A kind of numerical control processing equipment for outer grid wall panel

A processing technology and equipment technology, applied in the field of numerical control processing technology and equipment, can solve the problems of excessive thickness of the skin, poor roundness of the short shell, and inability to connect, and achieve the effects of high qualification rate, good fit and easy adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

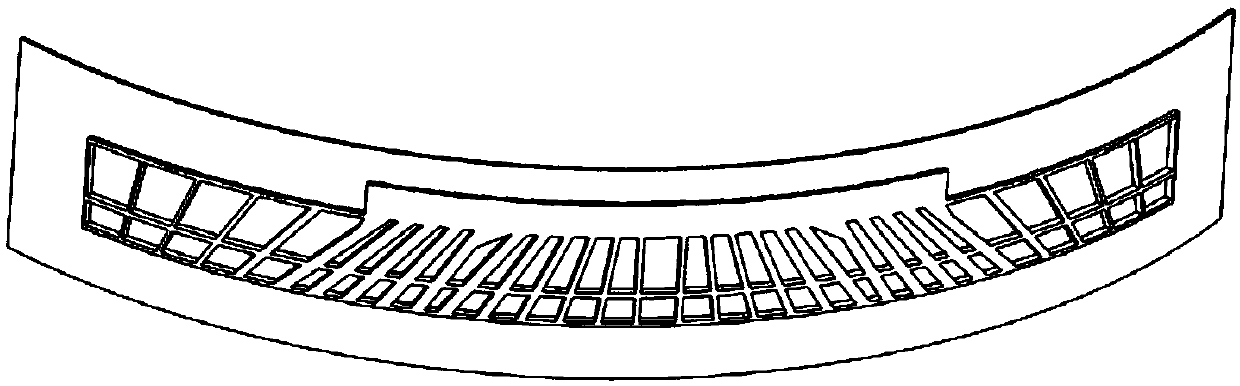

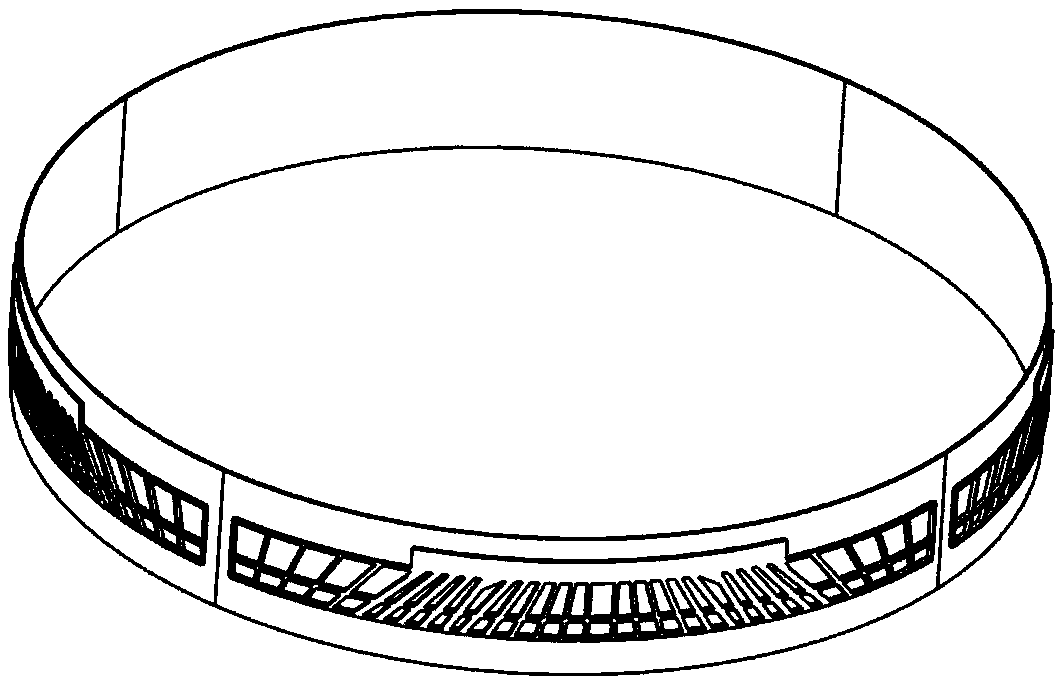

[0037] Hereinafter, the present invention will be described in detail by taking a certain type of single wall plate with an inner diameter of Ф3338mm shell as the object of elaboration. Each short shell (shell) is welded from four panels. The height of each panel is 510mm, the thickness of the panel skin is 1.5mm, the dimensional accuracy is ±0.1mm, the thickness of the panel ribs is 20mm, and the dimensional accuracy of the rib width is ±0.15mm, and the remaining thickness of the welding area is 7.7mm. For the specific structure, see figure 1 and figure 2 .

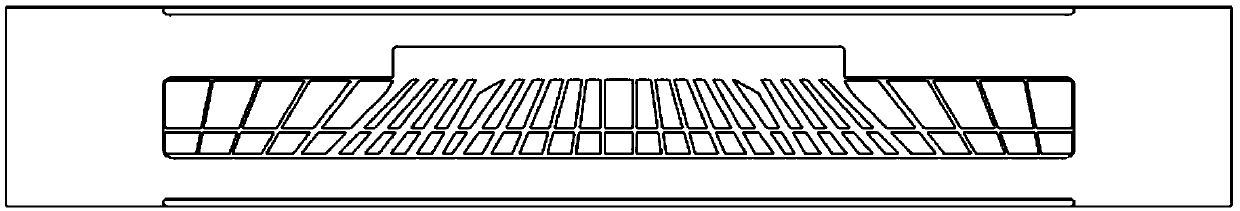

[0038] like Figure 5a , 5b , 6a, 6b, the equipment of the present invention includes a pressing plate 3, a tensioning device 2, a pressing device 5, and an arc tire 4 with a vacuum suction cup; specifically in this embodiment, it includes 28 groups of pressing plates, each in a row before and after 14 Groups; 16 groups of tensioning devices, 8 groups on the left and right; 4 groups of pressing devices, 2 groups o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com