Assembly-type variable-damping variable-stiffness viscoelastic damper and anti-seismic method thereof

A technology of viscoelasticity and shock absorbers, which is applied in the field of energy consumption and shock absorption, can solve the problems of low recycling rate of forming molds, large size of viscoelastic shock absorbers, uneconomical processing and manufacturing, etc., and achieve economical processing and manufacturing, repeated High utilization rate and resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

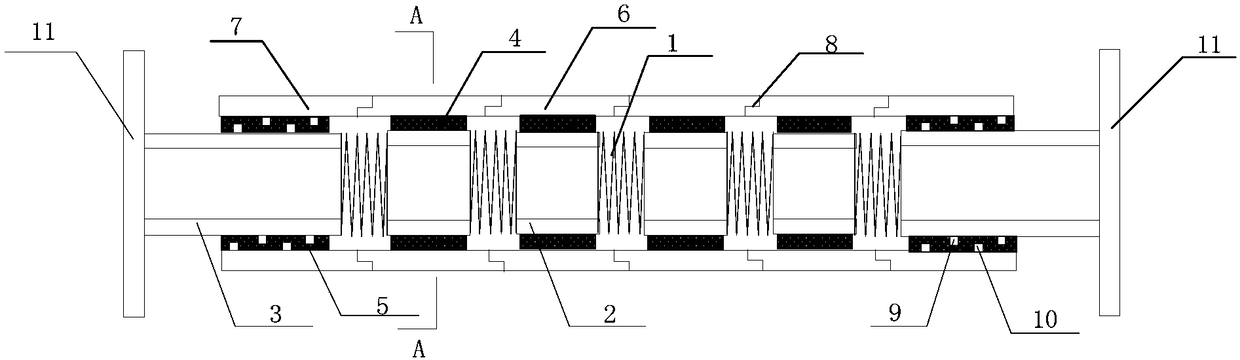

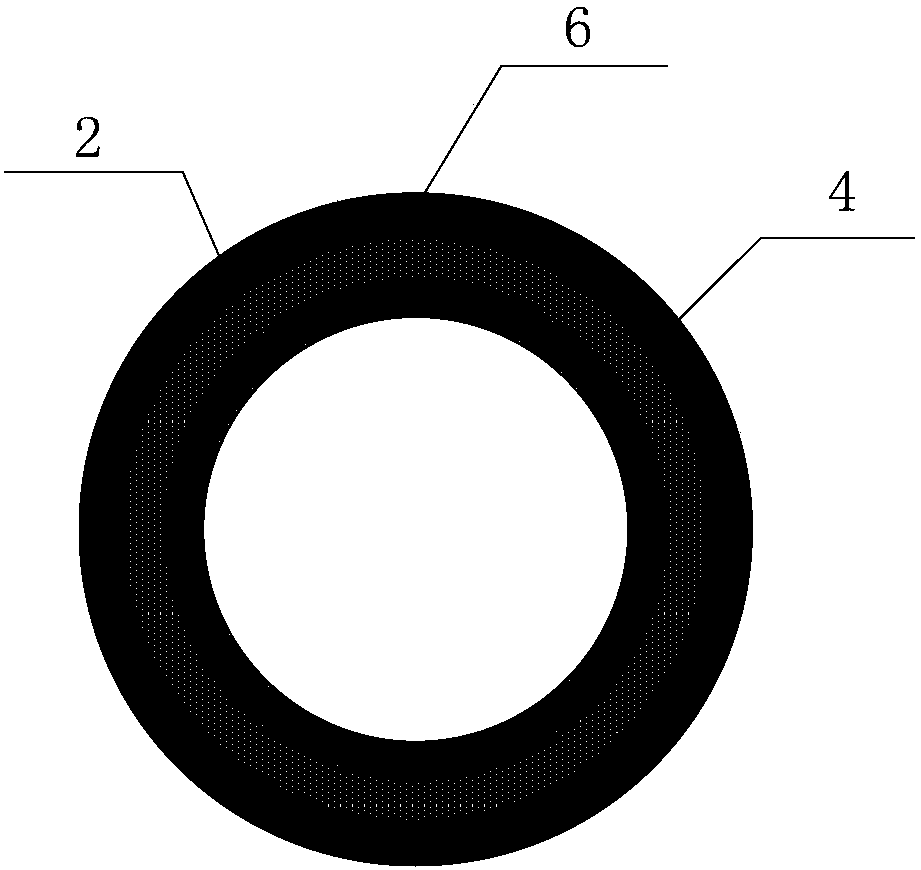

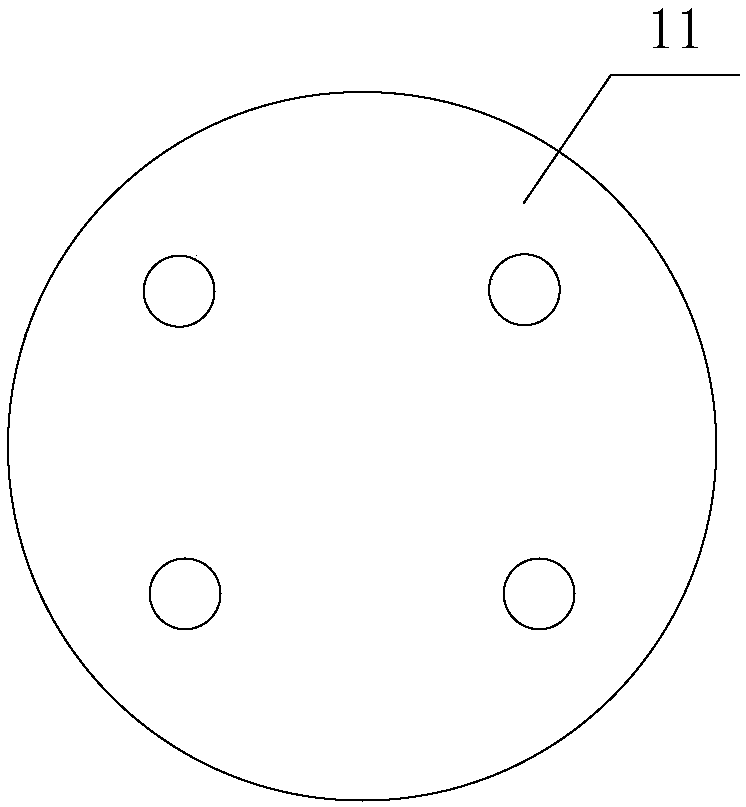

[0042] The assembled variable damping and variable stiffness viscoelastic shock absorber of the present invention is composed of a plurality of viscoelastic shock absorbers assembled as a whole large viscoelastic shock absorber. From the inside to the outside, it includes the spring 1 arranged at the center, the unit inner cylinder 2 connected with the spring 1, the end inner cylinder 3, the unit outer cylinder 6 sleeved outside the unit inner cylinder 2, and the unit inner cylinder 3 sleeved at the end The outer end outer cylinder 7 is filled with a viscoelastic material layer 4 between the unit inner cylinder 2 and the unit outer cylinder 6, and a viscoelastic material layer 5 is filled between the end inner cylinder 3 and the end outer cylinder 7. The viscoelastic material The layer 4 is connected to the unit inner cylinder 2 and the unit outer cylinder 6 through high temperature and high pressure vulcanization; the viscoelastic material layer 5 is connected to the end inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com