Vertical chain conveying system of coating production line

A coating production line and chain conveying technology, which is applied to the surface coating liquid device, coating, spraying device, etc., can solve the problems of large influence on the accuracy of the coating process, high cost of explosion-proof motors, and toxic gases , to achieve the effects of good adaptability, stable torque transmission and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

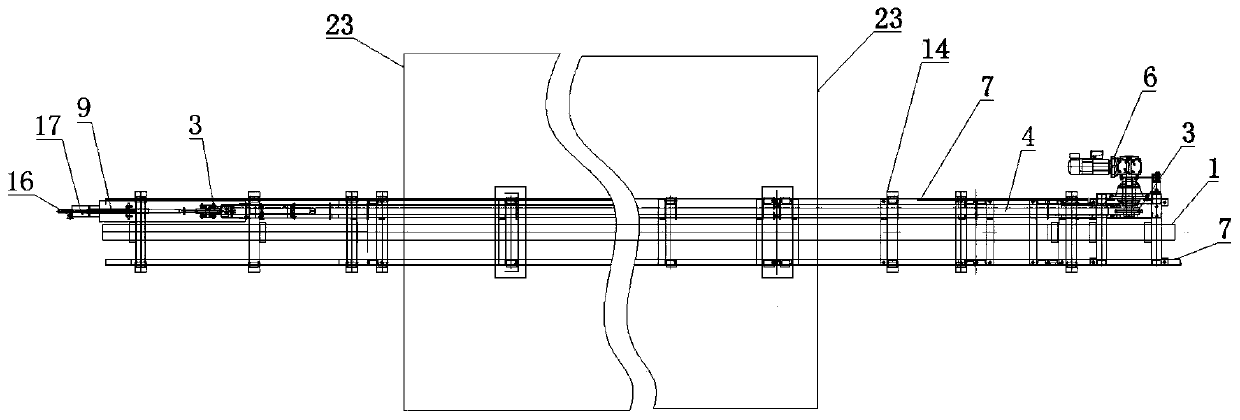

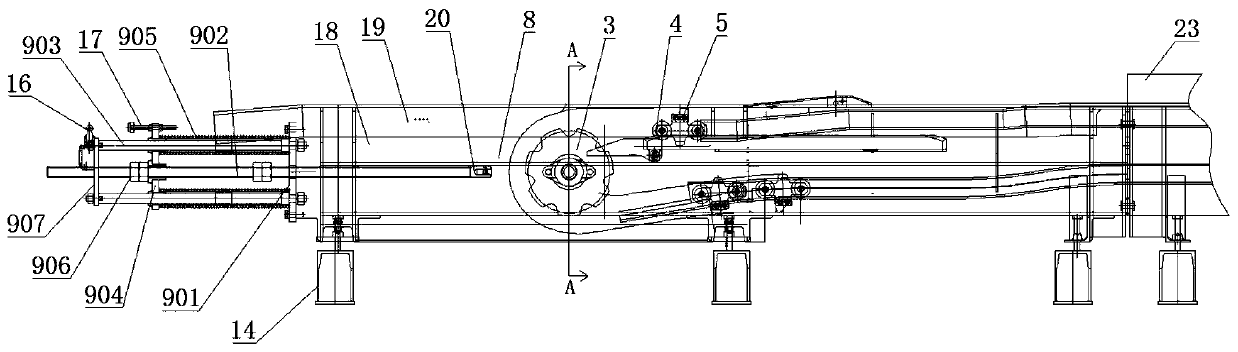

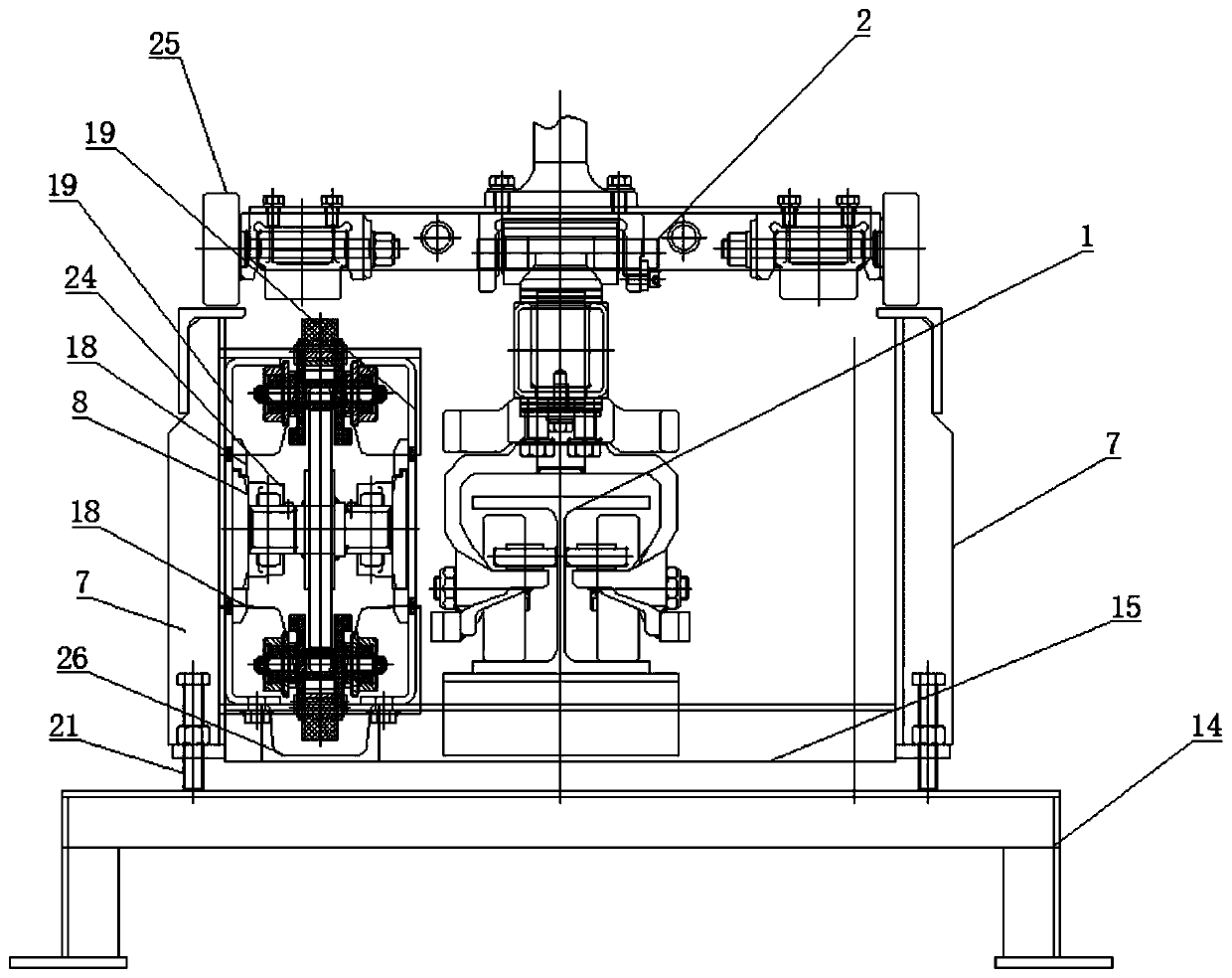

[0027] The specific embodiment of the present invention is like this: as Figure 1-9 As shown, a vertical chain conveying system of a coating production line includes a conveying slide rail 1 and a transport trolley 2 sliding on the conveying slide rail 1, and a chain transmission mechanism is provided on the outer side of the conveying slide rail 1; the chain transmission mechanism Including the support base 7, two sprockets 3 vertically arranged at both ends of the support base 7, the two sprockets 3 are provided with an endless chain 4, and the endless chain 4 is provided with a belt that can be clamped with the transport trolley 2. Chain push head 5, the outside of one end of support seat 7 is provided with motor d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com