A high-strength copper-clad steel wire

A copper-clad steel wire, high-strength technology, applied in the direction of rods/rods/wires/strip conductors, conductors, electrical components, etc., can solve problems such as easy breakage and low strength, and achieve increased strength, extended service life, and good society The effect of benefits and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

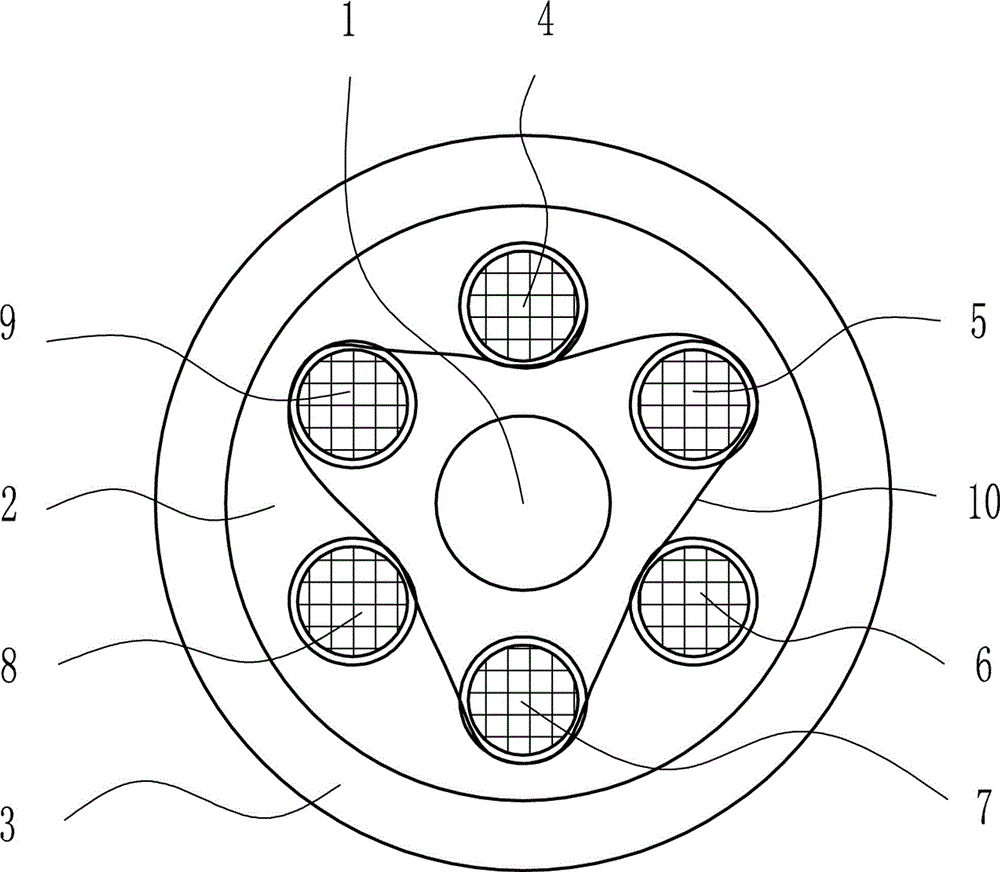

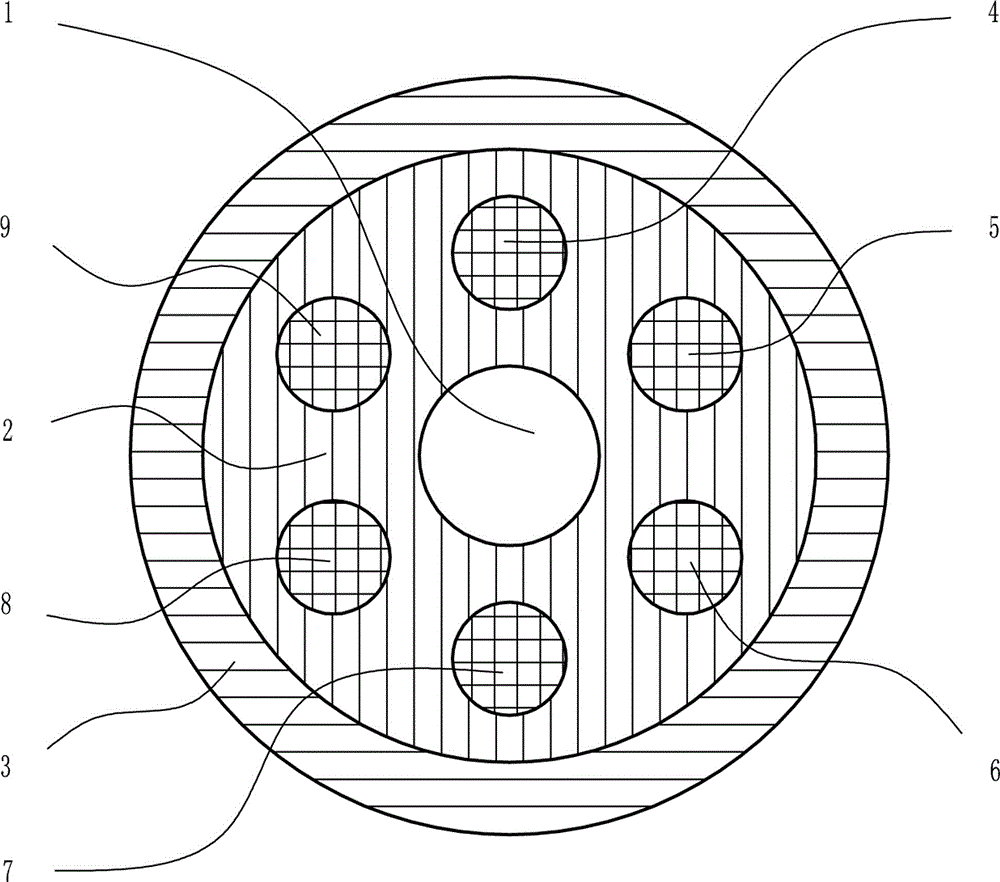

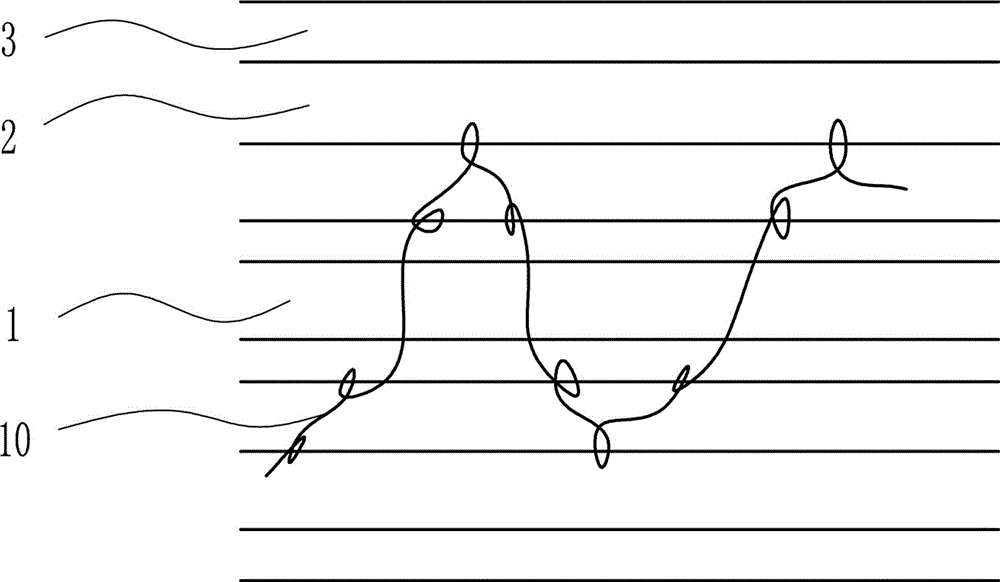

[0032] A high-strength copper-clad steel wire, such as figure 1 As shown, it includes soft iron layer 2, copper plating layer 3, steel wire I4, steel wire II5, steel wire III6, steel wire IV7, steel wire V8, and steel wire VI9; inside the soft iron layer 2, there is a hollow layer 1, soft iron layer 2 The hollow layer 1 is wrapped, and the carbon content of the soft iron layer 2 is 0.02% to 0.03%. In the soft iron layer 2, there are steel wires I4, steel wire II5, steel wire III6, steel wire IV7, steel wire V8 and steel wire VI9.

[0033] Steel wire Ⅰ4, steel wire Ⅱ5, steel wire Ⅲ6, steel wire Ⅳ7, steel wire Ⅴ8, and steel wire Ⅵ9 are evenly arranged in the soft iron layer 2 along the circumferential direction; the carbon content of steel wire Ⅰ4, steel wire Ⅱ5, steel wire Ⅲ6, steel wire Ⅳ7, steel wire Ⅴ8, and steel wire Ⅵ9 Both are 0.15% to 0.2%; a copper plating layer 3 is arranged outside the soft iron layer 2, and the copper plating layer 3 wraps the soft iron layer 2.

[...

Embodiment 2

[0038] A high-strength copper-clad steel wire, such as figure 1As shown, it includes soft iron layer 2, copper plating layer 3, steel wire I4, steel wire II5, steel wire III6, steel wire IV7, steel wire V8, and steel wire VI9; inside the soft iron layer 2, there is a hollow layer 1, soft iron layer 2 The hollow layer 1 is wrapped, and the carbon content of the soft iron layer 2 is 0.02% to 0.03%. In the soft iron layer 2, there are steel wires I4, steel wire II5, steel wire III6, steel wire IV7, steel wire V8 and steel wire VI9.

[0039] Steel wire Ⅰ4, steel wire Ⅱ5, steel wire Ⅲ6, steel wire Ⅳ7, steel wire Ⅴ8, and steel wire Ⅵ9 are evenly arranged in the soft iron layer 2 along the circumferential direction; the carbon content of steel wire Ⅰ4, steel wire Ⅱ5, steel wire Ⅲ6, steel wire Ⅳ7, steel wire Ⅴ8, and steel wire Ⅵ9 Both are 0.15% to 0.2%; a copper plating layer 3 is arranged outside the soft iron layer 2, and the copper plating layer 3 wraps the soft iron layer 2.

[0...

Embodiment 3

[0047] A high-strength copper-clad steel wire, such as figure 1 As shown, it includes soft iron layer 2, copper plating layer 3, steel wire I4, steel wire II5, steel wire III6, steel wire IV7, steel wire V8, and steel wire VI9; inside the soft iron layer 2, there is a hollow layer 1, soft iron layer 2 The hollow layer 1 is wrapped, and the carbon content of the soft iron layer 2 is 0.02% to 0.03%. In the soft iron layer 2, there are steel wires I4, steel wire II5, steel wire III6, steel wire IV7, steel wire V8 and steel wire VI9.

[0048] Steel wire Ⅰ4, steel wire Ⅱ5, steel wire Ⅲ6, steel wire Ⅳ7, steel wire Ⅴ8, and steel wire Ⅵ9 are evenly arranged in the soft iron layer 2 along the circumferential direction; the carbon content of steel wire Ⅰ4, steel wire Ⅱ5, steel wire Ⅲ6, steel wire Ⅳ7, steel wire Ⅴ8, and steel wire Ⅵ9 Both are 0.15% to 0.2%; a copper plating layer 3 is arranged outside the soft iron layer 2, and the copper plating layer 3 wraps the soft iron layer 2.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com