Ferritic stainless steel sheet for original pipe of bellows

A technology of stainless steel plate and corrugated pipe, applied in the field of ferritic stainless steel plate for corrugated pipe original pipe, which can solve the problems of insufficient and unavailable supply, and achieve the effects of excellent high-temperature fatigue characteristics, excellent processability, and excellent high-temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

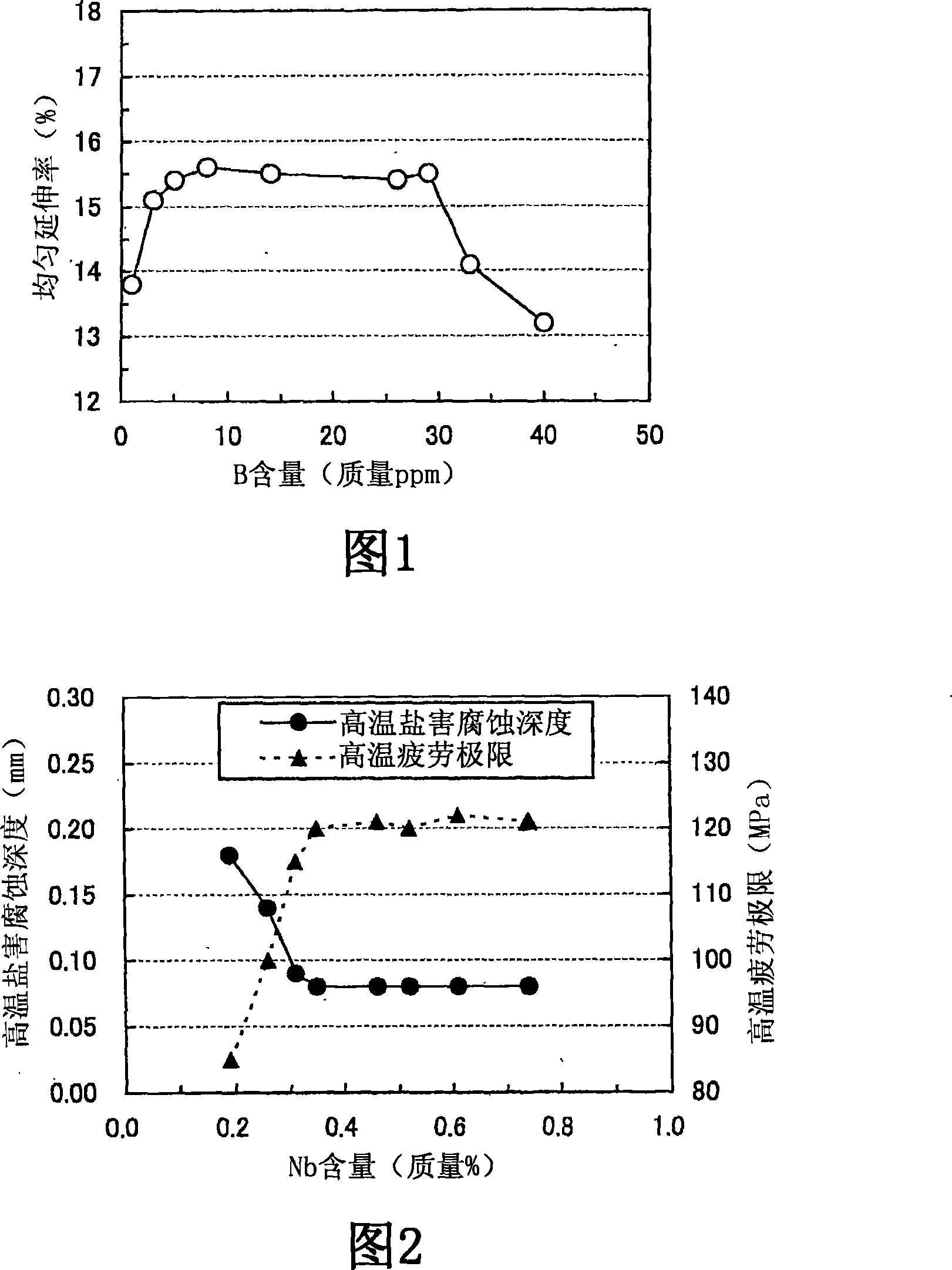

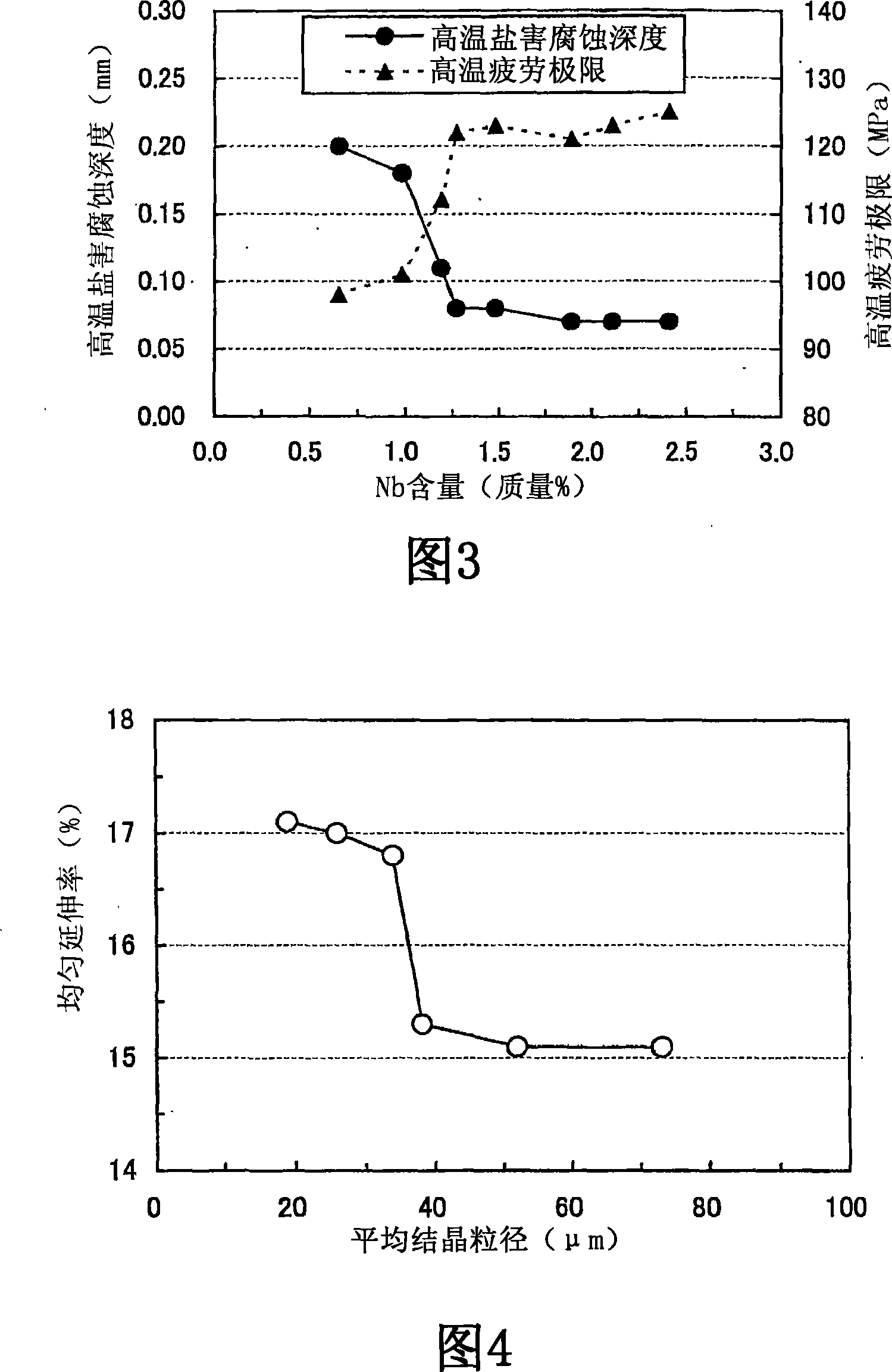

Embodiment 1

[0092] After smelting various steels with the composition shown in Table 1 in a high-frequency vacuum melting furnace and making 50kg steel ingots, after heating at 1170°C for 1 hour, carry out hot rolling with a final rolling temperature of 800°C, thereby producing A hot-rolled plate with a plate thickness of 3.5 mm. Then, after annealing the hot-rolled sheet at 1040° C. for 30 seconds, the oxide scale formed on the surface of the steel sheet is pickled and removed, and cold-rolled to form a cold-rolled sheet with a thickness of 0.4 mm, degreased Thereafter, annealing was performed at 1030° C. for 30 seconds to obtain a cold-rolled annealed sheet. From this cold-rolled annealed sheet, the above-mentioned special-shaped tensile test piece (parallel portion width: 150 mm, parallel portion length: 25 mm) was selected parallel to the rolling direction, and subjected to a tensile test, and the uniform elongation was measured. In addition, the above-mentioned high-temperature salt...

Embodiment 2

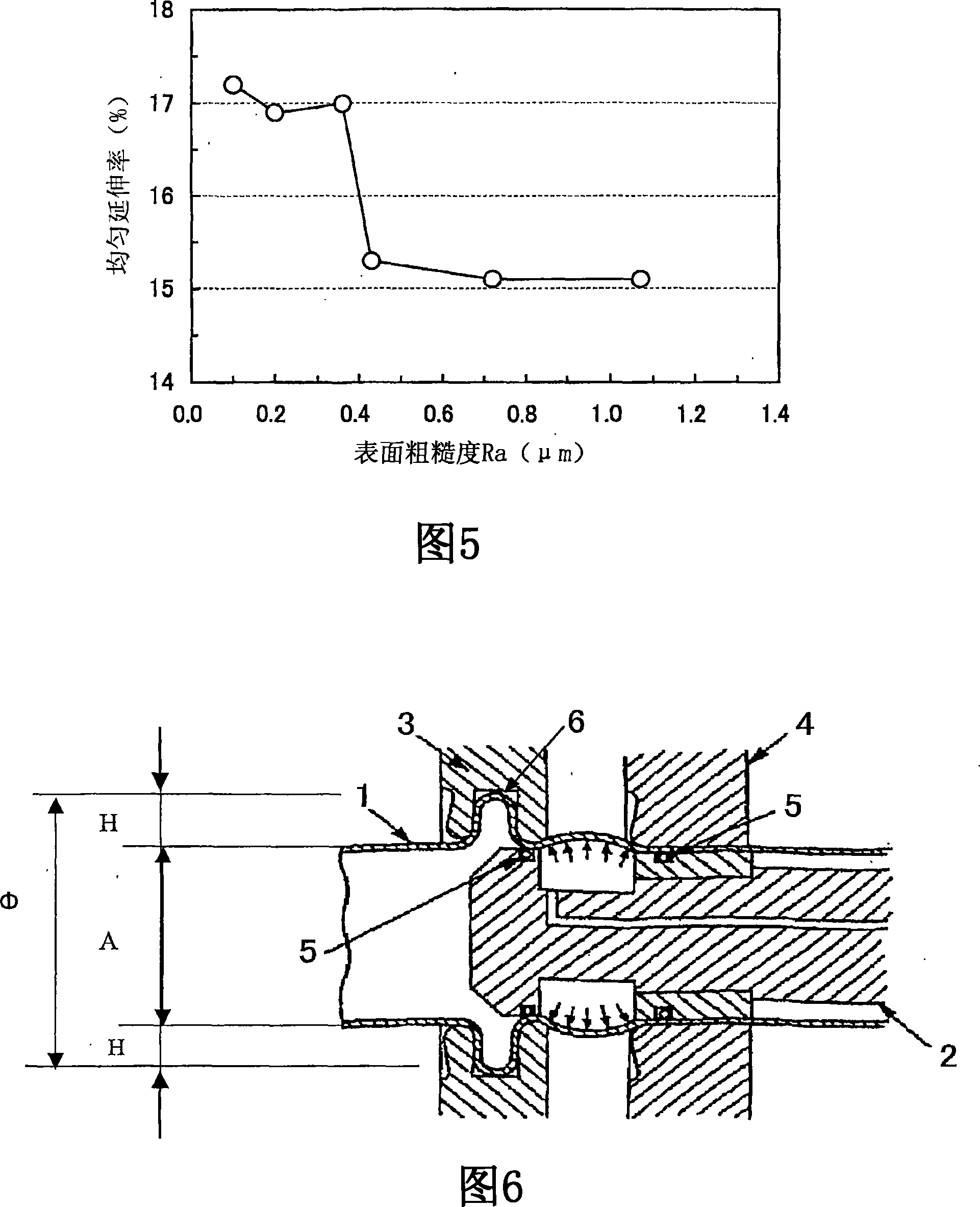

[0095] After smelting various steels with the composition shown in Table 3 in a high-frequency vacuum melting furnace and making 50kg steel ingots, after heating at 1170°C for 1 hour, hot rolling with a final rolling temperature of 800°C was carried out to produce A hot-rolled plate with a plate thickness of 3.5 mm. Then, after the hot-rolled sheet is annealed at 1040° C. for 30 seconds, the scale formed on the surface of the steel sheet is removed by pickling and cold-rolled to form a cold-rolled sheet with a thickness of 0.4 mm. After the plate is degreased, it is annealed at a temperature of 990 to 1050° C. for 30 seconds to change the average grain size D of the steel plate, thereby changing the average grain size of the cold-rolled annealed plate.

[0096] From this cold-rolled annealed sheet, the above-mentioned special-shaped tensile test piece (parallel portion width: 150 mm, parallel portion length: 25 mm) was selected parallel to the rolling direction, and subjected ...

Embodiment 3

[0099] After smelting various steels with the composition shown in Table 5 in a high-frequency vacuum melting furnace and making 50kg steel ingots, after heating at 1170°C for 1 hour, hot rolling with a final rolling temperature of 800°C was carried out to produce A hot-rolled plate with a plate thickness of 3.5 mm. Then, after annealing the hot-rolled sheet at 1040° C. for 30 seconds, the oxide scale formed on the surface of the steel sheet is pickled and removed, and cold-rolled to form a cold-rolled sheet with a thickness of 0.4 mm, degreased Thereafter, annealing was performed at 1030° C. for 30 seconds to obtain a cold-rolled annealed sheet. At this time, the surface roughness of the steel sheet was changed by changing the roughness of the work rolls during cold rolling (in the range of 0.07 to 0.80 μm in arithmetic mean roughness Ra). From this cold-rolled annealed sheet, the above-mentioned special-shaped tensile test piece (parallel portion width: 150 mm, parallel por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com