A method for making a vacuum port of a composite material mold

A composite material and manufacturing method technology, applied in the field of composite material molds, can solve the problems of difficult vacuum port processing, vacuum port stability and quality to be improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

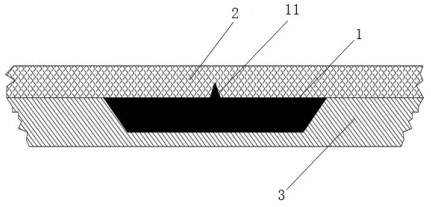

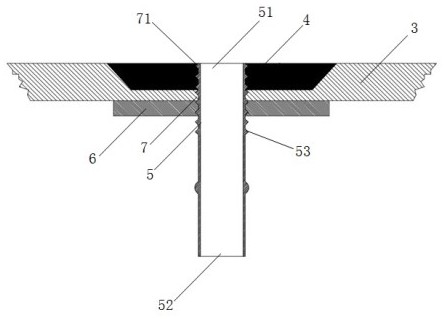

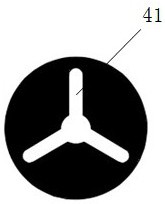

[0022] Such as Figures 1 to 4 As shown, a method for manufacturing a vacuum port of a composite material mold in this embodiment includes the following steps: S100: placing the embedded part 1 on the master mold 2; S200: after the support part 3 of the composite material mold is prepared, remove the Embedded part 1, put the vacuum port base 4 into the original embedded part position; S300: open the support part 3, and screw the connecting end 5 into the vacuum port base through the fastener 6. In the above technical solution, one end 51 of the connecting end 5 is located in the base of the vacuum port, and the other end 52 communicates with the vacuum system. When communicating with the vacuum system, it can be connected by a quick connector or by a clamp or the like. Thus, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com