven to swing, and therefore, the automatic take-up effect is realized through matching with a light source emitter and a photoelectric sensor; and moreover, balancing weights with different weights can be suitable for different pulling forces, on the cable, of wind power of different environments, so that practicability is improved.

Owner:湖南浩天翼航空技术有限公司

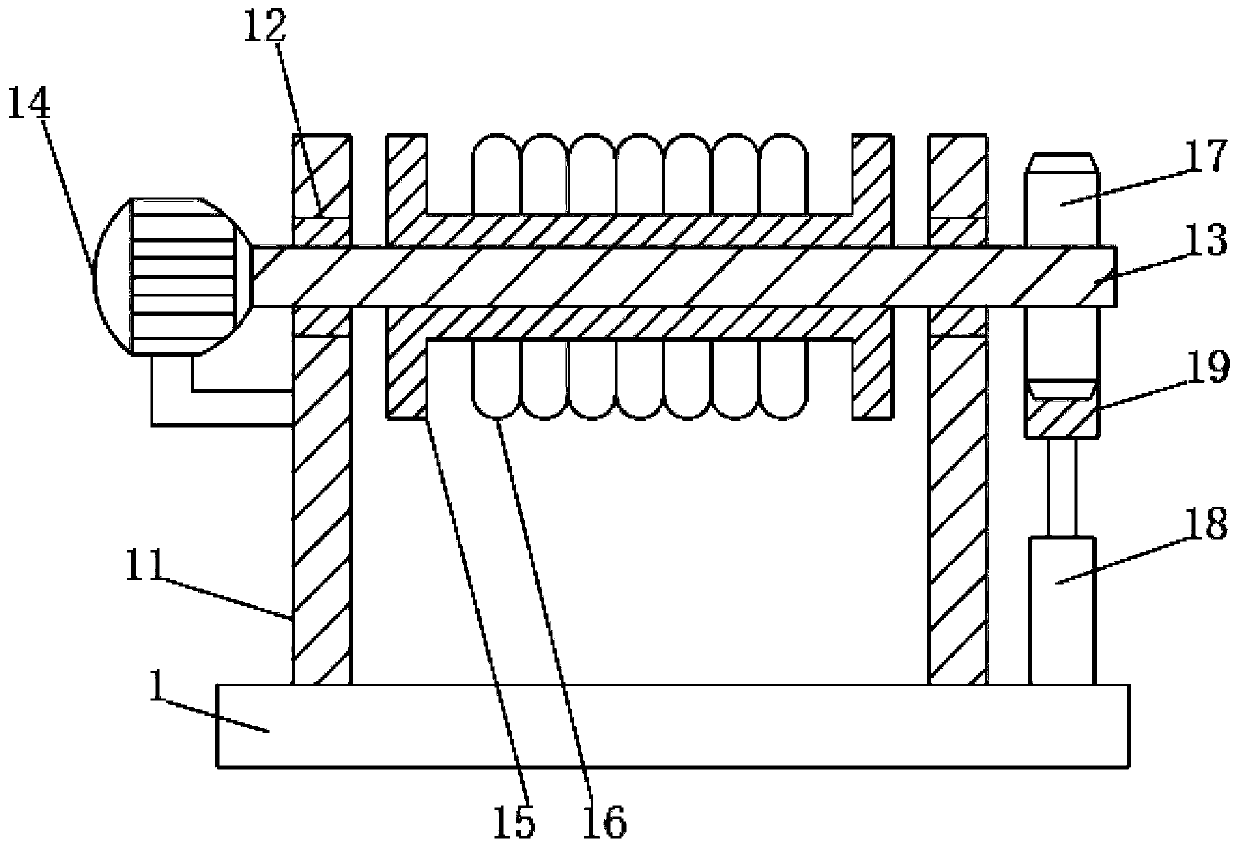

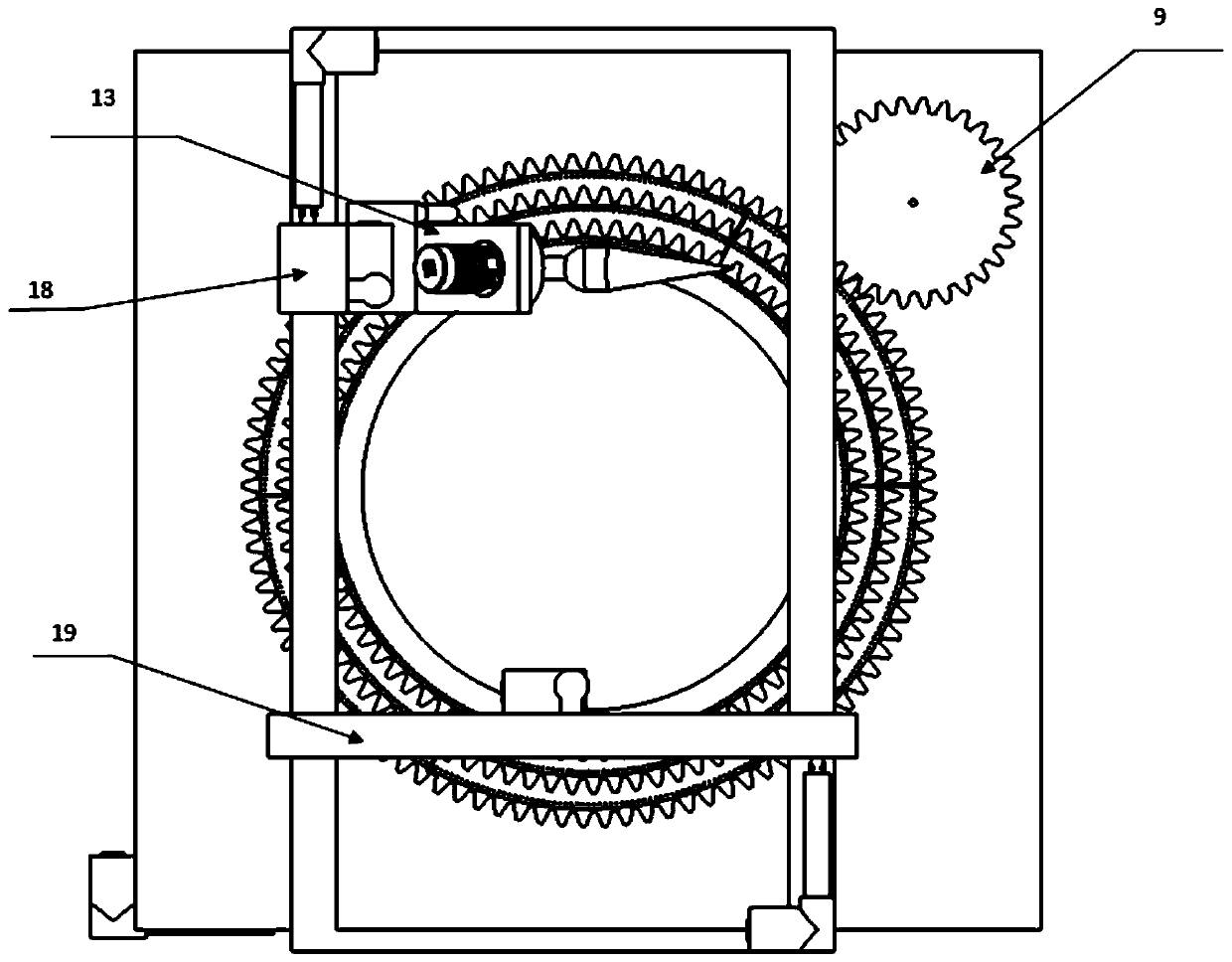

Toothed belt tensioning device

The invention relates to the field of mechanical equipment, in particular to a toothed belt tensioning device. The toothed belt tensioning device is characterized by comprising a base. A semi-sealed cavity is formed in the base in a cut-through mode. A toothed block is arranged in the semi-sealed cavity and fixedly connected to the base, and convex teeth are arranged on the surface of the toothed block. A pressing block is arranged above the toothed block, an interval is reserved between the pressing block and the surface of the toothed block, and the pressing block is installed in the base. The end surface of the opening end of the semi-sealed cavity, one lateral surface of the toothed block and part of the pressing block all incline downwards. The toothed belt tensioning device has the advantages that the toothed block is arranged in the trapezoid base, so that it is guaranteed that a toothed belt does not slide in a fixing device; the waist in the trapezoid structure can also guarantee that the toothed belt keeps tensioned or vertical or horizontal all the time.

Owner:韦乐海茨(上海)医药设备科技有限公司

A kind of numerical control processing equipment for outer grid wall panel

ActiveCN106425493BImprove fitImprove pass rateOther manufacturing equipments/toolsPositioning apparatusNumerical controlEngineering

The invention discloses numerical control machining technological equipment for outer-grid wall plates. The equipment comprises pressing plates (3), tension devices (2), tightly-pressing devices (5) and an arc blank (4) with a vacuum sucking disc. The arc blank (4) with the vacuum sucking disc is matched with a shell wall plate in radian. After being bent according to the radian of the shell wall plate, a to-be-machined flat plate is placed on the arc blank (4). The two ends, in the direction of the generatrix of the arc blank (4), of the bent to-be-machined flat plate are tightly pressed through the pressing plates (3), and the other two ends are tensioned in the tangential direction of the outer end of the bent to-be-machined flat plate through the tension devices (2); and after out-grid milling is completed, allowances, in the arc direction, of the two ends of the bent flat plate are cut off, and instead, the two ends of the bent flat plate are subjected to normal pressing through the tightly-pressing devices (5).

Owner:CAPITAL AEROSPACE MACHINERY +1

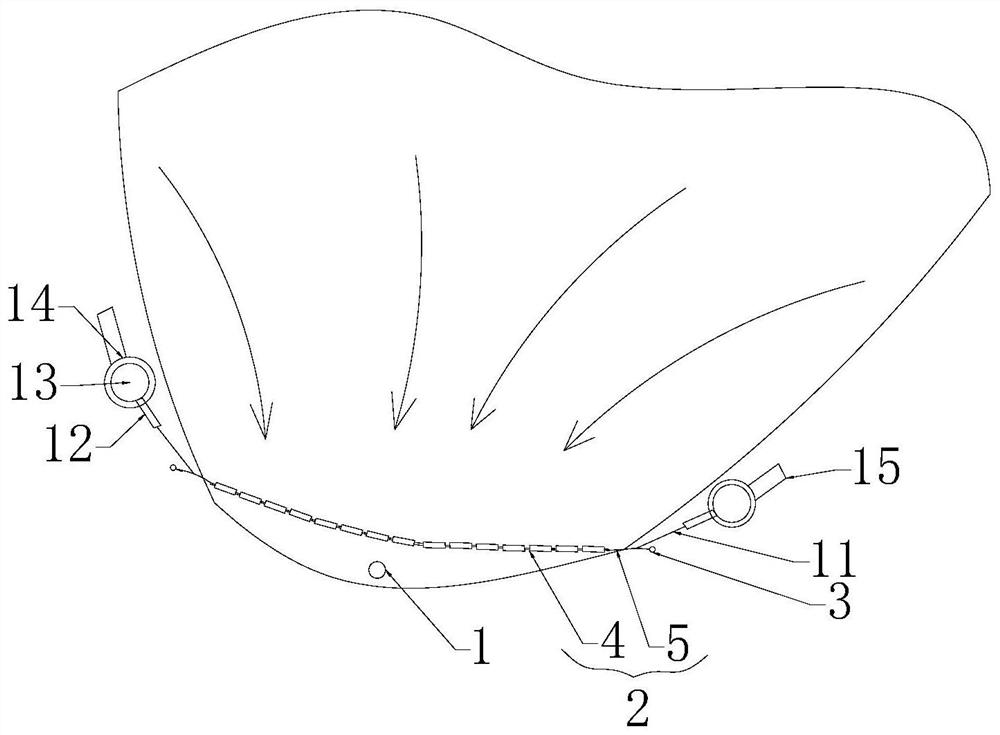

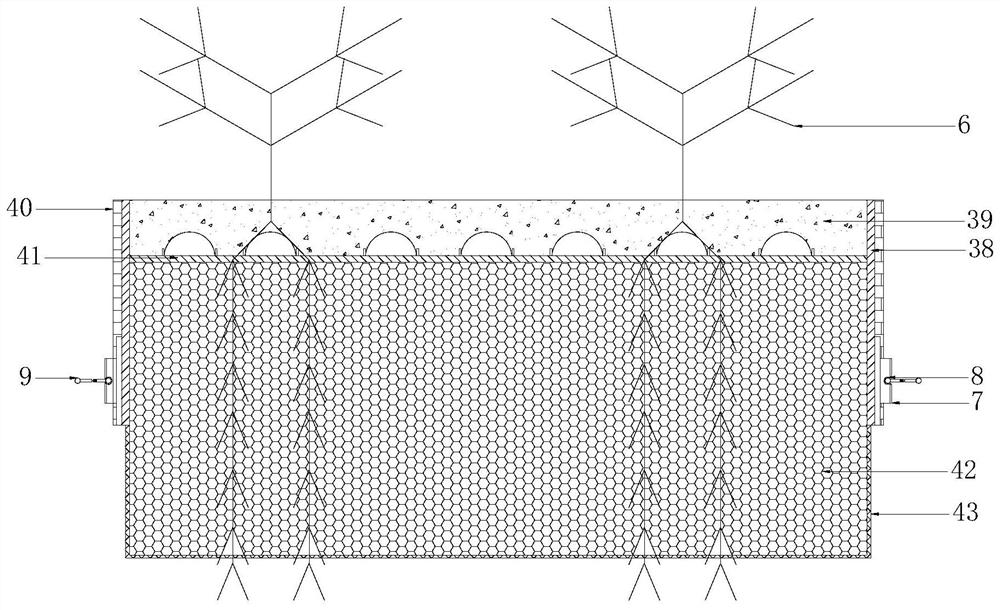

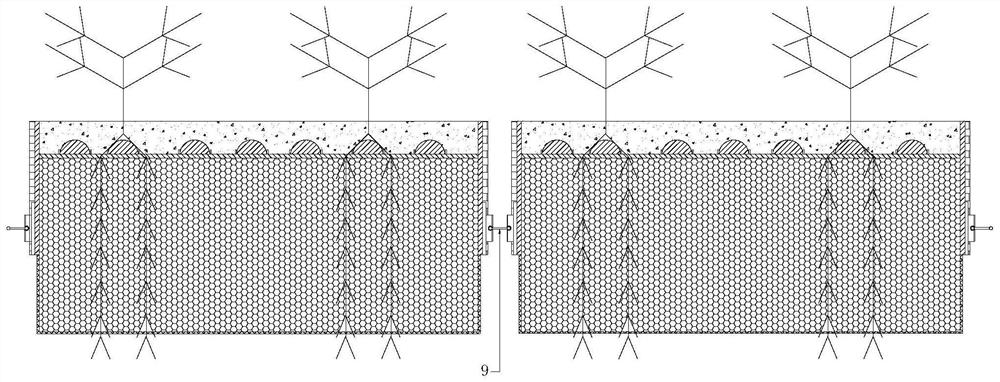

Debris cleaning device for urban garden landscape circulation pool

ActiveCN111359278BReduce work stressWith telescopic functionWater cleaningGeneral water supply conservationStructural engineeringMechanical engineering

The invention discloses a sundry cleaning device for an urban garden landscape circulating pool, which is characterized in that it includes a filtering device arranged at the water recovery entrance of the circulating pool, a dipping net, left and right positioning piles and a power generation structure, the filtering device It includes a plurality of suspensions and rigid ropes. Floating plants can be planted on the suspensions. Fixing strips are provided on the side of the suspensions. Spherical holes are opened on the side of the fixing strips. The spherical heads of the connecting structures are respectively loosely accommodated. In the spherical hole between adjacent suspensions, the connection structure has a telescopic function, and a plurality of suspensions are connected in series by the connection structure into a row, and rigid ropes are respectively fixed at both ends of the row; The left and right positioning piles are respectively fixedly arranged on the banks on both sides of the water recovery inlet, and the ends of the rigid rope one are respectively fixedly connected to the left and right positioning piles. The present invention can utilize the power of the circulating pool when recycling water, saving energy.

Owner:HEIHE UNIV

A cable tensioning device for high-altitude power construction

ActiveCN112909830BReduce labor intensityPrevent rotationApparatus for overhead lines/cablesControl theoryElectric cables

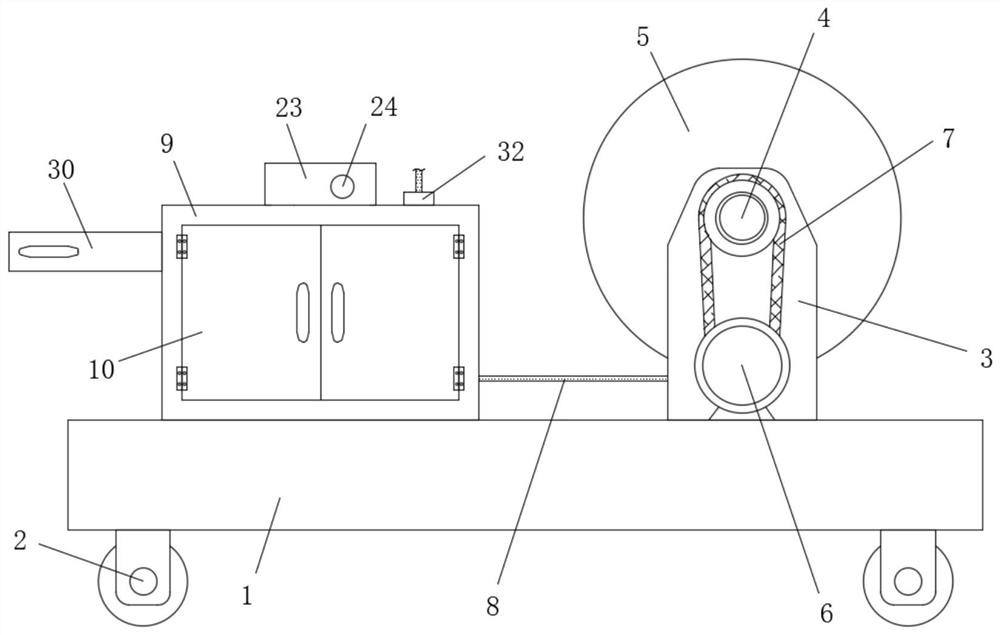

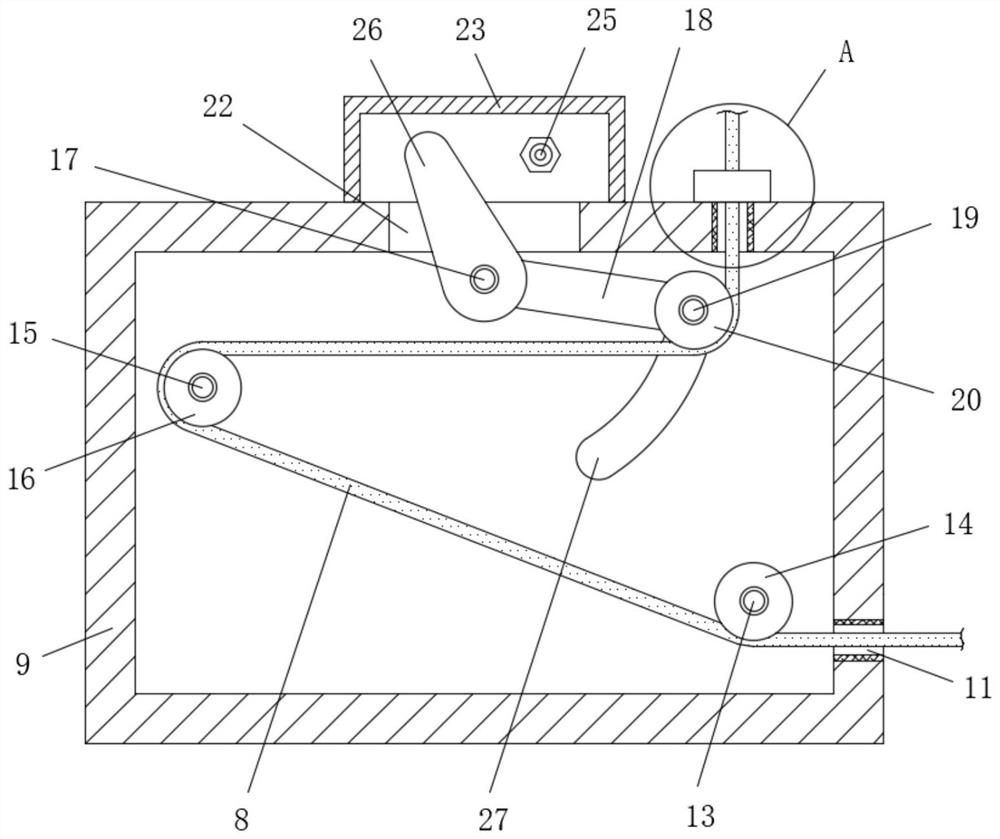

The invention discloses a cable tensioning device for high-altitude electric power construction, which includes a traveling mechanism and a supporting plate, the supporting plate is installed on one side of the traveling mechanism, and a steering mechanism, a swinging mechanism, and a winding mechanism are installed on the supporting plate. mechanism and anti-return mechanism, the steering mechanism is installed on one end of the support plate, the swing mechanism is installed on one side of the steering mechanism, and cooperates with the winding mechanism, and the winding mechanism is installed on one side of the swing mechanism . The invention can move to the utility pole by itself without the need for the staff to carry it, which greatly reduces the labor intensity of the staff, and the winding mechanism in the device can tighten the cable, and the swing mechanism can ensure that when the cable is tightened, The cable is evenly wound on the winding mechanism, which is convenient for the follow-up staff to deal with the cables uniformly. The anti-loop mechanism can prevent the winding mechanism from turning, and release the rolled cable again to ensure the tension of the cable. Quality, improving the efficiency of cable tensioning.

Owner:国网山东省电力公司曹县供电公司

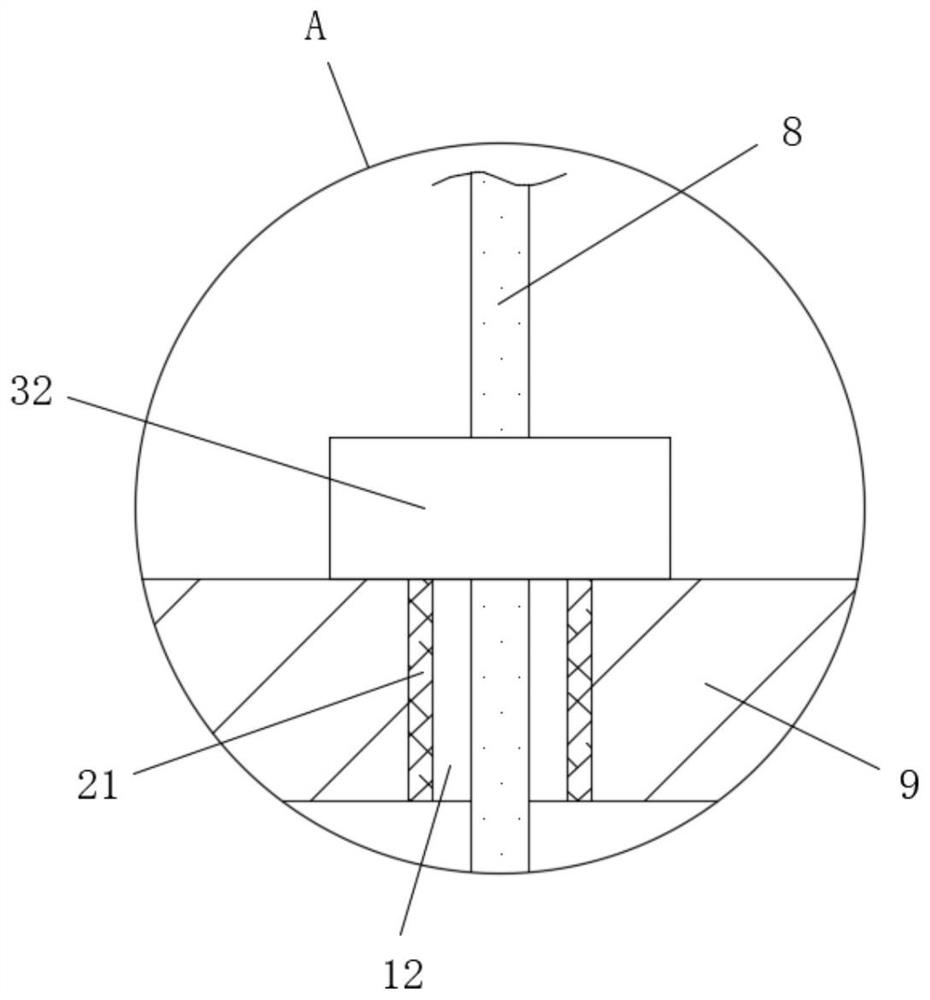

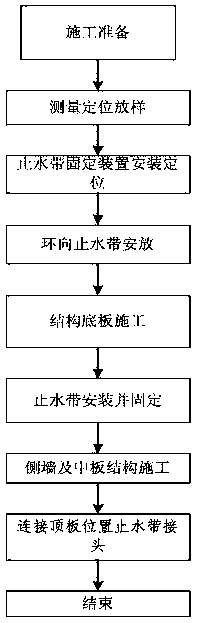

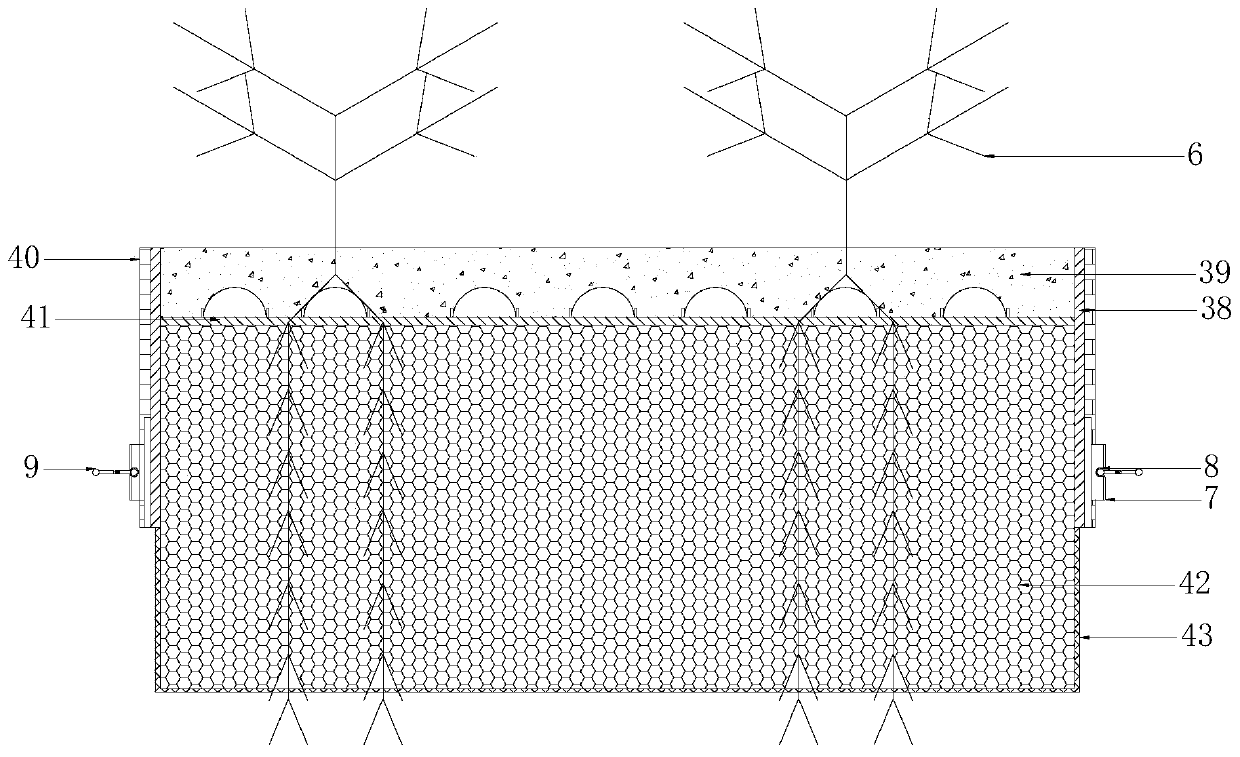

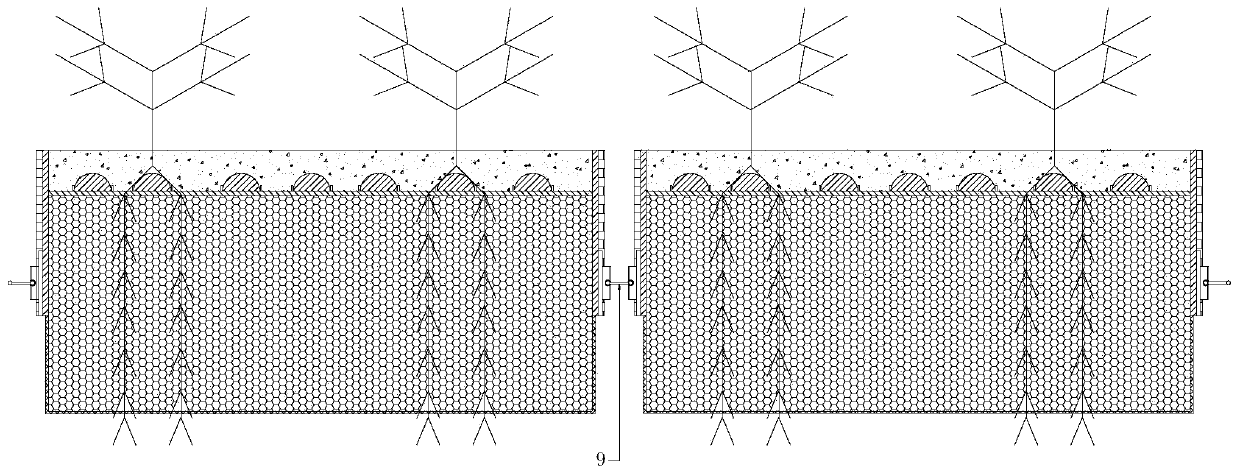

Fixing device for water-stop belt for rectangular cross-section of underground structure and rapid installation construction method

PendingCN111218957ASave materialSpeed up the construction progressArtificial islandsProtective foundationWater stopEnvironmental geology

The invention discloses a fixing device for a water-stop belt for a rectangular cross-section of an underground structure and a rapid installation construction method. The rapid installation construction method of the water-stop belt for the rectangular cross-section of the underground structure comprises the following steps of: step (1). performing construction preparation; step (2). surveying, positioning and lofting; step (3). installing and positioning the water stop belt fixing device; step (4). placing circumferential water-stop belts; step (5). constructing a structural baseplate; step(6). installing and fixing the water-stop belts; step (7). constructing side walls and a mid-plate structure; and step (8). connecting connectors of the water-stop belts at the position of a top plate. Only one connector is arranged on the full ring of each ring of water-stop belt; the connectors are arranged on the top plate easy to operate; construction joints of the side walls are formed and installed at one time; the quality of the connectors can be fully guaranteed; the quantity of the connectors is greatly reduced; and the amount of water leaking at the construction joints is greatly reduced.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP

Damping spacing bar clamped more firmly

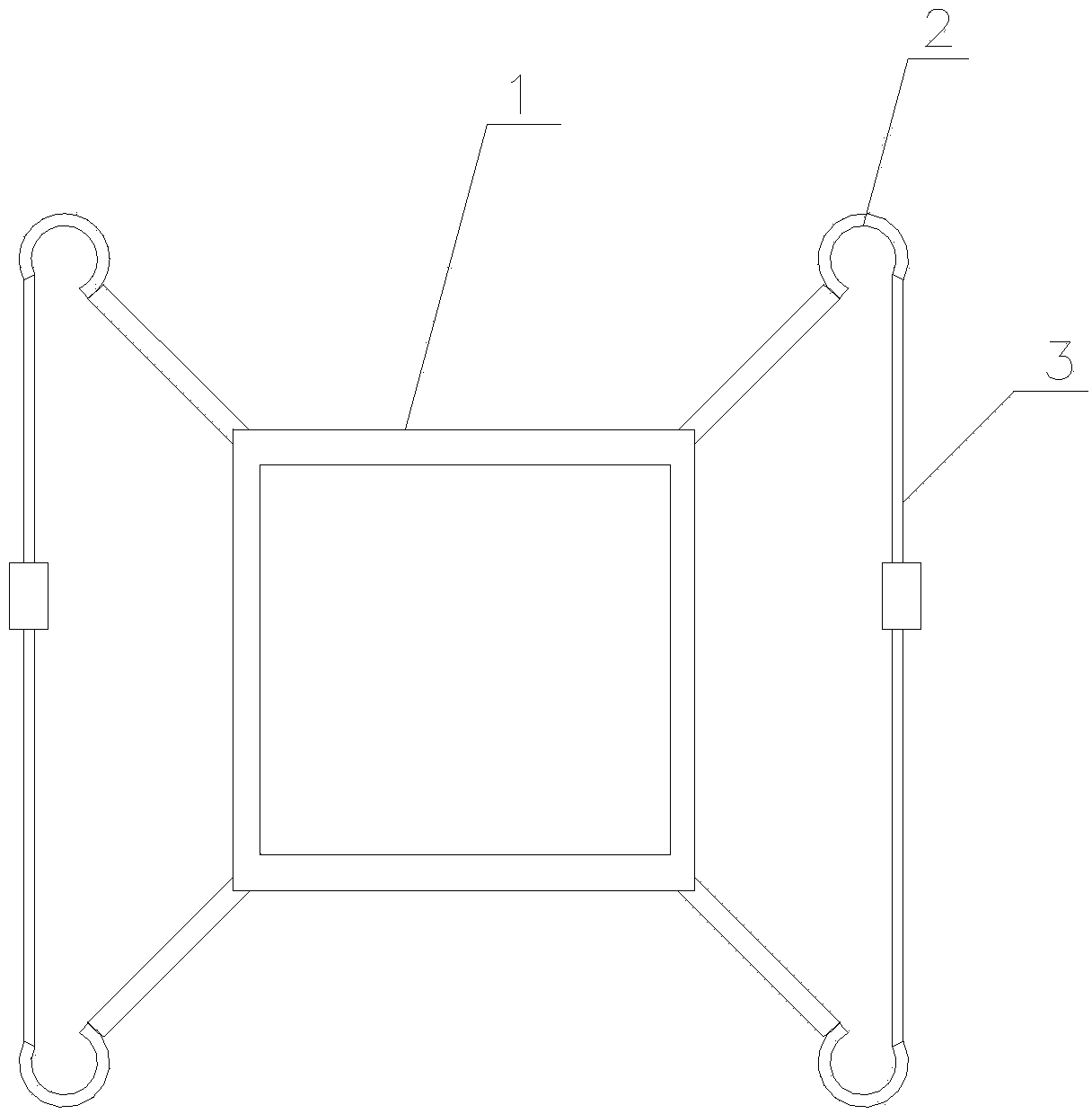

InactiveCN104009436AInhibit sheddingGuaranteed tautMaintaining distance between parallel conductorsEngineeringHigh pressure

The invention provides a damping spacing bar clamped more firmly, and relates to the technical field of high-voltage electricity power fittings. The damping spacing bar comprises a square supporting part and four wire clamps arranged on the square supporting part, wherein the wire clamps are in a hook shape, hooks of two wire clamps at the upper end of the square supporting part face downwards, hooks of two wire clamps at the lower end of the square supporting part face upwards, and the wire clamps on the same side are connected through a connector. The damping spacing bar is simple in structure and reasonable in design, and by means of the hooks opposite in pairs, the spacing bar is prevented from falling off to a certain degree and stability is enhanced; meanwhile, upper and lower wires are tensioned to a greater degree through the connector on the same side under the circumstance that the damping spacing bar does no fall off, the damping spacing bar is clamped on the wires more forcefully and is not prone to shaking, and damage to the wires is reduced.

Owner:ANHUI WEI LONG POWER EQUIP

Corner laying carbon fiber/resin composite product 3D printing repairing machine and method

ActiveCN111037923BWell laidGuaranteed tautAdditive manufacturing apparatusAdditive mnaufacturing with solid and fluid3d printFiber

Owner:NORTHEASTERN UNIV LIAONING

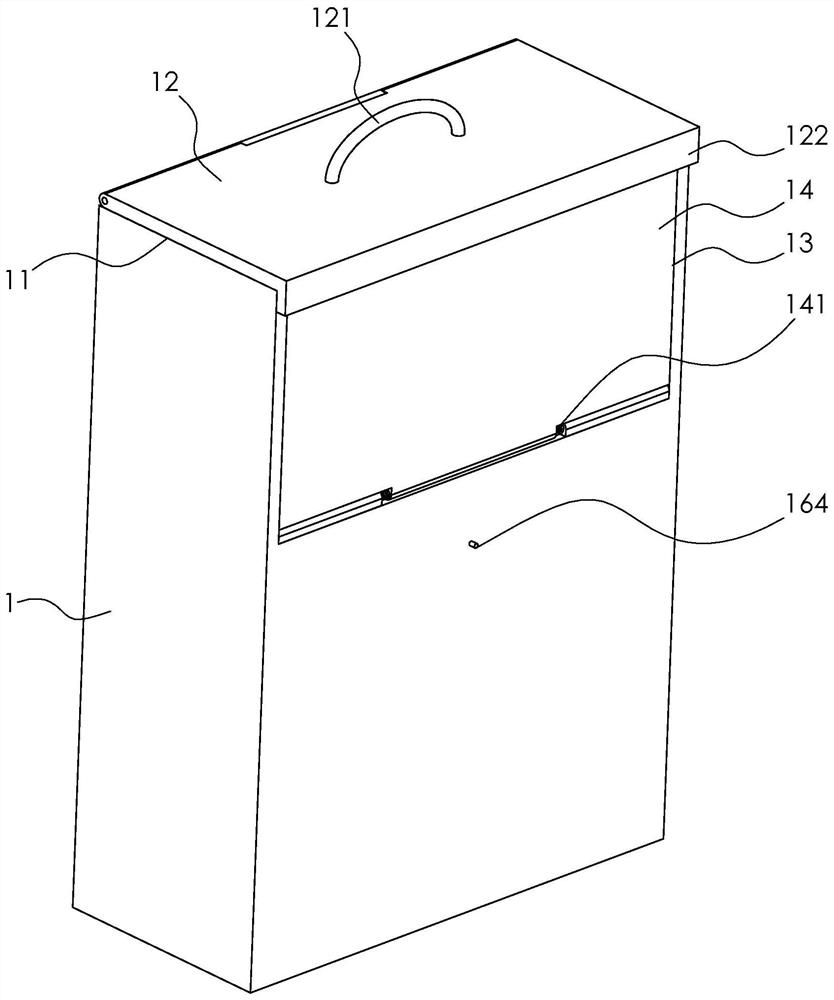

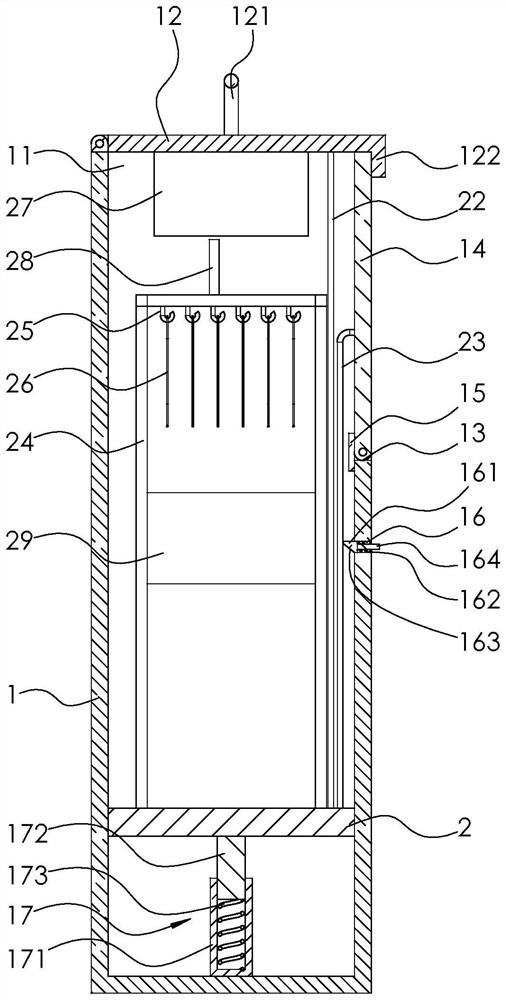

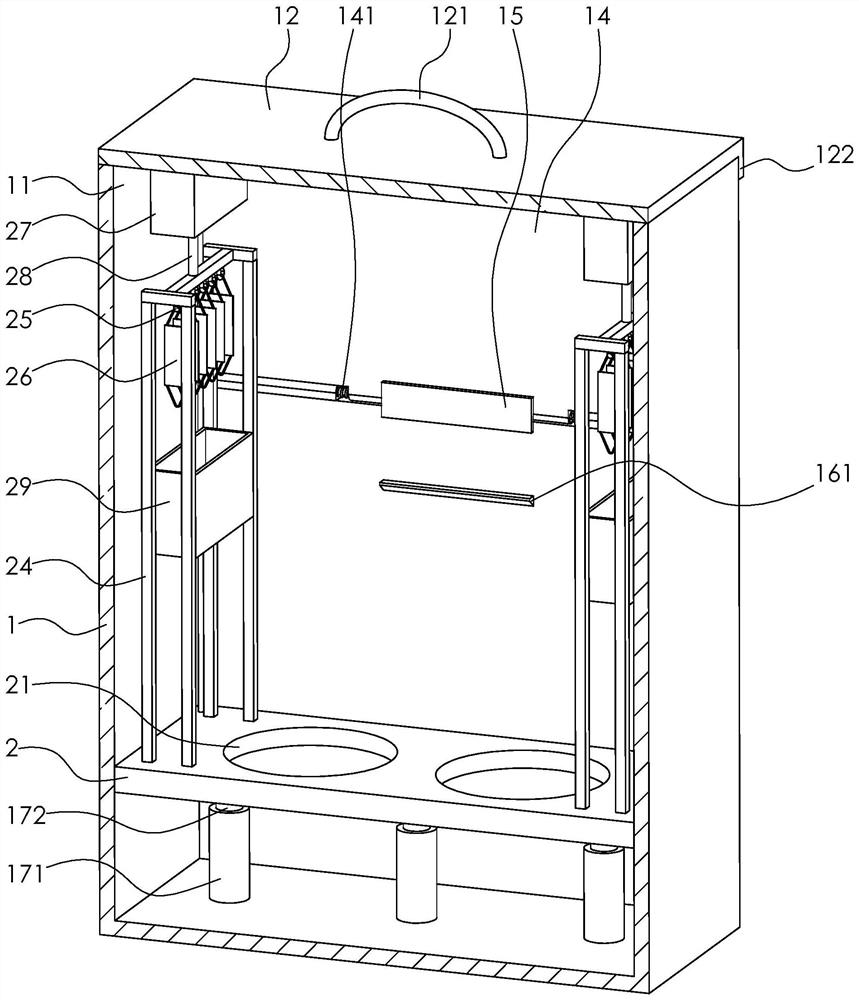

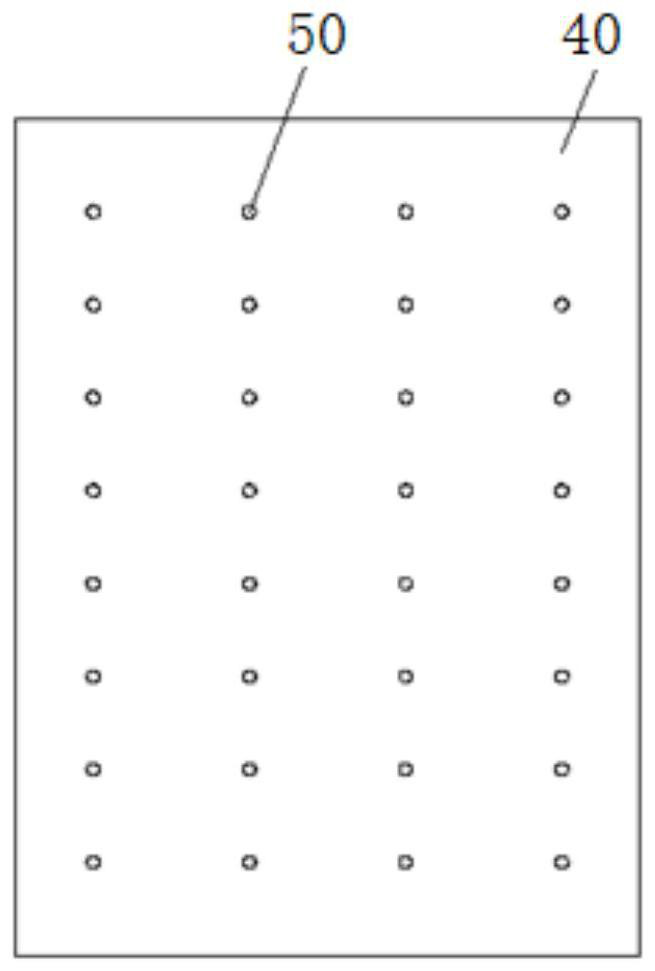

Fire extinguisher cabinet

The invention relates to the technical field of fire fighting equipment, in particular to a fire extinguisher box which comprises a box body, a first opening and a box cover are arranged at the upper end of the box body, a second opening and a box door are arranged on the side portion of the box body, the first opening and the second opening communicate with each other, and the end, away from the box door, of the box cover is rotationally connected to the box body; the end, facing the box door, of the box cover is attached to the upper end faces of the box body and the box door, the end, away from the box cover, of the box door is rotationally connected to the box body, and the rotating plane of the box cover and the rotating plane of the box door are parallel to the same vertical plane. A counterweight plate is slidably embedded in the box body in the vertical direction, the lower surface of the box cover is connected to the upper surface of the counterweight plate through a first connecting rope, and the side, facing the interior of the box body, of the box door is connected to the upper surface of the counterweight plate through a second connecting rope; the box door is connected to the box body through a torsion spring, and a positioning block for abutting against the box door is installed on the inner side of the box body. The fire extinguisher can be conveniently and rapidly taken out.

Owner:河南泰合消防工程有限公司

Magnetic pole protection structure, rotor, motor and rotor installation method

ActiveCN111342581BReduce temperature riseImprove efficiencyMagnetic circuit rotating partsManufacturing stator/rotor bodiesMagnetic polesElectric machinery

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

toothed belt tensioner

Owner:韦乐海茨(上海)医药设备科技有限公司

Sundry cleaning device of urban garden landscape circulating water pool

ActiveCN111359278AReduce work stressWith telescopic functionWater cleaningGeneral water supply conservationEnvironmental engineeringBiology

The invention discloses a sundry cleaning device of an urban garden landscape circulating water pool. The device is characterized in that the device comprises a filtering device arranged at a water recovery inlet of a circulating water pool, a dip net, left and right positioning piles and a power generation structure, the filtering device comprises a plurality of suspension bodies and a rigid ropeI, floating plants can be planted on the suspension body, a fixing strip is arranged on the side surface of the suspension body, spherical holes are formed in the side faces of the fixing strips, spherical heads of the connecting structures are loosely contained in the spherical holes between the adjacent suspension bodies respectively, the connecting structures have a telescopic function, the multiple suspension bodies are connected in series into a row through the connecting structures, first rigid ropes are fixedly connected to the two ends of the row respectively, the left positioning pile and the right positioning pile are fixedly arranged on the banks on the two sides of a water recycling inlet correspondingly, and the ends of the first rigid ropes are fixedly connected to the leftpositioning pile and the right positioning pile correspondingly. The sundry cleaning device can utilize the power of the circulating water pool when recovering water and save energy.

Owner:HEIHE UNIV

Improved electric power strain clamp

ActiveCN113067300AGuaranteed connection effectImprove connection rateAdjusting/maintaining mechanical tensionPhysicsEngineering

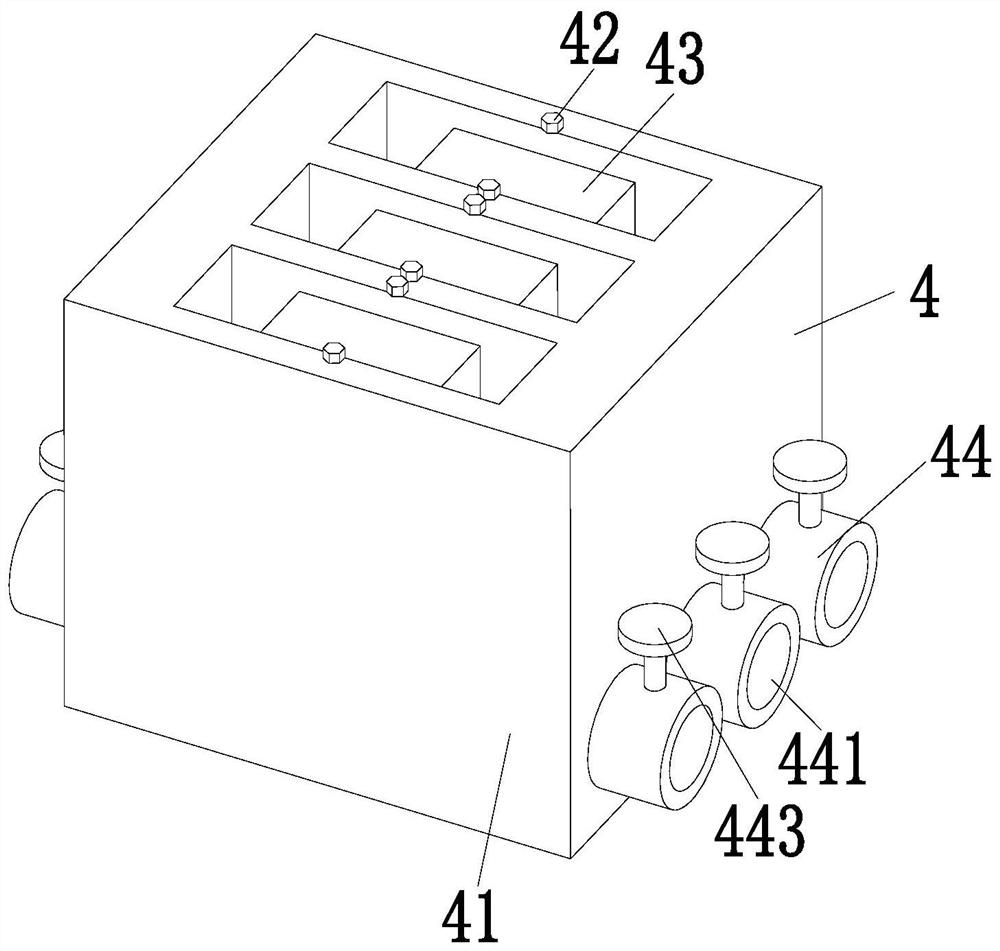

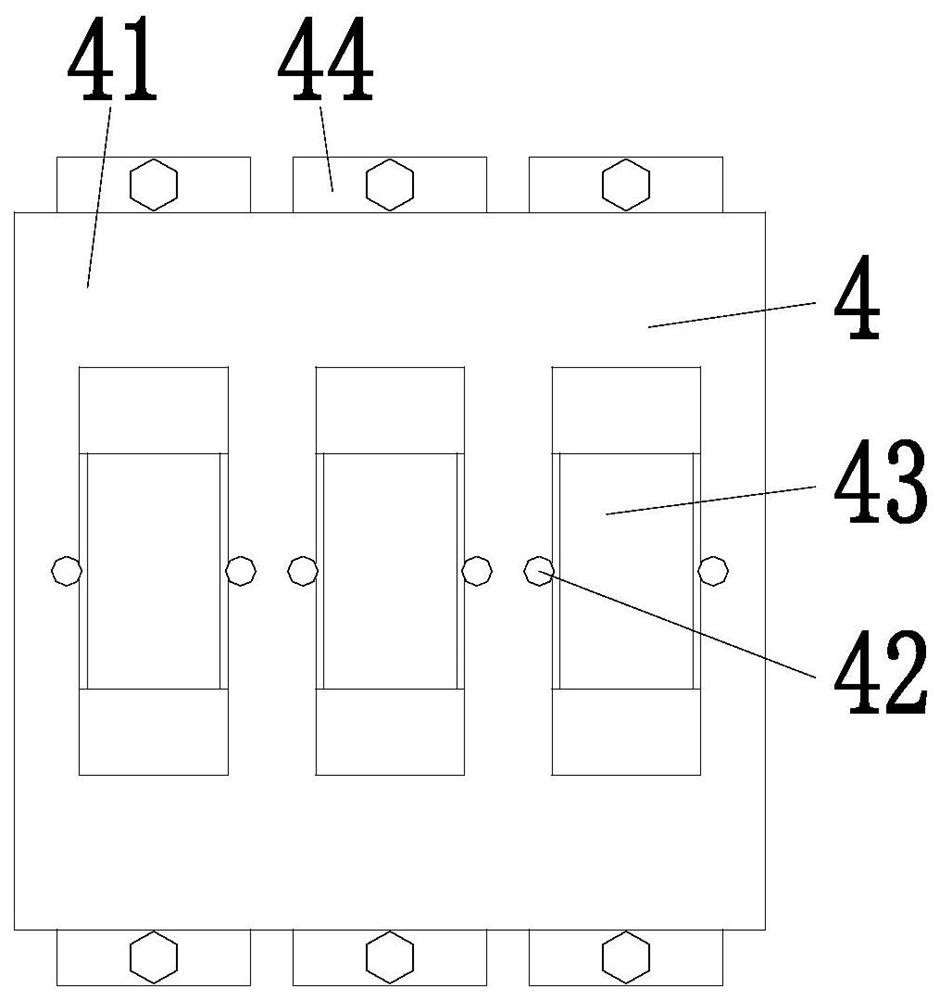

The invention provides an improved electric power strain clamp. The improved electric power strain clamp comprises a fixing sleeve, an auxiliary unit, an adjusting unit and a clamp unit, an auxiliary unit is installed on the outer wall of the top end of the fixing sleeve, the auxiliary unit is of a blocky structure, installation grooves are evenly formed in the two ends of the auxiliary unit respectively, adjusting units are arranged in the installation grooves of the auxiliary unit, and the wire clamp units are installed on the outer walls of the adjusting units; the electric power strain clamp solves the problems that in the installation and use process of an existing electric power strain clamp, when a wire and the clamp are connected and fixed, the installation angle of the wire cannot be adjusted through a worker, and therefore the connection effect of the wire is affected; and after the wires are connected, workers are inconvenient to require the tension of the wires according to the tightness of the wires, so that the wires are broken due to overlarge tension of the wires, and the wires are loosened due to dragging due to oversmall tension of the wires.

Owner:中安达电气科技股份有限公司

A 3D printer and method for corner-laying carbon fiber/resin composite products

ActiveCN111037922BGuaranteed tautGuaranteed arbitrary angleAdditive manufacturing apparatusAdditive mnaufacturing with solid and fluidFiberConverters

The invention relates to a 3D printer and method for corner-laid carbon fiber / resin composite products. The printer includes a processing platform, a filament-threading plate structure, and a fiber-resin multifunctional nozzle. When printing, the diameter of a single-layer filament-threading plate can be independently selected according to the size of the workpiece. , and the number of layers of the threading plate structure can be determined by the size of the workpiece to be processed. Choosing the appropriate number of layers of the threading plate structure can effectively save carbon fiber filaments and improve the efficiency of threading; the threading plate structure includes a detachable cutting shear , installed on the lower half of the uppermost threading board during the work process, is used to cut the carbon fiber filaments after each layer of threading is completed. The fiber resin multi-functional nozzle includes a laying nozzle, a thermoplastic material nozzle, a nozzle converter, and a heating nozzle. . This method can realize the laying of carbon fibers at any angle and can enhance the strength of carbon fiber filaments. This method saves materials and has high processing efficiency.

Owner:NORTHEASTERN UNIV LIAONING

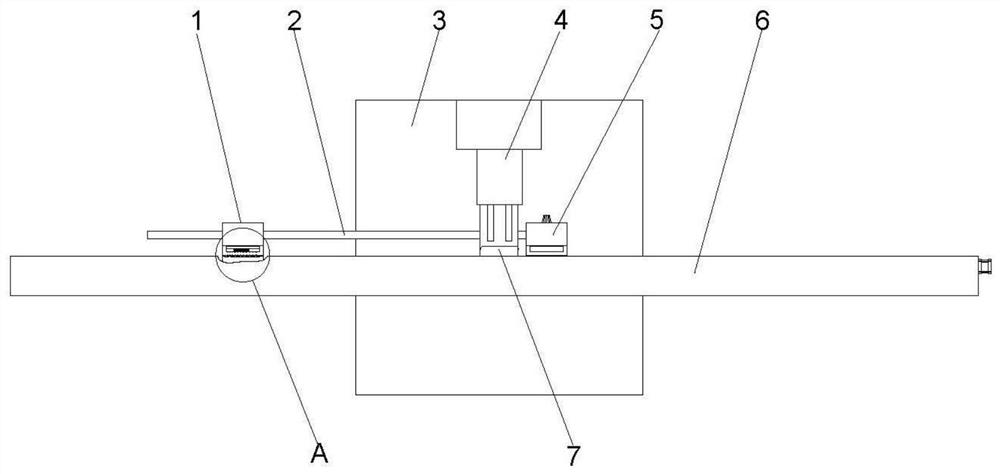

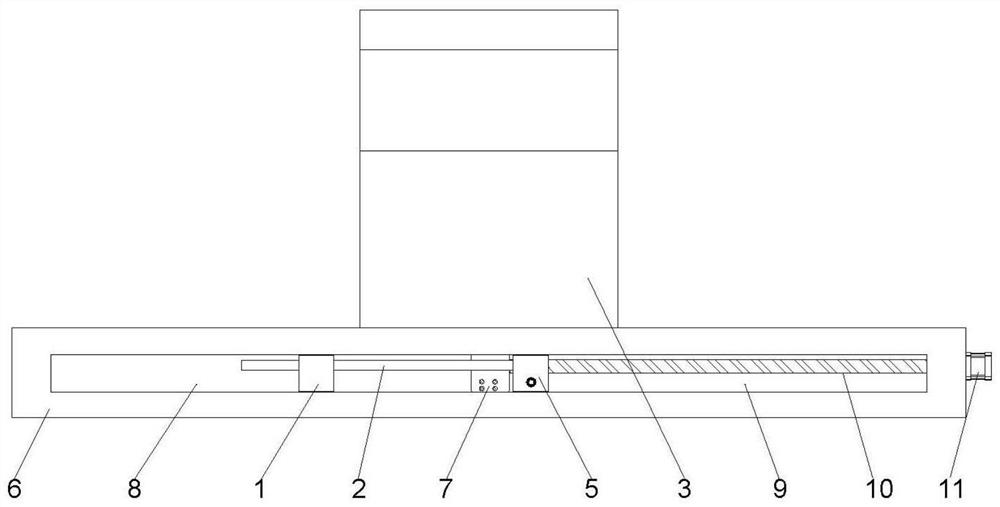

Bathrobe burr processor and processing method thereof

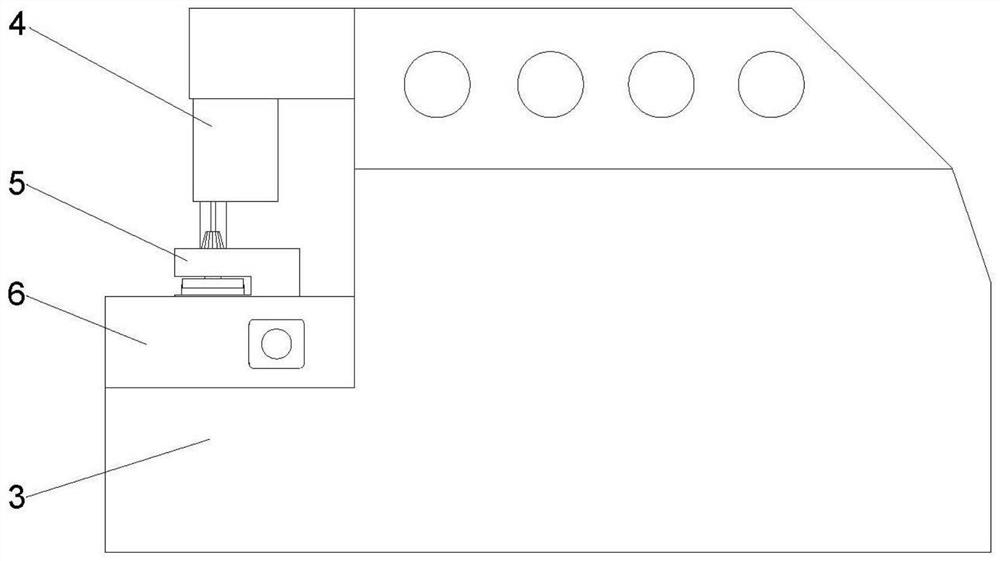

ActiveCN112695463AAvoid the phenomenon of different widthsEasy to fixWork-feeding meansPressersControl engineeringMechanical engineering

The invention discloses a bathrobe burr processor and a processing method thereof. The bathrobe burr processor comprises a machine seat, a rail and an edge locking power head are fixed to the machine seat, a driving clamping block and a driven clamping block are arranged on the upper end face of the rail, and the driving clamping block and the driven clamping block are arranged on the same straight line and are both in sliding connection with the rail. A first fixing rod is fixed to the driving clamping block, a first through hole matched with the first fixing rod is formed in the driven clamping block, the first fixing rod is located in the first through hole and slidably connected with the driven clamping block, a fastening assembly is arranged between the driven clamping block and the first fixing rod, and the edge locking power head is located between the driving clamping block and the driven clamping block and located above the straight line formed by the driving clamping block and the driven clamping block. The bathrobe burr processor has the beneficial effects that the distance between the driving clamping block and the driven clamping block can be freely adjusted; the positioning precision of equipment overlock is improved; the safety is high; the fixing efficiency is improved; and the fixing effect is good, and processing efficiency and processing quality are improved.

Owner:廷镁创智(浙江)服饰股份有限公司

A wire tightening device for electric installation

ActiveCN110867774BGuaranteed tautStuck stableApparatus for overhead lines/cablesInterference fitGear wheel

The invention discloses a wire-tightening device for electric power installation. The device comprises a base. Two side plates are fixedly installed on the base. A bearing is fixedly embedded in the side plates. A driving shaft is interference-fit in the bearing. A motor is fixedly installed on each side plate. The rotating shaft of the motor and the driving shaft are fixedly installed through a coupler. A winding drum is fixedly installed on the driving shaft, cables are wound on the winding drum, a gear is fixedly installed on the driving shaft, a first cylinder is fixedly installed on the base, and clamping teeth are fixedly installed on the piston rod of the first cylinder and the clamping teeth are meshed and connected with the gear. The cables can be released or tightened through thewinding drum. After the driving shaft is rotated and positioned, the clamping teeth can be matched with the gear to mesh so as to realize the clamping stability of the driving shaft, ensure that thecables can be tightened during construction and lift the cables from the bracket through the wire base, thus preventing workers from climbing in the bracket and reducing the occurrence of safety accidents.

Owner:中国南方电网有限责任公司超高压输电公司百色局

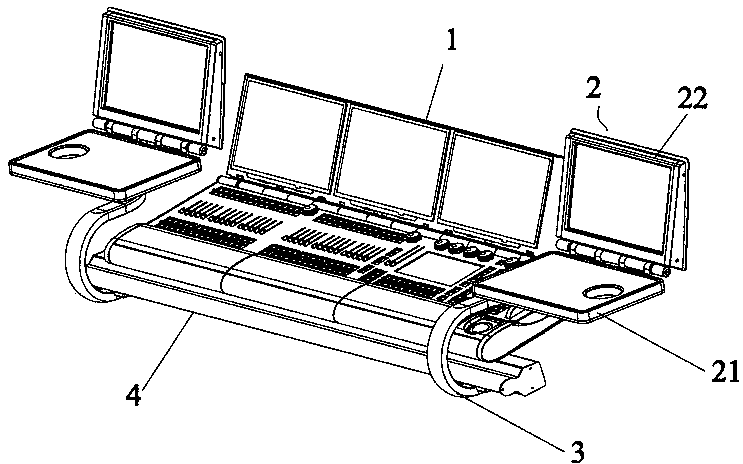

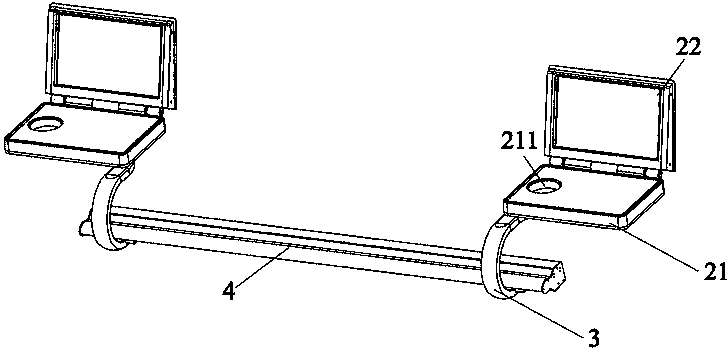

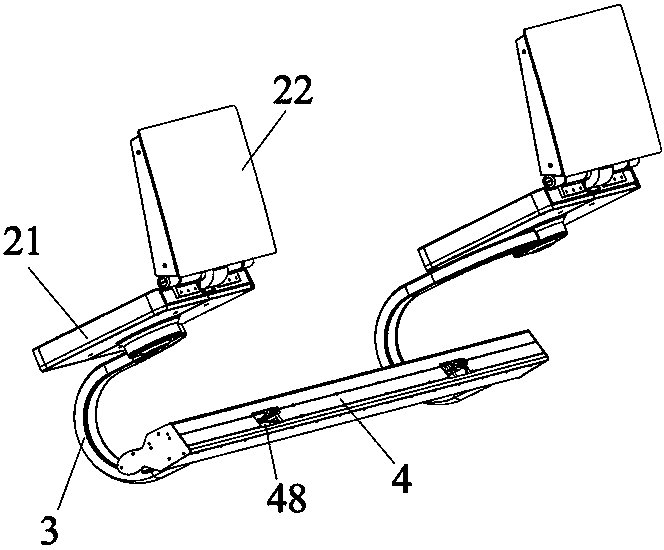

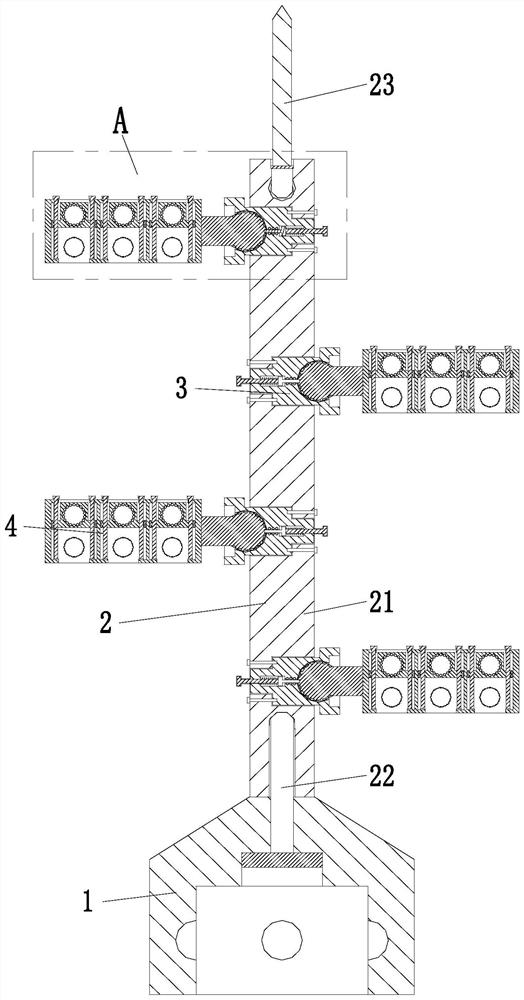

Light console convenient for wiring

ActiveCN102681593BDoes not affect operationEasy to operateControl mechanismEngineeringMechanical engineering

Owner:GUANGZHOU FINEART LIGHTING

An improved electric tension clamp

ActiveCN113067300BFirmly connectedEasy to install each otherAdjusting/maintaining mechanical tensionWire tensionClassical mechanics

The present invention provides an improved electric tension wire clamp, comprising a fixing sleeve, an auxiliary unit, an adjusting unit and a wire clamp unit; an auxiliary unit is installed on the top outer wall of the fixing sleeve, and the auxiliary unit is a block structure, Both ends of the auxiliary unit are evenly provided with installation grooves, the installation groove of the auxiliary unit is provided with an adjustment unit, and the wire clip unit is installed on the outer wall of the adjustment unit; When connecting and fixing the main wires and the wire clips in the process of use, the installation angle of the wires cannot be adjusted by the staff, thus affecting the connection effect of the wires; and it is not convenient for the staff to adjust the tightness of the wires after the wires are connected. The tension of the wire, so that if the wire tension is too large, the wire will break, and if the wire tension is too small, the wire will be pulled loose and cause danger.

Owner:中安达电气科技股份有限公司

Tensioning device and gel applying machine

PendingCN111545421AApply glue evenlyGuaranteed tautLiquid surface applicatorsCoatingsTension controlWebbing

The invention relates to the technical field of gel applying, in particular to a tensioning device and a gel applying machine. The tensioning device comprises a supporting frame, a first transmissionassembly and a second transmission assembly mounted on the supporting frame, and a driving assembly mounted on the supporting frame and used for driving a first transmission assembly and a second transmission assembly; and the tensioning device further comprises a first gear lever assembly mounted on the position, located at one side of the first transmission assembly, of the supporting frame anda second gear lever assembly mounted on the position, located on one side of the second transmission assembly, of the supporting frame. According to the tensioning device and the gel applying machine,aiming at a high-elasticity braid or lace tape gel applying machine, during gel applying, a braid is tensioned in advance to apply gel to the braid or a lace tape; and after gel applying, the unbakedbraid or the unbaked lace tape is loosened under the tension control of a traditional braid gel dripping machine, so that the braid or the lace tape recovers to the original elasticity and then is dried or wound.

Owner:东莞市鸿程机械有限公司

Directional sowing device and method for garlic based on machine vision

ActiveCN112913399BAchieve structural stabilityEnsure structural stabilityPotato plantersNeural architecturesAllium sativumImage identification

The present application discloses a device and method for directional garlic sowing based on machine vision, including: a device for dialing and arranging seeds, the garlic seed outlet of the device for arranging and arranging seeds is connected to the first end of the garlic seed transmission channel, and the first end of the garlic seed transmission channel The two ends are set at the garlic seed inlet of the garlic seed feature recognition and directional sowing mechanism, and an image collector is arranged directly above the garlic feature recognition and directional sowing mechanism, and the image acquisition end of the image collector faces the garlic feature recognition and directional sowing In the mechanism, it is used to collect the pose information photos of garlic seeds, and the garlic seed feature recognition and directional sowing mechanism recognizes and adjusts the garlic seed poses according to the pose information photos. It can complete the secondary seeding and sorting of garlic at one time, the directional and orderly transmission of garlic seeds, image recognition and directional sowing, which meet the agronomic requirements of garlic seed buds facing upwards, and the intensive design greatly reduces the space occupied by itself. And volume, strong integrity, satisfying the mechanized and intelligent sowing of garlic.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

A bathrobe processing machine and its processing method

ActiveCN112695463BAvoid the phenomenon of different widthsEasy to fixWork-feeding meansPressersControl engineeringMechanical engineering

Owner:廷镁创智(浙江)服饰股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com