toothed belt tensioner

A technology of tensioning device and toothed belt, which is applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., can solve the problem that the toothed belt is not vertical or horizontal, which affects the normal operation of the transmission device, and the main drive toothed belt Wheel load reduction and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

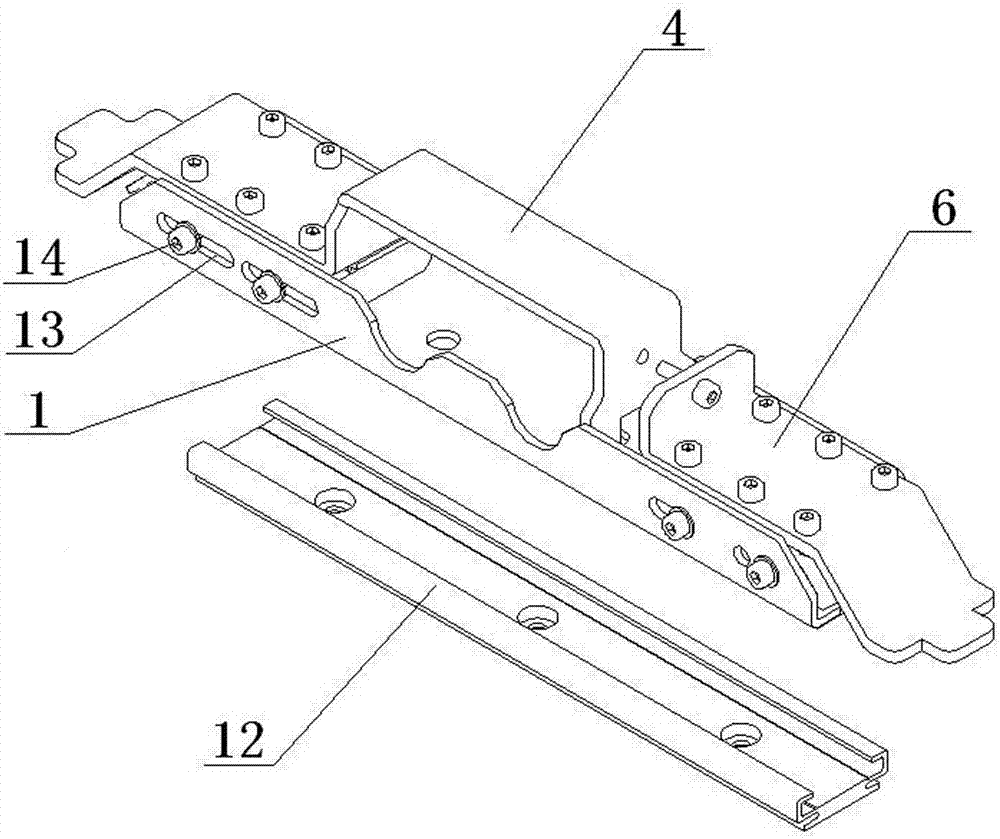

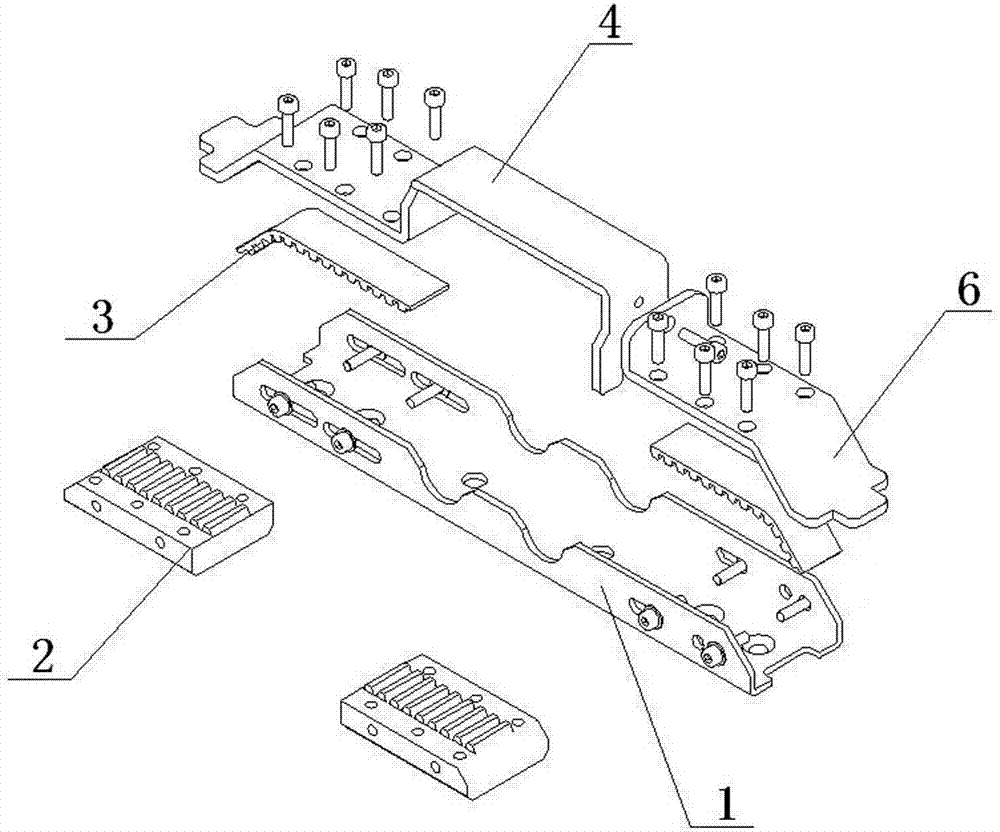

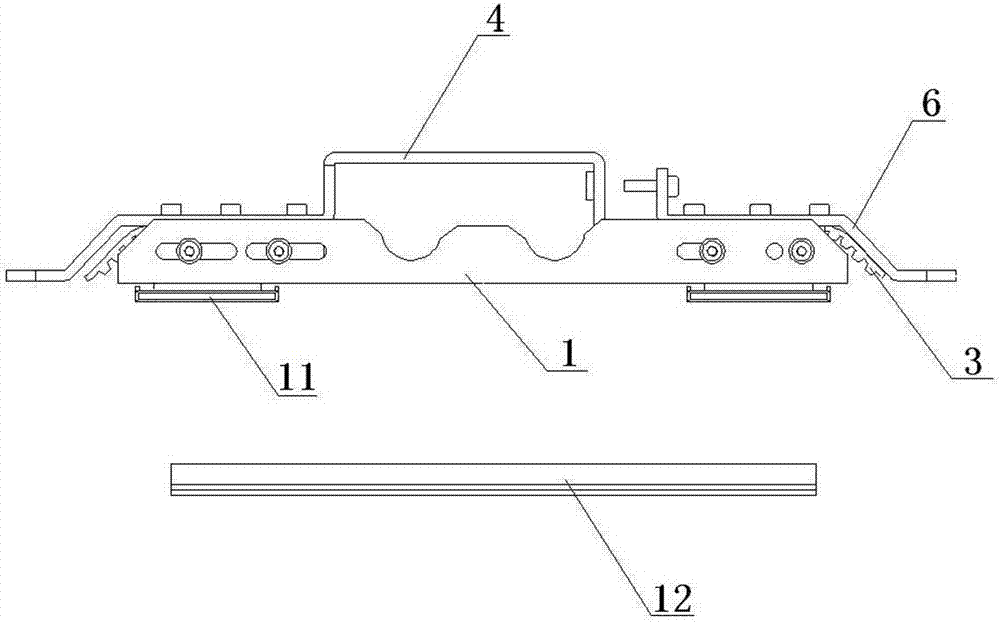

[0018] Example: such as figure 1 with figure 2 As shown, the toothed belt tensioning device in this embodiment mainly includes a base 1, a toothed block 2 and a toothed belt pressing block, wherein the toothed block 2 and the toothed belt pressing block are installed on the bottom of the base 1 respectively. The inside of the cavity is semi-closed, and the toothed belt pressing block is located above the toothed block 2.

[0019] Such as Figure 2-4 As shown, the cross-section of the base 1 is trapezoidal, and the openings at both ends of the semi-closed cavity inside it are inclined downward. A toothed block 2 is placed at the left and right ends of the semi-closed cavity surrounded by the base 1. The edge of the toothed block 2 is flush with the edge of the cavity surrounded by the base 1. Convex teeth that match the tooth profile. The base 1 is provided with a narrow and long through hole 13, and a bolt 14 is arranged in the narrow and long through hole 13, and the too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com