Aluminum-silicon alloy high-pressure heat treatment method and obtained product

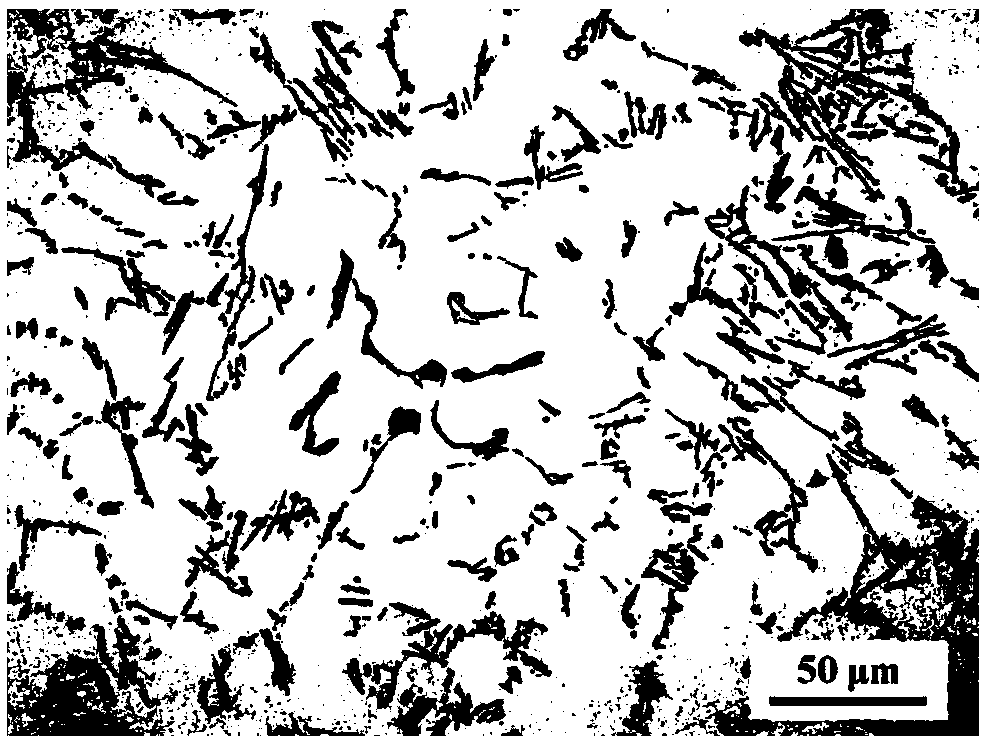

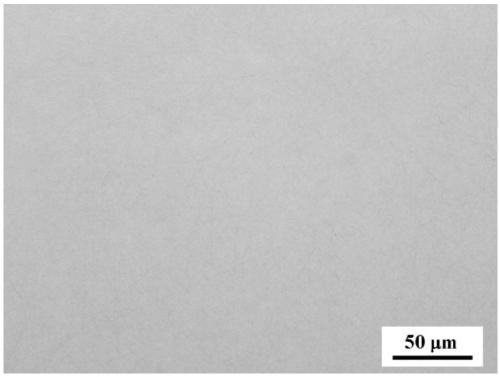

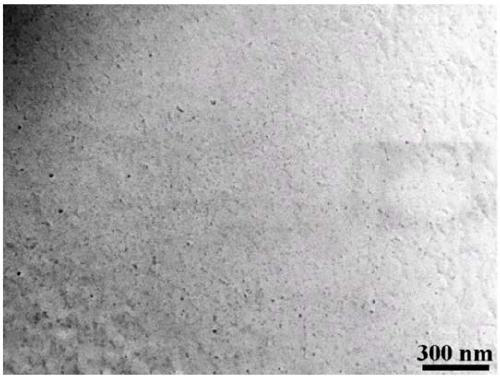

A heat treatment method, aluminum-silicon alloy technology, applied in the field of metal materials, can solve problems such as coarse silicon phase, and achieve the effects of alleviating stress concentration, excellent plasticity, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Adopt the method provided by the invention to prepare Al-7wt%Si alloy, concrete processing step is as follows:

[0050] Step 1: alloy melting;

[0051] Put industrial pure aluminum (99.7wt%) and industrial grade metal silicon (99.5wt%) into DD-25 high-frequency induction melting furnace, heat to 750°C to melt pure aluminum and metal silicon. After the raw materials are completely melted, they are kept at 750°C for 10 minutes, so that the silicon, magnesium, and copper elements can be completely diffused and dissolved to ensure a uniform melt.

[0052] Then blow high-purity argon with a graphite venting rod and add C2 Cl 6 Degassing and refining are carried out with the method, the gas flow rate is 0.8L / min, and the degassing time is 30min. After the melt is processed, let it stand for 10 minutes, wait for the temperature of the melt to drop to 720°C, and pour it into the L-shaped horizontal iron mold of the traditional casting stretching rod, and the cooling rate is a...

Embodiment 2

[0063] The product composition is the same as in Example 1, and the main difference with Example 1 is that the aging treatment time is 1h.

[0064] The aluminum-silicon alloy prepared by the method is subjected to a mechanical tensile test at room temperature, and the yield strength is 259MPa, the tensile strength is 330MPa, and the elongation at break is 30%.

Embodiment 3

[0066] The product composition is the same as in Example 1, and the main difference with Example 1 is that the aging treatment time is 10h.

[0067] The aluminum-silicon alloy prepared by the method of the invention is subjected to a mechanical tensile test at room temperature, and the yield strength is 277MPa, the tensile strength is 330MPa, and the elongation at break is 23%. The room temperature tensile curve of the alloy prepared in embodiment 1-3 is as figure 2 As shown, the elongation at break of the obtained alloys is above 20%. Alloys with different yield strength and uniform elongation can be obtained by changing the aging parameters reasonably. From the perspective of the engineering strain performance of the alloy, the aging treatment time of the alloy only added with silicon is preferably in the range of 0.1 to 1 h, and too long aging treatment time will not bring greater strain capacity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com