Drilling and assembling unit with transport tank body being provided with cable reel

A technology of cable reels and transport troughs, which is applied in earthwork drilling, mining equipment, tunnels, etc., can solve the problems of inconvenient observation of the working conditions of cable reels, easy hanging of cables on the ground, and potential safety hazards, etc., to ensure Safety, short aging life, and the effect of preventing even gas explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

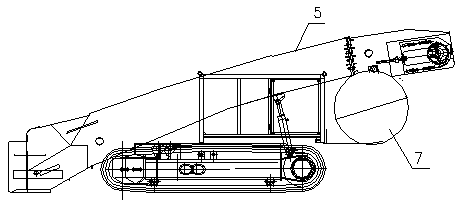

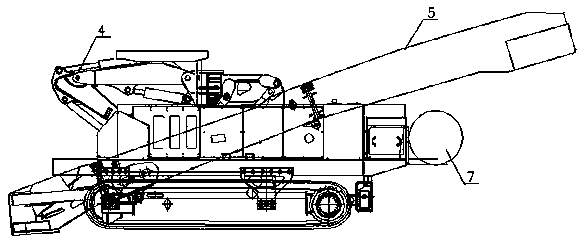

[0021] figure 1 and figure 2 For the prior art, the cable reel 7 is located at the bottom of the transport tank and the rear of the frame.

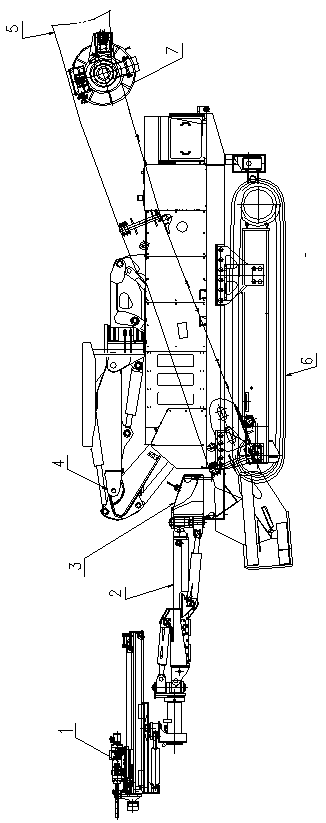

[0022] exist image 3 , Figure 4 , Figure 5 and Figure 6 Among them, a drilling unit with a cable reel on the transport tank, which includes a drilling machine 1, an excavating arm 4, a transport tank 5 and a walking mechanism 6, and the drilling arm 2 on the drilling machine is connected to the mobile The trolley 3 is connected, and the rear of the transport tank (preferably the side of the rear) is provided with a cable reel 8, and the cable drum includes a flange seat fixedly connected to the support plate 9 on the bottom surface of the rear of the transport tank 13. There is a bearing seat (not shown in the figure) on the upper part of the flange seat. The sprocket shaft 12 and the guide frame 10 (for supporting the cable 15) are arranged on the bearing seat. One end of the sprocket shaft is supported on the bearing seat, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com